Taylor Made Environmental Cruisair SMX II Guide

SMX II Control Systems (DX)

English

❖

INSTALLATION • OPERATION

Revised: 12-17-02

L-2066

LP-11

DIRECT EXPANSION SYSTEMS

For Direct Expansion SMX II Control Systems using these displays:

2❖❖

❖❖

❖English

L-2066

Table of Contents

This manual replaces manuals L-0634 and L-0503.

SMX II Control Systems • Introduction

Introduction ........................................................................ 3

SMX II Control Systems • Installation

Installing the SMX Keypad/Display .................................... 4

Installing the Power/Logic Box

(retrofit only) .................................................................... 4

Installing the Temperature Sensor

(remote systems and retrofit only) .................................. 4

SMX Interconnect Cable - Connecting

Keypad/Display To Power/Logic Board ............................ 5

Pressure Switches (retrofit only) ........................................ 5

SMX II Control Systems • Operation

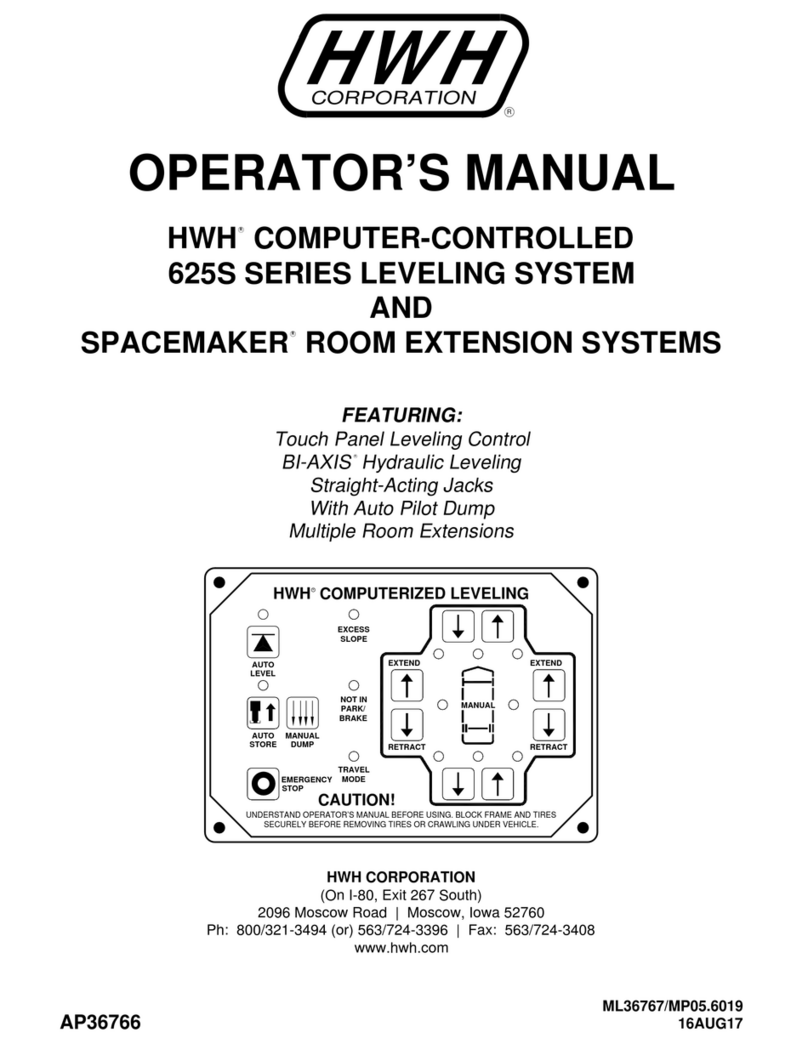

The SMX Keypad/Display .................................................. 6

The SMXir Remote Control ................................................ 7

Basic Operation 8

Power On ........................................................................... 8

System Off ......................................................................... 8

Selecting Setpoint .............................................................. 8

Displaying Temperature ...................................................... 8

Cool Mode .......................................................................... 8

Heat Mode ......................................................................... 8

Automatic Changeover....................................................... 8

Manual Fan Speed Control ................................................ 8

Automatic Fan Speed Control ............................................ 8

Adjusting Brightness .......................................................... 8

Using The Humidity Control Routine.................................. 9

Anti-Ice Routine ................................................................. 9

Seawater Temperature and Your Cruisair System ............. 9

Programming the SMX II System 9

Factory Memory Reset ...................................................... 9

Programming Summary Table ......................................... 10

Custom Programming Record ......................................... 10

Compressor Time Delay .................................................. 11

Fahrenheit/Celsius Display ............................................... 11

Compressor Differential ................................................... 11

Fan Response Differential................................................ 11

Low Fan Speed Adjustment ............................................. 12

High Fan Speed Adjustment ............................................ 12

Fan Mode ......................................................................... 12

AC Line Voltage Calibration ............................................. 12

Temperature Calibration ................................................... 13

Humidity Control Program 13

Programming The Time Period ........................................ 13

Programming The Dehumidification Time ........................ 13

Recommended Humidity Control Settings ...................... 13

Fault Shutdowns and Error Messages 14

Fault Codes ...................................................................... 14

High Pressure Shutdown ................................................. 14

Low Pressure Shutdown .................................................. 14

Old Low Pressure Shut-Down

(Models before March 1998) ......................................... 14

Low Voltage Shutdown ..................................................... 14

Software Error .................................................................. 15

Determining Your Software Version Number ................... 15

Quick SMX II Troubleshooting Guide ............................... 15

Owner’s Limited Warranty 16

Cruisair and Sentry Limited Warranty 18

Description of Figures 19

Cruisair Dealer Locator 31

3❖❖

❖❖

❖English

L-2066

Warning

This manual contains essential information concerning

the installation and operation of your SMX II control

system. It is very important that you read and under-

stand the contents of this manual before using the

equipment, and it should be kept on the boat for future

reference. If you have any questions about the con-

tents of this manual, contact your local Cruisair dealer

or the Taylor Made Environmental Service Department

for assistance.

Introduction

This manual covers the installation and operation of

Cruisair SMX II computerized controls for direct expansion

(DX) marine air conditioning systems. There are many

different parts required for a complete installation, so make

sure that you have all the necessary items when installing

the system.

Two different keypad/displays are available for use with

SMX II control systems. The original SMX II keypad/display

is rectangular and requires a large cutout in the mounting

surface. The SMXir keypad/display has a compact housing

with a decorative hinged cover, and is surface-mounted. An

optional remote control can be used with the SMXir keypad/

display. Hereinafter, this manual will refer to the original

SMX II keypad/display as SMX II. The terms keypad and

display are interchangeable.

Before installing the system, please read the warnings in

this manual.

If you have an SMX Net control system, refer to manual(s)

LP-25,

SMX Net Control Systems (DX) Installation and

Operation.

SMX II Control Systems • Introduction

4❖❖

❖❖

❖English

L-2066 Installation

SMX II Control Systems • Installation

Warning

Make sure all power is off before opening any

electrical box.

Installing the SMX Keypad/Display

To be operated satisfactorily, the SMX keypad/display

should be installed so it is both visible and accessible. It

should be placed in plain view and within easy reach of the

operator. Overhead locations are discouraged since they

make it very difficult to use the SMX control.

Select a spot on an interior, vertical surface. This can be an

inside or outside wall, partition or other permanent struc-

ture with rear access for wiring. The SMX control operates

on low voltage DC and is certified ignition-protected. The

space behind the SMX control does not have to be venti-

lated since the control components do not produce heat.

SMX II Only

The SMX II keypad/display requires a cutout of 2

9

/

16

" x 7

1

/

8

"

(65mm X 181 mm). (For SMXir keypad installation, refer to

drawing #086800 in the back of this manual.)

After cutting the hole for the keypad control, make sure it

fits and the printed circuit board is clear of the bulkhead

and that no objects of any kind are in a position to contact

the SMX circuitry. Plug the interconnect cable in and route it

to the Power/Logic (P/L) box. Refit the control in the hole

and secure it with four No. 6 x

3

/

8

inch screws. Hook the

decorative plastic cover at the top, press it flat from the top

down, and snap it in place at the bottom.

Retrofitting SMXir Keypad/Display to

Original SMX II or 3-knob

Adapter plates are available to cover the old vertical or

horizontal rectangular cutout and mount the SMXir keypad/

display. Part #5103612 is a black plate, and #5103612W is

white. Use adapter #4163805 to connect an existing CX

cable to the SMXir display. (Refer to the SMXCABLE

drawing, Figure 9, at the back of this manual.)

Installing the Power/Logic Box

(retro it only)

All SX and FX systems with integrated SMX II controls have

the P/L box already installed on the unit.

In selecting a location for the Power/Logic box, bear in mind

that several sets of wires will be connected to it. Refer to

installation diagrams in this packet.

•The SMX P/L board is ignition protected, enclosed, and

operates in ambient temperatures up to 130°F (54°C).

•The P/L box may be installed in any position.

•The P/L board dissipates heat when operating, and must

be installed in a ventilated location.

•The P/L box is NOT waterproof and must be placed

where it will NOT get wet.

The power input to the board can be 115V or 230V. The

board automatically adjusts to either voltage.

Installing the Temperature Sensor

(remote systems and retro it only)

The TSEP temperature sensor measures the cabin air

temperature and relays the information to the power/logic

board. The sensor is 1" long by ¼" diameter (25mm x 7mm

diameter) and is attached to a length of flat, 4-conductor

cable with a RJ-11 phone type plug at the end. Different

lengths of TSEP cables are available, from 2 feet to 80 feet

(.6m to 24m).

For best results, the sensor should be placed in the return

air path, away from the system evaporator coil. Directly

behind the return air grill is often a good location. The

sensor must not touch the evaporator coil, or be placed in

the discharge air.

With the TSEP in the return air path, use the default mode

of continuous fan operation for the most accurate tempera-

ture control. If intermittent fan operation is desired (fan on

and off with the compressor), the sensor must be wall

mounted on an INSIDE surface not subject to any influence

from heat outside of the area (including direct sunlight).

Thermistor covers are available from Taylor Made Environ-

mental, Inc. for wall mounting.

SX self-contained units with integrated SMX II P/L box will

have the TSEP already installed. On FX remote units, the

TSEP must be run from the P/L box on the FX unit to the

return air path of the cooling unit.

The TSEP cable plugs into the RJ-11 jack on the P/L board

marked “INSIDE TSE”. Coil up any excess cable, and tie out

of the way.

5❖❖

❖❖

❖English

L-2066 Installation

If you have a P/L board manufactured before 2000, you

might have a 3-pin TSE plug. Adapters are available to

connect the new TSEP cables to the old P/L boards. Refer

to the SMXCABLE diagram at the back of this manual.

SMX Interconnect Cable - Connecting

Keypad/Display To Power/Logic Board

Connection between the SMX II keypad and the Power/

Logic board should be made with a CX## cable. This is a

shielded, 3-conductor cable with 4-pin plugs on each end.

The plugs on each end of the cable are identical, and are

polarized. Make sure all 4 pins are engaged in the plug.

Systems with the SMXir keypad should use a CXP## cable.

These are flat cables with RJ-12 phone jack plugs on each

end.

Both CX and CXP cables are available in different lengths,

from 2 feet (.6m) to 80 feet (24m). Route the cable from the

power/logic board to the keypad. Plug the cable in at both

ends, and secure per low DC voltage standards.

Warning

The SMX interconnect (CX or CXP) and temperature

sensor cables (TSEP) transmit low voltage DC signals,

and outside interference can affect their operation. Do

not route these cables beside A/C power cables, high

voltage wiring, or antenna wires. Keep the cable runs as

short as possible to reduce the chance of interference.

Note

Standard phone cable will not work with SMX controls.

Pressure Switches (retro it only)

Standard SX and FX units that have an integrated SMX II

P/L box include both the high and low pressure switches,

already connected. The SMX P/L board to pressure switch

signals are low voltage DC, and connections can be made

with 22 gauge or larger wire.

High-Pressure Switch: A high-pressure switch must be

connected to the SMX P/L board. Most marine A/C units

have a high-pressure switch that can be used for the SMX

switch. It should be disconnected from its in-line application,

and connected to the SMX P/L board at the push-on

terminals labeled “HIGH PRESS”.

The wires that were connected to the high-pressure switch

should then be butt connected together, effectively bypass-

ing the switch. The SMX II control will now monitor the

switch and shut the unit down if a high-pressure fault is

sensed.

Low-Pressure Switch: A low-pressure switch is recom-

mended for SMX controlled systems, but is optional if the

original unit did not have a low-pressure switch.

To add a low-pressure switch, use Cruisair model A-201,

and either the A-204 sweat in TEE kit for remote condens-

ing units or the #4024100 service port TEE kit for ¼" flare

ports, such as on SH self-contained units.

Connect the wires from the low-pressure switch to the SMX

P/L board at the terminals labeled “LOW PRESS”.

If an existing low-pressure switch is used, bypass the switch

by butt connecting the old switch wires together.

6❖❖

❖❖

❖English

L-2066 Operation

The SMX Keypad/Display

The SMX II and SMXir keypad/displays are arranged for

logical operation. The button layouts on the SMX II and the

SMXir are similar, and the buttons perform the same

respective functions. See next page for keypad/display

diagrams.

1. Data Display

Large LED readout that provides indication of current

setpoint, temperatures, programmed values and error

messages.

2. Cooling Indicator

Lights when compressor is running in cooling mode.

3. Heating Indicator

Lights when compressor is running in heating mode.

4. Setpoint Indicator (SMX II Display Only)

Lights when setpoint is displayed. Off when inside

temperature is displayed.

5. SET Key

Press the SET key to display your currently selected

setpoint (the temperature you wish to maintain in the

cabin). The SET key also is used to dim the data display

readout.

6. UP-DOWN Keys

Press UP or DOWN to raise or lower the setpoint. Press

and hold keys for large changes. Note: if inside tem-

perature is displayed, touching the UP or DOWN key

will cause the setpoint to be displayed.

7. TEMP Key

Press once to display inside temperature. Press TEMP

twice, and the display will alternate between inside

temperature and setpoint. Press again to return to

inside temperature only.

Hint

You can display temperature in degrees Fahrenheit or Celsius.

8. OFF Key

Turns system off. Note that the data display remains on.

You can continue to adjust setpoint, display temperature

readings and activate the manual fan to circulate air

while the system is in the OFF mode.

9. Cool Mode Indicator

Lights when you press the COOL key to select the

cooling mode.

10. Heat Mode Indicator

Lights when you press the HEAT key to select the

heating mode.

11. COOL Key

Turns the system on in the cooling mode.

12. HEAT Key

Turns the system on in the heating mode.

Hint

Press both HEAT and COOL at the same time, and the sys-

tem will automatically switch between cooling and heating

mode. When in the automatic switchover mode, both the

COOL and HEAT indicators are lit.

13. Manual Fan Indicator

Lights when fan is running in manual mode.

14. SLOW-FAST Keys

Control fan speed when the fan is in the manual mode.

Pressing SLOW or FAST key when in automatic fan

mode will change the system into manual mode.

15. FAN Key

Selects manual or automatic fan control mode. Press

once to select manual control. Press FAN again to

select automatic fan speed control. In this mode, the

fan speed is controlled by the microprocessor as a

function of the difference between setpoint and inside

temperature.

16. Fan Speed Indicators

Row of five small LEDs below FAN key. Indicate the

current fan speed.

17. Inside Temperature Indicator (SMXir Display Only)

When illuminated, inside temperature is displayed.

When light is off, setpoint is displayed.

18. IR Receiver (SMXir Display Only)

Infrared remote receiver

19. Dehumid Key (Remote Control Only)

Changes system into the Humidity Control program.

20. Auto Switchover Key (Remote Control Only)

Places the system into automatic changeover mode, so

it will switch from cooling to heating as needed.

De initions

LED - Light Emitting Diode. An indicator light is used to de-

note mode or operating status.

Setpoint - The selected temperature you want to maintain in

the area being heated or cooled.

SMX II Control Systems •Operation

7❖❖

❖❖

❖English

L-2066 Operation

SMX II Keypad/Display

SMXir Keypad/Display

SMXir Remote Control

The SMXir Remote Control

The SMXir remote control keypad has the familiar layout of

the 10-button SMX keypad, and performs most of the same

functions. The remote can not be used to program settings.

Programming must be done at the keypad/display.

In addition to the standard keys, the SMXir remote also has

two quick-hit buttons that allow easy access to the humidity

control program and the automatic changeover mode.

The remote has three buttons that are not used on SMX II

systems. The Aux Heat, Aux Heat Auto Switchover, and the

Aux 1 buttons are for SMX Net systems only.

The SMXir remote control must be pointed at the SMXir

keypad/display, which has the IR remote receiver. The

remote will not work if the SMXir keypad/display has the

optional full coverage door and the door is closed.

See Figure 12 for SMXir Remote control angle and distance

range.

8❖❖

❖❖

❖English

L-2066 Operation

Basic Operation

Power On

When AC power is applied to the system at the circuit

breaker, the SMX microprocessor performs a self-check

and retrieves from permanent memory the last operating

configuration. This process takes about four seconds, after

which the system will begin operating just as it had been

when power was last turned off.

System O

Press the OFF key to turn the system off. Note that the

data display remains energized even when the system is

off. The fan can be turned on manually when the system is

in the off mode.

Note

The SMX has built-in protection against sudden power in-

terruptions. The system automatically stores the current

operating configuration in permanent memory every time

you make changes. (The new operation mode must be in

affect for 30 seconds before it is saved into permanent

memory.) When AC power is lost, the SMX system retains

these settings, and when AC power is restored it resumes

operation using the same settings as before.

Selecting Setpoint

Press the SET key and the current setpoint will be dis-

played. Press the UP or DOWN key to change the setpoint.

Displaying Temperature

To display cabin temperature, press the TEMP key. Press

TEMP twice for an alternating display of inside temperature

and setpoint. Press again to return to inside temperature

only.

Cool Mode

To enter the COOL mode, press the COOL key. The Cool

Mode Indicator will light to show that you have selected the

cooling mode.

The Cooling Indicator will be lit whenever the system is in

the cooling mode and the compressor is running. When the

compressor cycles off, the Cooling Indicator goes off, but

the Cool Mode Indicator stays on.

Heat Mode

Press the HEAT key to select HEAT Mode. The Heat Mode

Indicator will light to show that you have selected the

heating mode.

The Heating Indicator will be lit whenever the system is in

the heating mode and the compressor is running. When the

compressor cycles off, the Heating Indicator goes off, but

the Heat Mode Indicator stays on.

Automatic Changeover

Press the COOL and HEAT keys simultaneously for

AUTOMATIC CHANGEOVER between COOL and HEAT

Modes. Both mode indicators will light, to show that the

system is in the automatic changeover mode.

For the SMXir Remote Control only - Press the Auto

Switchover key to enter automatic changeover mode.

Note that the Cooling or Heating Indicator will come on

when the compressor is running to show when the system

is running in the cooling or heating mode.

Manual Fan Speed Control

Press the FAN key to select manual fan control. The Manual

Fan Indicator will light to show that it is in the manual mode.

Then use the SLOW and FAST keys to select the desired

fan speed.

Note that you can use the manual fan control to circulate air

even when the system is in the OFF mode.

Automatic Fan Speed Control

If in manual fan mode, press FAN key to select automatic

fan control. The Manual Fan Indicator goes off, and the

system will automatically adjust fan speed as the cabin

temperature deviates from the setpoint. As setpoint is

approached, the fan speed automatically slows. Once

setpoint is reached, the compressor cycles off and the fan

keeps running on low speed.

Adjusting Brightness

Pressing the SET key repetitively will dim the LED display.

Keep pressing SET to return to full brightness.

9❖❖

❖❖

❖English

L-2066 Operation

Using The Humidity

Control Routine

When engaged, the SMX humidity control routine automati-

cally turns the air conditioning system on at timed intervals

to remove moisture from the air. The system is pro-

grammed at the factory for average values. To change the

factory settings, see “Humidity Control Program”.

To start the dehumidification program:

•Press OFF.

•Press COOL, HEAT and FAN keys simultaneously.

For the SMXir Remote Control only

- Press the

Dehumid key to enter dehumidification mode.

•The data display will flash HU, indicating that the

program is active.

•To halt the dehumidification program, press any key. The

HU message will stop flashing.

Sa ety Note

Whenever the SMX system is in the dehumidification mode,

all of the system safeguard controls remain active. If the

seawater flow fails or if line voltage falls below preset limits,

the system will automatically shut down. If AC power is in-

terrupted, the system will automatically resume operation in

the dehumidification mode when power is restored.

Anti-Ice Routine

The SMX control will occasionally shut down the compres-

sor in the cooling mode to allow any ice that may have

formed on the evaporator coil to melt. The anti-ice shut-

down only occurs at inside temperatures lower than 70°F

(21°C).

In a 10-minute cycle period, the compressor will shut off for

15 seconds per degree below 70°F. For example, if the

inside temperature is 67°F, the compressor will shut off for

45 seconds every 10 minutes.

Seawater Temperature and

Your Cruisair System

The basic principle behind an air conditioner or a heat

pump is the movement of heat. In an air conditioner, heat is

removed from the inside cabin and released to the seawa-

ter. In reverse-cycle heating, the refrigerant flow is reversed

and heat is extracted from the seawater and discharged

into the living space. The efficiency of the system operation

depends on both the seawater and cabin temperatures.

In cooling, the air conditioner will work best in seawater

temperatures below 90°F (32°C). At higher water tempera-

tures, the unit may work, but at reduced capacity. A high-

pressure shutdown can occur at higher water temperatures.

In heat mode, the opposite is true. As the water gets colder,

there is less heat available, and the heating performance

drops. Full heating capacity is obtained at about 55°F

(13°C). Performance drops to about 50% of rated capacity

in 40°F (4.4°C) water. Below this, the system pressure can

be so low that the unit will shut down on low-pressure fault.

This problem is compounded when the cabin is cold also.

The low pressure shutdown routine is such that the unit will

try many times to heat up the cabin enough to raise system

pressure and continue running.

Warning

Do not operate your A/C unit in water that is colder

than 38°F (3.3°C). Doing so could lead to water

freezing in the condenser coil which can cause

damage to the unit.

Programming the SMX II System

SMX control systems are programmed at the factory for

average values. For optimum performance, you may wish to

change these settings to suit your individual preferences.

All programming steps are entered by pressing the OFF

key, followed by the SET key, then simultaneously depress-

ing the two or three keys noted in the table below. Success-

ful entry into a programming mode is indicated by the

presence of a decimal point to the right of the two displayed

characters. To raise or lower a value, touch the UP or

DOWN keys. To exit the programming mode, touch the OFF

key. (The SMXir Remote Control can not be used to

program the system.)

Factory Memory Reset

You can use the memory-reset sequence to restore all

programmed functions to the factory default settings.

To restore programmed functions to factory setting:

•Press OFF, SET and FAN simultaneously.

•Press SET.

•After a delay, the memory will be reset from stored

values. After another delay, the display will come back on

normally.

10 ❖❖

❖❖

❖English

L-2066 Operation

Programming Summary Table

Custom Programming Record

Use table below to keep track of any program changes. If a Factroy Memory Reset is performed, then all parameters will revert

back to factory default settings as outlined in the Programming Summary Table above.

Programmable Function Keystroke Combination Factory Setting Range

Factory Memory Reset OFF & SET & FAN, then SET See table below before reset

Compressor Time Delay DOWN & SET & UP 0 0 to 70 sec.

Fahrenheit/Celsius DOWN & TEMP & UP F F or C

Compressor Differential SLOW & FAN 12 4 to 24

Fan Response Differential COOL & SLOW 4 2 to 8

(SLOW & FAN & FAST Before 8/98)

Low Fan Speed DOWN & SET 32 30 to 56

High Fan Speed SET & SLOW 60 41 to 90

Fan Mode (Cont. or Int.) DOWN & FAN & UP C C or I

AC Line Voltage Calibration DOWN & UP - ± 1%

Temperature Calibration SET & UP - ± 1%

HU Precirculation TEMP & DOWN 10 Min. 10 Min.

HU Dehumidification TEMP & SET 30 Min.

HU Time Period TEMP & UP 12 Hrs.

See “Humidity

Control Program”

Unit Location

(Cabin #, Salon, etc.)

Programmable Function Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 Unit 6 Unit 7

Fahrenheit/Celsius

Auxiliary (Electric) Heat

Setpoint Differential

Fan Mode (Cont. or Int.)

Low Fan Speed

High Fan Speed

Fan Response Differential

HU Dehumidification

HU Time Period

11 ❖❖

❖❖

❖English

L-2066 Operation

Compressor Time Delay

(Factory Default: 0 seconds)

This function is used when you have more than one unit on

board. To prevent electrical overload due to multiple

compressors starting when turning on power to the system,

or when power is interrupted, each SMX unit should be

programmed with a different time delay.

Time delay can be set in increments of 1 second. On older

systems (before 8/98) the time delay is set in 10-second

increments, up to 70 seconds.

To program time delay, go to each SMX switch, and follow

these steps:

•Enter the programming mode: Press OFF, Press SET

•Press DOWN, SET and UP simultaneously. The delay in

seconds will be displayed.

•Use the UP or DOWN keys to change the time to the

desired setting.

•Press OFF to exit the programming mode.

At initial power-up, you will see the countdown for each

compressor on the data display, if you are in the TEMP

mode. The countdown will not appear in the SET mode.

Fahrenheit/Celsius

Display

(Factory Default: Fahrenheit)

You can choose to view temperature in degrees Fahrenheit

or Celsius.

To select Fahrenheit or Celsius:

•Enter the programming mode: Press OFF, Press SET

•Press DOWN, TEMP and UP simultaneously.

•Use the UP or DOWN key to select F for Fahrenheit or C

for Celsius.

•Press OFF to exit programming mode.

Note

If you switch from Fahrenheit to Celsius for temperature

displays, the compressor restart differential will also oper-

ate on degrees Celsius. Thus, the factory-set compressor

restart differential will be 1.5°Celsius, which is too wide. To

correct this, reset the differential value from 12 to 6. This

will provide a differential of 0.75°C, or about 1.4°F.

This will also affect the Fan Response Differential, which is

factory set at a value of 4, or 0.5°Fahrenheit. When chang-

ing from Fahrenheit to Celsius, you should reset the Fan

Response Differential from 4 to 2. This will provide a fan

differential of 0.25°C, or about 0.5°F.

Compressor Di erential

(Factory Default: 12 = 1.5°)

The compressor differential is the temperature change

needed for the compressor to cycle on and off. The factory

setting of 1.5°Fahrenheit should be adequate for most

applications. Differential selections are available in incre-

ments of 1/8°. Thus, to select one degree, you should

choose 8 (for 8-eighths).

To program the compressor differential:

•Enter the programming mode: Press OFF, Press SET

•Press SLOW and FAN simultaneously. The restart

differential will be displayed.

•Use the UP or DOWN key to change the setting.

•Press OFF to exit the programming mode.

Hint

Be careful not to set your compressor restart differential too

low, since it will cause the compressor to start and stop

quite often. This will place an undue load on your electrical

system and also wear out your compressor faster.

Fan Response Di erential

(Factory Default: 4 = 0.5°)

When the fan is in the automatic mode, its speed is

governed by how far the room temperature differs from the

setpoint. The fan runs faster when the difference is great.

As the room cools or warms, the temperature approaches

setpoint, and the fan slows down automatically. The amount

of temperature rise in the room above setpoint needed to

cause the fan to increase in speed one step is called “fan

speed differential”. It can be adjusted from 1/4°to 4°, in

1/8°increments.

The fan speed range is divided by the SMX microprocessor

in five equal increments. If the fan response differential is

set at 1/2°, the fan speed will change 20% for each 1/2°of

temperature deviation from setpoint. Lowering the fan

speed differential will cause the fan to increase speed

quickly as temperature changes. Raising the fan speed

differential will result in slower fan speed changes for a

given temperature change. The factory setting of 1/2°

Fahrenheit is good for most applications, but you may wish

to try a slightly higher setting in your salon and a lower

setting in your stateroom.

To adjust fan response differential:

•Enter the programming mode: Press OFF, Press SET

•Press COOL and SLOW. The differential will be displayed

in increments of 1/8°.

•Use the UP or DOWN key to raise or lower this value.

•Press OFF to exit the programming mode.

12 ❖❖

❖❖

❖English

L-2066 Operation

Note

On SMX II systems built before 8/98, press SLOW, FAN and

FAST simultaneously to adjust fan response differential.

Low Fan Speed Adjustment

(Factory Default: 32)

You can adjust the lowest fan speed to suit individual

preferences. For instance, you may wish to decrease the

low fan speed setting in your stateroom to minimize fan

noise.

To adjust low fan speed:

•Enter the programming mode: Press OFF, Press SET

•Press DOWN and SET simultaneously. The current low

speed reference number will be displayed (factory set

at 32).

•Press UP or DOWN to raise or lower speed reference

number.

•Press OFF to exit the programming mode.

Hint

You should normally keep the low fan speed at the highest

possible setting, consistent with a comfortable noise level,

for most efficient operation of your Cruisair system. Run-

ning the fan speed too slow can damage the compressor.

High Fan Speed Adjustment

(Factory Default: 60)

A blower will often reach its highest speed at a voltage

lower than full line voltage. For example, at a line voltage of

120V, the blower might reach its fastest speed at 110V. At

higher voltages, the bower speed will not increase signifi-

cantly.

The SMX High Fan Speed Adjustment allows you to set the

maximum high-speed voltage to the threshold of the blower

high-speed response. Because SMX breaks up the fan

speed voltage steps into 5 equal parts (between the low-

speed and high-speed adjustments), accurately setting the

high-speed adjustment can help ensure that each fan

speed step results in a noticeable change of fan speed.

To adjust the high fan speed:

•Enter the programming mode: Press OFF, Press SET

•Press SET and SLOW simultaneously. The current high-

speed reference number will be displayed (factory default

is 60).

•While listening to the fan noise level, use the UP key to

raise the displayed value past the point that you can hear

an increase in the fan noise level.

•Press the DOWN key to lower the voltage until you hear

a drop in fan speed, then raise that number up by 2 or 3

to ensure that it is set at the highest speed.

•Press OFF to exit the programming mode.

Fan Mode

(Factory Default: Continuous)

You can select continuous fan operation or instruct the fan

to cycle on and off with the system compressor.

To select continuous or intermittent fan:

•Enter the programming mode: Press OFF, Press SET

•Press DOWN, FAN and UP simultaneously.

•Use the UP or DOWN key to select C (continuous) or

I (intermittent).

•Press OFF to exit the programming mode.

Hint

If you select intermittent fan operation, you should relocate the

thermistor from the return air duct to an inside wall to best

sense room temperature. Check with your dealer or call the

Cruisair Applications Department for more information.

AC Line Voltage Calibration

The SMX control assembly has a built-in voltmeter that

senses AC line voltage. The microprocessor automatically

responds to sustained low-voltage conditions by shutting

down the air conditioning system to prevent compressor

damage.

At installation, the SMX voltmeter is calibrated to line

voltage within +/- 1%.

To check or recalibrate AC line voltage:

•Enter the programming mode: Press OFF, Press SET

•Press DOWN and UP simultaneously. Line voltage will be

displayed in 2 digits. On 115V systems, 95V appears as

95, 100V as 00, and 120V as 20. For 230V systems the

reading shows 1/2 of line voltage, therefore, 190V will

appear as 95, 200V as 00, and 230V as 15.

•To check accuracy or to calibrate, turn off all on-board

AC loads and measure the line voltage with an accurate

voltmeter.

•If the SMX displayed voltage is not correct, press the UP

or DOWN key to enter the correct value.

•Press OFF to exit the programming mode.

13 ❖❖

❖❖

❖English

L-2066 Operation

Temperature Calibration

Typically, the temperature sensor is within 1 or 2 degrees of

actual room temperature. If off by more, it can be calibrated

to read actual temperature.

To calibrate the thermistor:

•Enter the programming mode: Press OFF, Press SET

•Press SET and UP simultaneously. The sensed tempera-

ture will be displayed.

•Place an accurate thermometer beside the thermistor

you are using and compare the temperatures.

•Use the UP or DOWN key to adjust the displayed

temperature to the correct value.

•Press OFF to exit the programming mode.

Humidity Control Program

The SMX dehumidification program automatically runs the

air conditioning system for a programmed time period to

help control humidity in the boat. The dehumidification

program works in 3 stages:

The fan comes on at high speed to circulate air for 10

minutes.

The fan then drops to low speed, and the compressor

cycles on in the cooling mode to dehumidify.

After the dehumidification cycle, the system turns off. The

process repeats according to the programmed time period.

The compressor time delay setting will affect when the

dehumidification cycle starts. Every 1-second of compres-

sor delay equals a 6-minute advance into the dehumidifica-

tion cycle. This can cause the dehumidification cycle to skip

the first running and wait until the next time period.

The factory default settings are:

Overall time period ......................... 12 hours

Precirculation cycle ........................ 10 min.

Dehumidification cycle ................... 30 min.

The factory settings are adequate for most moderate

climates and boats. For humid climates, you may wish to

shorten the overall time period and extend the dehumidifi-

cation time. In dry climates, you can select longer intervals

between cycles and a shorter dehumidification time.

Programming The Time Period

(Factory Default: 12 hours)

The time period determines how often the system performs

the dehumidification process. You can select intervals of 2,

4, 6, 8, 10, 12, 14 or 16 hours. Chose a shorter time period

in climates with high humidity.

To select time period:

•Enter the programming mode: Press OFF, Press SET

•Press TEMP and UP simultaneously. The display will

show the overall time period in hours.

•Use the UP or DOWN key to select the desired time

period.

•Press OFF to exit the programming mode.

Programming The

Dehumidi ication Time

(Factory Default: 30 minutes)

The dehumidification time determines how long the com-

pressor runs in the dehumidification mode. You can select

10, 20, 30, 40, 50 or 60 minutes. Select a longer dehumidi-

fication time in humid climates.

To select dehumidification time:

•Enter the programming mode: Press OFF, Press SET

•Press TEMP and SET simultaneously. The display will

show the time period in minutes.

•Use the UP or DOWN key to select the desired time

period.

•Press OFF to exit the programming mode.

Recommended Humidity Control Settings

Outside Relative Time Dehumid.

Temperature Humidity Period Time

Below 80°F 75-85% 12 hrs 10 min

(27°C) Above 85% 8 hrs 20 min

80°- 90°F 75-85% 10 hrs 30 min

(27°- 32°C) Above 85% 6 hrs 40 min

Above 90°F 75-85% 8 hrs 40 min

(32°C)

Above 85% 6 hrs 60 min

14 ❖❖

❖❖

❖English

L-2066 Operation

Cooling Mode:

When the LP switch first opens, the unit will run for 2

minutes, then shut down for 50 seconds. It will do this 4

times. If the switch has not closed, the unit will shut down

for 15 minutes, and flash “LO PS”on the display. After 15

minutes of shut down, the 2 minutes on, 50 seconds off

cycle starts again.

If, after 18 attempted compressor starts, the low-pressure

switch does not stay closed, the unit will go into a sustained

shutdown and flash “LO PS”.

If the LP switch closes at any time before the sustained

shutdown, the unit will then operate normally.

Heating Mode:

If the LP switch opens, the fan will automatically change to low

speed to try and raise system pressure. It will run for 11

minutes in this mode. Note that the fan speed can not be

adjusted at this time. Any attempt to raise fan speed will result

in “LO PS”being flashed, while the unit continues to run.

After 11 minutes, the unit will run for 2 minutes, then shut

down for 50 seconds. It will do this 4 times. If the switch has

not closed, the unit will shut down for 15 minutes, and flash

“LO PS”on the display. After 15 minutes of shut down, the

2 minutes on, 50 seconds off cycle starts again.

If, after 18 attempted compressor starts, the low-pressure

switch does not stay closed, the unit will go into a sustained

shutdown and flash “LO PS”.

If the LP switch closes at any time before the sustained

shutdown, the unit will then operate normally.

Old Low Pressure Shut-Down

(Models be ore March 1998)

The low-pressure shut down fault program was different on

units built before March to May of 1998. On the early units,

if the low-pressure switch opens (suction pressure drops

below 35 psi) and stays open for 2 minutes, the unit will

shut down. If the pressure rises and the switch closes, the

unit will restart. It will attempt 5 restarts, and then go into a

sustained shut down, flashing LO - PS. Press the OFF key

to reset the system.

Low Voltage Shutdown

The low-voltage protection feature is always active. If AC

line voltage drops and remains below 100 volts (200 volts

for a 230V system) for more than three minutes, the SMX

shuts down the entire system. The display will flash LO-AC

(for low AC). This is a sustained shutdown, and the system

will not resume operation even if the line voltage rises to

normal levels. To reset, press the OFF key.

Fault Shutdowns and Error Messages

The SMX control contains built-in safeguards designed to

protect your air conditioning system from damaging

conditions. These are described below.

Hint

Your system must be equipped with a high-pressure switch

and low-pressure switch for the high- and low-pressure shut-

down to operate. You should check with your dealer to make

sure these important protective devices are installed properly.

Fault Codes

If an operational failure occurs, the display will flash one of

the following fault code messages. Fault code displays are

cancelled by pressing OFF.

High Pressure Shutdown

In the cooling mode, if head pressure rises above 400-425

PSI (usually caused by loss of cooling water flow, refriger-

ant gas overcharge or dirty condenser) the SMX will

attempt three restarts, then shuts down the entire system.

The display will flash the legend HI-PS (for high pressure).

This is a sustained shutdown, and even when the pressure

falls after shutdown, the system will remain off until reset by

pressing the OFF key.

In the heating mode, a rise in head pressure above the set

limit (usually caused by poor airflow or incorrect charge) will

cause the compressor to cycle off for two minutes, allowing

the heat in the coil to dissipate. This readies the system for

recycling in the heating mode. The compressor will then

continue to cycle, based on input from the high-pressure

switch, until the cabin temperature reaches setpoint, after

which compressor cycling is automatically restored to

normal thermostatic control.

Low Pressure Shutdown

When installed, the low-pressure switch is monitored by the

SMX control. The low pressure switch opens when the

suction pressure drops below 30 psi, and resets at 45 psi.

The low-pressure fault routine operates differently in the

cooling and heat modes.

Fault Code Meaning Result

LO / AC Operating voltage remained Shutdown

below 100V for 3 min. (or 200V

for 230V system)

HI / PS* Head pressure above 425 PSI Shutdown

LO / PS* Suction Pressure below 30 PSI Shutdown

PE Program error in software Shutdown

* Note: The “PS”in the high pressure and low pressure fault

warning can be confused as “P5”on the SMX LED display

15 ❖❖

❖❖

❖English

L-2066 Operation

Hint

For the low voltage shutdown function to work properly, the

SMX internal voltmeter should be calibrated. This is nor-

mally accomplished at installation. To check or recalibrate

line voltage, see “Programming Summary Table”.

So tware Error

Whenever power is applied to the SMX, the microprocessor

goes through an automatic self-check and software loading

process. If all is well, the SMX loads the most recent

operating configuration from its internal memory, and turns

on normally. If a program fault is found during the self-

check, the error message PE will be displayed.

Likewise, the self-diagnostic routine runs continuously

whenever the SMX system is on. If a system fault is

detected, the system shuts down, and the PE error mes-

sage appears.

If this message occurs, contact your nearest Cruisair

dealer, or call the Factory Service Department in Rich-

mond, Virginia (804-746-1313) for assistance.

Determining Your So tware

Version Number

When you call your dealer or the factory for service assis-

tance, it’s helpful to know the Software Version Number for

your SMX system.

SMX II Systems (Before 8-1-98)

To display your software number:

•Press OFF.

•Press OFF, SET and FAN simultaneously.

•Press COOL twice until display reads 68.

•Press UP once. The display should read Version Number.

•Press SLOW until display reads F2.

•Press UP once. The display should read Revision Level.

All SMX Systems (After 8/98)

To display your software number:

•Press OFF, then SET.

•Then press COOL and DOWN simultaneously. The

display will read Version Number.

•Press UP once. The display should read Revision Level.

Quick SMX II Troubleshooting Guide

Problem: SMX Display Not On

Possible Solution:

1. Turn circuit breaker on

2. Check CX/CXP cable and connections

3. Replace keypad/display

4. Replace Power/Logic board

Problem: Erratic Temperature Display

Possible Solution:

1. Perform a Factory Memory Reset

2. Check temperature sensor, cable and connection

3. Ensure the temperature sensor is installed properly

4. Calibrate temperature

5. Replace Power/Logic board

Problem: Erratic system operation

Possible Solution:

1. Perform a Factory Memory Reset

2. Check CX/CXP cable and connections

3. Check temperature sensor, cable and connection

4. Replace keypad/display

5. Replace Power/Logic board

Warning

The Power/Logic board operates at 115VAC or

230VAC. Make sure the power is off before removing

the cover of the Power/Logic box.

Contact an authorized Cruisair servicing dealer if the

problem continues, or for replacement parts.

16 ❖❖

❖❖

❖English

L-2066

Owner’s Limited

WARRANTY

As hereinafter described, Taylor Made Environmental, Inc. limits the duration of any implied warranty to the duration of

the underlying express warranty and also disclaims any liability for consequential or incidental damages arising from

any application, installation, use or malfunction of any warranted product.

Section I

What does the Limited Warranty cover?

Products manufactured by Taylor Made Environmental, Inc.

(TME) are under limited warranty to be free from defects in

workmanship or materials under normal use and service

with the obligation of TME under this limited warranty being

limited to replacing or repairing any component(s) which

shall disclose defects within the time limits defined in

Section III and which, upon examination by TME, shall

appear to the satisfaction of TME to be defective or not up

to specifications.

This Limited Warranty is made in lieu of all other

express warranties, obligations, or liabilities on the

part of TME. In addition, TME shall not be responsible

for any incidental or consequential damages.

In those

instances in which a cash refund is made, such refund shall

effect the cancellation of the contract of sale without

reservation of rights on the part of the purchaser. Such

refund shall constitute full and final satisfaction of all

claims which purchaser has or may have against TME

due to any actual or alleged breach of warranty, either

express or implied, including, without limitation, any

implied warranty of merchantability or fitness for a

particular purpose. Some states do not allow the exclu-

sion or limitation of incidental or consequential damages so

the above limitation may not apply to you. The terms and

conditions of this warranty shall be governed by the laws of

the Commonwealth of Virginia.

The Dealer is not an agent for TME except for the purpose

of administering the above warranty to the extent herein

provided, and TME does not authorize the dealer or any

other person to assume for TME any liability in connection

with such warranty, or any liability or expense incurred in

the replacement or repair of its products other than those

expressly authorized herein. TME shall not be responsible

for any liability or expense except as is specifically autho-

rized and provided in this section.

TME reserves the right to improve its products through

changes in design or material without being obligated to

incorporate such changes in products of prior manufacture,

and to make changes at any time in design, materials, or

part of units of any one year's model, without obligation or

liability to owners of units of the same year's model of prior

manufacture.

This warranty gives you, the purchaser, specific legal rights,

and you may also have other rights which vary from state to

state. You also have implied warranty rights, including an

implied warranty of merchantability, which means that your

product must be fit for the ordinary purposes for which such

goods are used.

The duration of any implied warranty

rights is limited to the duration of the express warranty

as found in Section III.

Some states do not allow limita-

tions on how long an implied warranty lasts, so the above

limitation may not apply to you.

Section II

What does this Limited Warranty not cover?

This Warranty Shall Not Apply to:

1. Failures resulting from improper installation or use

contrary to instructions.

2. Failures resulting from abuse, misuse, accident, fire, or

submergence.

3. Any part manufactured by TME which shall have been

altered so as to impair its original characteristics.

4. Any parts which fail as a result of misuse, improper

application or improper installation.

5. Items not manufactured by TME, i.e., items which are

purchased from another manufacturer and supplied as

received by TME without alteration or modification

except as any part of an TME-manufactured unit or

component.

6. Components or parts used by or applied by the pur-

chaser as an integral part of products not manufactured

by TME.

Installation and application of TME components is not

warranted by TME because TME has no control or authority

over the selection, location, application, or installation of

these components.

Section III

What is the period of coverage?

See the previous section entitled Warranty Periods.

All TME components bear a data plate on which there are

model and serial numbers. The serial number is date coded.

To determine whether or not any TME component is in

warranty, proceed as follows:

Products Products

17 ❖❖

❖❖

❖English

L-2066

L-0123 Revised: 7-19-01

1. Determine the manufacture date of the component from

the serial number on the data plate. If you are not

familiar with the date code, write or call the TME

Customer Service Department at (804)746-1313, to

obtain the manufacture date. The hours of the Cus-

tomer Service Department are 8:00 am - 5:00 pm USA,

Eastern Time Zone) Monday through Friday excluding

holidays.

2. It is possible that there might exist a considerable time

lag between the date a component is manufactured and

the date it is put in service. In such instances, the date

of manufacture could indicate that the item is out of

warranty. However, based on the date the equipment is

first put in service, the item may still be covered by the

TME warranty described in Section I. For proof of date

put in service, TME will require a copy of the bill of sale

of the TME equipment from the installer or new boat

dealer to the original owner.

Section IV

How do you get service? Please Read the follow-

ing Warranty Procedure.

WARRANTY PROCEDURE

If the failure of a TME component is determined to be

covered under the TME warranty and the time in service is

determined to be within the warranty time limit, the owner

has the following three options:

1. Preferred option: Have an TME authorized Servicing

Dealer perform the work needed. The customer should

call TME's Service Department for a recommendation

as to the closest dealer. If the customer already knows

an authorized servicing dealer, the dealer should be

contacted directly.

2. If the customer contacts TME's Service Department for

a Servicing Dealer and TME has no one in that particu-

lar area, TME will authorize the use of a local service

company and TME will work with the local company to

assist in any way possible.

3. The customer may send his equipment back to the

factory to have the repair work done. TME will make

every effort to return the equipment to the customer

within a three week time period. If the claim represents

a legitimate warranty problem, TME will pay the freight

both ways. TME prefers option one and two, if at all

possible.

The customer may contact the TME Service Department at

(804) 746-1313.

W RNING

Taylor Made Environmental, Inc. (TME) manufacturers of Cruisair, Grunert, Marine

Air, Sentry and Tundra Products, makes the following safety warnings concerning

the application, installation, use and care of its products. Although these warnings

are extensive, there may be specific hazards which may arise out of circum-

stances which we have not outlined herein. Use this as a guide for developing an

awareness of potential hazards of all kinds. Such an awareness will be a key

factor in assuring your SAFETY and comfort.

ELECTRICITY - Many TME products operate on 115, 230 or 440 volt AC power.

Such voltages can be LETHAL; therefore, the chassis, cabinets, bases, etc., on all

components must be grounded together and connected to the vessel's grounding

system. Sparks can occur as switches, thermostats and relays open and close in

the normal operation of the equipment. Since this is the case, ventilating blowers

for the removal of hazardous fumes or vapors should be operated at least 5

minutes before and during operation of any TME product or group of TME

products. All electrical connections must be covered and protected so accidental

contact cannot be made by persons using the equipment, as such contact could

be LETHAL.

ELECTROLYSIS - Electrical leakage of any component can cause electrolytic

deterioration (electrolysis) of thru-hull components which could result in leakage

serious enough to sink a vessel which could result in loss of life. All TME

components must be kept clean and dry and checked periodically for electrical

leakage. If any electrical leakage is detected, the component should be replaced

or the fault causing the leakage corrected before the component is put back into

service.

GAS - CRUISAIR, MARINE AIR, GRUNERT and TUNDRA components utilize R-22

(Chlorodifluoromethane), R134a refrigerant (Tetrafluoroethane), R-407C (which

contains Diflouromethane (HFC-32), Pentafluoroethane (HFC125), and 1.1.1.2 -

Tetrafluoroethane (HFC134a)), or R404A (R125/R143a/R134 (44%/52%/4%))

which are non-toxic, non-flammable gases; however, these gases contain no

oxygen and will not support life. Refrigerant gas tends to settle in the lowest areas

of the compartment. If you experience a leak, evacuate all personnel, and

ventilate area. Do not allow open flames in the area of leaks because refrigerant

gas, when burned, decomposes into other potentially LETHAL gases. Refrigerant

components operate at high pressure and no servicing should be attempted

without gloves, long-sleeved clothing and eye protection. Liquid refrigerant gas

can cause severe frost burns to the skin and eyes.

VENTILATION - To cool or heat air, CRUISAIR, MARINE AIR and GRUNERT

components are designed to move air through a heat exchanger by a blower or

propeller fan. This design necessarily produces a suction on one side of the air

handling component and a pressure on the other side. Air handling components

must be installed so that the suction-pressure action does not: (1) pressurize an

area to the extent that structural failure occurs which could cause harm to

occupants or bystanders, or (2) cause a suction or low pressure in an area where

hydrogen gas from batteries, raw fuel vapor from fuel tanks, carbon monoxide

from operating propulsion engines, power generators or heaters, methane gas

from sewage holding tanks, or any other dangerous gas or vapor could exist. If an

air handling unit is installed in such a manner that allows potentially lethal gases

or vapors to be discharged by the air handling unit into the living space, this could

result in loss of life.

Maximum protection against the introduction of dangerous gases or vapors into

living spaces can be obtained by providing living spaces which are sealed from all

other spaces by use of airtight bulkheads and decks, etc., and through the

introduction of clean air into the living space. Bear in mind that the advent of air

conditioning, whether it be for cooling or for heating, naturally leads to the practice

of closing a living space tightly. Never close all windows and doors unless

auxiliary ventilating systems, which introduce clean outside air into the living

space, are used. Always leave enough window and door openings to provide

adequate ventilation in the event potentially lethal gases or fumes should escape

from any source.

CONDENSATE - All cooling units produce water condensate when operating on

the cooling cycle. This water must be drained from the cooling unit overboard. If

condensate is allowed to drip on a wooden structure, rotting or decay and

structural failure may occur which could result in loss of life. If condensate is

allowed to drip on electrical components, deterioration of the electrical compo-

nents could result in hazardous conditions. When an air conditioning system is in

operation, condensate drains may be subjected to negative pressure. Always

locate condensate drains as far as possible from points where engine waste and

other dangerous gases are exhausted so no such dangerous gases can be drawn

into the condensate drains.

Warning

Never sleep in a closed area on a boat when any equipment, which functions as a

result of the combustion of a volatile fuel, is in operation (such as engines,

generators, power plants, or oil-fired heaters, etc.). At any time, the exhaust

system of such devices could fail, resulting in a build-up of LETHAL gases within

the closed area. Warning Revised: 7-19-01

18 ❖❖

❖❖

❖English

L-2066

Cruisair and Sentry Limited Warranty

WARRANTY PERIODS

Please read and keep this document with your important paperwork. Use it as a reference in the future. If you have any

questions, please contact the Cruisair Service Department at (804)746-1313 for clarification.

Note: Any model or replacement part that has been installed due to a warranty failure will carry onlythe remainder of the

original warranty. All warranties begin when the customer takes possession of the equipment. The warranty is extended to all

owners of the equipment commencing the date the original owner takes possession of it. Proof of original purchase may be

required. Fuses and MOV’sare used as safety devices to protect Cruisair equipment against over-current conditions caused

by lightning or inductive switching environments. These are not covered under warranty. We reserve the right to change our

warranty policies and procedures as well as our warranty allowances without notice.

Cruisair Direct Expansion (DX)

and Modulating Systems

•New, complete system installation using any member of

the SMX family.

The warranty includes the pump.

2 year warranty including Parts and Labor

•New, complete system installation using an electro-

mechanical control (3-knob).

The warranty includes the pump.

1 year warranty including Parts and Labor

•New, complete model sold as a partial system retrofit to

an existing system.

Includes SMX family.

1 year warranty including Parts and Labor

Cruisair Tempered Water

•New, complete system installation using any member of

the SMX family.

2 year warranty including Parts and Labor

NOTE: Excludes pump which has a 1 year warranty

•New, complete model sold as a partial system retrofit to

an existing system.

Includes SMX family.

1 year warranty including Parts and Labor

Sentry Battery Chargers

•New SM or FR series installation.

2 year warranty including Parts and Labor

•New G-series installation.

1 year warranty including Parts and Labor

Cockpit Freezers/Re rigerators-Fish Boxes

•New installation of entire system including condensing

unit, line sets, evaporator, etc.

1 year warranty including Parts and Labor

•New complete model sold as a partial system retrofit to

an existing Cruisair system.

1 year warranty including Parts and Labor

•New installation of condensing unit only, with line sets,

evaporators, etc. done by others i.e. not Cruisair pre-

charged line sets and evaporators.

1 year warranty including parts and labor on

mechanical and electrical parts of condensing

unit only.

Replacement Parts

•Replacement parts and components - example: A-509,

40401-30.

90 day warranty, Parts only

•Replacement Compressors for other than Tempered

Water Systems - example: R3101-16T, DX equipment -

installed in an existing Cruisair system or a competitor’s

system.

1 year warranty including Parts and Labor

•Replacement compressors for Tempered Water -

example: 30130-36 installed in an existing Cruisair

system.

1 year warranty including Parts and Labor

•A Tempered Water compressor - example: 30130-36

installed with competitor’s equipment.

90 day warranty, Parts only

Revised: 10-17-02 L-0694

19 ❖❖

❖❖

❖English

L-2066

Description o Figures

Fig. 1 SXR7-16CK; 115/230V, 50-60Hz

Dwg No. 82570, P-967

Fig. 2 SX7-24CK; 115/230V, 50-60Hz

Dwg No. 082577, P-1023

Fig. 3 FX5-36CK; 115/230V, 50-60Hz

Dwg No. 083703, P-1048

Fig. 4 FX48RC; 230V, 50-60 Hz

Dwg No. 083704, P-1049

Fig. 5 FX20DC-FX48EC; 230V-460V, 3Ph, 50-60 Hz

Dwg No. 084901, P1050

Fig. 6 SMX II Retrofit, Typ. 3-knob

Dwg. No. 084001, P-1063, A-284

Fig. 7 SMX II Retrofit, F20C-48RC, to 3-knob term. strip

Dwg No. 082605, P-1065,A-279

Fig. 8 SMX II Retrofit, F20C-48RC, to cond. unit

Dwg No. 082606, P-106, A-279

Fig. 9 SMXCABLE; Cable Diagrams; Old and New P/L Boards

Fig. 10 SMXir Mounting Template and Instructions

Dwg No. 086800, P-1077

Fig. 11 Replacement DX SMX II Parts

Fig. 12 SMXir Remote Control Operation Range

Dwg No. SKA-1247-rev1

20

L-2066

Fig.1 - SXR7-16CK - 115/230V, 50-60Hz

This manual suits for next models

1

Table of contents

Popular Control System manuals by other brands

Siemens

Siemens DMS8000 Connectivity guide

Nordson

Nordson Eclipse EPC-30 Series instruction sheet

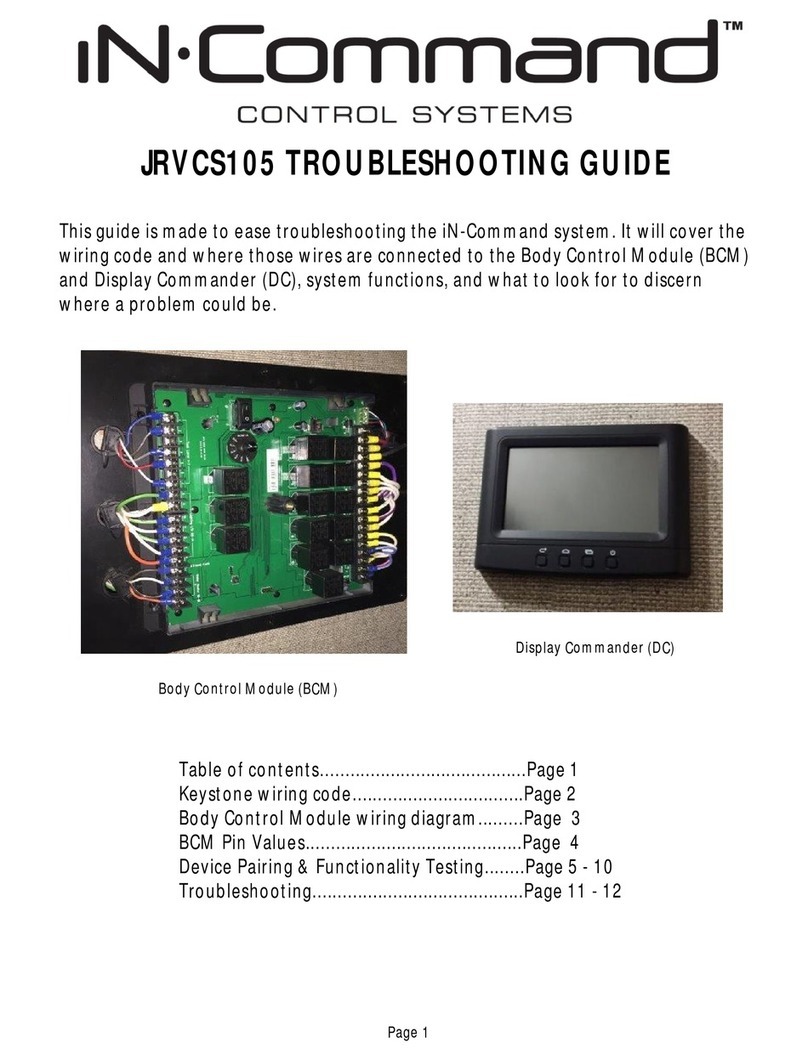

ASA Electronics

ASA Electronics iN-Command JRVCS105 troubleshooting guide

A-T Controls

A-T Controls TRIAO TMC-4 Installation and operation manual

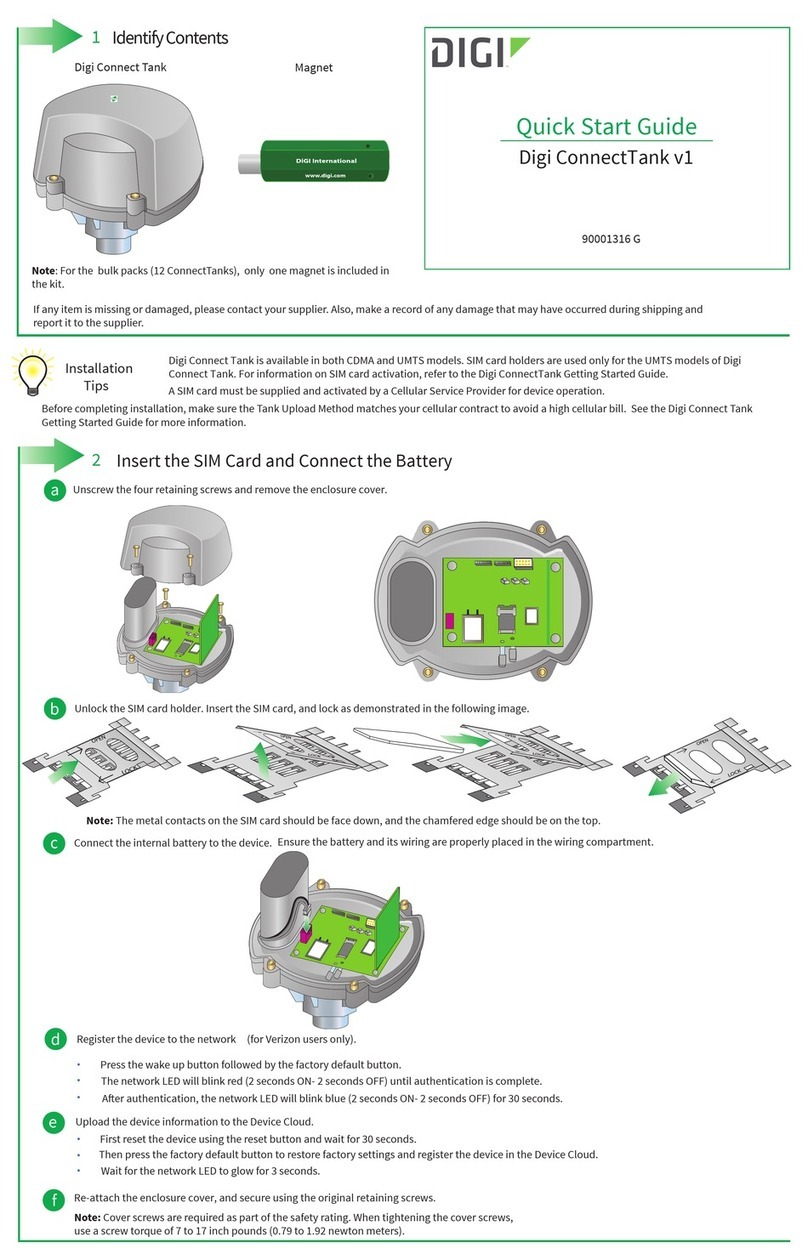

Digi

Digi ConnectTank v1 quick start guide

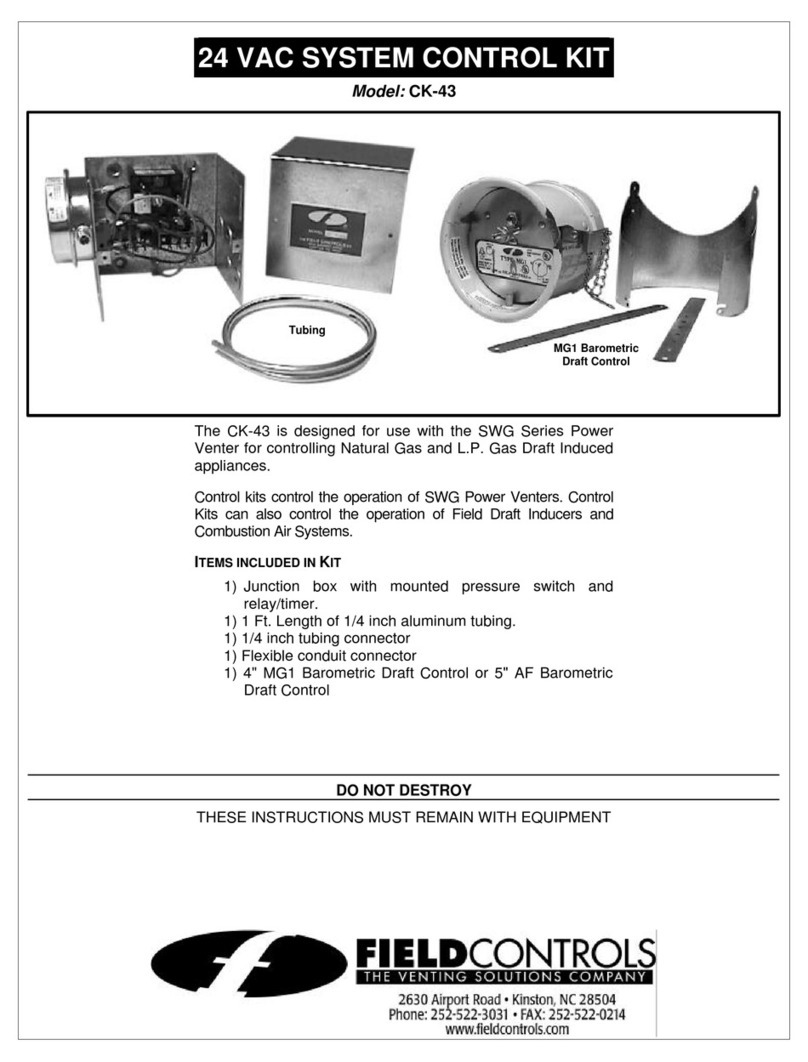

Field Controls

Field Controls CK-43 manual

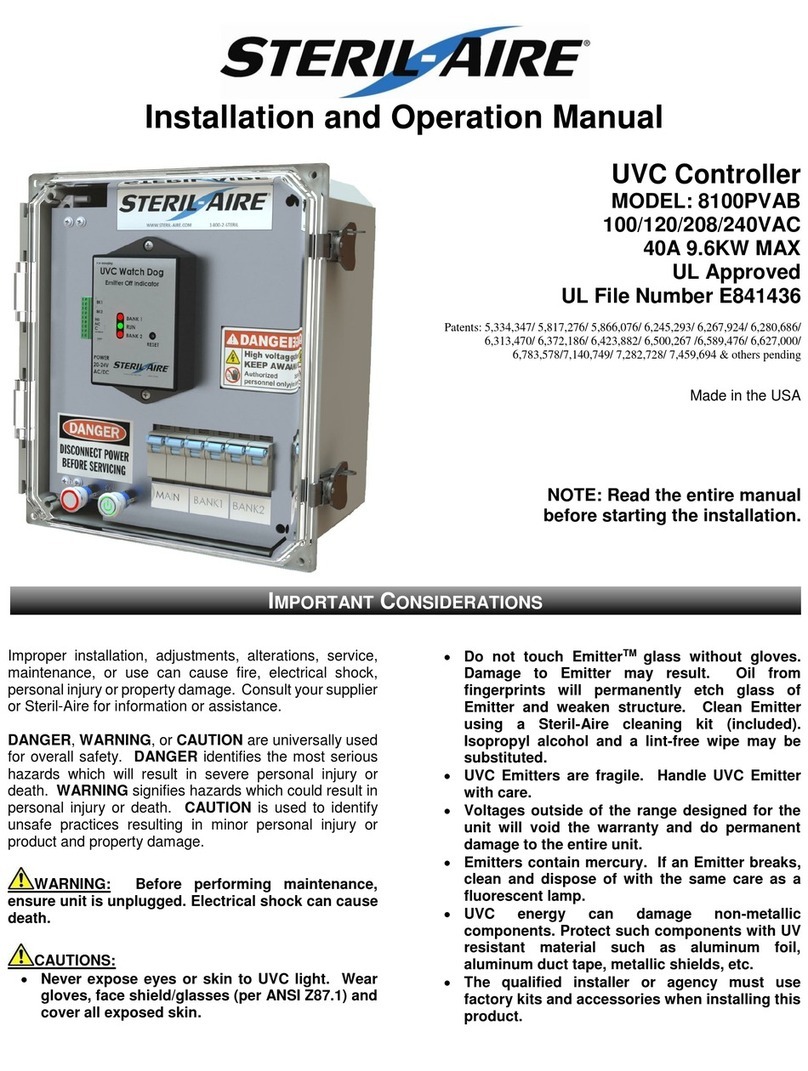

Steril-Aire

Steril-Aire 8100PVAB Installation and operation manual

Emec

Emec J DIGITAL CL operating manual

Nordson

Nordson PowderPilot HD manual

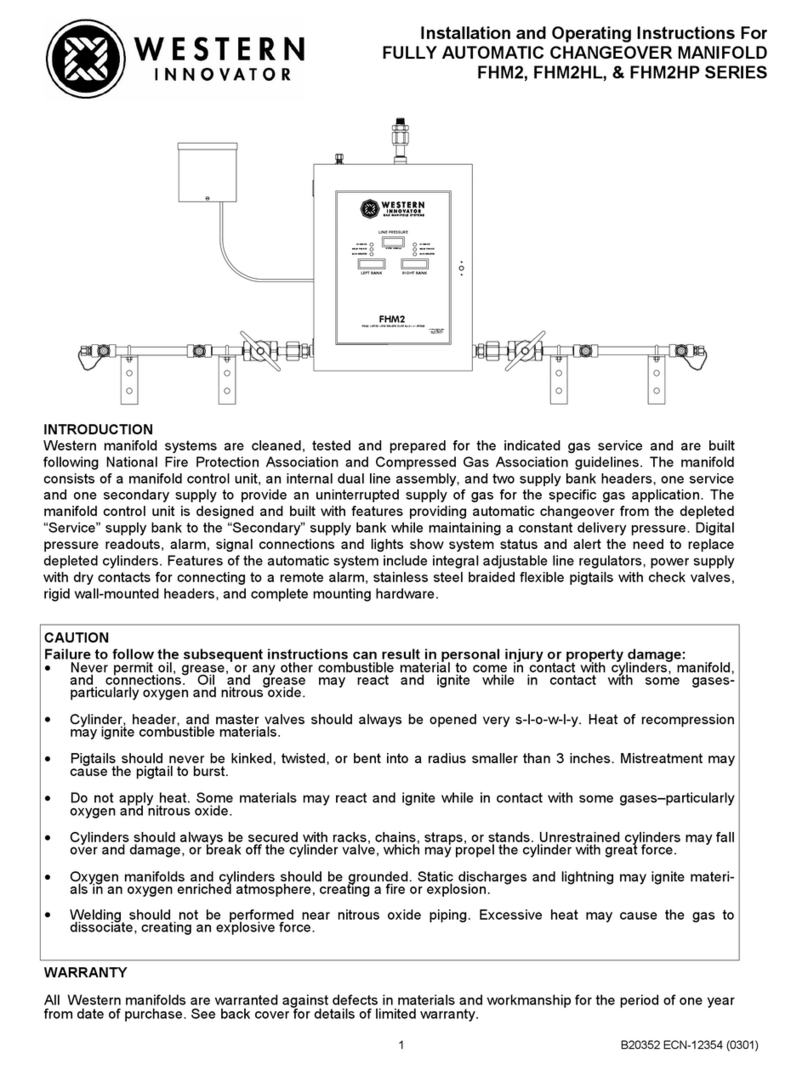

Western Innovator

Western Innovator FHM2 SERIES Installation and operating instructions

rotork

rotork p3 Technical manual

Ingersoll-Rand

Ingersoll-Rand Xe-145M instruction manual