Taxan Super Vision IVm User manual

,.

.'~

.

:'.:',

- I •

:-,

\",,':'-;-.:''''!

\.,

-:

, '

••

,":"

':

':

c,

.:

• '

:."

••

, : <

. ." .

.•

'

,"",

," .

..

:"'<;/<':;,C;"

SERVICE

"MANUAL

.

.\

.'

.

r

i,

.

. I

I

..

i .

.1

.

12"

'.

COLOR DISPLAY'

SUPER

VISION

DOtlI

DrYl~M

.

, ' . '. , . . TM

-SUPER

VISION

fbJ3JillJlflnlJ{][I1J

, .

IMPORTANT

SERVICE

SAFETY

;

Operatic.n,of monitor outside

of

cabinet

or

with back removed

involves a shock hazard. Work

on

these models should only

be

performed

by

those who arll thoroughly familiar. with prccau-

..

tions neCessary when working on high voltage equipment

•.

Exercise care

when

servicing this chassis with power applied.

Many 8 plus and high voltage

RF

terminals are exposed which.

if

carelessly contactlld. can cause serious shock

or

result

in

dam-

age

to

the

chassis. Maintain interconnecting ground lead con-

. ncetions

bet.ween

chassis.escutcheon and picture tube dag cluster

when operating chassis. The

+8

Adj.Control in this monitor is

sealed

in

order

to.protect

the user from X-ray irradiation.The

...

'

B Adj.Control should

oot

normally have

to

be

adjusted.But

iC

it

is

..

cr

Ie

it

is replaced due to damage.check the +B voltage to as-

sure that.

it

is within specifications

after

adjustment.Then seal

this control according

to

the manuCacture's specification.

Certain H Y failures can increase X-ray radiation. Monitors

should

not

be

operated with HYlevels exceeding the

specified

rating

for

th«;

chassis

type. The maximwn operating H Yspecified

for

the

chassis used

in

these

monitor

is

22

KV

at

zero beam current with a line voltage

of

120Y

AC.

Higher voltage may also increase possibility of failure

in

H·Ysupply.

It

is

important

to

maintain

specified values

of

aU

components'

in

the horizontal and high voltage circuits and anywhere else in

the

monitor

that

could cause a rise in high voltage

or

operating

supply voltage.No changes should

be

made

to

the original de-

sign

olthe

monitor.Components shown in the shaded areas od

the schematic diagram

and/or.

identified

by

&. *

in

the re-

placement.

parts

list should

be

replaced only with exact Factory

recommended replacement

parts.

The use

of

unauthorized

substitute

parts_ may create a shock.

fire.X- ray

radiation.or

other

hazard.

To determine the presenCe

of

high voltage.use an accurate.high

. impedance.H Ymeter connected between

the

second anode leitd

and the CRT dag

groundin~

device_When servicing the High

Yoltage System.remove

static

charge

e~om

it

by

connp.cting a

10K

ohms resistor in series with an insulated wire (such as a

test probe) between picture tube

dag

and 2nd anode lead.

(AC,

line cord disconnected

Crom

AC

supply.)

The picture tube. used in this·

monitor

employs integral implo-

sion protection.Replace with a tube at the same type number

,Cor

continued

safety.Do

not

IiCt

picture tube by the neck.Han-

dIe

the picture tube only when wearing shatter-proof goggles

and

after

discharging the high voltage completely.Keep l)ttiers

withoutshafter-proofl goggles away.

When

removing springs

or

spring mounting

parts

from the

chassis.shatter-proof gottgles

must

be worn.Keep others without

shatter-proof

goggles away.

••••

e'

SAFETY INSPECTION • •

lor

e'

•

Before returning the monitor to

the

user. per

Corm

the following

safelY checks:

INFORMATION

Super Vision IV/IVM

Super Vision

640/630

• • •

...

PROTECT YOUR CUSTOMER • • • • •

Llnspect all lead dress

to

make certain

that

leads

are

not

pinched and

that

hardware

is

not lodged between the chassis

and, other metal

parts

in the monitor.

2.Replace all protective devices such

as

non·metaUic control

knobs.cabinet back.l\djustment covlu·s.shields.etc.

3.To

be

sure tllat no shock

hazarc!exists.a

check

for the pres·

enee

oC

leakage current should

be

made

at

eech exposed

metal'

part

having a return

path

to

the chassis(jack.cabinet metal.

screw heads. knobs.shaftli.etc.)in the following manner.

Plug the

AC

line cord directly into a 120Y

AC

receptacle.(Do

not use an Isolation Transformer during these checks. )All

tP.Sts

must be repeated with' the

AC

Hne

cord plug connections.

l'e~

versed.

(If

necessary.a non-polarized

AC

adapter

plug must

be'

used for .the purpose

of

completing these checks.

Do

not other-

wise operate the monitor with an

adapt,.r.)

Ie

available.measure leakage current using an accurate leakage

current tester.Any reading oCO.35MA

or

more· is excessive and

indicates

II

potential shock hazard which must

be

corrected

be-

Core

returning the monitor

to

the owner.

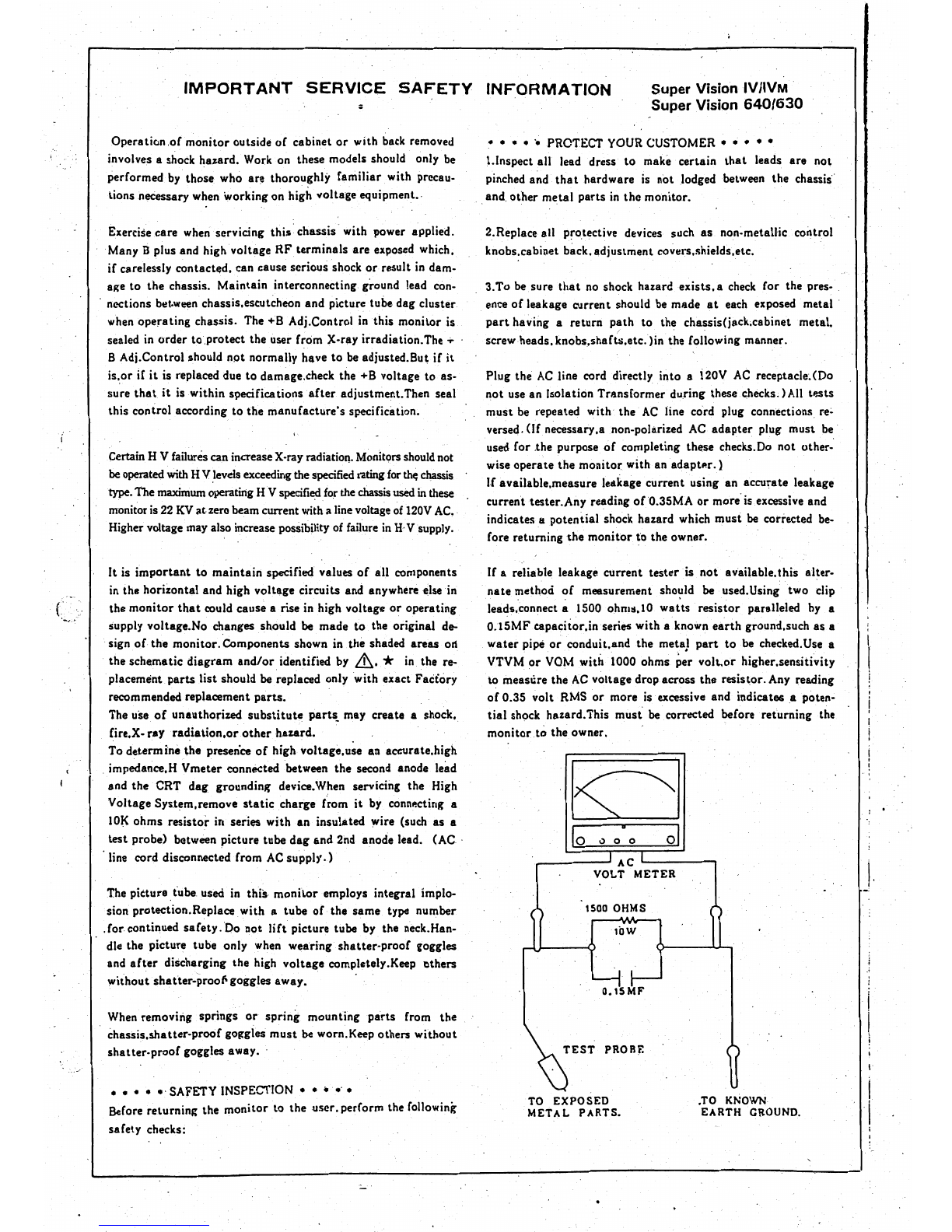

If

a reliable leakage current tester is not available.this alter-

nate method

of

meesurement

sho~I1d

be

used.Using two clip

leads.connect a 1500 ohm:l.l0

watts

resistor paralleled

by

a

0.15MFeapacitor.inseries

with a known

earth

ground.such as.a

water

pipe

or

conduit.and the meta}

part

to

be checked.

Use

a

VTYM

or

YOM with 1000 ohms per

volt.or

higher.sensitivity

to measlire the

AC

voltage drop across the resistor.

Any

reading

of

0.35 volt RMS

or

more is excessive and indicate&a

poten~

tial

shock hazard.This

must

be

corrected before returning the

monitor

to the own.er. !

!

. ,

0)

a 0

_-----'ACL------,

VOLT

METER

\.

I

1500

OHMS

lOW

O.ISMF

TEST

PROBE

I

TO

EXPOSED .TO KNOWN

METAL

PARTS_

EARTH

GROUND. I

, .

IMPORTANT

NOTICE

FOR

SERVICE PERSONNEL BEFORE SERVIC'ING

PLEASE READ BEFORE ATTEMPTING SERVICE

1.' While

the

monitor

isin

operation, do

not

attempt

to

connect

or

disconnect any wires.

10',

sis 2. Make sure

the

power cord is,disconnected before replacing any components

in

the monitor.'

rol

3. When

the

power

is

on, do

not

attempt

to

short any portion

of

the circuit. This shorting may

cause damage

to

the

transistors

in

the monitor.

as·

lal

4.

When servicing

the

H;

V.

area,

be

certain tl:lat

the

C.

R~

T anode is.safely discharged

to

ground

Ill. before removing

the

anode cap.

)0

5. Caution, must be exercised

when

servicing this monitor.

;I.S

,The regulator has no current Iimitinganq even a momentary short

of

an

output

voltage could

~e-

cause destruction

of

the

pass transistors.

be

!r-

gt'

i

le-

I ,

I

tr

..

i

ip

I

I '

a

a

"'

i,

a

ly

Ig

~-

Ie

/

....

- 1 -

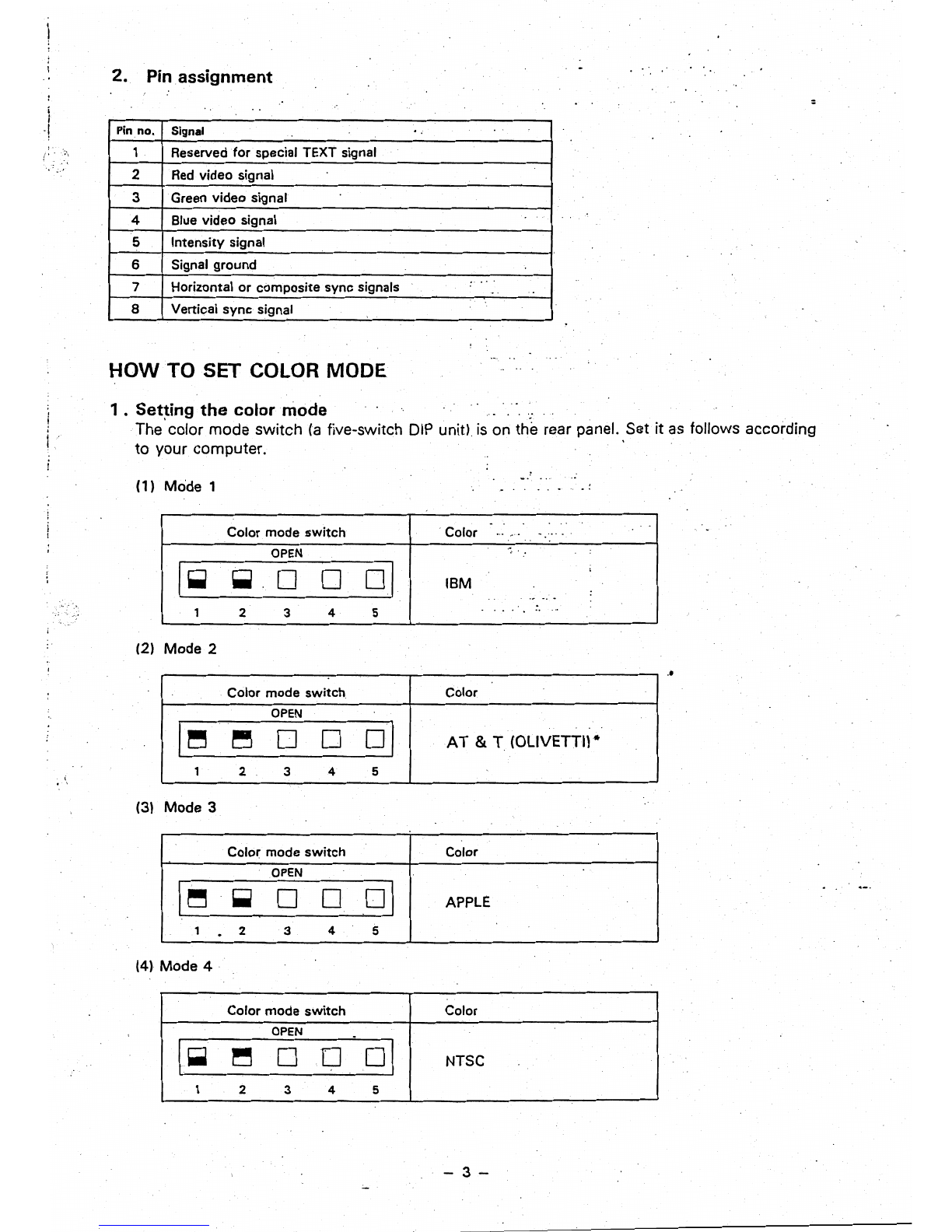

IProduct.Outline

'I

This model

is

a 12-inch color display monitor,

used

for a personal computer terminal.

Its

input

is

TIL

s~parate

signals. The input terminal

is

an

8-pin

DIN

)ack.

Specifications

CAT

Signal

input

'

Power Supply

Wattage

Cabinet

Dimensions

Weight

Scanning

frequency

OPERATION

12-inch

type

with

646.8

mm R

• Facing: Non-glare' face 'plate

Facing: Glare face plate

• Screen phosphor:

630/640

Separate

R,

G,

B,

I,

H, V

•

R,

G,

B,

I:

."

Positive

• Sync: Positive or negative

Local commercial

power

supply

SOW

Plastic

630/640A,

B,

S

,

630/640U,

J

B22

(Short persfstence)

322

(W)

x

309

(H)

x

372

(D)

mm

.

12

kg

24.S

kHz (Horizontal)

54.3

Hz (Vertical)

1.

Plug

the display

and

the computer into

AC

outlets.

2. Set

the

color mode switch

on

the

rear

panel.

3. Connect the signal input terminal

sm

the

rear

panel

to

the computer using the optional cable.

4. Turn on display monitor

and

computer.

5.

The

green

power indicator (just

above

tbe power'switch), lights, then the

CRT

·screenbrightens.

(There

may

be

9haracters displayed.)

6.

After the monitor warms up,

set

brightness

and

contrast if necessary.

7. Position of the image, image

area,

and

focus

are

preset at

the

factory,

so

you

don't have

to

adjust

these. Depending

oriyour

computer, image width, height,

and

position may differ from

the

stan-

dard settings',

In

such a

case,

reset

as

necessary (controls

are

on

the

rear panell.·

SIGNAL INPUT CONNECTORS

. .

Signals

are

input through a DIN

8P

connector.

Each

signal

is

assigned

as

following:

1. Pin

assignment

[REAR

VIEW]

.-

2 -

2.

Pin

assignment

:

i

.!

Pin

no.

Signal

1 Reserved

for

special TEXT signal

2

Red

video signal

3 Green video signal

4 Blue video signal

5 Intensity signal

6 Signal ground .. .

7 Horizontal

or

composite sync signals

~.

..

8 Vertical

sync

signal

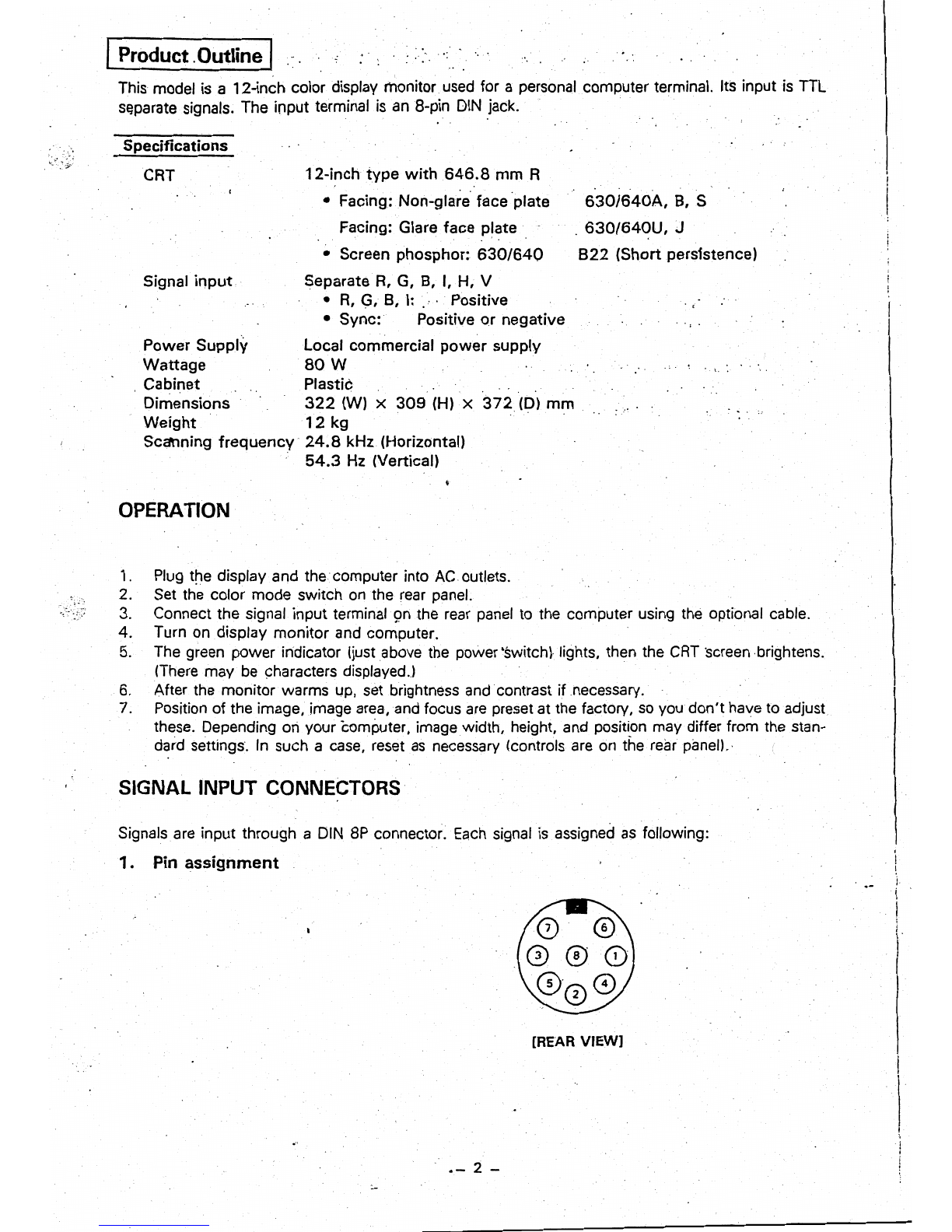

HOW

TO SET COLOR MODE

1 .

Set~ing

the

colarmade

.;

The

color mode switch

(a

five-switch

DIP

unit)

is

on the rear panel. Set it

as

follows according

to your computer.

(1) Mode 1

.

Color mode

switch

.Color ...

~'.

. .

..

' .

I- OPEN ,

~

0 0

oj

IBM :

.,.

~.

. .

..

..

1 2 3 4 5

(2) Mode 2

..

Color mode

switch

Color

OPEN

AT

& T (OLIVETTI)*

I~

~

0 0

01

1 2 3 4 5

(3) Mode 3

Color mode

switch

Color

I~

OPEN

01

~

0 0 APPLE

1 . 2 3 4 5

(4l

Mode

4·

Color mode

switch

Color

I- OPEN .

~

0 D

01

NTSC

1 2 3 4 5

-3-

•

Note

-ADDENDUM

fgr

AT&T

PC6300

and compatibles

630/640

E,

U.

A,B.

S are factory-set to use

with

IBM PC/XT/AT

Of

compatibles. You may need the following adjustment

.in

order

to

obtain maximum performance in display when you use withAT&T PC6300. PC6300

PLUS

computer

and

compatibles.

,.

Curl at top Turn H.

HOLD

counter-clockwise.

Turn

HoPOSI

clockwise.

D

.2. Small screen size

al

Horizontal size Turn

H.

SIZE

c;ounter-clockwise.

bl

Vertical size Turn

V.

SIZE

counter-clockwise.

CJ

3. Characters missing

at

top

Turn

V.

HOLD

clockwise

..

-4-

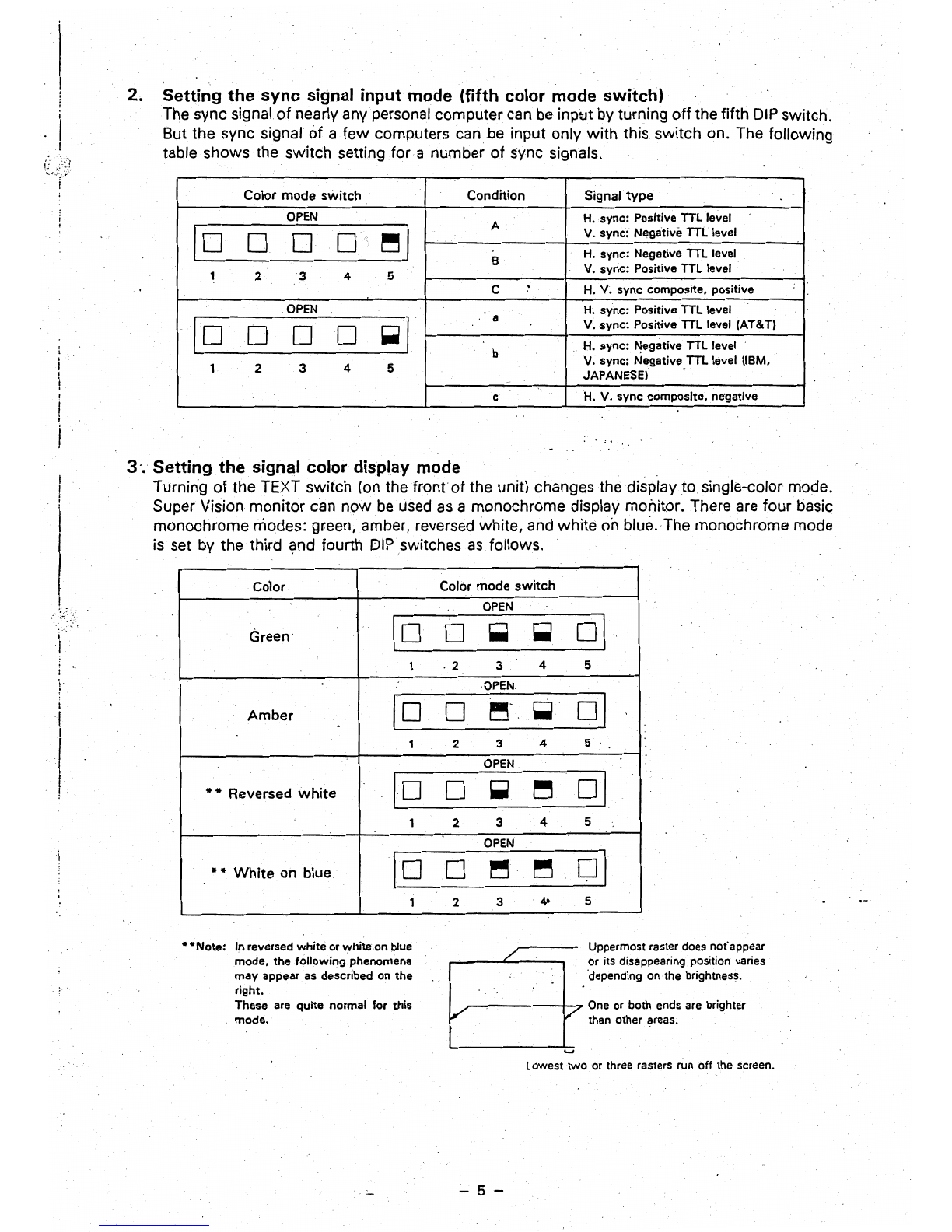

2.

Setting

the

sync

signal input

mode

(fifth color

mode

switch)

The sync signal of nearly any personal computer can

be

inp~t

by turning off the fifth

DIP

switch.

But the sync signal

of

a few computers can be input only with this switch on. The following

table shows the switch setting

for

a number of sync signals.

Color mode switch Condition Signal type

OPEN

H. sync: Positive TTL level

A V. sync: Negative TTL level

10

0 D 0

~I

H. sync: Negative TTL level

8 V. sync: Positive TTL level

1 2 3 4 5 .

C H. V. sync composite, positive

OPEN

H. sync: Positive TTL level

a

V.sync:

Positive TTL level (AT&T)

10

0 0 0

~I

H. sync:

~egative

TTL level

b

V.

sync: Negative,TTL level (18M,

1 2 3 4 5 JAPANESE)

e'

c

H.

V.

sync

composite. ne'gative

3

'.

Setting

the

signal color display

mode

Turnin'g

of

the TEXT switch

(on

the

front

of the unit) changes the display

to

single-color mode.

Super Vision monitor can nowbe

used

as

a monochrome display monitor. There are four basic

monochrome modes: green, amber, reversed white,

and

white

on

blue.

The

monochrome mode

is

set by the third and fourth DIPswitches

as

follows.

, ' I

,

color

Color

mode

switch

OPEN, '

I Green'

10

D

~

~

01

1

,2

3 4 5

r 10 0

OPEN

01

i

~.,

~-

Amber

3 4 5

I -1 2

\0

OPEN

01

l

~

,

••

Reversed

white

0 ~

~

1 2 3 4 5

OPEN

*.

White

on

blue

10 0

~

~

01

1 2 3 4- 5

-

-Note:

In reversed whiteor white on blue Uppermost raster does nofappear

/'

mode,

the

following phenomena or its disappearing position varies

may appear

as

described

on

the 'depending on the brightness,

right.

These are quite normal for this

One

or both

ends

are

brighter

V

mode. v than other

areas

.

......

lowest

two or three rasters run

off

the screen.

- 5 -

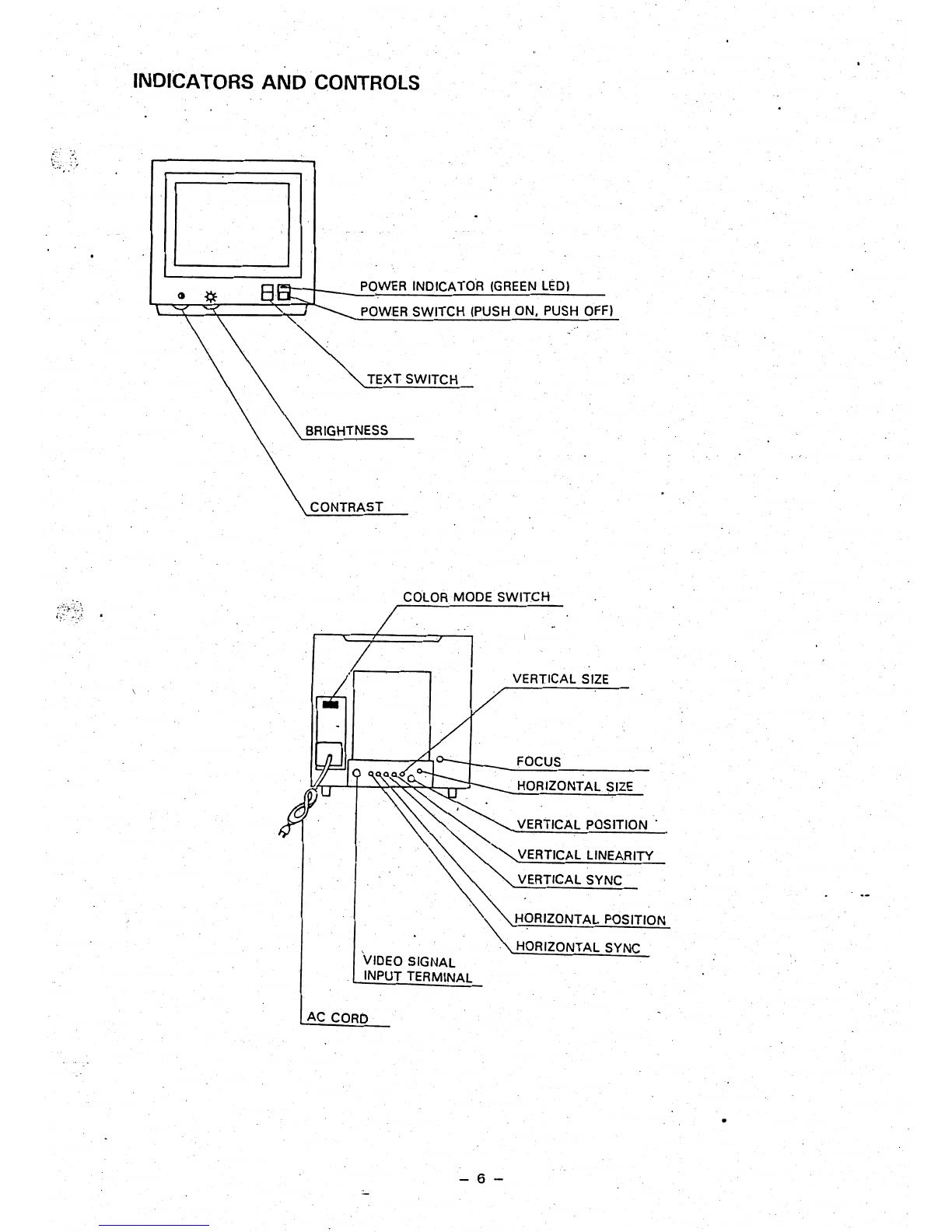

INDICATORS·

AND

CONTROLS

POWER

INDICATOR

(GREEN

LEDI

POWER

SWITCH (PUSH ON. PUSH

OFF)

TEXT SWITCH

BRIGHTNESS

CONTRAST

COLOR

MODE SWITCH

VERTICAL

SIZE

FOCUS

. HORIZONTAL

SIZE

VERTICAL

POSITION·

~

'"

""'VERTICAL

LINEARITY

•

'\:

VERTICAL SYNC

.•

'.'

~ORIZONTAL

POSITION

.

'"

HORIZONTAL SYNC

VIDEO SIGNAL

INPUT TERMINAL

AC

CORO

- 6 -

(

..

I

I

.

I

ADJUSTING THE DISPLAY

;

1. H. SIZE

If the horizontal size

of

the screen image

is

too short or too long. adjust the

H.

SIZE

control for

the correct

size.

(See illustration

1.)

2.

V.

SIZE

If the vertical

size

of

the screen image

is

too short or too long, adjust

theY.

SIZE

control for the

correct size.

(See

illustration

2.1

.'

3. H.

POSt

If the screen image shifts horizontally. adjust the H.

pas!.

control fora correct image.

(See

illustra-

tion

3.)

.

4.

V.

POSI.

·If the

scree~image

shifts vertically, adjust the

V.

POSI.

control for a correct image.

(See

illustration

3.1

5. H. HOLD

If the screen image has horizontal stripes or if

the.

image moves left or right, adjust the

H.

HOLD

control for a clear stable image.

(See

illustration

4.1

6,

V.

HOLD ,

If the screen image moves or overlaps vertically, adjust the V. HOLD control for

astable

image.

(See

illustration

4,1

7.

FOCUS

Adjust the focus· for the sharpest image.

(See

illustration

6.1

8. V. LIN.

Adjust the

y.LlN

control so

the

height of characters

is

even over the whole screen.

(See

illustration

7.1

9.

CONTRAST

Turning

the.

CONTRAST control clockwise increases the contrast, turning it counterclockwise

.decreases the contrast.

10.

BRIGHT

Turni'ng the

iRIGHT

control clockWise

makes

the screen brighter, turning it counterclockwise makes

it darker.

11.

SUB-CONTRAST

To adjust the subcontrast, display a screen of characters then turn the

BRIGHT

control to the

clic~

stop position, and the CONTRAST control fully clockwise.

Now

adjust the SUB-CONTRAST control

(VR

140) to the position just before the characters ·become saturated

..

12.

H. CENTER

To adjust horizontal centering turn the

BRIGHT

and the CONTRAST controls fully clockwise with

nothing displayed on the screen. Then adjust the

H.

CENTER

VR

(R742) so that the raster

is

centered

on the screen.

-

7-

13.

SIDE-pee

Depending on computer models with which display monitors

are connected, pincushion or

barre'!

distortion appears on the

right and left edge portions of their screen areas

as

shown

in

Fig.

1

..

The distortion

on

the right and left screen portions

can

be

minimized by turning the "SIDE-PCC" potentiometer,

clockwise or counter-clockwise, for optimum distortion-

correction results.

1\

J\

I \ I \

I ,

r I I I

\ I \ I

\ I

" "

:-. . .

~

•

- 8 -

I

f

" ,

, ,

!

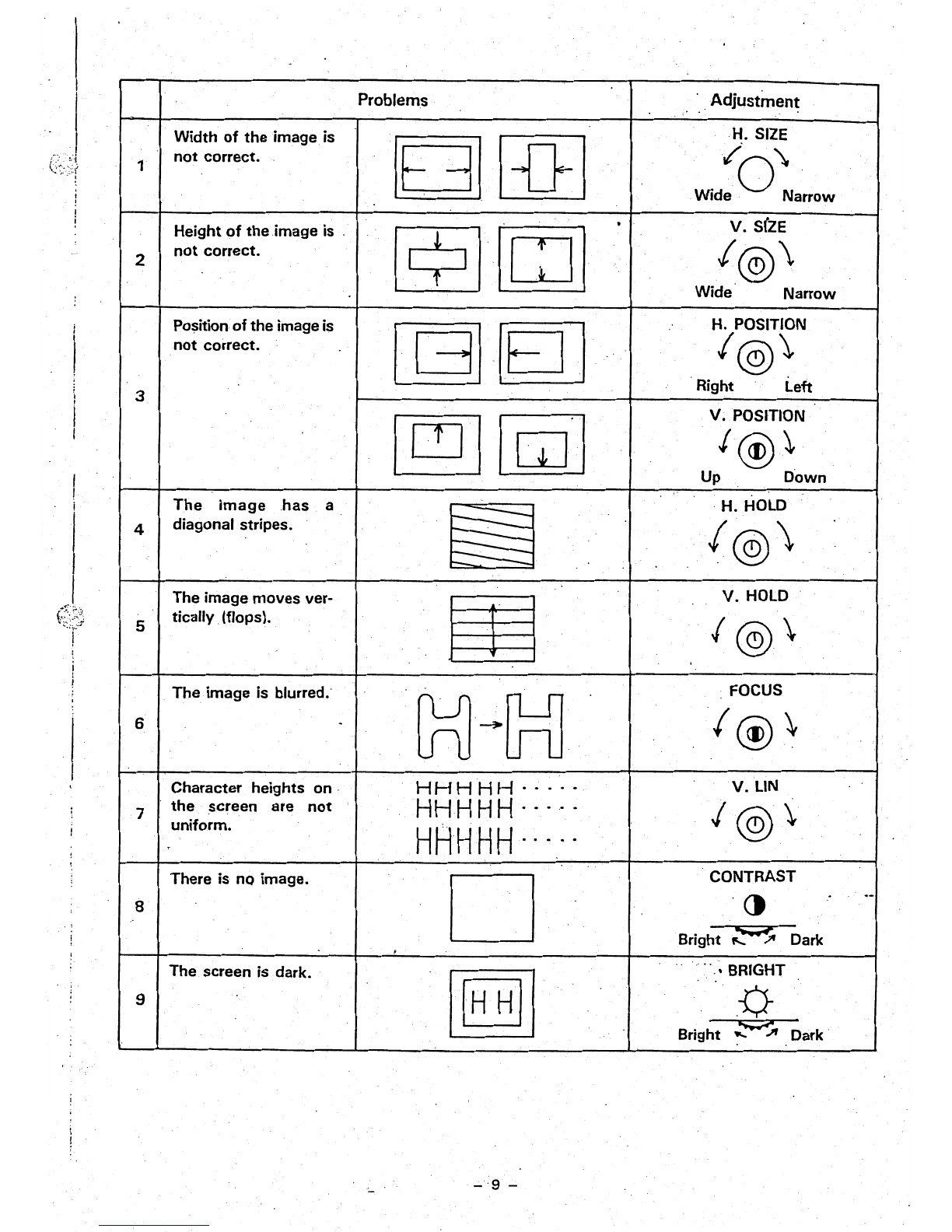

Width

of

the image,is

not

correct.

1

Height

oftheimage

is '

not

correct.

2

Position

of

the image is

not

correct.

3

The

image

,has,

a

diagonal stripes.

4

The image moves ver-

tically,(flops).

5

The image is blurred. .

6

Character 'heights

on,

the

screen are

not

7

uniform.

c

There is

nQ

image.

8

The screen is dark.

9

Problems

BJ

BlJ

[2J[C] .

~·lEIJ

[gTI

[E5J

§§

m

~~G=l1

HH

H H H

.....

HH

HHH

.....

HHHHH··

~,"

D

, ,

I~II

'

,Adjustmen~

, ,

,H. SIZE

w~:O~a"ow

V.

S(ZE

I@\

Wide Narrow

H.

POSITION

/@\

Right Left

V.

POSITION

I

@)

~

Up

Down

,H.

HOLD

I@\

V.

HOLD

I

@\

FOCUS

I@\

V.lIN

I@\'

'CONTRAST

.

.-

ct

Bright ;::-s Dark

"

"','

BRIGHT

P-

Bright

.z-A

Dark'

..;.'9 -

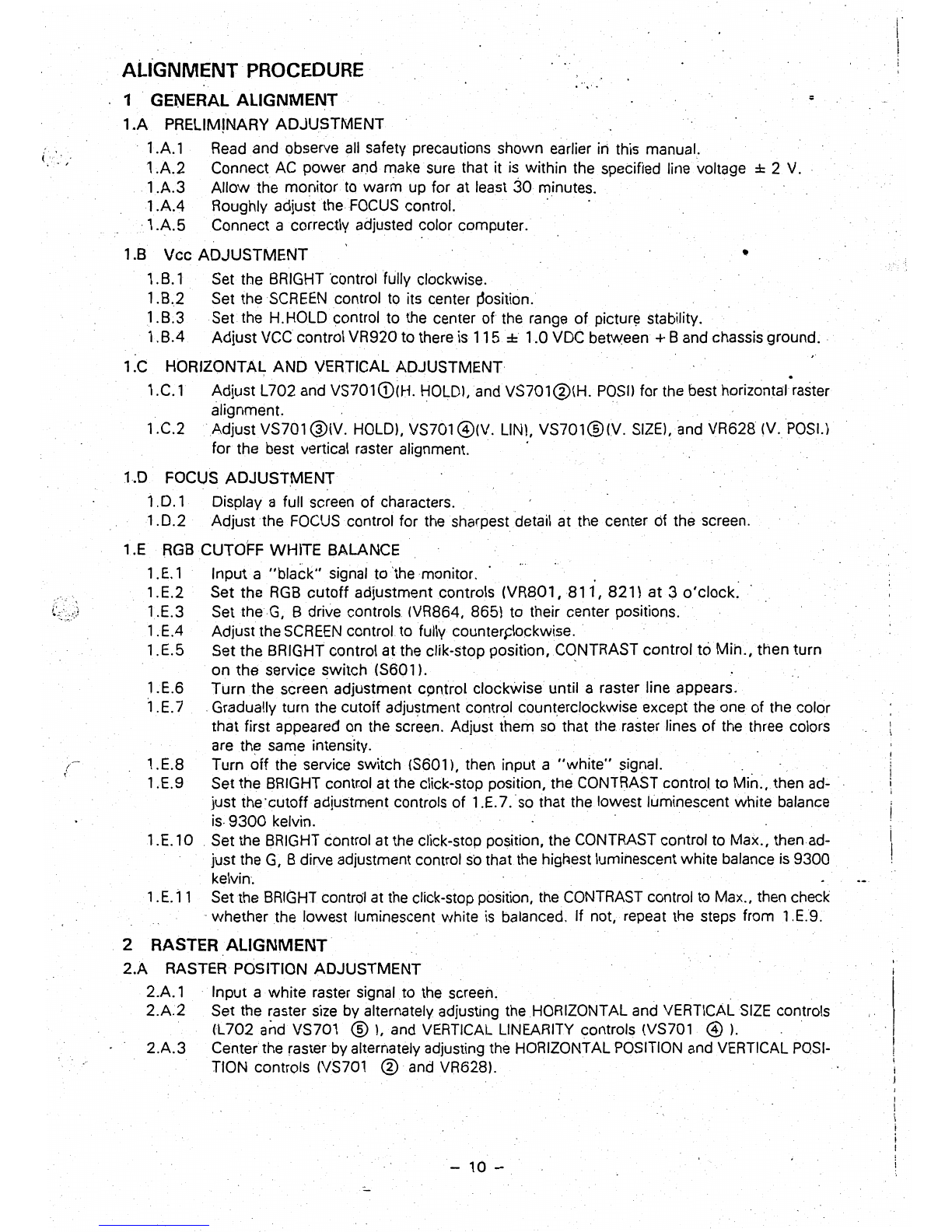

ALIGNMENT PROCEDURE

;

1 GENERAL ALIGNMENT

1

.A

PRELIMINARY ADJUSTMENT

.

1.A.l

Read

and

observe

all

safety precautions shown earlier iii this manual.

1.A.2 Connect

AC

power

and

make

sure

that it

is

within the specified line voltage ± 2

V.

1.A.3 Allow the monitor

to

warm up for at least

30

minutes.

1.AA

Roughly adjust the

FOCUS

control.

·1.A.5

Connect a correctly adjusted color computer.

1.B Vec ADJUSTMENT •

1.B.1· Set the

BRIGHT

'control fully clockwise.

1.B.2 Set the

SCREEN

control

to

its center

~osition.

1.B.3

Setthe

H.HOLDcontrol to

the

center

of

the range of

pictur~

stability.

1.

BA

Adjust vcecontrol VR920 to there

is

115 ±

1.0

VOC

between +Band chassis ground.

1.C HORIZONTAL AND VERTICAL ADJUSTMENT .

1.C.1 Adjust L702 and VS701G)(H. HOLDl,and VS701@(H.

POSIl

for

the

best horizontal raster

alignment. " .

1.C.2 .Adjust VS701 @(V. HOLD),

VS701

@(V. LIN), VS701@(V. SIZEl,and VR628

(v.

POSI.)

for

the best vertical raster alignment.

1.D FOCUS ADJUSTMENT

1.

D.

1 Display a full screen of characters

..

1.0.2

Adjust the

FOCUS

control for

the

sharpest detail

at

the center of the screen.

1.E

RGB

CUTOFF WHITE BALANCE

1.E.1 Input a

"black"

signal to 'the monitor. . . .

1.E.2 Set the

RGB

cutoff adjustment controls (VR801,

811,

821)

at

3 o'clock.

1.E.3 Set

theG,

B drive controls (VR864, 865) to their center positions.

1.EA

Adjust the

SCREEN

control to fully counters:lockwise

..

1.E.5 Set the BRIGHT control

at

the clik-stop position, CqNTRAST control t6 Min., then turn

on the service switch (S601)'

1.E.6 Turn

the

screen adjustment cpntrol clockwise until a raster line appears.

1.E.7 .Gradually turn the cutoff adjustment control counterclockwise except the one of the color

that first appeared on the screen. Adjust them

so'

that

the

raster lines of

the

three colors

are the same intensity.

1.E.8 Turn off the service switch (S601), then input a

"white"

signal.

1.E.9 Set the

BRIGHT

contr.ol

at

the

click-stop position, the

CONTRAST

control

to

Min

..

then ad-

just the'cutoffadjustment controls of 1.E.7.so that the lowest luminescent white balance

is·

9300

kelvin.

1.E.l0

Set the

BRIGHT

control at the click-stop position, the

CONTRAST

control to Max., then ad-

just the

G,

8 dirve adjustment control

so

thatthe highest luminescent white balance

is

9300

kelvin.

1.

E.l1

Set

the

BRIGHT

control

at

the

click-stop position,

the

CONTRAST

control to Max., then check

..

whether the lowest luminescent white

is

balanced.

If

not, repeat the steps from 1.E.9.

2 RASTER ALIGNMENT·

2.A

RASTER POSITION ADJUSTMENT

2.A.l

. Input a white raster signal to

.the

screen.

."

2.A.2

Set the raster

size

by

alternately adjusting the HORIZONTAL

and

VERTICAL

SIZE

controls

(L702 and VS701

®),

and

VERTICAL

LINEARITY

controls (VS701

@).

.

2.A.3

Center the raster

by

alternately adjusting the HORIZONTAL

POSITION

and

VERTICAL

POSI-

TION contrQls

(VS701

®

and

VR628l.

-

10

-

I

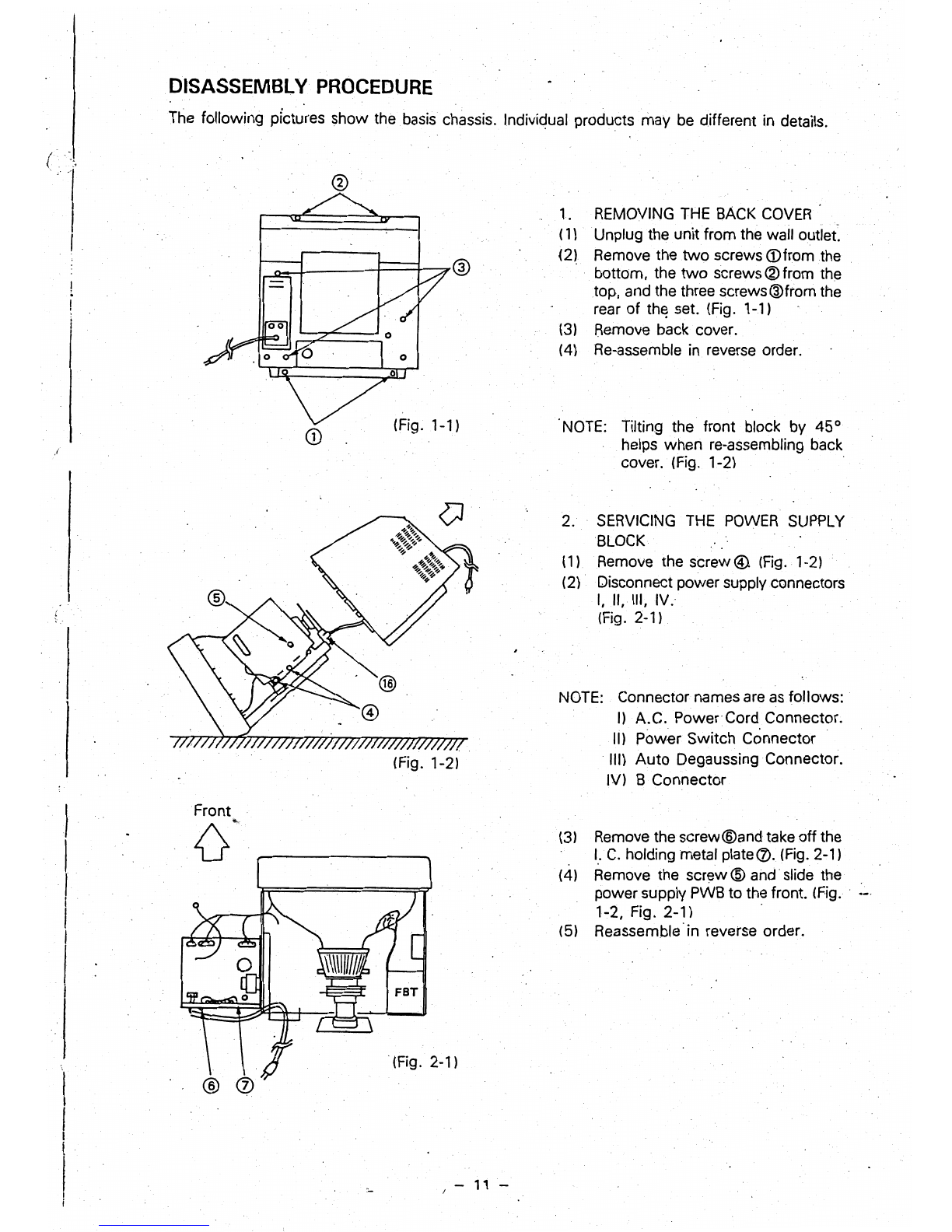

DISASSEMBLY

PROCEDURE

The following pictures

show

the basis chassis. Indiviqual products

may

be different in details.

(

.'

/

1. REMOVING THE BACK

COVER

{1) Unplug the

unitfrom

the wall outlet.

(2) Remove the

two

screws

(j)from

the

bottom,

the

two

screws®from the

top, and the three

screws@from

the

rear

of

th~

set. {Fig. 1-1}

(31

Remove

back

cover.

(4)

Re-assemble in reverse order.

o

(Fig. 1-1) NOTE: Tilting the front block by 45°

CD

helps

when

re-assembling back

cover. (Fig. 1-2)

2. SERVICING THE POWER SUPPLY

BLOCK

(1) Remove the screw@. {Fig. 1-2)

(2)

Disconnect

power

supply Connectors

I,

II, III, IV.

(Fig.

2-1).

NOTE: Connector names are as

follows:

I)

A.C.

Power'Cord

Connector.

II)

Pow€r

Switch

Connector

III)

Auto

Degaussing Connector.

(Fig. 1-21 IV) B

Connector

Front

(3)

Remove the

screw®and

take

off

the

{]'

I.

C.

holding metal plate

<£>.

(Rg. 2-1)

(4)

Remove the

screw@

and slide the

power

supply PWB to the front. (Fig

...•

,

1-2, Fig. 2-1)

(51

Reassemble'in

reverse order.

FBT

(Fig. 2-1)

-

11

-

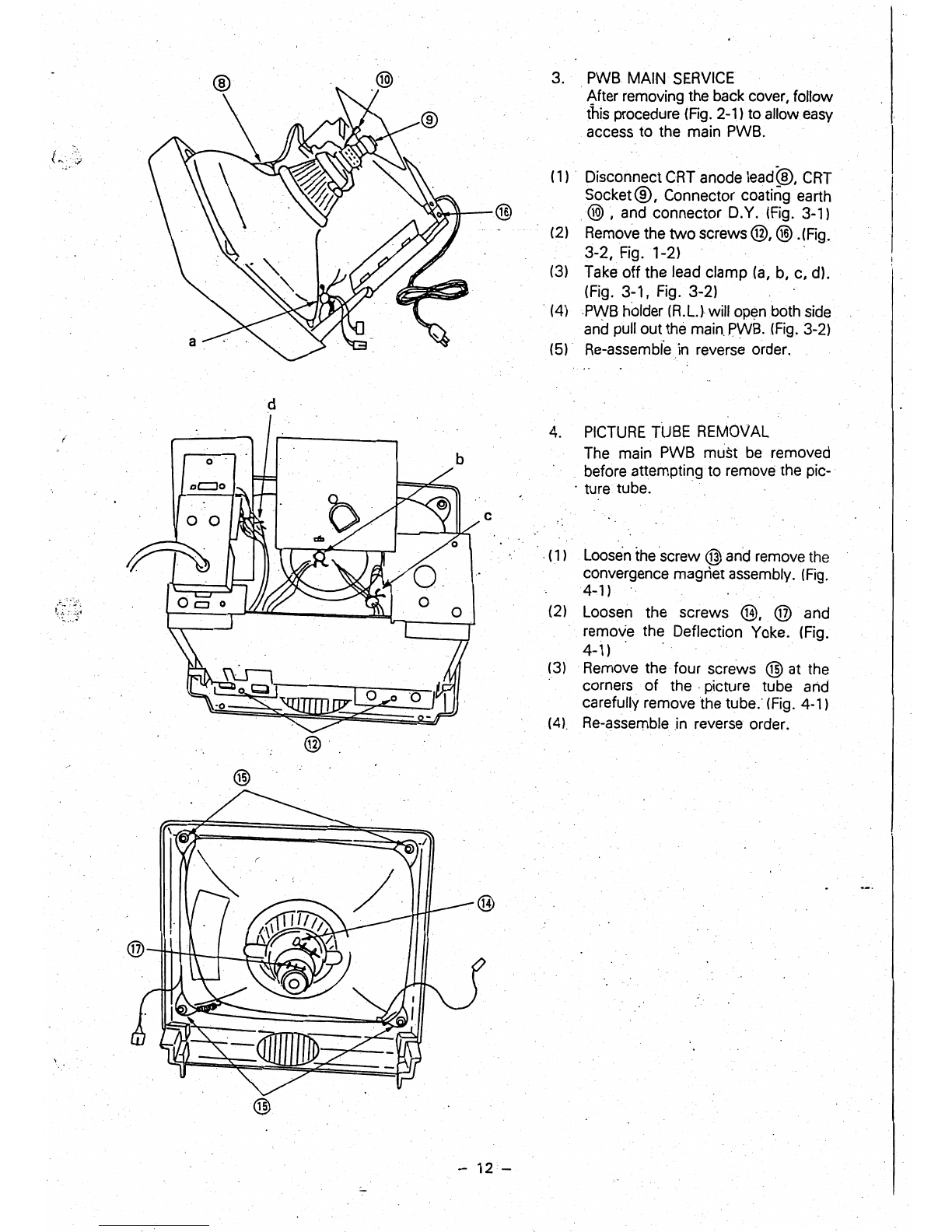

3.

PWB

MAIN

SERVICE

.

~fter

removing the back cover, follow

this procedure

(Fig.

2-1) to allow

easy

access to the main

PWB.

(1)

. Disconnect

CRT

anode lead@,

CRT

Socket®, Connector coating earth

@,

and connector D.Y.

(Fig.

3-1)

(2)

Remove the

two

screws@,@.(Fig.

3-2, Fig. 1-2)

(3) Take

off

the lead clamp

(a,

b, c, d).

(Fig. 3-1, Fig. 3-2)

.

(4)PWB

holder

m.LJ

will open

.both

side

and

pull out the

main.

PWB.(Fig, 3-2)

(5)' Re-assemble in reverse order.

d

4.

PICTURE

TUBE

REMOVAL

The main PWB must

be

removed

before attempting to remove the pic-.

.

turetube.

c

.

(1

)

Loosen

the

screw @ and remove the

convergence magnet assembly.

(Fig.

4-1

)

(2) Loosen the screws

@,

@ and

remove the Deflection Yoke. (Fig.

4-1)'

.

(3) .Remove the four screws ® at the

corners of

the·

picture tube and

carefully remove the tube.'

(Fig.

4-1)

(4).

Re-assemble.in reverse order.

®

®

-

12

-

,.""--

~."';::;

\

.

~;':,~

';

~-----

1./,."

----'-------_....

;,;;

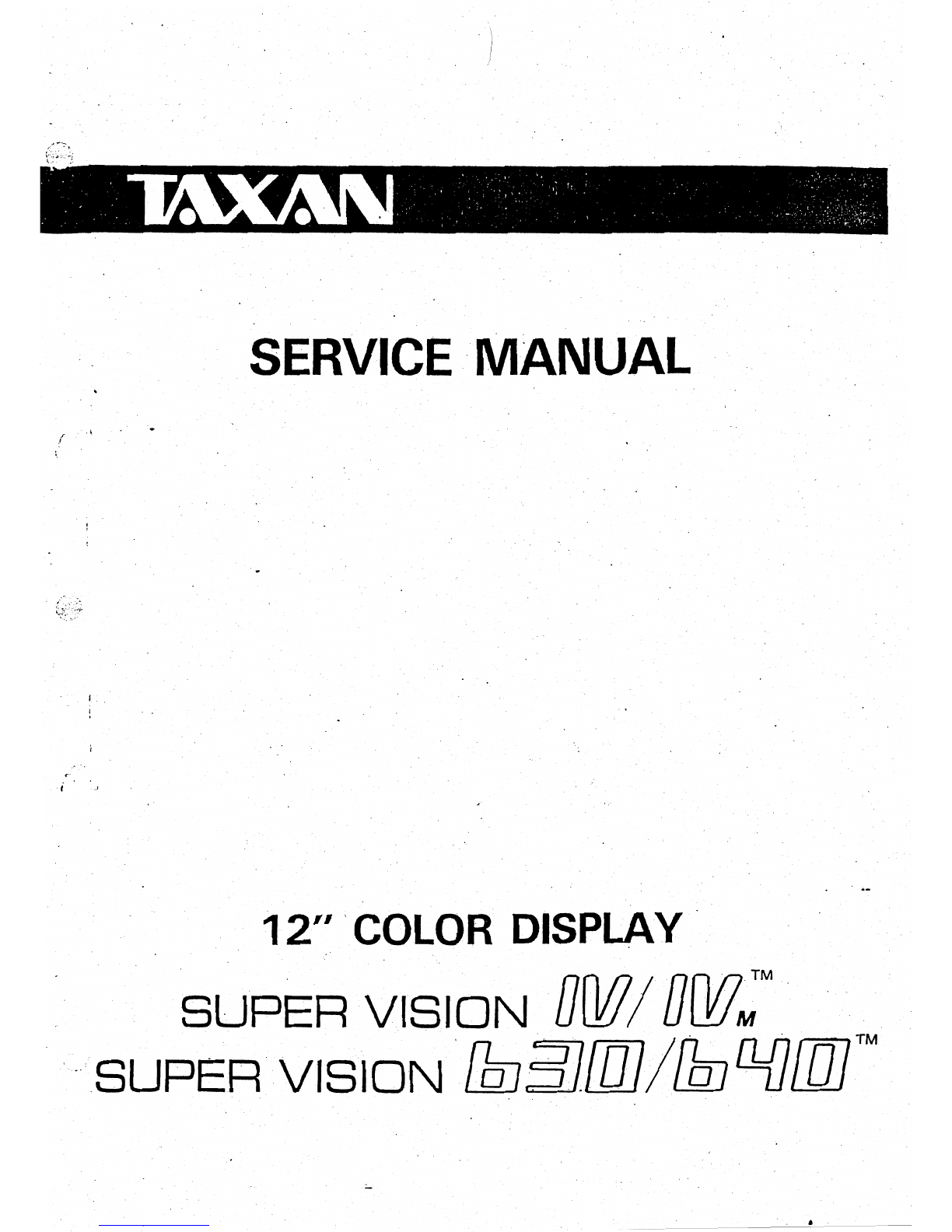

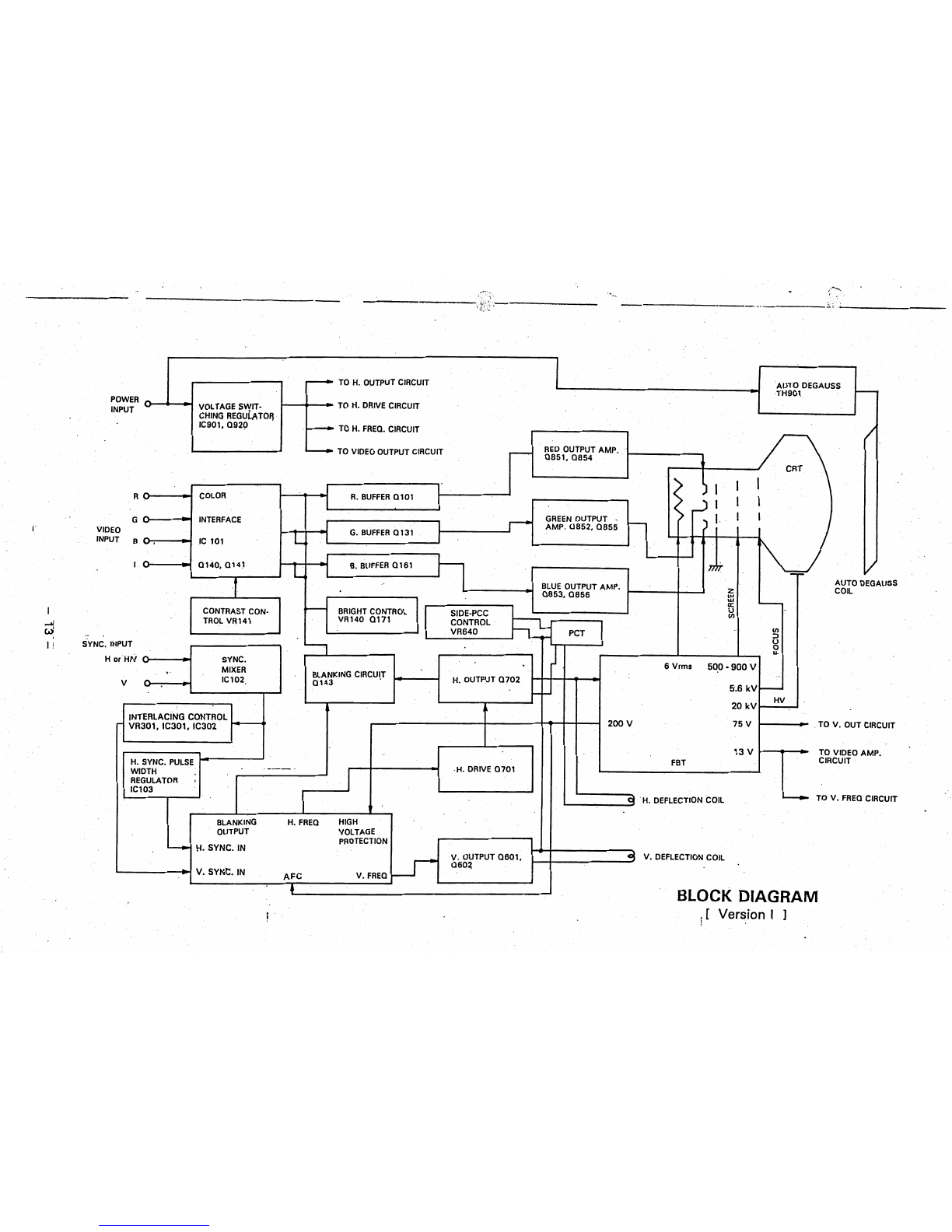

POWER

INPUT 0 ,

-I

VOLTAGE 5yt1T-

CHING

REGULA

TOil

TO

H.

O~TPUT

CIRCUIT

I----.~--

TO

H.

DRIVE

CIRCUIT

AUTO DEGAUSS

THSOI.

I

VIDE

INPU

0

T

R"-

G

B_

\

I

ICSOl,OS20

COLOR

INTERFACE

.IC

tOl

I C

J

L L

TO

H.

FREO.

CIRCUIT

flCUIT

R.

BUFfER

0101

I

I

G.

BUFFER

0131

J

r-

.r-

RED

OUTPUT AMP•. -

0851.0854

GREEN

OUTPUT -

AMP.

0852.

0855

I--

;~

>

+

~

I

I

)

I.

I

I

I

I

I

I

CRT ,

)

.....

W

I'

--

1"-

0140.0141

CONTRAST CON·

TROL

VR141

SYNC. I

JPUT

H

lrHN

_ SYNC.

,. MIXER

V

...

IC102.

J

INTERLACING CONTROL

VR301,

IC30t,

IC302

J

B.

BUFFER

0161

L

t--

BRIGHT

CONTROL

VR140

0171

=t

BLANKING CIRCU!T

0143

.'

BLUE

OUTPUT AMP.

0853,01156

SIDE·PCC

CONTROL· N:i

VR640

PCT

H. OUTPUT

0702

t-

U

200

V

6 Vrms

17'17:

z

w

w

a:

(J

~

'--

.

III

III

::l

u

0

u.

1

500

-900

V

5'.6

kV

~

20

kV

HV

75V

AUTO

DEGAUSS

COIL

V. OUT CIRCUIT

H. SYNC.

PULSE

WIDTH

REGULATOR

\

ICl03

._.

__

. J -H.

DRIVE

0701

fBT

-.9

'H.

OEFLE,...",·

....

u ,.._.f

13V

~

VIDEO AMP.

CUlT

V.

FREO

CIRCUIT

L--.

BLANKING

OUTPUT

H.

SYNC.

IN

V.

SYNC. IN

H.FREO

AFC

HIGH

VOLTAGE.

PROTECTION

V.

FREO

~

V.

OUTPUT0601,

060~

~

V.

DEFLE

t

BLOCK

DIAGRAM

\[

i Version I ]

...

---.'

\.:

:

TO

H. OUTPUT CIRCUIT AUTO DEGAUSS

TH901

POWE~

0

.1

VOLTAGE SWIT·

1----1~-.

TO

H.

DRIVE CIRCUIT

INPUT . CHING REGUl.A

TOR

IC901.0920

TO

H.

FREO.

CIRCUIT

I I C

REO

OUTPUT AMP.

OB51.0B54

CRT

RCUIT

.--

..

I I

j 1

~

I

COLOR

R

R.

BUFFER

0101

I I I

G"

INTERFACE

GREEN

OUT,,;UT I 1

- .

r-

) I )

AMP.

0852.

0855

VIDE )

r-

G.

BUFFER

0131.

INPU B "

IC

101 L 1

-

.1

I

0140.0141

B.

BUFFER

0161

1)",

"

~F

L I

1 AUTO DEGAUSS

BLUE

OUTPUT AMP. z COIL

0853.0856

w

w

a:

CONTRAST CON-

BRIGHT

CONTROL u

......

-

II)

"-

TROL

VR141

VR140.0171

.f::>.

en

I

PIN

DISTORTION J

PCT

:>

1 CONTROL VR640

1702

u

SYNC.

IN

PUT a

'"'"l

...

rHN

_

Ho

SYNC. 6 Vrms

500

·900

V

MIXER Bt.ANKING

CIRCUI.T

V

0143

,..

IC102 H. OUTPUT

0702

5.6

kV

t---

t-

HV

22

kV

LETTER

QUALITY

200

V

75

V • OUT CIRCUIT

CONTROL

0301.

VR301. IC301.

0302

12

V VIDEO AMP.

UIT

FBT

·H.

DRIVE

0701

H.

SYNC.

PULSE

REGULATOR

IC103

~

FREO

CIRCUIT

_~

H.

DEFLE--'-"

-_

..

I J

BLANKING H.

FREQ

.

HIGH

..

OUTPUT VOLTAGE

PROTECTION

L---+

H. SYNC.

IN

V.OUTPUT0601.

.

.:9

V.

DEFL

0602

V. SYNC.

IN

AFC

V.

FREO

~

..

t BLOCK

DIAGRAM

,':.

.~.

-(

....

.:.

..

.:,~.r:l!'~~

.'''.,

•••.

,.''

.........

~11

...

~

••

-

...

,.~'''''

...

,

.....

'''

......

-'''

..

~

••

'''.,

....

,.=-

......

v.""

..

'"""''''':.~.lRi.I!t,=..,.:,

.

..:w

...

,

....

,.:I,.·cY-ersion

II.

1.,

....

•

't

"

.':.

~:"',

'::11

! I ...

!'

....

J,:..·

••

!~.-If~:

1.

Operation Principles

'1-1

Voltage regulator circuit

Primary rec· Voltage regulation

AC INPUT

0--

tification

0901

ICeOl

Voltage detection

,

I

I

I

I

I

1

,i

Output

transformer

T901

,---I

1

Secondary Output

rectification

+115

V

0940

The voltage

regulat~:>r

circuit

of

this unit uses a switching regulator system.

In

other words,

the input

AC

supply voltage

is

rectified to'unfiltered

DC

voltage by the primary rectifier Circuit.

This voltage

is

converted to high-frequency

pulses

by the voltage regulator

IC

(lC90

1)

which

simultaneously performs pulse width control for regulation

of

a secondary rectification output.

The

DC

output

with

no ripple

{+

115V)

is

obtained by the secondary rectifier

0940

following

the passage through the output transformer T901. This

IC

has a built-in overcurrentprotection

circuit.

1-2

Video circuit

(1) Color interface

circuit

Color

setting

switch

S101

Video i

nput

-r I

R

Red

video

buffer

0101

-I , " I

, ,

Color

interl"ce

G I

Green video

buffer

0131

IC101 I

L

B I I

I,

L I

Blue video

buffer

0161

~

Contrast

con-

ABl

trol circuit Blanking output

~

Blanking pulse

0140.0141,

0143'

VR141

+12

V

,

+5

V oUtput

Brighlnessconlrol

"-

Q142,

1.-

VR142 '

I

\'

"

\:

I,

i:

I;

I!

Ii

11

""

I'

i'

Ii

I:

I

!:

Ii

q

Ii

I!

~

"

i

To video

output

amplifier circuit

The input video signals'R,

G,

B,

I

are

combined

by

IC101 into optional colors (e.g. IBM colors,

Apple colors, standard colors) set up by the color setting switch

S1

01

and sent to the respec-

tive video buffers

(0101,

'0131;

0161), The output voltage level of the color

in~erface

ICl

01

''':'-1"5

:.:

(

I •

(

can

be

controlled by

the

contrast circuit of

0140,0141,

VR141, which permits

screen

brightness·

control. The contrast circuit also has

an

ABL circuit attachment

which,prevents

the

CRT

beam current from increasing abnormally when trouble occurs.

The blanking circuit

0143

and brightness control

VR

142 connected between the color in-

terface and video buffers

are

used for blanking and black level control.

(2) Video amplifier circuits

AI

R

RED

OUTPUTAMP.

0851.0854

G G

From video

GREEN

OUTPUT

AMI(.

To CRT

buffer

circuit

0852,0855

cathode

L,

.,

,

j

B B

BLUE

OUTPUT AMP.

0853,0856

L

B.K.G control VRS01,

VRI311, VRS21

The

R,

G,

B;

video signals composed by the color interface circu"it pass thr·ough the video

buffer circuitsand are entered

in

the respsctive

R,

G,

Bvideo output amplifiers where they

are amplified to about 5b Vp-p for output to the

CRT

cathode. The background (B.K.GJ

control resister VR801 (red), VR811 (green), VR821 (blue) which serve to fix the

CRT

cutoff

level are connected between the video output amplifiers and the

CRT

cathode.

1-3 Vertical deflection circuit

r-l

H.SYNC.PULS'

~

To

blanking circuit

WIDTH REGULATOR .

IC103

17

101

;

SY(lC

com-

-I

Sync:

I.

V.

blanking shaping J

separator

I position L J

8

. I

IC102

I

I

' 7

J.

I

I Oscillation J Amplification J

L J I

61 3 4 1

V.lIN

V.

SIZE

+7L

~603

Sync: selector

switch

S101

bit

5

IC701

+12

V

Vertical

output

VerticalDY

0601.

Q602

-

16

-

The sawtooth oscillating voltage isgenerated by

the'

charge

and

discharge of C603. During

a vertical flyback period,'C603

is

charged from pin @ of

the

IC701 by the switching i

transistor inside the

IC.

During a scanning period, it

is

discharged by the resistor R602 ~

and the verticallinearlitycontrol

VS701

@ connected to·pin @ of the

IG.

As aresult, i

....

the potential slowly decreases. When this potential reaches the same level

as

that applied ,

to pin

Q)

of

the

IC,

the charging starts again by the switching transistor in the

IC,

I

i

corresponding to the flyback period. Meanwhile, the output voltage applied to the deflection

yoke

is

amplified by the amplifier circuit inside the

IC

and.

applied to the vertical output

transistor Q601,

0602

from pin

CD

of the

IC.

These transistors drive the vertical

DY.,

:1

;

I

I

I

I

••

1.

----J

I I Scanning period

Flyback period I

I

:!

I

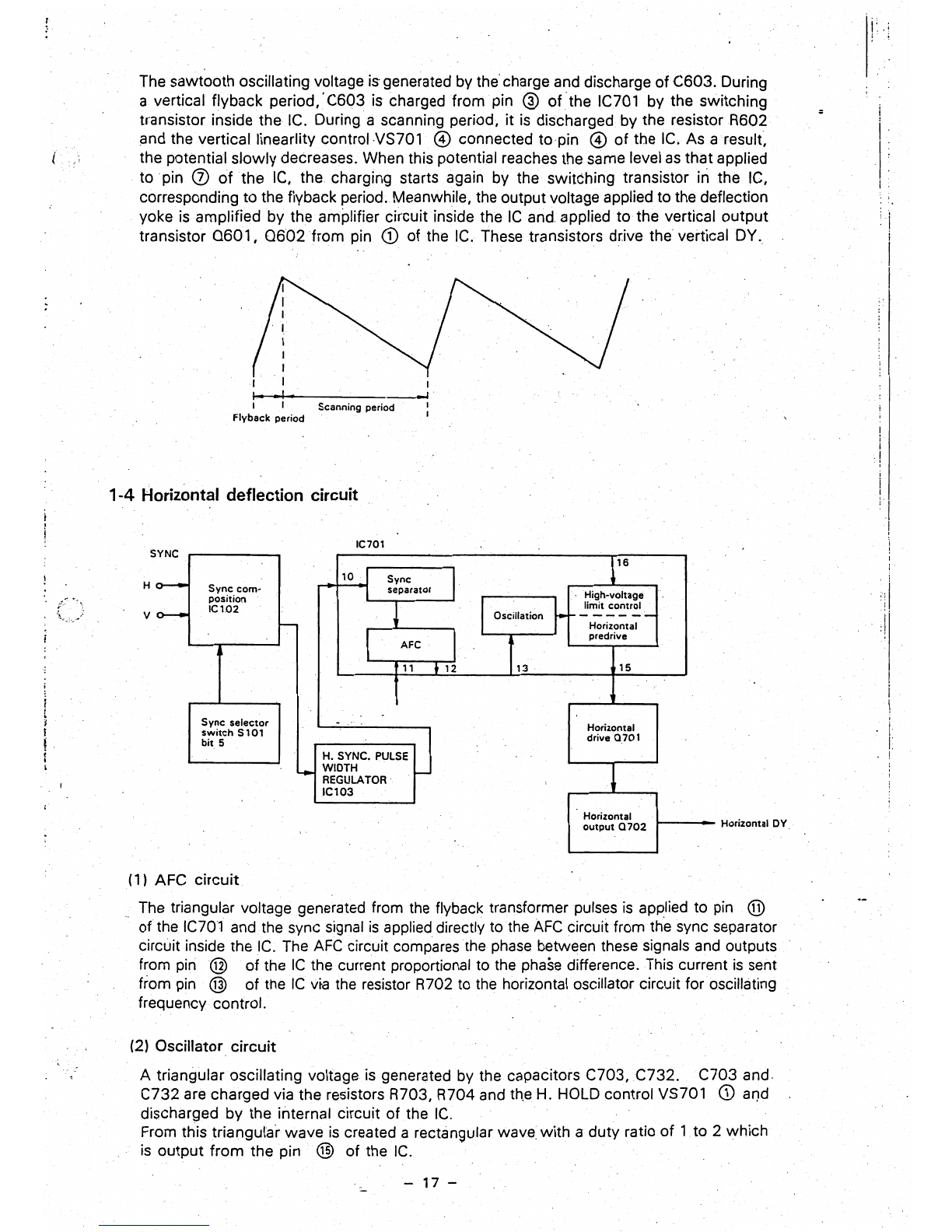

1-4

Horizontal deflection circuit

IC701

SYNC J

16

10

I Sync

H

0--

Sync

com·

separator

I , High·voltage

position

IC102

limit control

v

0--

IOscillation

~

---~--

f-

Horizontal

;

t

Sync

selector

I

switch

S101

L

bit

5

;

I

L

(1)

AFC circuit,

predrive

AFC

l I

l,3

''

11

• 12 15

. Horizontal

drive 0,701

H.

SYNC.

PULSE

"-

WIDTH

-

REGULATOR I

ICt03

Horizontal Horizontal

DY

output

0702

'.

The

triangular voltage generated from

the

flyback transformer

pulses

is

applied to

pin

®

of the

IC701

and the sync signal

is

applied directly

to

the

AFC

circuit from the sync separator

circuit inside the

IC.

The

AFC

circuit compares the

phase

between

these

signals

and

outputs

from

pin@

of the

IC

the current proportional to

the

phase

difference.

This

current

is

sent

from

pin

® of the

IC

vta

the

resistor R702

to

the

horizontal oscillator circuit for oscillating

frequency control.

(2) Oscillator circuit

A triangular oscillating voltage

is

generated

by

the capacitors

C703,C732.

C703 and.

C732

are

charged via the resistors R703, R704 and

th,e

H.

HOLD

control VS701

<D

ar)d

discharged by the internal circuit of the

IC.

From this triangula'r wave

is

created a rectangular

wave:

with a duty ratio

of

1,

to 2 which

is

output from the pin @ of the

IC.

-17 -

(''.

~.

. .

•

"(3) Horizontal drive, horizontal ouput circuit

Since

an

approximate 400 mAp-p must flow

in

the base of the horizontal outputtransistor

0702,

the oscillating voltage

is

amlifiedby the drive circuit composed of 0701 and T701.

Consequently, a linearlyincreasing current flows

in

the coil.

VVhen

Q702

is

non-conducting,

the current previously flowing in

0702

comes to

flowinC717,

C718, C719 for resonance

with these capacitors

and

the coil.

Athalf

of

the resonance cycle, the current direction iSJeversed and the current nowflows

through the damper diode (inside 0702)

+'.

By

making

0702

conducting again while the

current flows

in

this diode, a periodic sawtooth current

is

allowed to flow

in

thehorizontal

coil.

,

..

,L" i r

;/

't

a

702

conduction Resonance Damper diode +11 "

630/640

E,

A,

8,

J,S

period period conduction period

An

approximate 1

kVp-p

pulse voltage generated

by

resonance of the capacitors

and

coil

is

boosted by T703

(FBT)

and

supplied to

each

CRT

electrode, the vertical output circuit, video

circuit, etc.

(4) High-voltage

limit

control circuit

If a high voltageapplit;d to

CRT

from T703

(FBT)

rises abnormallyfor some reason

and

exceeds approximately 28 kV, the high-voltage detector voltage output from pin 0 of

T703

(FBT)

is

applied to pin @

of

IC701, which stops the output

of

the horizontal

predrive inside the IC701.

9

r.

'"

. !.

"

.

;

..

-

18

-

This manual suits for next models

3

Table of contents

Other Taxan Monitor manuals