Taxan Ergovision 740 LR User manual

ee

oe

coueal!’

Game!

Ges.

Se

Ae

ee,

TY

L

hex

oe

Brertincs

TPAXAN

Document

Title:

Ergovision

740

LR

&

740

TCO

Service

Manual

001

Nigel

Inkson

issue

Number:

Issued

By:

Revisions:

001

Original

Issue

22/05/96

Document

Control

Date

of

Issue:

22/05/96

oe

on

ee

|

th

i

f..

ee

ee

ee

bbvssrene

ie

Safety

Standards

and

Approvals

This

monitor

complies

with

DHHS

Rules

21

CFR

Subchapter

J

Applicable

at

date

of

manufacture.

Certified

to

comply

with

che

limits

for

a

Class

B

computing

device

pursuant

to

part

15

of

FCC

rules

Please

refer

to

instructio~s

included

FCC

notice

in

the

user’s

manual

if

this

equipment

is

suspected

of

causing

interference

tc

radio

reception.

Important

Safety

Notice

This

equipment

conizins

special

components

which

are

important

for

safety.

These

critical

parts

should

only

be

replaced

with

the

parts

specified

by

the

manufacturer

in

order

to

prevent

X-radiation,

shock,

fire

or

other

hazards.

Do

not

modify

the

orginal

design.

Mi

Preface

i

Before

You

Start

General

Safety

Precautions

1.

Use

an

isolation

transformer

in

the

power

line

and

AC

supply

to

troubleshoot.

2.

When

servicing,

observe

the

original

lead

dress,

espe-

cially

in

the

high

voltage

circuits.

If

a

short

circuit

is

found,

replace

all

parts

which

have

been

overheated

or

damaged.

3.

Before

turing

the

display

on,

measure

the

resistance

between

B+

line

and

chassis

ground.

Connect

the

nega-

tive

side

of

an

ohmmeter

to

the

B+

fines

and

the

positive

side

to

chassis

ground.

Each

line

should

have

more

resisstance

than

the

following

specifications:

|

+200V

134.5KQ

|

}

TV

60.51KQ

(eee

ees

ee

ee

PER

Bak

|

+15V

27.13KQ

|

4.1502

4.

Potentials,

as

high

as

26kV

are

present

when

this

display

is

in

Operation.

Operation

of

the

display

without

the

rear

cover

involves

the

danger

of

a

shock

hazard

from

the

display

power

supply.

Servicing

should

not

be

at-

tempted

by

anyone

who

is

not

thoroughly

familiar

with

the

precautions

necessary

when

working

on

high

volt-

age

equipment.

Always

discharge

the

anode

of

the

pic-

ture

tube

to

the

display

chassis

before

handling

the

tube.

5.

After

servicing,

be

sure

to

check

the

items

listed

in

the

Safety

Checkout,

below

before

returning

the

serviced

unit

to

the

customer.

Safety

Checkout

The

following

checks

must

be

made

after

correcting

the

original

service

problem

and

before

the

unit

is

returned

to

the

customer.

1.

Check

the

area

of

your

repair

for

unsoldered

or

poorly

soldered

connections.

Check

the

entire

board

surface

for

solder

splashes

and

bridges.

2.

Check

the

inter

board

wiring

to

ensure

that

no

wires

are

pinched

or

coated

with

high-wattage

resistors.

3.

Check

that

all

control

knobs,

shields,

covers,

ground

Straps

and

mounting

hardware

have

been

replaced.

Makde

absolutely

sure

you

have

replaced

all

the

insula-

tors.

4,

Look

for

any

unauthorized

replacement

parts,

particu-

larly

transistors,

that

may

have

been

installed

dueing

a

previous

repair.

Point

them

out

to

the

customer

land

recommend

their

replacement.

5.

Look

for

parts

which,

though

functioning,

show

obvious

signs

of

deterioration.

Point

them

out

to

the

customer

and

recommend

their

replacement.

6.

Check

the

line

cord

for

cracks

and

abrasion.

Recom-

mend

the

replacement

of

any

such

line

cord

to

the

customer.

7.

After

making

any

repair,

check

the

B+

and

HV

to

see

whether

they

are

at

the

values

specified.

Make

sure

your

instruments

are

accurate;

if

your

HV

meter

always

shows

a

low

HV,

check

the

meter

to

ensure

it

is

not

malfunctioning.

8.

Carry

out

the

leakage

current

checks

as

detailed

below

overleaf,

Leakage

Current

Cold

Check

1.

Unplug

the

AC

cord

and

connect

a

jumper

between

the

two

prongs

on

the

plug.

2.

Turn

on

the

display

power

switch.

3.

Use

an

ohmmicter

to

measure

the

resistance

value

be-

tween

the

jumpered

AC

plug

and

cach

exposed

metallic

cabint

part

on

the

display,

such

as

scre«heads,

terminals

control

shafts,

etc.

When

an

exposed

metallic

part

has

a

return

path

to

the

chassis,

the

reading

should

be

between

240k

and

5.2M.

When

exposed

mets:

does

not

have

a

return

path

to

the

chassis,

the

reading

must

be.

vy

i,

Leakage

Current

Hot

Check

1.

Plug

the

AC

cord

into

the

AC

outlet.

Do

not

use

an

isolation

transformer

for

this

check.

2.

Connect

a

1.5k,

10

watt

resistor

in

parallel

with

a

0.15F

capacitor

between

each

exposed

metallic

part

on

the

set’

and

a

good

earth

ground

(see

How

to

Find

a

Good

Earth,

below)

as

shown

in

the

diagram

below.

Leakage

Current

Hot-Check

Circuit

AC

VOLTMETER

oY

—~O

o

0.15nF

=

MW

15002,

10W

To

instrument's

—*

exposed

metal

parts

Example

of

Leakage

Current

Hot-Check

Circuit

Good

earth

ground

3.

Use

an

AC

voltmeter

with

1000

ohms/volt

or

more

sensitivity

to

measure

the

potential

across

the

resistor.

4.

Check

each

exposed

metallic

part,

and

measure

the

voltage

at

each

point.

5.

Reverse

the

polarity

of

the

AC

plug

in

the

AC

outlet

and

repeat

the

above

measurements.

6.

The

potential

at

any

point

should

not

exceed

0.75

volt

RMS.

A

leakage

current

tester

(Simpson

Model

229,

RCA

WT-540A

or

equivalent)

may

be

used

to

make

the

hot

checks.

Leakage

current

must

not

exceed

0.5

milliamp.

Ifa

measure-

ment

is

outside

of

the

specified

limit,

there

is

a

possibility

of

a

shock

hazard

and

the

monitor

should

be

repaired

and

re-

checked

before

it

is

returned

to

the

customer.

How

to

Find

A

Good

Earth

A

cold

water

pipe

is

a

guaranteed

earth

ground;

the

cover

plate

retaining

screw

on

most

AC

outlet

boxes

is

also

at

earth

ground.

If

the

retaining

screw

is

to

be

used

as

your

earth

ground,

verify

that

it

is

at

ground

by

measuring

the

resistance

between

it

and

a

cold

water

pipe

with

an

ohmmeter.

The

reading

should

be

zero

(0)

ohms.

If

a

cold

water

pipe

is

not

accessible,

connect

a

60-100

watt

trouble

light

(not

a

neon

lamp)

between

the

hot

side

of

an

AC

power

receptacle

and

the

retaining

screw.

Try

both

slots,

if

necessary,

to

locate

the

hot

side

of

the

line.

The

lamp

should

light

at

normal

brilliance

if

the

screw

its

at

ground

potential

Trouble

light

Mie

Ohmmeter

AC

Wall

Socket

Cold

water

pipe

How

to

Check

for

Earth

Ground

Table

of

Contents

[Section

1)

Product

Specification

1.1.Monitor

Control

Locations

&

Functions

.

2...

0

ee

ee

ee

1-1

1:2:Product

Overview.

6.6

eck

a

ee

Re

te

ew

Oe

Ee

1-2

1:3:CRT

Characteristics:

«ise

sok

Zak

de

Ae

OE

ee

SR

1-2

44.

Power

SpeciliGations:

o.&

%-%.4

a

wi.

cameta

Ae

he

Ge

eae

eee

we

ewe

GAS

1-2

PVA

ATPOWErSUDDIV:

4.

Gas

GE

eee

Reh

Be

ae

ee

a

ee

Ee

ew

S

1-2

1.4.2.PowerManagement

...

0...

2

1-2

1.5.Video

Specifications.

2

0.

ee

1-2

1.5.1.Video

Amplifier

Performance.

........

Rade

eae

ba

Ses

eh

det

va

a

Meee

a

Peery

Gack

1-2

1.5.2.Video

Input

Signal

Characteristics

..

0.

0

ee

ee

1-2

1.6.Syne

Inpub’Signal

Characteristics:«-

«

x-y.4.4

ste

aw

G

hee

oh

ok

eA

ge

we

1-2

Os

Separate:

Synce

sei

2

cet

neta

we

Ea

a

een

Ohne

aint

AO

ee

1-2

4:

6:2.Composite:Sync.

sk

sce

eta

wa

RB

a

ek

ee

ede

1-2

16:3:;Syne-On-Greens:..4,

ats.

isk

a

ee

ees

PS

Posed

Sah

eee

he

Ae

ae

ee

1-3

Te7-Environmentalis

25.4.

248

ae

ee

a

ae

ER

Ae

te

en

Ae

ee

ee

1-3

1.7.1.Temperature/Humidity/Altitude

.......

teddies

ee

ates.

tf

oe

a

eas

1-3

1752

Vibration

Test.

sa

vee

ised

Gea

we

AA

oe

we

ene

ek

be

ae

Gee

1-3

TFS

sDIOD

MOS

4:

ate

te

ok

Aad

va

GE

ee

ee

Ee

OT

a

1-3

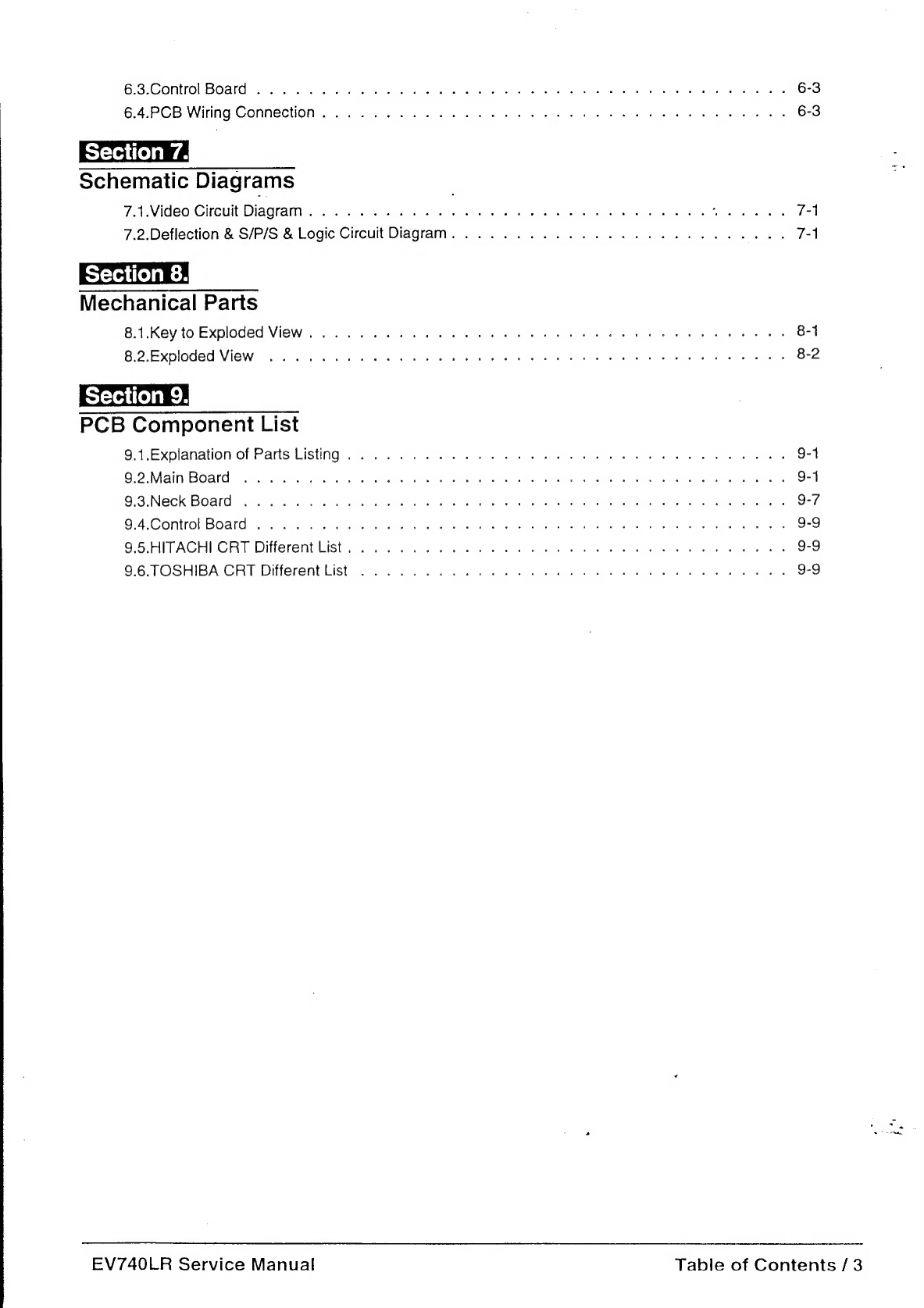

1.8.Preset

Timing

Modes

.

2...

1-3

[Section

2.

Disassembly

Instructions

2.1.Removing

the

Rear

Cover

2.

10.

2-1

2.2.Remove

Top

Shield

and

Rear

Shield...

2...

2

ee

ee

2-1

2.3.Internal

Disassembly

(Right

Side).

2

2

2

2-1

2.4.Internal

Disassembly

(Left

Side)

.

2...

ee

2-1

2.5.Removing

the

Neck

Board

&

Main

Board...

1...

es

2-2

2.6.Remove

the

Control

Board

..

2...

2.

2-2

[Section

3,

Theory

of

Operation

3.1

ySwitehing

Power

Supply”

4.02

4.0.

2g

Aes

ieee

A

Eb

be

Be

a

ee

et

3-14

Sol

WwAUtO-degauSsing:

6...

ad

ota

aoe

Sayer

ae

Sl

be

ae

aes

we

deat

ed

3-2

3.1.2.Suspend

Mode

Operation

..

1...

3-2

3.2.The

Deflection

Circuit.

2.

3-2

3.2.1.16301

LM1291

Video

PLL

System

for

Continuous-Syne.

2...

ee

3-2

3.2.2.1C301

LM1291

Pin

Descriptions

..

2...

2.2...

ee

3-4

3.2.3.1C302

LM1295

DC

Controlled

Geometry

Correction

System

2...

2.

...02..

3-5

3.2.4.1C302

LM1295

Pin

Descriptions

..

2...

ee

3-5

3.2.5.Vertical

Deflection

Circuit.

2.

0

2

2

ee

ae

ee

ee

ee

3-6

3.2.6.Geometry

Correction

Circuit

2...

3-7

3.2.7.Structure

of

Horizontal

Deflection

Circuit.

2

2

ee

3-7

3:2.8.X-RAY

Protection:

Citeult

.205

cee

ew

op

a

we

ee

3-12

S279:

The

FOCus

Circuit

oa

sye,

oe

ier

Bel

a

eS

OH

ad

ee

he

Sd

A

3-12

EV740LR

Service

Manual

Table

of

Contents

/

1

3.2.10.Horizontal

linearity

and

CS

Switching

|

.

3.3.Video

Amplifier...

2...

002,

3.4.Microprocessor

And

Sync

Processing

......

.

Section

4

Setup

Adjustments

4.1.Preparing

the

Display

for

Adjustment

...

2...

4.1.1.Test

Equipment

Required...

0.0.2.2...

4.2.Adjustment

Procedures

........020022..,

4.2.1.Adjustment

Sequence

...........,

4.2.2.Preset

Timings

Used

During

Adjustment

4.3.High

Voltage

Verification...

.......022.

4.4.G1

Voltage

Adjustment...

.....000000.

4.5.Background

Brightness

Setting

..........

4.6.Screen

Brightness

Adjustment...

.....020..,

4.7.Magnetic

Field

Configuration.

.......20202..,

4.8.Raster

Center

Verification

.......0002,

4.9.Tilt

Verification

2.2.0.0...

.000000000,

4.11.Color

Misconvergence

.............

4.12.Primary

Test

Mode

Performance

Adjustments

.

4.13.Performance

Adjustments

for

All

Preset

Modes

4.14.lmage

Performance

Verification

..

2.0.0...

4.15.Uniformity

Verification.

.

2...

4.16.Brightness

Verification

Hg)

FN

Ae

we

ae

4.17.Display

Size

Stability

2...

000.0000

20.,

4.18.Color

Purity

Verification...

2...

4.19.Video

Noise...

.

2...

ee

4.20.Power

Saving

Check

.........,..0.2..

4.21.DDC

1/2

Data

Writing...

2...

[Section

5.

Troubleshooting

5.1.No

Display

at

Power-on

..

2...

.0.020002..,

5.2.No

X-ray

Operation...

2...

2...

5.3.No

Video

Operation

........0..00020..

5.4.Poor

VerticalLinearity

..........0.00.,

5.5.Poor

Horizontal

Linearity...

2...

2

5.6.Poor

Uniformity...

5.7.Tilted

Display

Area...

5.8.Misconvergence

............0.....,

5.9.Poor

Regulation

.

2...

00000020204,

5.10.PoorFocus

...............0.

0...

[Section

6,

Printed

Circuit

Boards

6.1.Neck

Board...

.....02.2.20,022..,

6.2.Main

Board

......2.2.,20202202..,

2/

Table

of

Contents

6:3:

Control:

Board’

ss

sch.

acee

y,

ae

a

we

Bah

Soe

IS

al

ak

ae

a

Se

6-3

6.4.PCB

Wiring

Connection...

2.

ee

6-3

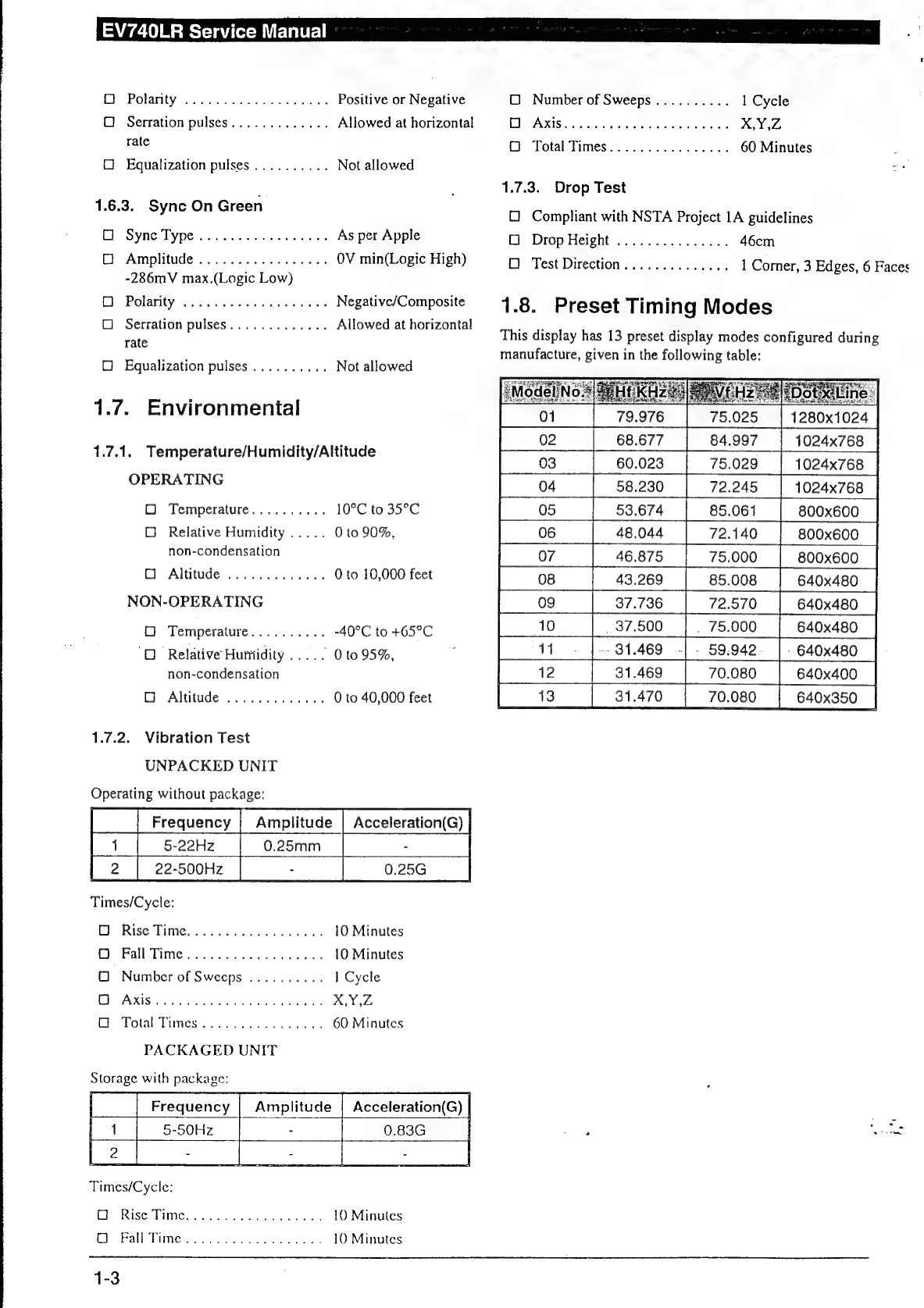

Schematic

Diagrams

7.1.Video

Circuit

Diagram

.

6.

1

toluene

7-1

7.2.Deflection

&

S/P/S

&

Logic

Circuit

Diagram...

2...

ee

ee

7-1

Mechanical

Parts

Be

Key

to-Exolodad

Views

«oce's

ak:

b

Aes)

AR

a

ee,

©

OS

He

Be

a

OR

eS

8-1

6:2.Exploded

VieW:

25

Lak

lise

dete

ee

ae

a

ee

a

et

eed

ea

gS

he

8-2

[Section

9!

PCB

Component

List

9.1.Explanation

of

Parts

Listing...

ee

9-1

9:2"

Main

Board:

c.g

8

sara

Ce

acds

Foc

hee

A

ee

er

ee

ER

ae

ee,

ee

ee

te

9-1

9:9:Neck

Board!

2-23

oso.

Gls

8 a

Rte

ws

ate

a

ee

od

te

a

A

a

9-7

9:4.

Control:

Board.

2.3

05.

eo

ee.

te

SIS

ER

ey

Ge

oie

at

pe

he

eB

We

we

9-9

9.5.HITACHI

CRT

Different

List.

2.

2

2.

9-9

9.6.

TOSHIBA

CRT

Different

List

2...

2

9-9

EV740LR

Service

Manual

Table

of

Contents

/3

Notes

4/

Table

of

Contents

EV740LR

Service

Manual

~

Product

Specification

Tate

Monitor

Control

Locations

and

Functions

........-

1-1

1.2.

Product

Overview

...

2...

0.

cee

eee

eens

1-2

13;

CRT

CharacteristicS

..

0...

6c

cee

eee

eee

1-2

1.4.

Power

Specifications.

0.6...

.

eee

eee

eee

eee

1-2

1.5.

Video

Specifications

....

6...

cere

eee

eee

ees

1-2

1.6.

Sync

Input

Signal

Characteristics

........-..++-.

1-2

Tet

Environmental.

......00

00

ee

eee

eee

teenies

1-3

1.8.

Preset

Timing

Modes

......-.-.

seer

tress

1-3

EV740LR

Service

Manual

:

:

:

1.1.

Monitor

Control

Locations

&

Functions

TAXAN

crconsion

rin

laongs

‘s

Set

\

EPA-POLLUTION

PREVENTER

SELECT

aDjUST

f

N“N

v4

és

7s

c

}

Se

7

N

x

“N

4

~~

4

_~

Y

XS

/

SS

DEG

SELECT/

CED)

ei

Oo

|

:

|

ies

ae

rae)

:

©

|

|

KEY

TO

BUILT-IN

MONITOR

CONTROL

FUNCTIONS

Manual

Degauss

and

Ractery.

Se

ing

Recall

unction

Digital

control

for

manual

degauss

of

monitor

at

the

normal

condition

and

for

recall

the

origional

factory

setting,

during

OSD

pattern

is

on

screen.

Thumbwheel

for

Adjusting

Setting

and

OSD

Function

Selection

Thumbwheel

for

adjusting

the

setting,

clockwise

for

increasing

and

counterclockwise

for

decreasing

and

selection

the

OSD

function

icon.

Push

Button

for

OSD

|

Press

to

call

up

OSD

function

into

screen

and

confirm

the

thumbwheel

ON/OFF

and

enter

for

icon.

Thumbwheel

Enter

Confirm

Increase

/

decrease

raster

black

level

using

thumbwheel

adjusting,

Brightness

Control

:

B

clockwise

for

increasing

and

counterclockwise

for

decreasing.

utton

Contrast

Control

Butto

Increase

/

decrease

video

gain

using

thumbwheel

adjusting,

clockwise

for

n

increasing

and

counterclockwise

for

decreasing.

Hard

power

On/Off

button.

Adjacent

LED

is

lit

when

on.

The

LED

color

is

green

for

normal

condition

and

change

to

orange

for

DPMS

condition.

—

Power

On/Off

1-1

:

Product

Specification

1.2.

Product

Overview

[]

EPA

energy

star.............

standby

<

30

watts

The

monitor

installed

in

the

EV740LR

(RMH

7H11)

phom

described

in

this

service

manual

has

the

following

features:

1.5.

Video

Specifications

O

17

inches

0.26mm

dot

pitch

conventional

CRT

1.5.1.

Video

Amplifier

Performance

30-85

kHz

horizontal

scanning

:

.

;

O

Bandwidth

(dot

rate).........

135MHz

O

Thirteen

preset

modes

:

:

;

;

O

Typical

10%~90%

rise

and

fall

times

calculation

5.5ns

1

Universal

segmented

auto

range

power

supply

: ;

;

;

.

O

Video

generator

rise/fall

times

.

2ns

maximum

O

VESA/NUTEK/EPA

compliant

power

management

;

O

Scope

and

probe

bandwidth

...

350MHz

minimum

41.3.

CRT

Characteristics

O

Probe

capacitance

...........

2.5Pf

:

O)

Overshoot/Undershoot

.......

10%

maximum

O

Screen

Size,............005.

17

inches

:

fC]

Sync

on

green

..............

Amphitude:714mV

O

Faceplate

Type............-.

Fs

maximum

Sync

on

Green

Amplitude:286mV

maximum

O

Orientation.............0045

Landscape

C

Phosphor

Dot

Pitch..........

0.26mm,

1.5.2.

Video

Input

Signal

Characteristics

delta

atvangement

a

:

O

Video

Type

................

Analog

Oo

aan

GUNG

edn

es,

ear

Fi

Amplitudes

ceneniucesley

ss

700mV

maximum

a

oe

etree

ae

:

cee

O

Video

Input

Impedance.......

75

Ohms+1%

cic

a

ee

1

Optional

DDC

1/2B

Video

Connector

Pin

Assign-

O

Phosphor

Type.............-

P22

fients:

CO

Phosphor

Persistence.........

Medium

Short

O

Faceplate

Properties..........

ASN

coating,

mn

on

nner

anti-static,

anti-reflection

|

pin.

Signal

|

O

Standard

Light

Transmission...

53.5%

Typical

Red

video

Bd

:

Sync

return

1.4.

Power

Specifications

Monitor

GND

12

|

SDA(bi-directional)

|

1.4.1.

Power

Supply

13

1H.

sync

O

A/C

Receptacle

..........-0.

1EC320

14

|V.

sync

(VCLK)

_|

O

Power

Supply

Type..........

Universal

|

15

[SCL

O

A/C

Line

Voltage

Ranges

.....

88VAC-132VAC

180VAC-264VAC

O

A/C

Line

Frequency

Ranges

...

50Hz/60Hz+3Hz

|

YOO®O®

O

Inrush

Current..............

30A/132V

or

|

©®O®O®

@

SOA/264V

(at

cold

start)

ig

Q®R

OG

O

Leakage

Current.............

<3.5mA

|

sai=s

=

O

Degauss

.............-.

000

Automatic

and

Manual

(20

minutes

for

a

full

recovery)

1.6.

Sync

Input

Signal

Characteristics

1.4.2.

Power

Management

Oo

Summary

of

operating

states:

1.6.1.

Separate

Sync

Automatic

O

Syne

Type

.......

2.2

eee

TTL

EE

ONELY

:

ad

Time

O

Amplitude

..............0.0.

2.4V

minimum

green

not

applicable

(Logie

High),

0.8V

max.(Logic

Low)

orange

<3

seconds

QO

Polartly

..

0.0.0.0...

ee

eee

Positive

or

Negative

orange

<10

seconds

(1

Equalization

pulses

..........

Not

allowed

orange

<10

seconds

Shan’

;

1.6.2.

Composite

Sync

|

green

not

applicable

" ;

;

mot

O

Syne

Type

......

62...

eee

TTL

O

Signaling

compliant

with

VESA

DPMS

guidelines

:

}

aot

O

Amphtude...........0..00.

2.4V

minimum

O

Nutek

1992

guidelines........

suspend

<

30

watts;

(Logic

High),

0.8V

max.(Logic

Low)

off

<

8

watts

EV740LR

Service

Manual

La

O

Polarity

................2..

Positive

or

Negative

O

Serration

pulses.............

Allowed

at

horizontal

rate

(

Equalization

pulses..........

Not

allowed

1.6.3.

Syne

On

Green

O

Syne

Type..............04.

As

per

Apple

O

Amplitude

.................

OV

min(Logic

High)

-286mV

max.(Logic

Low)

O

Polarity

................04.

Negative/Composite

Ol

Serration

pulses.............

Allowed

at

horizontal

rate

O

Equalization

pulses.......,..

Not

allowed

1.7.

Environmental

1.7.1.

Temperature/Humidity/Altitude

OPERATING

O

Temperature..........

10°C

to

35°C

O

Relative

Humidity

.....

0

to

90%,

non-condensation

O

Altitude

.............

NON-OPERATING

0

to

10,000

feet

O

Temperature..........

-40°C

to

+65°C

‘O

Relative

Huntidity

.....

0

to

95%,

non-condensation

O

Altitude

.............

0

to

40,000

feet

Vibration

Test

UNPACKED

UNIT

1.7.2.

Operating

without

package:

|__|

Frequency

|

|_i_|

5:22

|

22-500Hz

Times/Cycle:

Amplitude

Acceleration(G)

O

Rise

Time..................

10

Minutes

O

Fall

Time..................

10

Minutes

O

Number

of

Sweeps

..........

I

Cycle

EAS

Soa

eile

aes

ten

tieat

X,Y,Z

C

Total

Times

................

60

Minutes

PACKAGED

UNIT

Storage

with

package:

Acceleration(G)

|

0.83G

Amplitude

Frequency

5-5O0Hz

Times/Cycle:

O

Rise

Time...........0..00.,

10

Minutes

O

Fall

Time........0.....0...

10

Minutes

1-3

O

Number

of

Sweeps..........

1

Cycle

ED

AXIS

oes

pices

eons

bee

ke

a

eed

X,Y,Z

O

Total

Times................

60

Minutes

1.7.3.

Drop

Test

O

Compliant

with

NSTA

Project

1A

guidelines

O

Drop

Height

...............

46cm

O

Test

Direction..............

1.8.

Preset

Timing

Modes

This

display

has

13

preset

display

modes

configured

during

manufacture,

given

in

the

following

table:

eDoti

1280x1024

|

1024x768

1024x768

1024x768

800x600

800x600

800x600

|

43.269

640x480

_|

|

_o9

37.736

640x480

_|

640x480

640x480

|

12

31.469

640x400

31.470

640x350

_|

68.677

60.023

58.230

53.674

48.044

46.875

‘3

CINE

Be

j=)

jee)

1

Corner,

3

Edges,

6

Faces

_

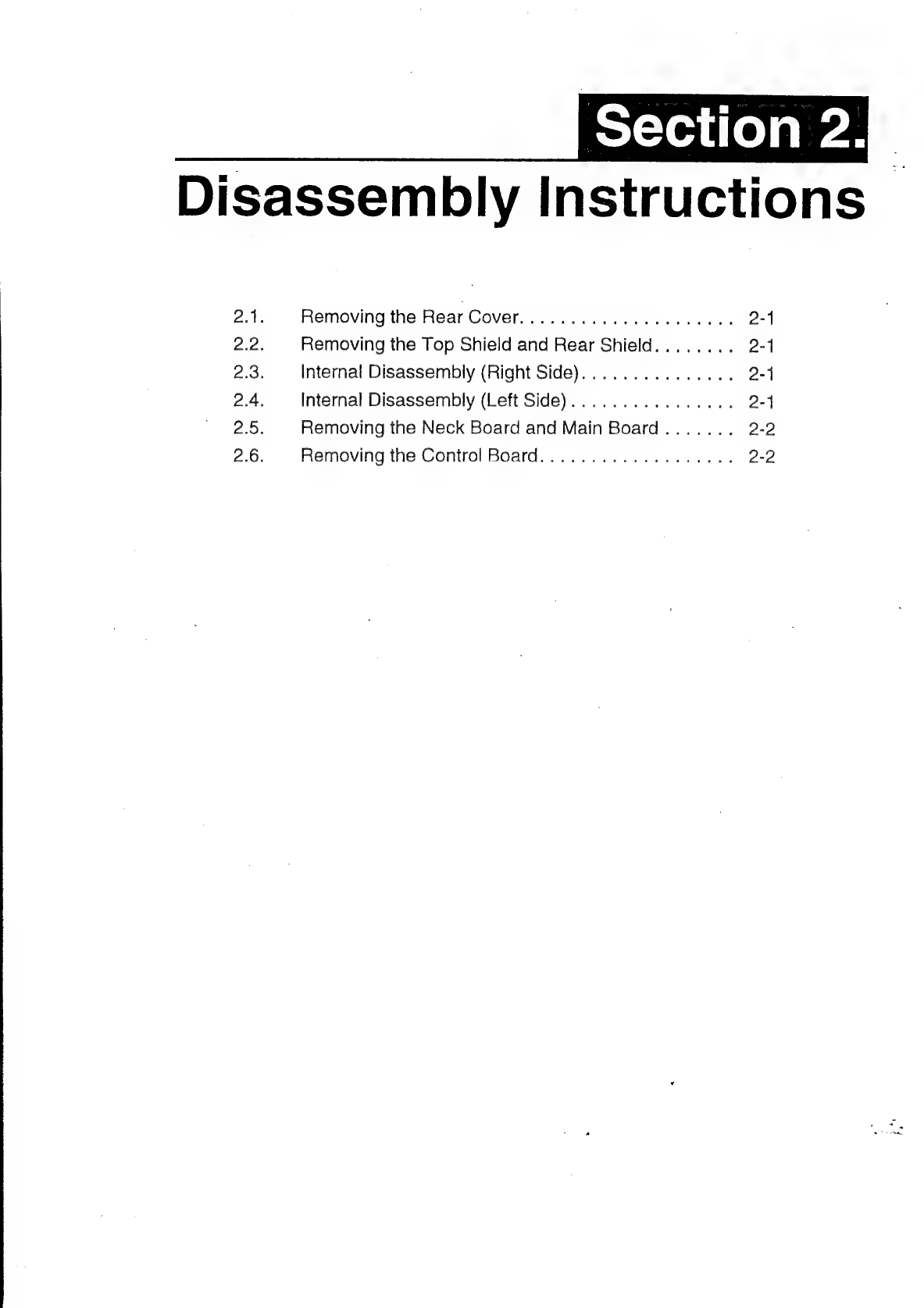

ss

Disassembly

Instructions

—

2A;

Removing

the

Rear

COVE

sd

aN

Million

Dawe

Ota

kes

6

2-1

22.

Removing

the

Top

Shield

and

Rear

Shield........

2-1

2.3,

Internal

Disassembly

(Right

Side)...............

2-1

2.4.

Internal

Disassembly

(Left

Side)................

2-1

2.5.

Removing

the

Neck

Board

and

Main

Board

2.6.

Removing

the

Control

Board................05.

2-2

3

EV740LR

Service

Manual

;

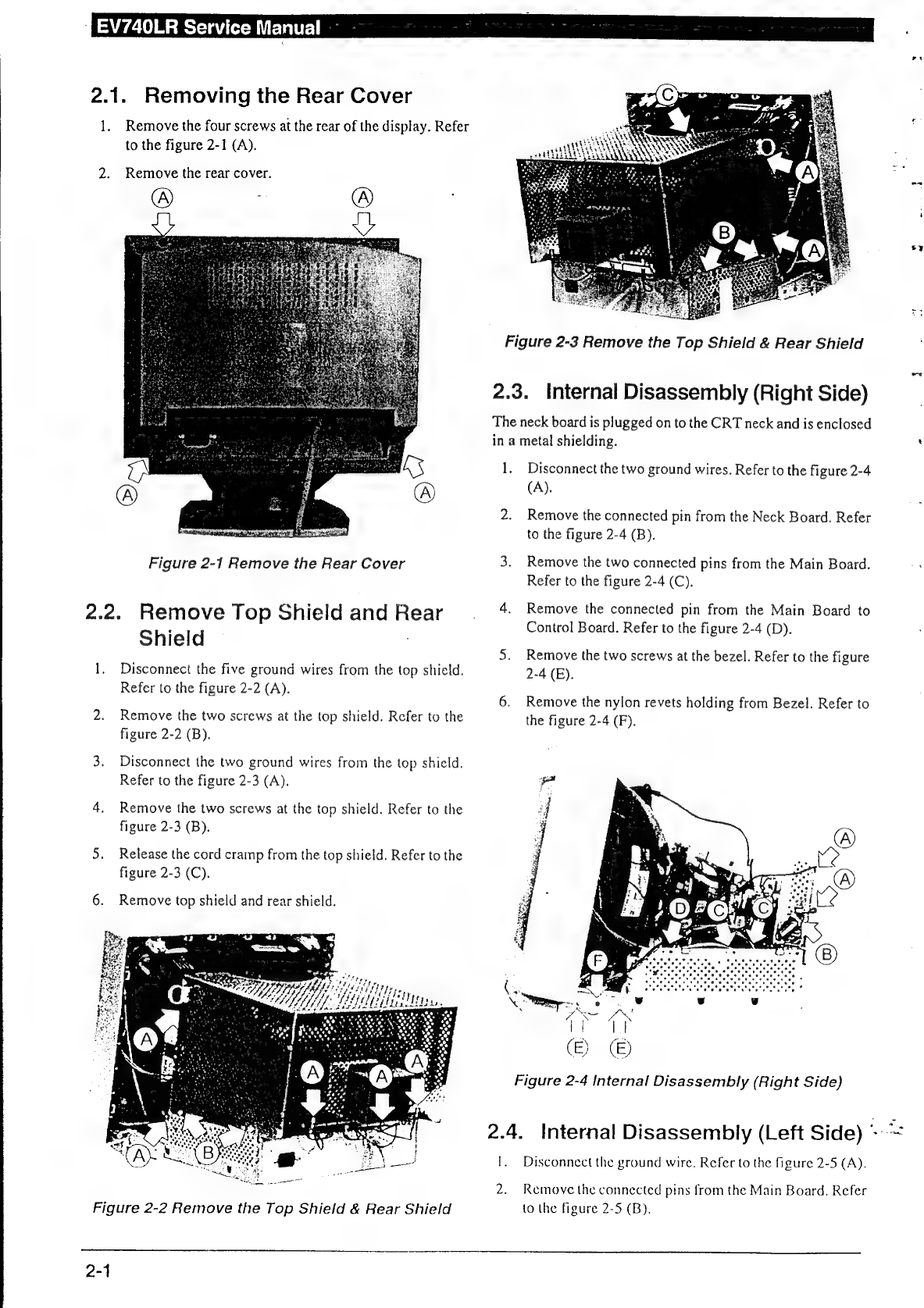

2.1.

Removing

the

Rear

Cover

1.

Remove

the

four

screws

at

the

rear

of

the

display.

Refer

to

the

figure

2-1

(A).

2.

Remove

the

rear

cover.

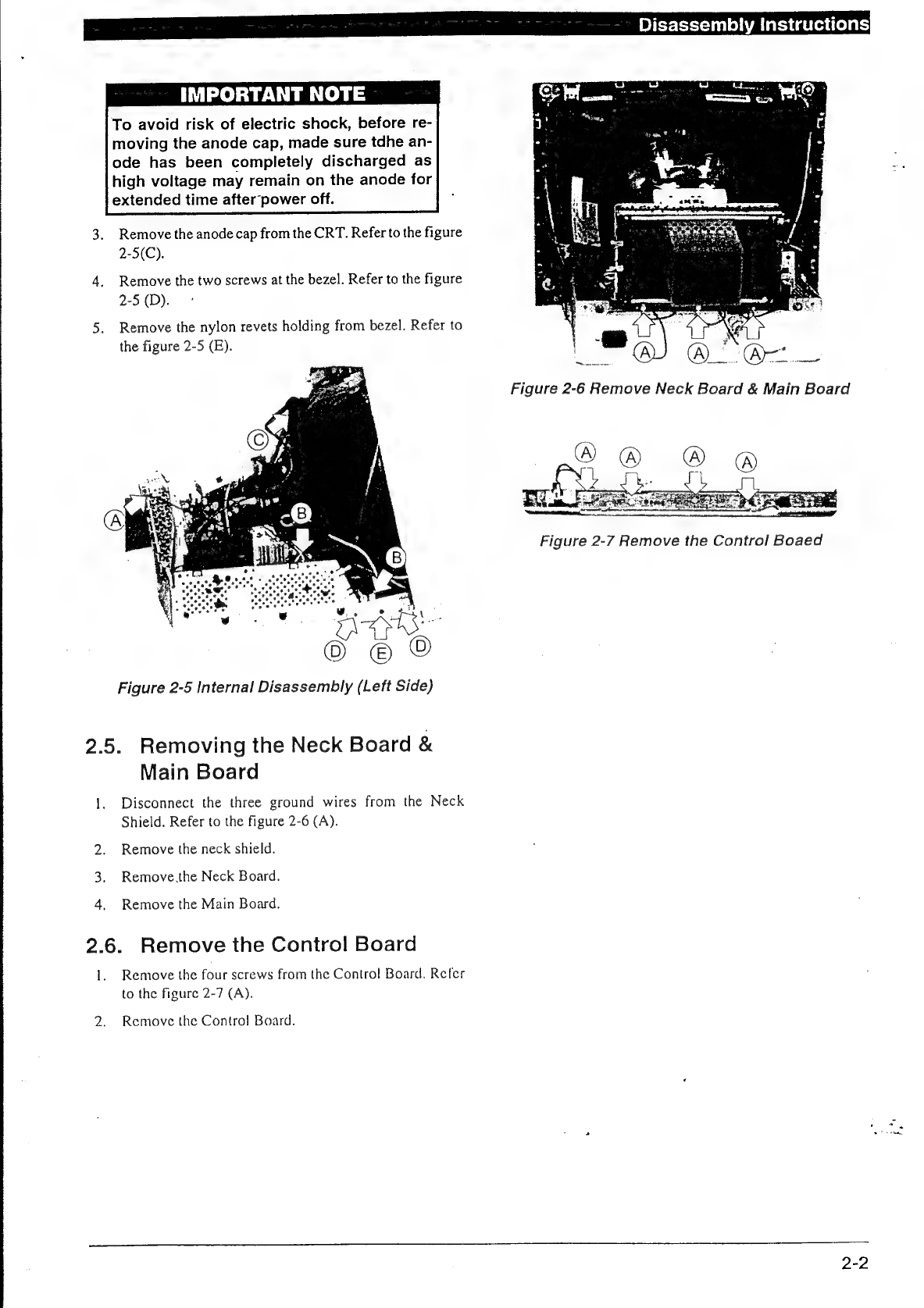

Figure

2-3

Remove

the

Top

Shield

&

Rear

Shield

2.3.

Internal

Disassembly

(Right

Side)

The

neck

board

is

plugged

on

to

the

CRT

neck

and

is

enclosed

in

a

metal

shielding.

1.

Disconnect

the

two

ground

wires.

Refer

to

the

figure

2-4

(A).

2.

Remove

the

connected

pin

from

the

Neck

Board.

Refer

to

the

figure

2-4

(B).

Figure

2-1

Remove

the

Rear

Cover

3.

Remove

the

two

connected

pins

from

the

Main

Board.

Refer

to

the

figure

2-4

(C).

2.2.

Remove

Top

Shield

and

Rear

_

4.

Remove

the

connected

pin

from

the

Main

Board

to

Control

Board.

Refer

to

the

figure

2-4

(D).

Shield

5.

Remove

the

two

screws

at

the

bezel.

Refer

to

the

figure

1.

Disconnect

the

five

ground

wires

from

the

top

shield.

2-4

(E).

Refer

to

the

figure

2-2

(A).

=

A)

6.

Remove

the

nylon

revets

holding

from

Bezel.

Refer

to

2.

Remove

the

two

screws

at

the

top

shield.

Refer

to

the

the

figure

2-4

(F).

figure

2-2

(B).

3.

Disconnect

the

two

ground

wires

from

the

top

shield.

Refer

to

the

figure

2-3

(A).

an

ze)

a

4,

Remove

the

two

screws

at

the

top

shield.

Refer

to

the

figure

2-3

(B).

]

5.

Release

the

cord

cramp

from

the

top

shield.

Refer

to

the

figure

2-3

(C).

6.

Remove

top

shield

and

rear

shield.

Figure

2-4

Internal

Disassembly

(Right

Side)

2.4.

Internal

Disassembly

(Left

Side)

=~

1.

Disconnect

the

ground

wire.

Refer

to

the

figure

2-5

(A).

2.

Remove

the

connected

pins

from

the

Main

Board.

Refer

Figure

2-2

Remove

the

Top

Shield

&

Rear

Shield

to

the

figure

2-5

(B).

2-1

rs

Ss?

Disassembly

Instructions

IMPORTANT

NOTE

To

avoid

risk

of

electric

shock,

before

re-

moving

the

anode

cap,

made

sure

tdhe

an-

ode

has

been

completely

discharged

as

high

voltage

may

remain

on

the

anode

for

extended

time

after

power

off.

3.

Remove

the

anode

cap

from

the

CRT.

Refer

to

the

figure

2-5(C).

4.

Remove

the

two

screws

at

the

bezel.

Refer

to

the

figure

2-5

(D).

5.

Remove

the

nylon

revets

holding

from

bezel.

Refer

to

the

figure

2-5

(E).

Figure

2-7

Remove

the

Control

Boaed

Figure

2-5

Internal

Disassembly

(Left

Side)

2.5.

Removing

the

Neck

Board

&

Main

Board

1.

Disconnect

the

three

ground

wires

from

the

Neck

Shield.

Refer

to

the

figure

2-6

(A).

2.

Remove

the

neck

shield.

3.

Remove.the

Neck

Board.

4.

Remove

the

Main

Board.

2.6.

Remove

the

Control

Board

1.

Remove

the

four

screws

from

the

Control!

Board.

Refer

to

the

figure

2-7

(A).

2.

Remove

the

Control

Board.

EV740LR

Service

Manual

Notes

2-3

3.1.

3.2.

3.3.

3.4.

Theory

of

Operation

Switching

Power

Supply

The

Deflection

Circuit

Video:

AMDIING!

«40st

scan

ae

eat

eas

eee

eS

3-12

Microprocessor

and

Sync

Processing............

3-13

EV740LR

Service

Manual

_

|

3.1.

Switching

Power

Supply

The

switching

power

supply

(SPS)

used

in

this

display

is

a

150W

flyback

mode

type.

The

power

supply

provides

seven

outputs

(B+,

77V,

15V,

-15V,

6.3V

,415V

and

+5V).

Please

refer

to

schematic

diagram

for

details

of

the

circuit

layout.

The

input

voltage

is

from

88VAC

—

264VAC

with

an

input

frequency

of

47Hz

—

63Hz.

as

shown

in

figure

3-1.

The

current

first

passes

through

the

EMI

control

circuit

and

is

regulated

to

DC

by

the

bridge

diodes

(BD901)

and

filter

capacitor

(C907).

During

rectification

a

large

current

surge

is

generated

and

as

C907

has

a

very

low

impedance

while

being

charged

the

fuse,

on/off

switch

and

bridge

diode

are

all

liable

to

be

damaged.

Forthis

reason,

a

thermal

resistor

(NTCR)

is

added

before

the

bridge

diode

in

order

to

limit

the

large

current

surge

generated

during

the

charging

of

the

capacitor.

During

rectification,

C910

is

charged

through

R903

and

R904.

When

C910

is

charged

to

16V,

IC901

3842A

starts

to

operate

(for

details,

of

the

functions

of

this

IC,

please

refer

to

the

relevant

data

sheet)

and

outputs

a

pulse

signal

from

Pin

6

to

set

the

transistor

Q902

in

the

ON

state.

At

this

time,

transformer

T903,

which

is

connected

in

parallel,

starts

to

store

power.

When

the

current

passing

through

the

resistor

R914,

and

the

supplementary

current

from

R957

and

R964

into

Pin

3

of

IC901

reaches

1.1V,

IC9O1

is

reset,

causing

the

energy

stored

by

the

transformer

to

reach

the

rated

value.

In

order

to

prevent

the

transformer

from

being

saturated

and

causing

damage

to

the

transistor,

when

transistor

Q902

is

in

the

OFF

state,

the

energy

stored

in

the

transformer

T903

is

released

into

the

secondary

coil

and

is

regulated

through

the

various

output

loops

and

filters

and

converted

to

the

required

DC

output.

In

addition

to

this,

at

the

appropriate

time,

the

windings

pin!

—

pin2

supply

Pin

7

of

IC9Q1

with

a

fixed

power

supply

for

normal

operation.

Also,

when

windings

pin2

—

pin3

are

in

power

saving

active

state,

power

is

supplied

to

Pin

7

of

IC901

for

normal

operation.

In

any

of

the

above

cased,

the

output

pulse

is

terminated

and

the

FET

is

turned

off,

causing

the

voltage

on

the

output

of

the

FET

to

rise

rapidly,

and

the

voltage

across

the

winding

of

the

primary

to

reverse

in

polarity,

thus

tending

to

reset

the

flux

within

the

core.

At

this

point,

the

diodes

D915,

D925,

D917-

D920

and

D926

on

the

secondary

supply

winding

become

forward

biased

and

begin

to

conduct,

thus

transferring

energy

from

primary

to

the

secondary,

and

charging

the

secondary

capacitors.

There

is

also

secondary

winding

the

primary

side

of

the

power

supply

which,

through

diode

D908

and

Q901

recharges

the

control

IC901

reservoir

capacitor

C910.

This

supply

then

keeps

the

IC901

running.

In

the

event

of

a

secondary

short

circuit,

the

supply

fails

to

recharge,

thus

the

voltage

across

C910

drops

to

a

threshold

limit

below

which

the

[C901

cuts

out

and

returns

to

its

low

current

load

operation.

During

normal

operation,

the

supply

rails

charge

until

the

error

amplifier

realized

by

IC903

on

the

secondary

begins

to

turn

on

the

opto-coupler,

PH901.

At

this

point,

the

photo-tran-

sistor

of

this

opto-coupler

on

the

primary

side

begins

to

conduct,

draining

current

from

the

primary

control

IC901

supply

through

diode

D907

and

D928.

Under

normal

operation

IC903

regulates

the

current

flow

through

PH901,

and

hence

determines

the

output

voltage

of

the

error

amplifier

internal

to

IC901.

Various

passive

compo-

nents

around

[C903

and

IC901

set

the

gain

compensation

for

optimum

stability

and

regulation

characteristics.

In

the

event

of

a

fault

condition

occurring,

either

Q904

may

be

turned

on

by

the

lack

of

voltage

at

pin2

of

IC901

or

zener

diode

ZD903

may

conduct,

due

to

excessive

voltage

on

the

primary

IC901

supply.

In

the

latter

case,

the

triac

Q903

will

fire,

thus

dragging

down

the

output

of

the

control

IC901

error

amplifier,

which

in

turn

will

limit

the

duty

cycle

and

reduce

the

output

voltage.

It

will

stay

in

this

mode

until

the

AC

input

power

is

removed.

PMG1CONTROL

|.

FROM

LOGIC

CIRCUIT

PMG1———

CIRCUIT

Q905

weasel

ISOLATION

FEEDBACK

prea

Moe

Shoes

CIRCUIT

ats

CIRCUIT

[

PH901

1C903

|

loss

a

Bin

tel

FROM

FBT

oe

:

PULSE

SYNC

CIRCUIT

PWM

CONTROL

CIRCUIT

|

MAIN

SWITCH

30Khz~85Khz

‘|

Q907

a

UC3842A

(1C901)

Pe

_

qQg902

FUSE

Om

B5VAC~264VAC

AC

IVP

tp

Ue

EMI

CIRCUIT

T902

AUTO

OR

MANUAL

|!

|

DEGAUSSING

CIRCUIT

|

Q91i5,RL901

ft

j

FILTER

CIRCUIT

BD901

’

ee

te

PTV

I

Wid

ion.

te

eed

te?

>

15V

POWER

X'FORMER

O/P

RECTIFIER

pssy

12V

|

an

@EILTERS

eo

oeeeaesy

ae

|

———-+

CIRCUIT

|

|

NC

,

»

6.3V

ei

T903

Sy

|

»

5V

-

=»

B+

(200V)

Figure

3-1

Switching

Power

Supply

Block

Diagram

3-1

"e

i

Theory

of

Operation

When

the

feedback

signal

passing

through

the

main

77V

output

is

completed,

the

transistor's

duty

cycle

is

adjusted

through

the

transfer

to

Pin

2

of

IC901

3842A

of

the

primary

coil

by

PH901

4N35

and

IC903

TL431,

stabilizing

the

output

current.

At

this

time,

it

is

important

to

note

that

before

the

feedback

signal

is

established,

the

charge

level

of

C917

cannot

trigger

Q903

SCR

or

it

will

cause

a

faulty

power

startup.

In

addition,

in

order

to

synchronize

the

supply

power

and

moni-

tor

and

reduce

noise

that

will

cause

interference

to

the

display,

in

the

area

D913

the

monitor's

feedback

transformer

gets

a

feedback

signal

in

order

to

ensure

synchronization

between

the

power

supply

and

monitor,

with

synchronization

in

the

range

30kHz

—

85kHz.

Because

the

power

operating

fre-

quency

changes

with

the

monitor

causing

changes

in

the

value

of

IP,

(the

value

of

LP

is

fixed

while

the

value

of

IP

increase

or

decreases

according

to

the

frequency),

this

affects

the

test

value

of

Pin

3

of

IC901

3842A.

This

causes

the

total

power

supplied

to

vary

according

to

the

frequency,

so

a

compensa-

tion

value

is

provided

by

D914

in

order

to

reduce

the

differ-

ence

in

total

power

for

different

frequencies.

In

addition,

because

the

AC

input

ranges

from

85VAC

to

264VAC,

this

causes

the

value

of

the

direct

current

on

the

DC

bus

to

vary,

affecting

the

rise

rate

of

IP,

the

oscillator

and

the

duty

cycle,

and

causing

the

test

value

obtained

at

Pin

3

of

IC9O1

to

vary.

To

resolve

this,

a

compensation

value

is

provided

by

R964

and

R957

which

reduces

the

difference

resulting

from

the

different

input

voltages.

3.1.1.

Auto-degaussing

=

‘When

base

of

Q915

connector

is

in

high

state,

the

transistor

Q915

2SC945P

is

on,

causing

the

relay

to

jump

from

Normal

Open

(N.O.)

to

Normal

Close

(N.

C.):to

perform

auto-degaussing

operations.

The

du-

ration

of

this

operation

is

controlled

by

a

logic

pulse

and

lasts

approximately

6

(six)

seconds.

When

tran-

sistor

Q915

enters

the

OFF

state

and

the

relay

returns

to

N.O.

to

terminate

the

auto-degaussing

operation

is

completed.

3.1.2.

Suspend

Mode

Operation

Two

feedback

ratios

can

be

selected,

both

sensing

from

the

78V

rail.

In

the

event

of

Q905

being

turned

on

by

micro

processor,

additional

current

is

drawn

from

the

virtual

earth

node

of

IC903,

thus

causing

the

power

supply

to

serve

the

rail

to

a

high

voltage,

nominally

78V.

This

is

trimmed

by

resistor

R937,

R940

and

R941.

The

other

supply

raif

are

predeter-

mined

ratios

of

this

winging,

being

+15V,-

12V,+6.3V

and

+200V

nominally.

In

addition,

a

low

voltage

primary

side

winding

feeds

the

control

IC901

directly

through

D907

turning

off

the

control

[C901

supply

through

Q901,

which

would

otherwise

dissi-

pale

excessively.

When

Q905

is

turned

off,

the

78

V

rail

drop

to

around

17V.

In

this

case,

the

primary

control

supply

fed

through

D907

drops

to

a

value

that

is

below

the

level

needed

to

sustain

operation.

Instead,

Q901

begins

to

conduct

and

the

higher

voltage

supply

winding

taken

via

D908

is

used

to

keep

the

primary

side

powered

up

with

minimal

power

losses.

The

5V

power

supply

is

driven

by

one

of

two

sources,

In

normal

operation

when

the

78V

is

present,

the

5V_.

regulator,

IC902

is

fed

from

the

15V

rail

through

diode

D921.

When

switched

to

standby

mode

(78V

rail

drops

to

12V)

then

the

15V

rail

drops

too

low

to

supply

IC902.

In

this

case

Q906

take

over

and

main-

tains

the

supply

to

IC902

at

around

9V.

In

addition

to

the

5V

regulated

supply,

in

normal

operation

there

is

also

a

15V

regulated

supply

take

from

the

15V

rail.

To

ensure

that

micro

processor

gets

a

good

5V

power

supply,

there

is

a

power

good

detection

circuit

.

formed

by

Q801

and

Q802.

This

monitors

the

supply

going

into

the

5V

rail

(not

the

5V

rail

directly).

It

detects

whether

there

is

sufficient

voltage

to

enable

the

SV

regulator

to

work

effectively.

It

is

not

a

detection

of

the

5V

rail

itself,

but

relies

upon

the

premise

that

the

regulator

is

not

faulty

and

that

there

is

no

faulty

load

condition

on

the

5V.

During

power

up,

there

is a

delay

to

the

signal

at

the

output

of

the

threshold

comparator

Q801

and

Q802

a

caused

by

ZD801

and

C801,

in

order

to

allow

the

micro

Circuit

time

to

stabilize.

The

threshold

is

cho-

sen

such

that

the

RESET

line

drops

low

at

least

25ms

before

the

SV

drop

out

of

regulation.

—

L

Finally

a

synchronization

pulsé

taken

from

the’

oii

zontal

output

stage

maintains

the

SMPS

operating

frequency

in

sync

with

the

horizontal

scan.

D913

injects

a

pulse

which

prematurely

triggers

the

oscil-

lator

within

IC901

which

would

otherwise

run

at

a

frequency

lower

than

the

minimum

required

sync

frequency.

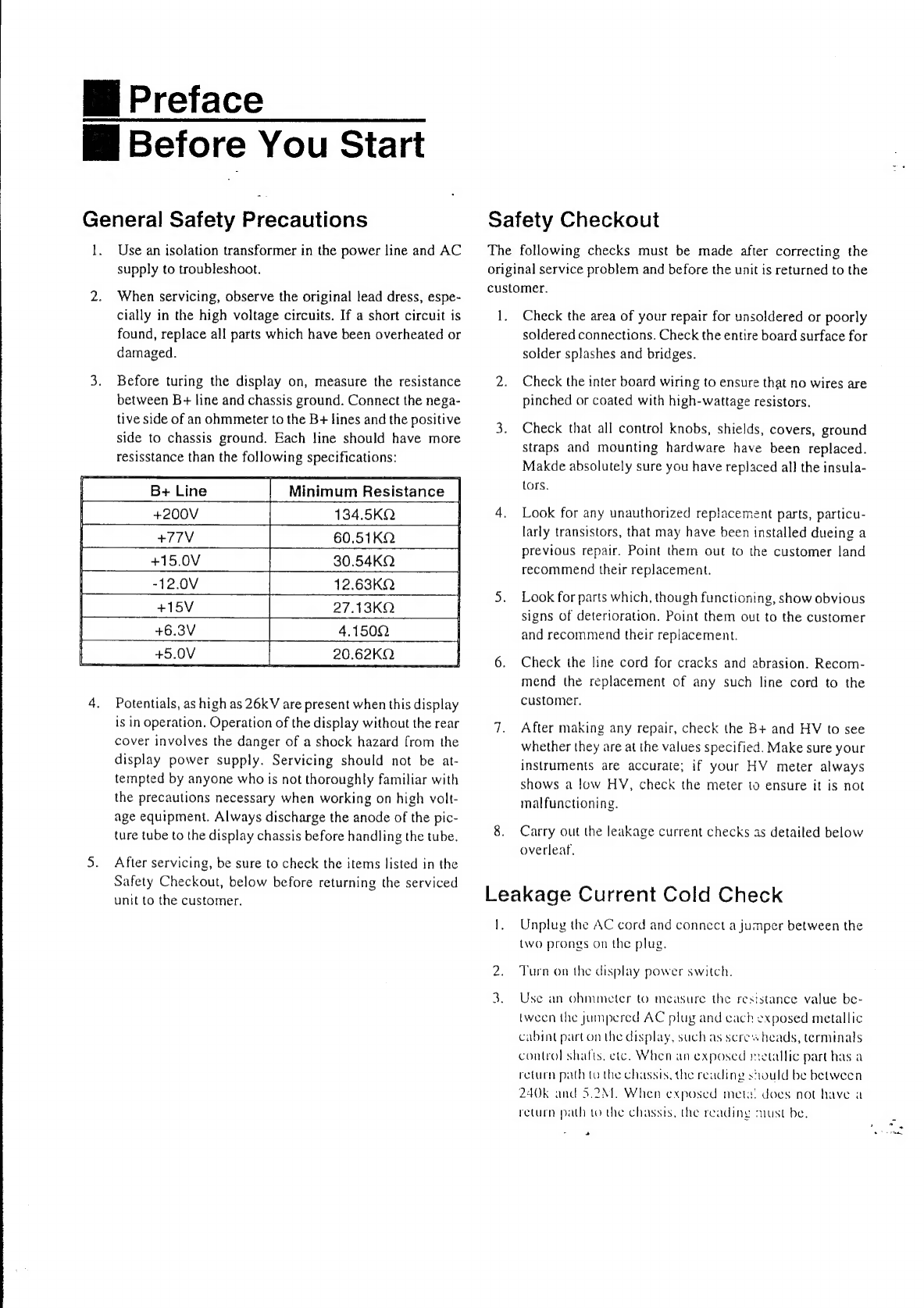

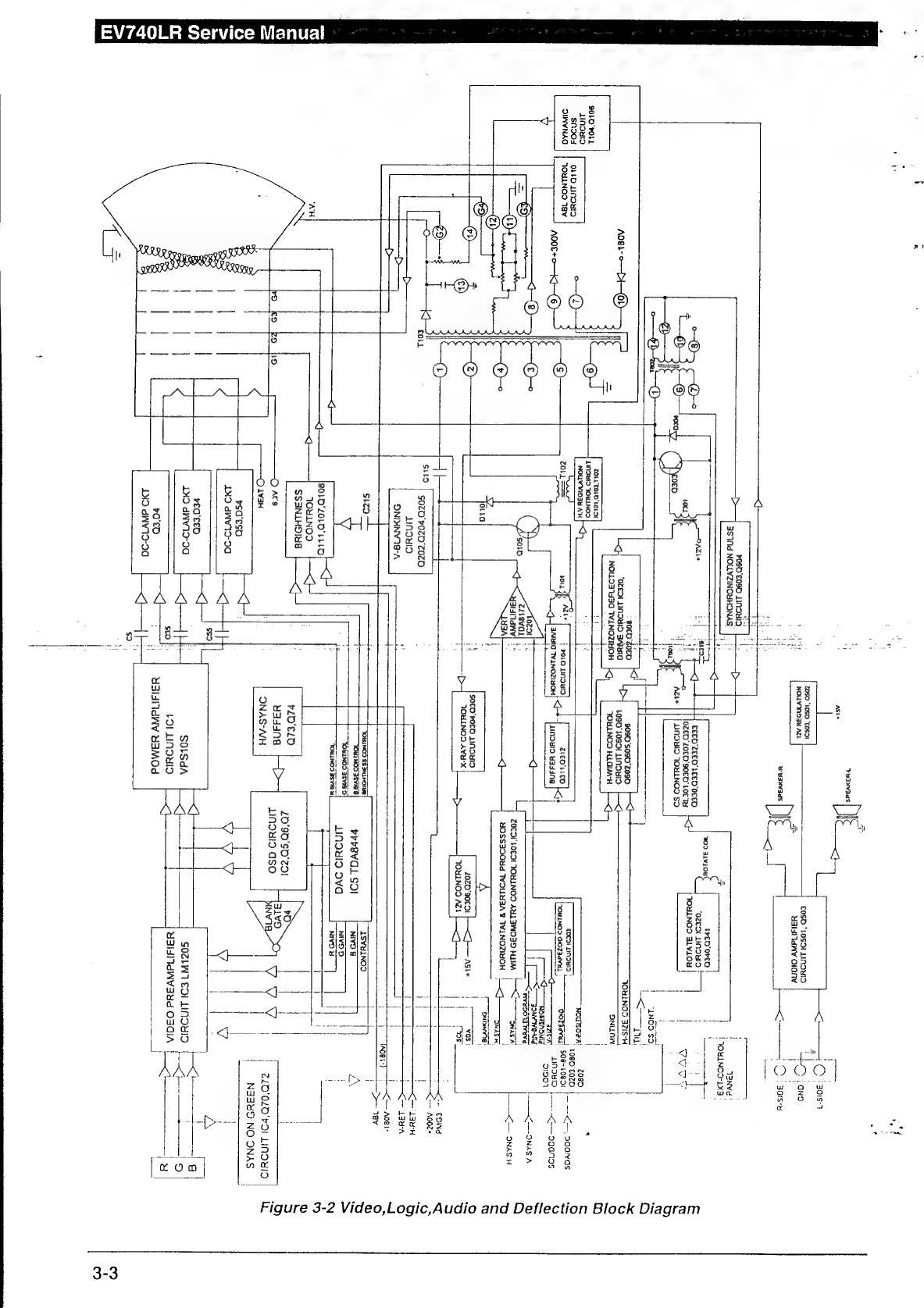

3.2.

The

Deflection

Circuit

Please

refer

to

the

block

diagram

of

the

deflection

circuit

and

video

circuit

and

Logic

circuit

as

shown

in

figure

3-2.

3.2.1.

IC301

LM1291

Video

PLL

System

for

Con-

tinuous-Sync

The

LM

[291

is

an

integrated

horizontal

time

base

solu-

tion

specifically

designed

to

operate

in

continuous-sync

video

monitors.

If

automatically

synchronizes

to

any

H

ferquency

from

30kHz

to

85kHz

and

provides

the

drive

pulse

to

the

high

power

deflection

circuit.

Available

sync

processing

includes

a

vertical

sync

sepa-

rator

and

a

composite

video

syne

stripper.

An

internal

syne

selection

scheme

giyes

highest

priorily

to

separate

Hand

V

syne,

then

composite

sync,

and

finally

syne

on

video,

no

external

switching

between

sync

sources

is

necessary,

The

LM1291

provides

polarity-normalized..*2

H/HV

and

V

sync

outputs,

along

with

logic

flags

which

show

the

respective

input

polarities.

The

design

uses

an

on-chip

FVC

(Frequency

to

Voltage

Converter)

to

set

the

center

frequency

of

the

VCO

a

a

a

a

3-2

EV740LR

Service

Manual

ee

yuaxvads

me

Aste

2OSO

“LSD

‘LOSd1

EOSD

'$0S91

LINDHID

af

Ono

<a

ae

Poa

ee

eee

=

walsngWy

o1lany

pee

wusyvaes

ic

L

-——<t-——

2

|

308-s

1

eeted

cst

—}-

the

it

¥09D'£090

LINDuia

i

1

3S1Nd

NOLLWZINONHONAS’

|

;

;

TBNV¢!

|

|

AOULNOD-L¥3

|

WOO

BivLOW

____

Hed

‘OREO

eee

ae

°

ney

ceed'zeeo'ree‘occo

Soe

nou

i

|

:

oi

toc

0Z€0'L0E'90£0'

LOE

Te

!

|

vege

rc0

06D

LINDYID

TONLNOD

SD

|

|

:

|

are

14ND

$5,

-

i

oles

Til

:

BOED'Z0ED

TOUINOD

SzIS-H

“OzEDt

LINDUID

BAwIO

:

NOILD31330

WWLINOZIMOH

JOYXLNOD

HLGIM-H

ONLLAA

5‘

ZOLLEOLD'L0151

byl

Li

|

BOLD

POLL

LINDUID

WOwLNOD

ahs

ji

:

LINDwID

NOLLYIADBY

A'H

[

7

a

ROUBOEA!

‘dochters

snoo4

OLLD

UNDUIS

:

COC

LINDuID

|

—o-<,

D00N0S

OINVNAG

|

|

TOXLNOD

TEV¥

i

Adle

{

revo

sinsuta)

-,

}

zeonico

|}

rOULNOD

OIOTBEVuL

|

-———sersaval

508-1081

<

BAINIG

TWLNOZINOH

LINDYID

W3IINE

|

~

—

Fi

UNIEID

|

.___<__

dganos

at

|

=e

OMTENDNTE

290)

PS

aanv

ve

x

[4

wo

se

rt

t

Reso

Weve

——I---

DNAS

A

Lhe

Fa

fbi

aistiawy}

|

ZOCOK'

LOCD!

TOWLNOD

AULINOZO

HIM

l

<

SAAS.

——<——

oNas

H

€3Al-

HOSS3I0Nd

TYOULWEA

¥

WLNOZINOH

|

<4

i

[ee

eS

Eee

ee

©

fe

A

1

Sare

:

SOED'POED

LINDUID

;

|

——~

sr

:

20Z0'9091

ASte

0G

TOS!

AOMINOD

AVE

YOULNOD

AZt

|

roe

J

-

i

|

ae

COW

1

-

=

A00z+

!

:

f

ar

—<—

LaaH

a

ee

pe

ADBL

>

Tey

TORINO)

SEIN

HONE

LSVYLNOD

i

Swath

brrSVaL

Sol

NIV

S

|

A

OUINGS

BSviE

5

‘

ecient

LINDYID

OVA

WOUINOS

FS

VIE

&

{

i

g

BOLD'ZOLO'LELO

|

Sa

———<}

TOULNOD

|

SSANLHOS

FLD

ELD

10'90'S0'291

LD

dAV19-50

yasane

->~

2

bb»

linoyioaso

|

|

ie

et

ONAS-/H

|

re

VV

VY

|

ZLD'OLD'FO!

LINDUID

|

|

N3BYD

NOONAS

|

saves

1

140

dwwI0-90

Vv

|

ere

=e

i

|

rea'eed

7

|e

1x9

diW10-00

z

SOLSGA

|

ly

GOZLWT

EDI

LINDUID

fs

ee

5

7

Lol

LINDUID

i

YBISIIdDWVSed

OSCIA

a1

y

|

ra'ed

1

|

UBIaMdWy

BaMOd

tote

clnat

m

Y

rae

so

|

-2

Video,

Logic,Audio

and

Deflection

Block

Diagram

Figure

3

3-3

This manual suits for next models

1

Table of contents

Other Taxan Monitor manuals