Taymor CONCIERGE 100 User manual

CONCIERGE 100

PROFESSIONAL SERIES

ELECTRONIC DEADBOLT

USER GUIDE

IMPORTANT SAFETY INFORMATION 1

TOOLS NEEDED FOR NEW INSTALLATION 2

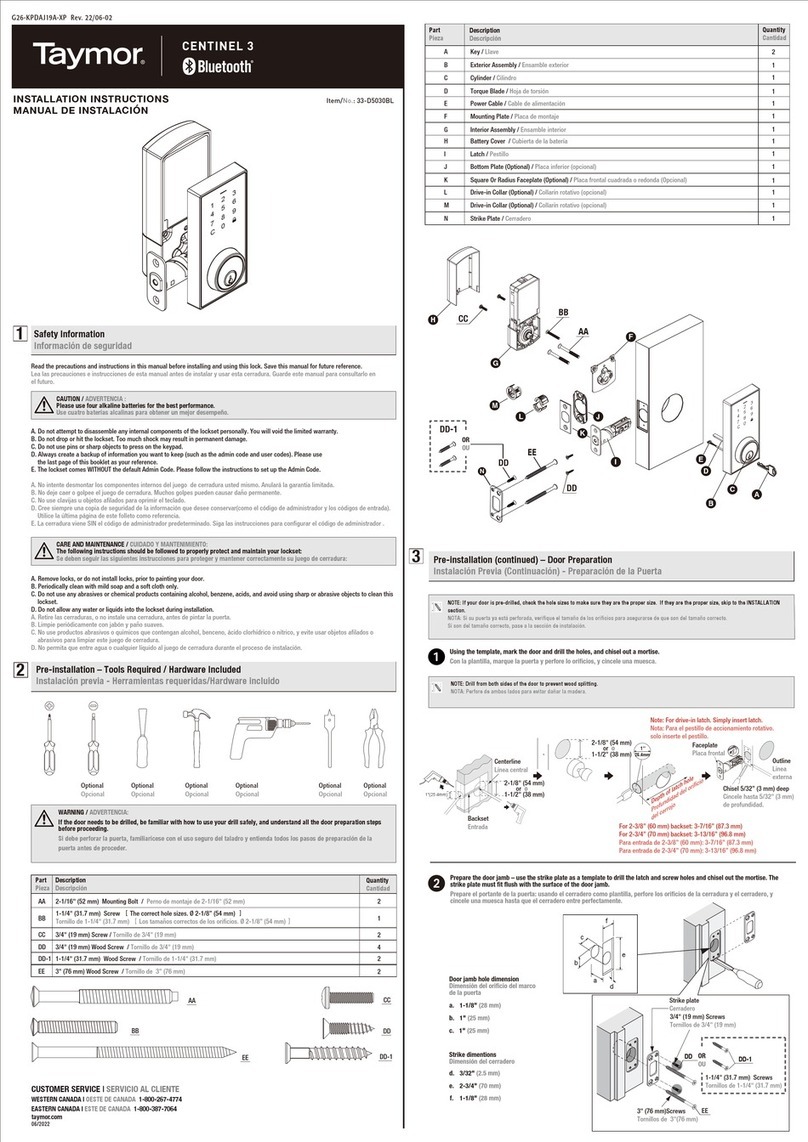

COMPONENTS OF ELECTRONIC KEYPAD DEADBOLT 3

DOOR PREPARATION 4 - 7

INSTALLATION 8 - 13

OVERVIEW OF FUNCTIONS 14

KEYPAD LIGHTS & WARNINGS 15

CODES INFORMATION 16

PROGRAMMING

1. AUTOMATIC BOLT DIRECTION ADJUSTMENT 17

2. CHANGE PROGRAMMING CODE 18

3. ADD/DELETE USER ENTRY CODE 19

4. DELETE ALL USER ENTRY CODES AT ONCE 20

5. TEMPORARILY DISABLE ALL USER CODES 21

6. CREATE A DISPOSABLE USER ENTRY CODE 22

7. “AUTO LOCK” FUNCTION 23

8. MUTE ON/OFF 24

9. RESTORE FACTORY SETTING 25

OPERATION 26 - 27

TROUBLESHOOTING GUIDE 28 - 29

INFORMATION PAGE 30

WARRANTY 31

CONTENTS

IMPORTANT SAFETY INFORMATION

! WARNING

1. Do not use any abrasives or any chemical products containing any substance of alcohol, benzene,

hydrochloric acid or nitric acid, and avoid sharp or scratching objects to clean this lockset.

2. Do not let any water or liquid into lockset during installation process.

! IMPORTANT SAFETY INSTRUCTION

1. Do not attempt to disassemble any internal components of the lockset personally. You may run the

risk of voiding the limited warranty.

2. Do not drop or hit the lockset.

3. Do not use sharp objects to press key buttons.

4. Always create a backup of information you want to keep (such as programming code and use

codes). Please use the last page of this booklet as your reference.

5. Please change programming code before operating this lockset.

! CARE AND MAINTENANCE

The following care instructions should be followed to ensure a long lasting finish:

1. Remove locks, or do not install locks, prior to painting your door.

2. Periodically clean with mild soap and a soft cloth only.

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

1

• PENCIL

• CHISEL

• TAPE MEASURE

• HAMMER

• PHILLIPS SCREWDRIVER

• 1” (25 mm) & 1/8” (3 mm) DRILL BITS

• 2-1/8” (54 mm) HOLE BORING KIT

• POWER DRILL

• 2” (51 mm) 6D COMMON NAIL

• 4 - AA 1.5V ALKALINE BATTERIES

TOOLS NEEDED FOR NEW INSTALLATION

2

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

3

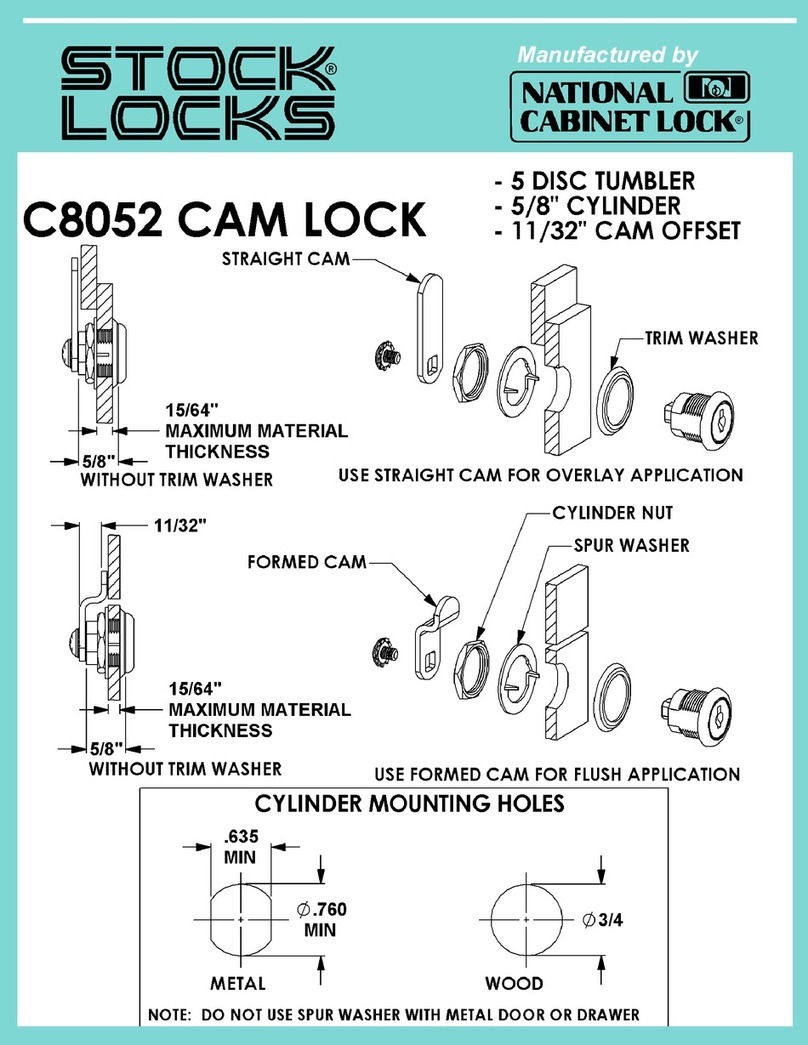

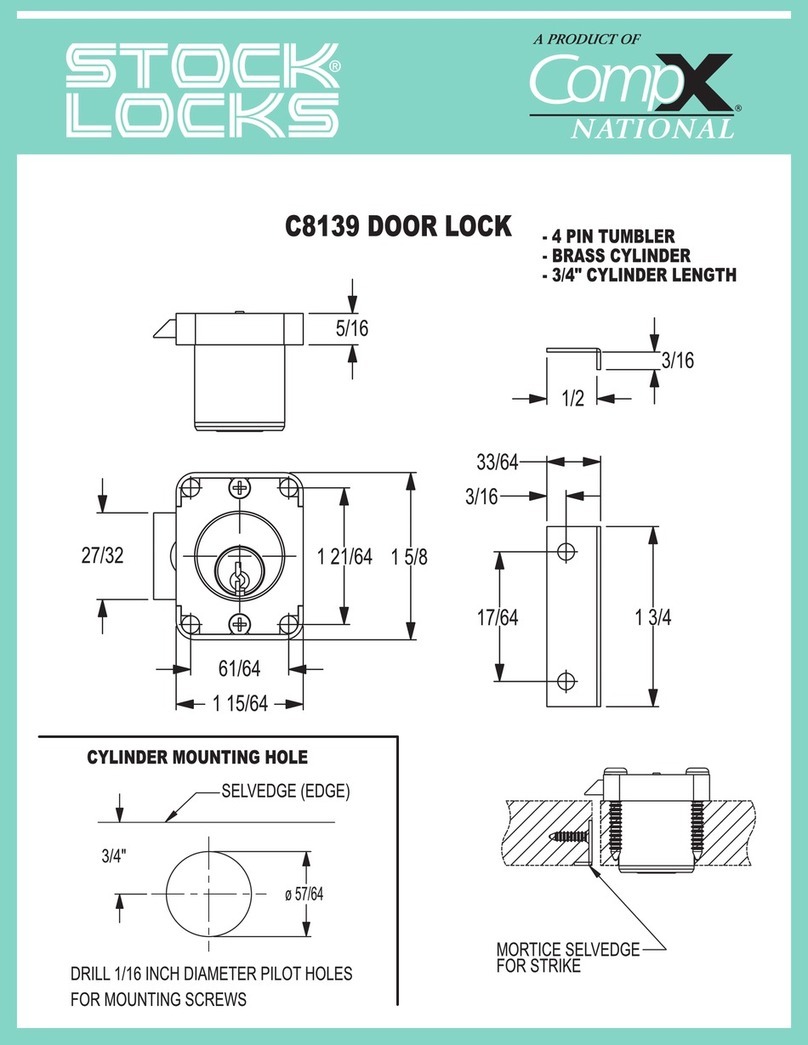

COMPONENTS OF ELECTRONIC KEYPAD DEADBOLT

INTERIOR BATTERY COVER

WOOD

SCREWS

METAL

SCREWS

MOUNTING

BOLTS

MOUNTING

PLATE

INTERIOR ASSEMBLY

WOOD

SCREWS

LATCH

RUBBER GASKET

CYLINDER

TORQUE

BLADE

CYLINDER

EXTERIOR ASSEMBLY

IC WIRE

4

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

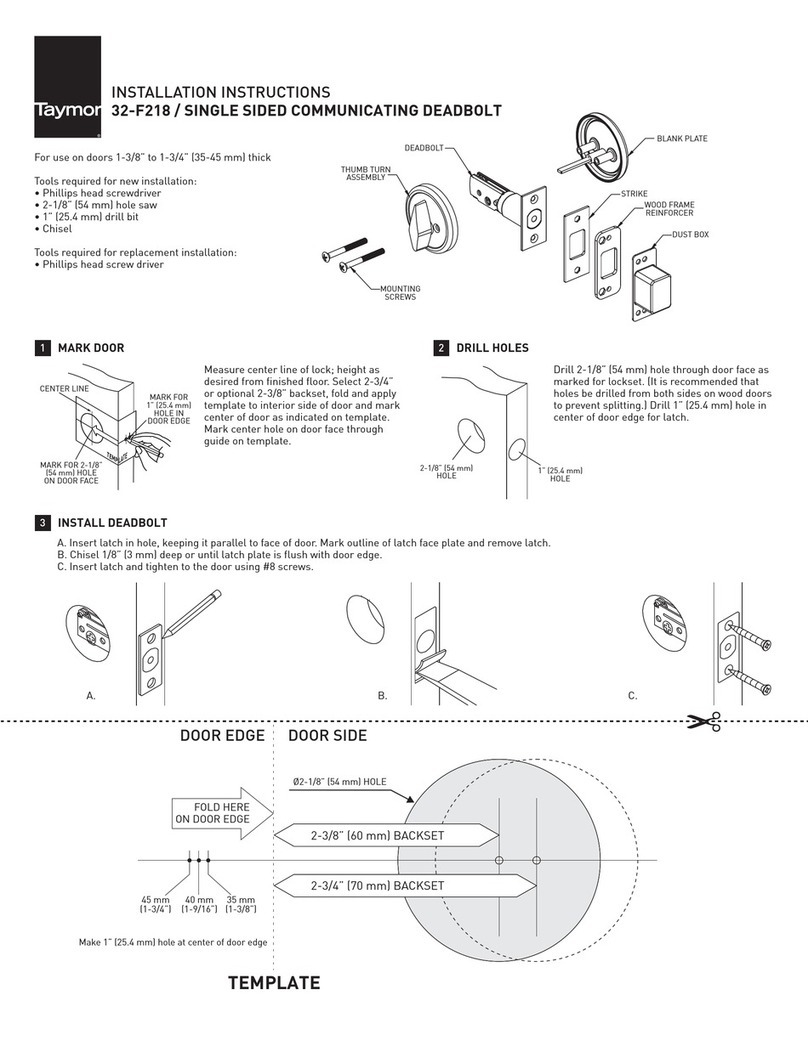

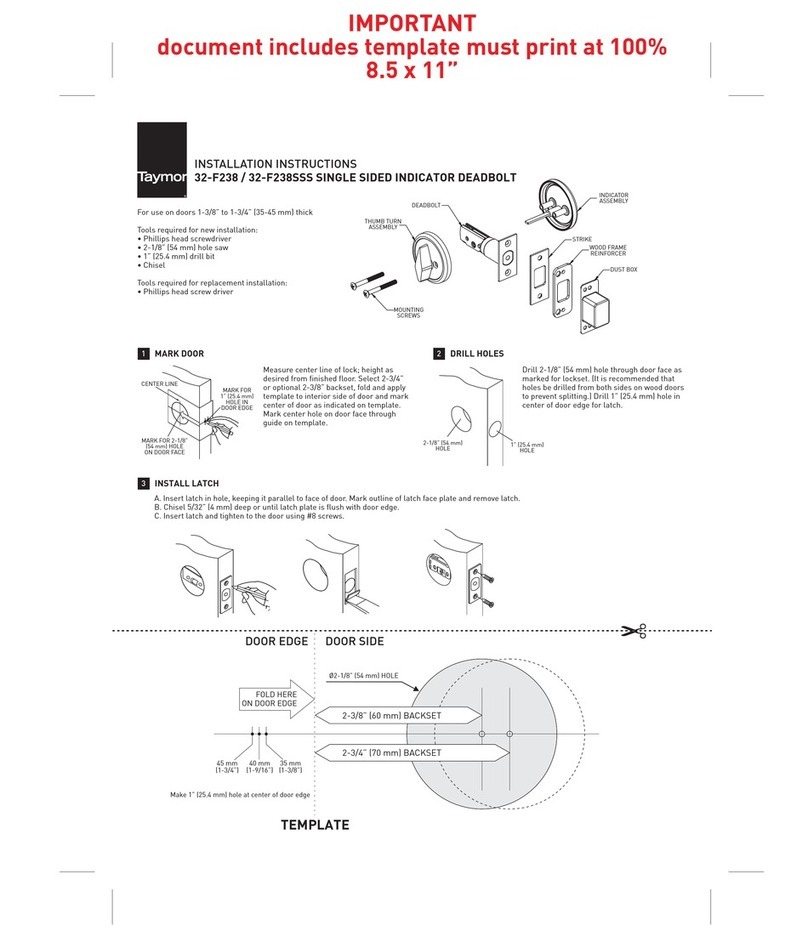

TEMPLATE

CENTERLINE

MARK DOOR EDGE APPROXIMATELY

3” TO 6” (75 mm TO 150 mm) ABOVE

THE ENTRY KNOB OR LEVER

DOOR PREPARATION

1 MARK DOOR WITH TEMPLATE (ATTACHED SEPARATELY)

Note: If replacing an existing lock or installing in a pre-drilled door, begin with page 8.

a. Use TEMPLATE to mark centerline on door for deadbolt about 3” to 6” (75 mm to 150 mm) above

the existing knob or lever.

b. Stand so door swings towards you. Align template on centerline and fold template as shown.

CENTERLINE

BACKSET

DRILL 1/8” (3 mm) PILOT HOLE

1”

(25 mm)

2-1/8”

(54 mm)

DRILL 1/8” (3 mm) PILOT HOLE

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

5

DOOR PREPARATION

2 MARK AND DRILL PILOT HOLES

Select backset. Mark and drill pilot holes

as shown.

6

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

DOOR PREPARATION

3 USING THE TEMPLATE MARKS AS A GUIDE

a. Drill a 2-1/8” (54 mm) hole on the door face from both sides to prevent wood from splitting.

b. Drill a 1” (25 mm) hole in the door edge for the latch.

c. Use the latch faceplate as a pattern for the mortise and pilot holes. Chisel 1/8” (3 mm) deep.

Faceplate should fit flush.

Note: for drive-in latch, simply insert latch.

a. b. c.

2-1/8”

(54 mm)

1”

(25 mm)

FACEPLATE

OUTLINE

CHISEL 1/8”

(3 mm) DEEP

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

7

DOOR PREPARATION

4 PREPARE DOOR JAMB AND INSTALL STRIKE PLATE

a. To identify the center of the strike: insert the latch, close the door;

using the latch faceplate as a guide, mark horizontal centerline and

outline of the strike. Ensure the center of the faceplate and the

center of the strike are aligned.

b. Chisel 5/64” (2 mm) deep along the strike outline to allow the strike

to be aligned with the door frame.

c. Insert the strike and tighten it with wood screws.

Door jamb hole dimension

a. 1-3/16 (30 mm)

b. 1-3/8” (35 mm)

c. 1” (25 mm)

Strike dimension

d. 9/32” (7 mm)

e. 2-15/16” (75 mm)

f. 1-5/16” (33 mm)

a.

b.

c.

A

B

C

D

E

F

8

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

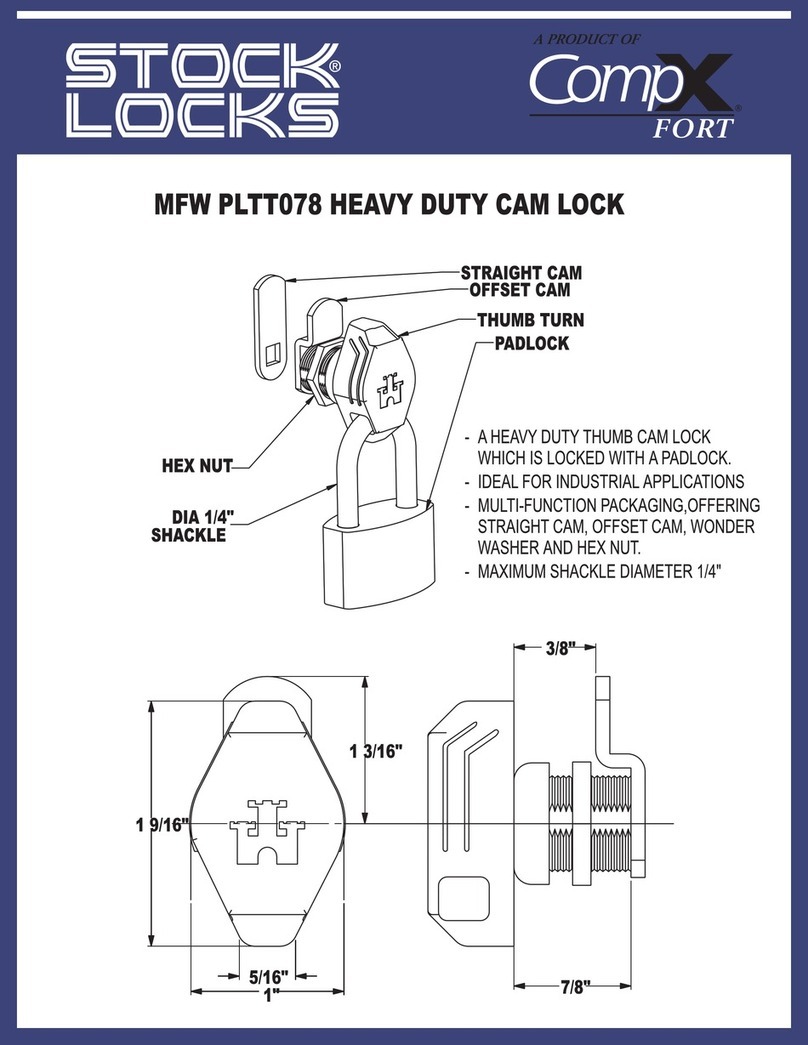

INSTALLATION 6 WAY LATCH

1 6 WAY LATCH

To Change Latch Faces

1. Use a flat-head screwdriver to separate

the faceplate form the backplate.

2. Snap the selected faceplate onto the

backplate.

Latch Backset Adjustment

To rotate the latch case as following

illustration for backset 2-3/4” (70 mm)

or reverse direction for 2-3/8” (60 mm)

Drive-in Installation

Make sure the round faceplate is properly

aligned as illustrated and snap it to the

latch case. DRIVE-IN LATCH

2-3/4” (70 mm)

1B

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

9

INSTALLATION

2 INSTALL LATCH IN MORTISED AREA OR DRIVE-IN LATCH

If your door is set up to use a standard type latch, please install it with the 3/4” (20 mm) screws

that are provided. If you use the drive-in latch, please tap it into place.

BACKSET

FACEPLATE

3/4” (20 mm) WOOD SCREWS

OR

DRIVE-IN LATCH TAP

LATCH

FLUSH

WOOD BLOCK

(NOT INCLUDED)

10

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

INSTALLATION

3 a. Make sure latch is in retracted position.

b. Insert the cylinder into exterior assembly with cylinder torque blade inserted through hub of the

latch in a horizontal position.

c. Pass the IC wire under the latch to the interior side of the door.

a. b. c.

IC WIRE

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

11

INSTALLATION

4 INSTALL INSIDE THE MOUNTING PLATE

a. Carefully pass the IC wire through the wire hole

on the mounting plate.

b. Making sure that the exterior assembly and

cylinder are pressed flush against the exterior

door, insert the mounting bolts and tighten.

c. Check the vertical alignment for the mounting

plate and exterior assembly.

d. Test. Using the key, retract and extend the bolt

a few times to test for smooth action.

e. If action feels rough, loosen screws and realign

the mounting plate and exterior assembly.

KEEP PARALLEL

MOUNTING PLATE

MOUNTING BOLTS

IC WIRE

12

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

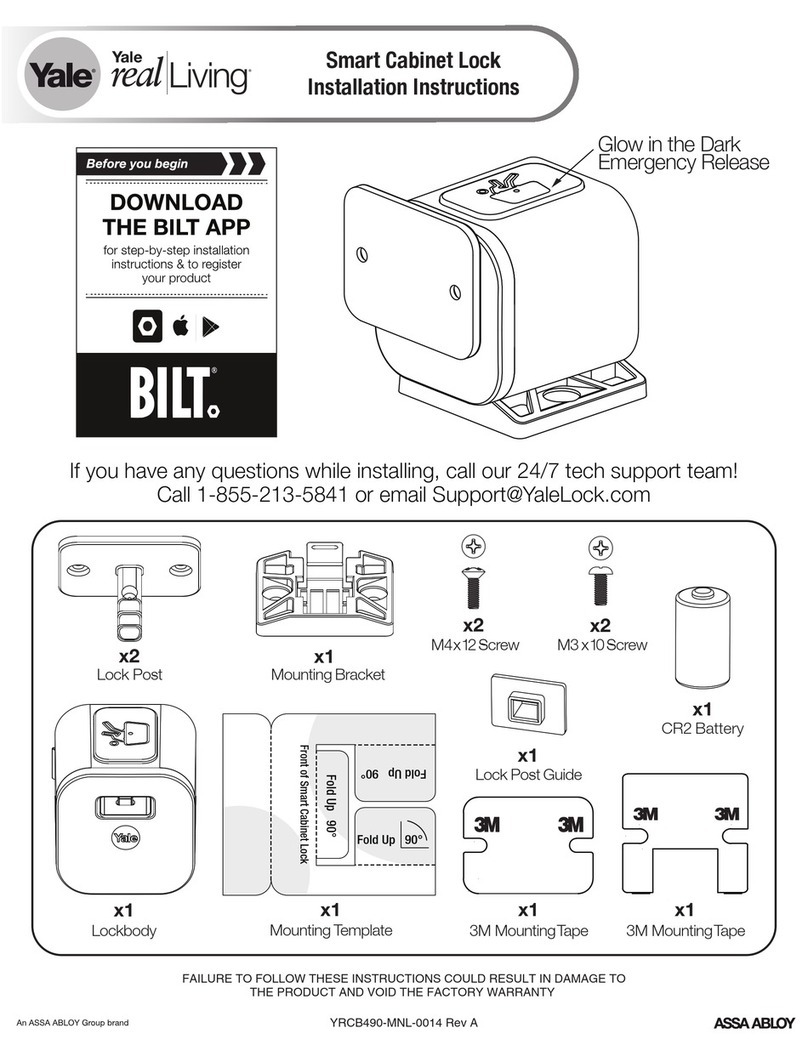

INSTALLATION - DOOR HANDING

5 IDENTIFY THE DOOR HANDING

a. Face the door from inside

b. The door is “left-handed” if the hinges are on the left hand side of the door.

c. The door is “right-handed” if the hinges are on the right hand side of the door.

6 ADJUST INTERIOR TURN PIECE

a. Turn the turn piece to the left when it is a “right-handed” door.

b. Turn the turn piece to the right when it is a “left-handed” door.

LEFT-HANDED RIGHT-HANDED

INTERIOR

EXTERIOR

HINGE

DOOR

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

13

INSTALLATION - RECEIVER MODULE

7 INSTALL RECEIVER MODULE

a. Remove the battery cover (push it up and pull it out).

b. Connect the IC wires and ensure the cylinder torque blade is engaged with the turn piece then

attach the interior assembly to the door with the metal screws.

c. Insert 4 (AA) 1.5V alkaline batteries and place the cover back onto the interior assembly.

BATTERY

COVER

METAL

SCREWS

WOOD

SCREWS

a. b. c.

14

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

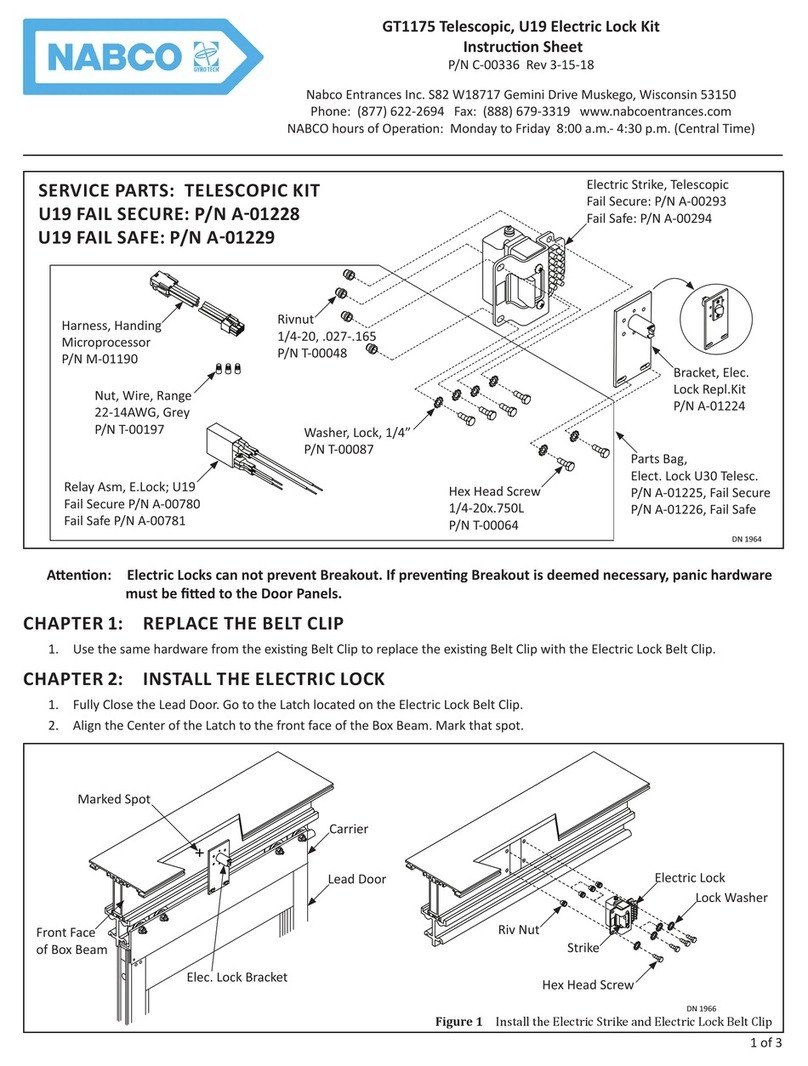

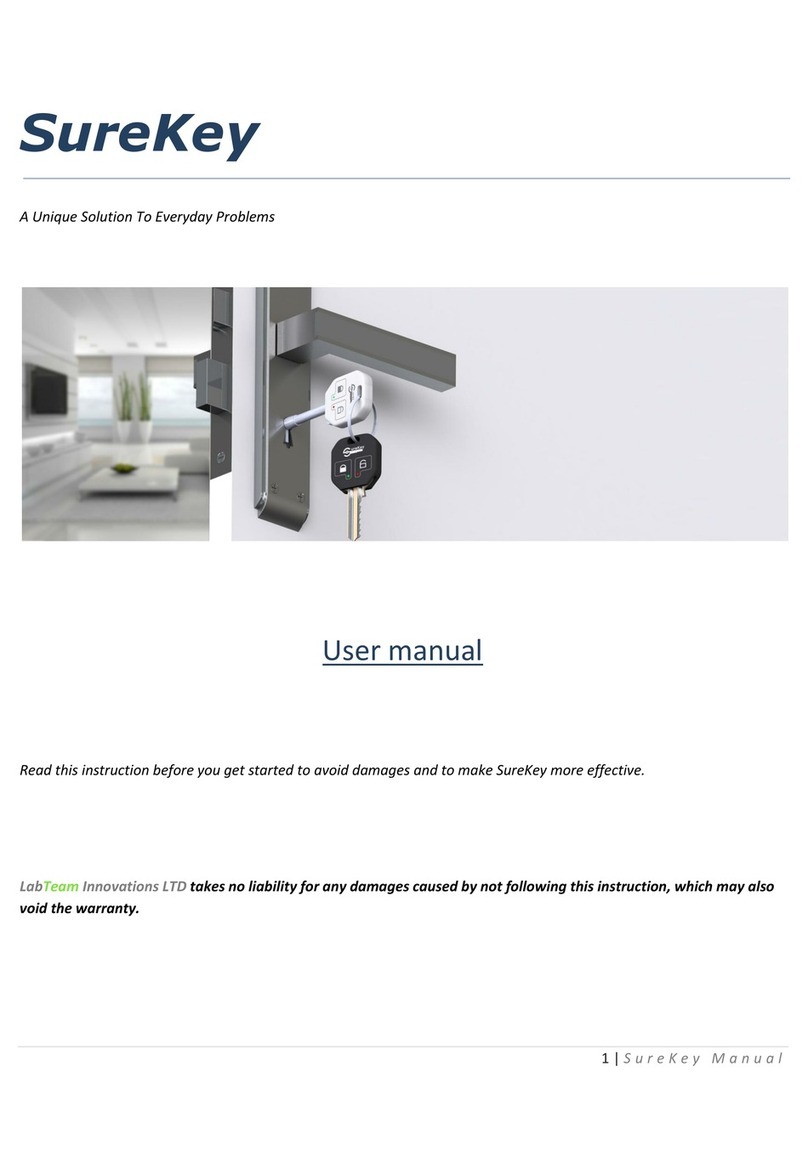

OVERVIEW OF FUNCTIONS

1. PROGRAMMING BUTTON

Programming Button is for entering codes,

clearing errors, and setting functions.

It’s also a “Lock” Button.

2. KEYPAD WITH NUMBER BUTTONS

For inputting codes, 4-10 digits in length.

3. CYLINDER

Retract/Expand latch bolt by key from outside.

4. RUBBER GASKET

To prevent water leaking through

exterior assembly.

5. BATTERY COVER

6. BATTERY HUB

Four (AA) Alkaline Batteries

(sold separately)

7. “R” BUTTON (RESET)

Restore default setting

8. TURN PIECE

Retract/Expand the latch bolt

from inside.

1

2

3

4

6

7

8

5

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

15

KEYPAD LIGHTS & WARNINGS

LED INDICATOR LIGHT

1. Flashes “Green” once when operating function is performed properly.

2. Flashes “Green” twice when programming function is performed properly.

3. Flashes “Red” three times when operating function was not performed properly.

4. Flashes “Red” five times following five unauthorized entry attempts - the keypad will be disabled for

45 seconds.

5. Flashes “Orange” three times when system was restored to default setting.

6. Flashes “Orange” slowly while in programming mode.

AUDIO WARNINGS

1. One “Beep” - operating function was performed properly.

2. Two “Beeps” - programming function was performed properly.

3. Three “Beeps” - operating function was not performed properly.

LOW BATTERY WARNING

LED indicator flashes “Red” and constant “Beep” sound is on for 10 seconds. Please replace batteries.

Note: • The lock can still be operated via regular key.

• All settings are stored in the memory and will not be affected even when the batteries are replaced.

16

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

CODE INFORMATION

PROGRAMMING CODE

1. Programming code provides ability to program/reprogram the deadbolt, and change/delete/add

individual user codes.

2. Programming code cannot be used to unlock the deadbolt.

3. Only one programming code is allowed, 4-10 digits in length.

4. The factory preset programming code is 0-0-0-0, and can be changed anytime if needed.

USER ENTRY CODE

1. User entry code allows the individual user to lock and unlock the deadbolt.

2. The factory preset user entry code is 1-2-3-4. Please delete it and create your personal, unique user

entry code as soon as the deadbolt is installed.

3. User entry code can be 4-10 digits in length.

4. Maximum of 6 user entry codes can be programmed into one deadbolt.

5. An individual user entry code can be changed/deleted/added to the lockset only by using a valid

programming code.

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

17

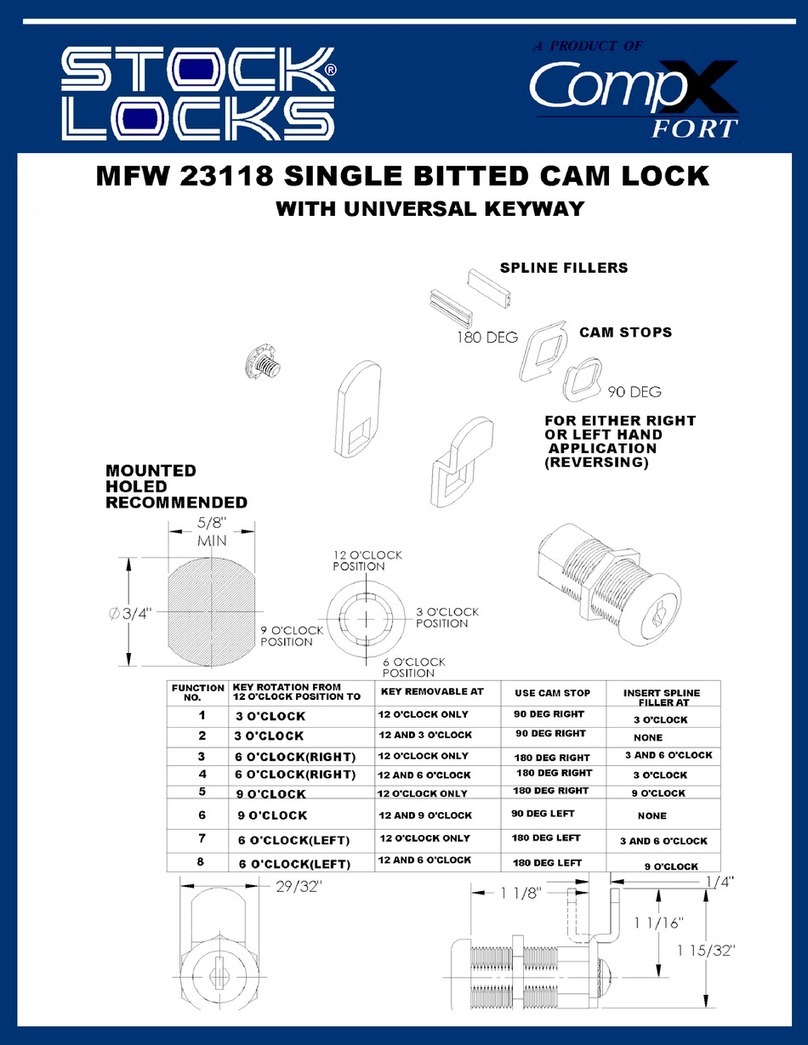

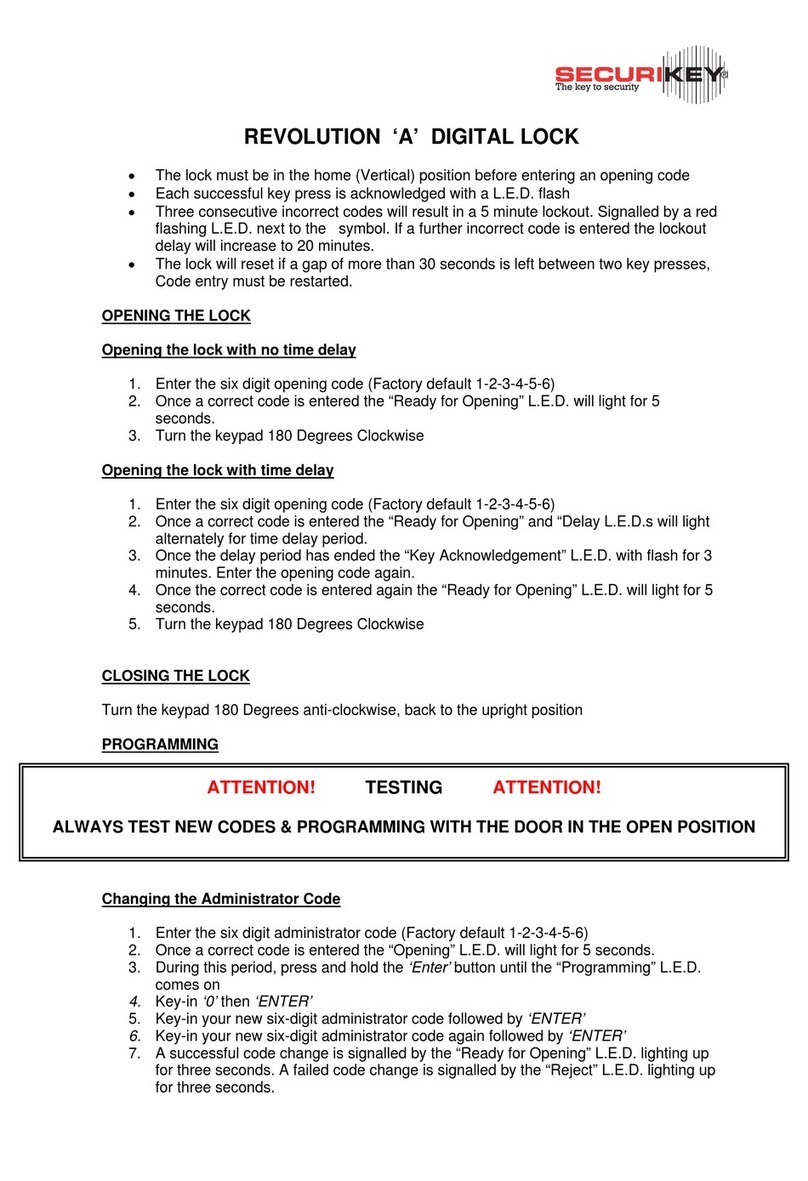

PROGRAMMING

AUTOMATIC BOLT DIRECTION ADJUSTMENT

Deadbolt throw direction is automatically adjusted to left or right-handed door.

1. Deadbolt should be in unlocked position.

2. Make sure the interior thumbturn position is identified properly according to door handing.

(see page 12).

FUNCTION STEPS

Detect Left/Right Hand

Door Installation

Enter

Programming

Code

Press

“

0

”

18

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

PROGRAMMING

CHANGE PROGRAMMING CODE

IMPORTANT: The factory preset programming code is 0-0-0-0 and needs to be changed to a unique

6 digit number before operating the deadbolt.

1. Deadbolt should be in unlocked position.

2. LED indicator flashes “Orange” while in programming mode. LED indicator flashes “Green” twice

with 2 long “Beeps” when programming function is performed correctly. LED indicator light flashes

three times with three “Beeps” when programming function is performed incorrectly.

Note: wait for at least 6 seconds or press and repeat programming steps if programming error

was committed.

3. Every programming step should be performed in 6 seconds or less.

FUNCTION STEPS

Change

Programming

Code

Enter

Programming

Code

Press

“

4

”

Enter

Programming

Code

Table of contents

Other Taymor Lock manuals