Taymor CONCIERGE 400 PROFESSIONAL Series User manual

CONCIERGE 400

PROFESSIONAL SERIES

ELECTRONIC DEADBOLT

USER GUIDE

06/2016

IMPORTANT: Before first use,

please read page 19 in the User

Guide for important instructions.

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

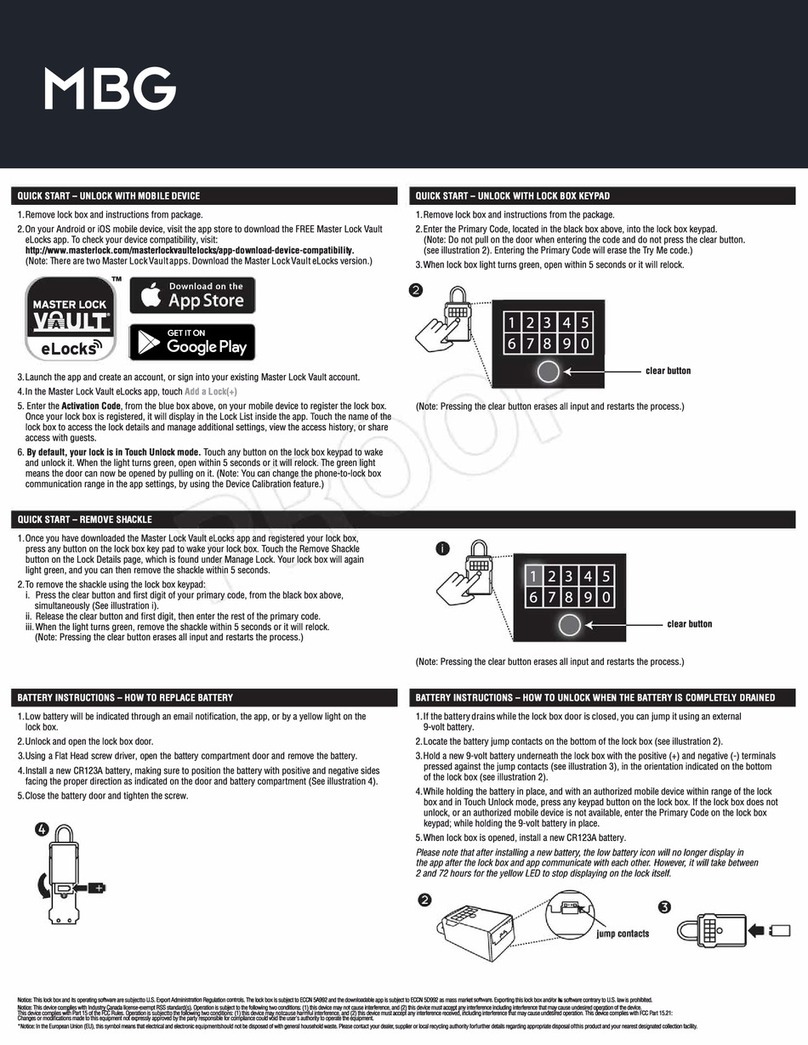

IMPORTANT SAFETY INFORMATION 1

TOOLS NEEDED FOR NEW INSTALLATION 2

COMPONENTS OF ELECTRONIC KEYPAD DEADBOLT 3

DOOR PREPARATION 4 - 8

INSTALLATION 9 - 19

OVERVIEW OF FUNCTIONS 20

CODES INFORMATION 21

PROGRAMMING

1. CHANGE PROGRAMMING CODE 22

2. ADD NEW USER ENTRY CODE OR SINGLE ENTRY CODE 23

3. ENABLE/DISABLE THE GUIDING CODE 24

4. DELETE USER ENTRY CODES 25

5. ENABLE/DISABLE VACATION MODE 26

6. VOLUME CONTROL 27

7. SET UP AUTO-LOCK TIME DELAY 28

8. ENABLE/DISABLE AUTO-LOCK FUNCTION 29

9. RESTORE FACTORY SETTING 30

OPERATION

1. HOW TO LOCK/UNLOCK THE LOCKSET 31

2. SECURITY MODE 32

TROUBLESHOOTING GUIDE 33 - 38

INFORMATION PAGE 39

WARRANTY 40

CONTENTS

1

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

IMPORTANT SAFETY INFORMATION

! WARNING

1. Do not use any abrasives or any chemical products containing any substance

of alcohol, benzene, hydrochloric acid or nitric acid, and avoid sharp or

scratching objects to clean this lockset.

2. Do not let any water or liquid into lockset during installation process.

Note: Electronic mechanisms may be sensitive in cold, harsh conditions particularly

if the environment is also humid. In these conditions, the manual key may be the

most convenient method to operate the lock.

! IMPORTANT SAFETY INSTRUCTION

1. Do not attempt to disassemble any internal components of the lockset

personally. You may run the risk of voiding the limited warranty.

2. Do not drop or hit the lockset.

3. Do not use sharp objects to press key buttons.

4. Always create a backup of information you want to keep (such as programming

code and user entry codes). Please use the last page of this booklet as your

reference.

5. Please change the programming code before operating this lockset.

! CARE AND MAINTENANCE

The following care instructions should be followed:

1. Remove locks, or do not install locks, prior to painting your door.

2. Periodically clean with mild soap and a soft cloth only.

3. Do not use any abrasives or chemical products containing alcohol, benzene,

hydrochloric acid or nitric acid, and avoid using sharp or abrasive objects to

clean this lockset.

4. Do not let any water or liquid into lockset during installation and care processes.

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

2

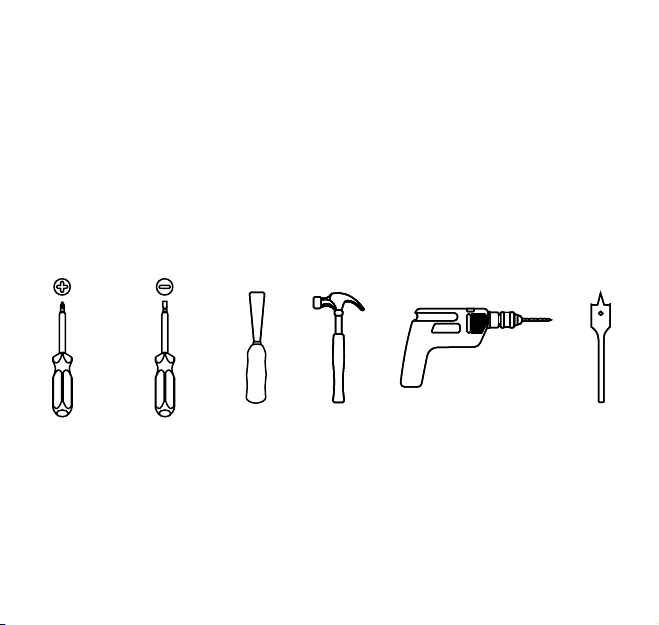

• PHILLIPS SCREWDRIVER

• FLAT HEAD SCREWDRIVER

• CHISEL

• HAMMER

• 1” (25.4 mm) and 2 -1/8” (54 mm) OR 1-1/2” (38 mm) HOLE BORING KIT

• POWER DRILL

• 4 - AA ALKALINE BATTERIES

TOOLS NEEDED FOR NEW INSTALLATION

OPTIONAL OPTIONAL OPTIONAL OPTIONAL OPTIONAL

3

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

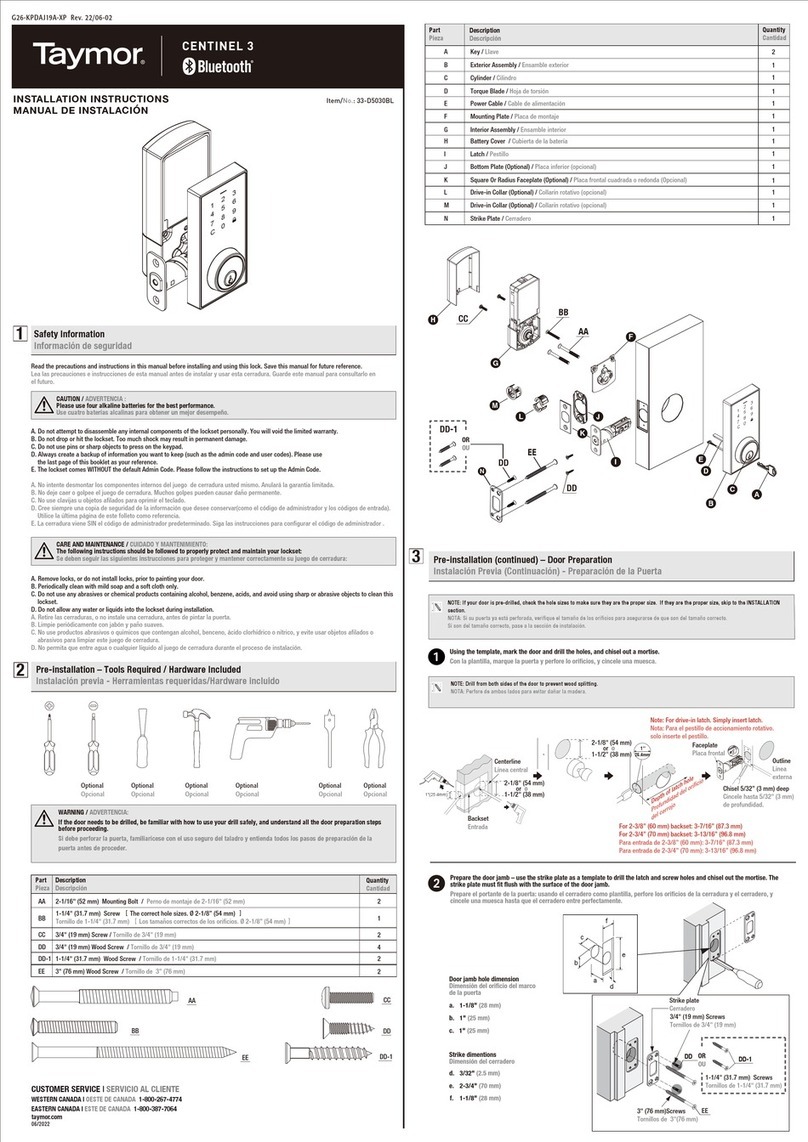

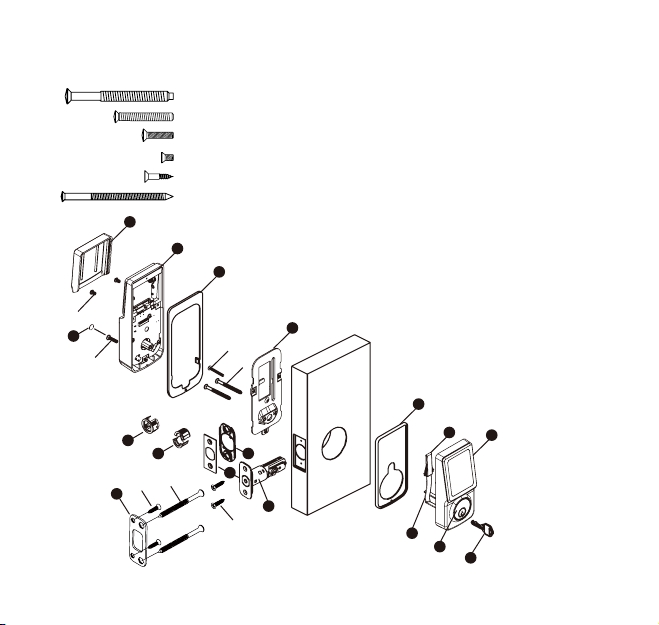

COMPONENTS OF ELECTRONIC

KEYPAD DEADBOLT

A. Key (2)

B. Exterior Assembly

C. Cylinder

D. Tailpiece

E. Power Cable

F. Exterior Gasket (Optional)

G. Mounting Plate

H. Interior Gasket (Optional)

I. Interior Assembly

J. Battery Cover

K. Latch

L. Bottom Plate (Optional)

M. Square or Radius Faceplate

(Optional)

N. Drive-In Collar (not assembled)

O. Drive-In Collar (assembled)

P. High Security Strike Plate

Q. Screw Hole Cover

AA. 2-1/8” Mounting Bolt

BB. 1-1/4” Screw

CC. 13/16” Screw

DD. 5/16” Screw

EE. 3/4” Wood Screw

FF. 3” Wood Screw

QTY.

2

1

1

2

4

2

AA

BB

CC

DD

EE

A

G

F

EB

I

H

J

C

D

K

M

L

N

O

Q

P

FF

EE

TEMPLATE

CENTERLINE

MARK DOOR EDGE APPROXIMATELY

3” TO 6” (75 mm TO 150 mm) ABOVE

THE ENTRY KNOB OR LEVER

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

4

DOOR PREPARATION

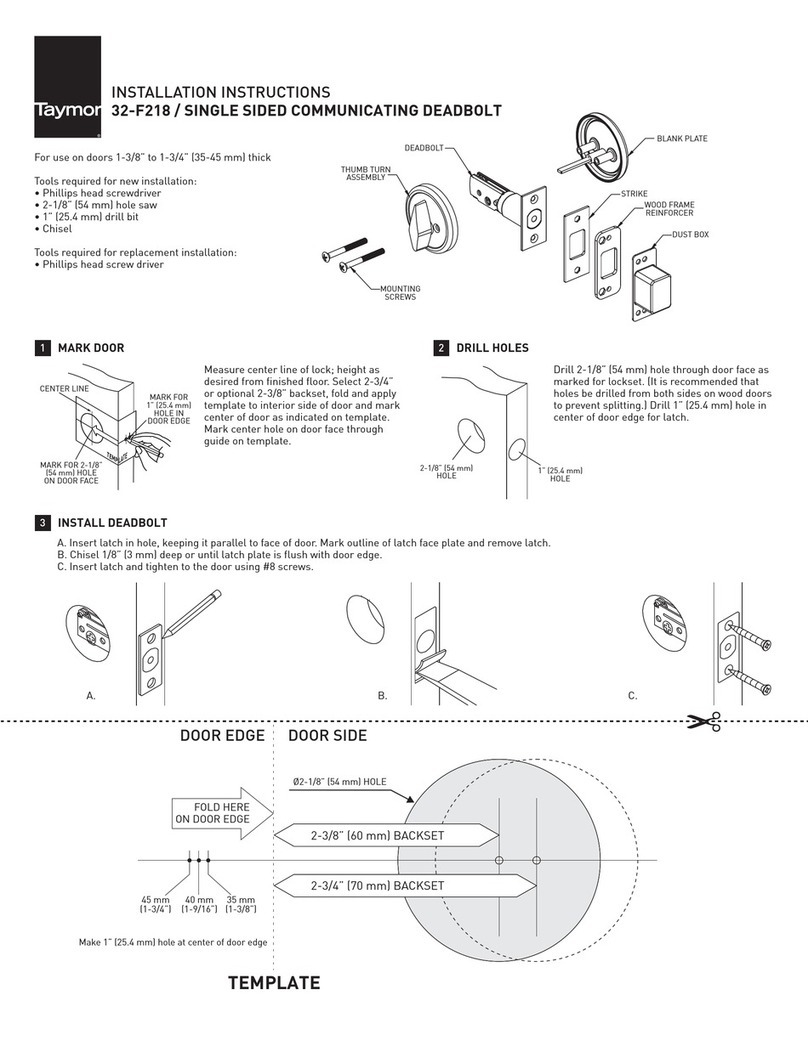

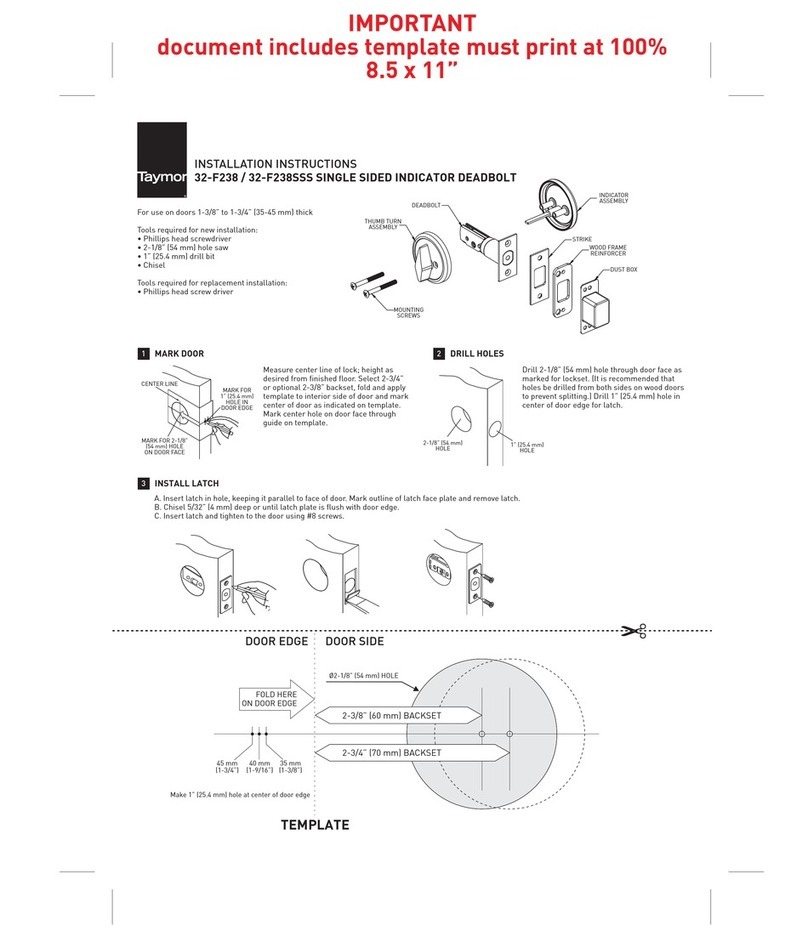

1 MARK DOOR WITH TEMPLATE (ATTACHED SEPARATELY)

Note: If replacing an existing lock or installing in a pre-drilled door,

begin with page 9.

a. Use TEMPLATE to mark centerline on door for deadbolt about

3” to 6” (75 mm to 150 mm) above the existing knob or lever.

b. Stand so door swings towards you. Align template on centerline

and fold template as shown.

5

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

DOOR PREPARATION

2 MARK AND DRILL PILOT HOLES

Select backset. Mark and drill pilot holes as shown.

CENTERLINE

BACKSET

DRILL 1/8” (3 mm) PILOT HOLE

1”

(25 mm)

2-1/8” OR 1-1/2”

(54 mm) (38 mm)

DRILL 1/8” (3 mm) PILOT HOLE

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

6

DOOR PREPARATION

3.1 DRILL HOLES

a. Drill a 2-1/8” (54 mm) hole on the door face from both sides to

avoid wood splitting.

b. Use a 2” (51 mm) 6d common nail and press it from inside the

2-1/8” (54 mm) or 1-1/2” (38 mm) hole through the pilot hole to

mark centerlines on jamb exactly opposite center of deadbolt

latch hole.

2-1/8”

(54 mm)

7

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

DOOR PREPARATION

3.2 DRILL HOLES

c. Drill a 1” (25 mm) hole in the door edge for the latch.

d. Use faceplate as a pattern for mortise and pilot holes.

Chisel 5/32” (4 mm) deep. Faceplate should fit flush.

Note: For drive-in latch, simply insert latch.

e. Install as shown for appropriate latch type. Ensure bevel

faces door jamb.

CHISEL 5/32”

(4 mm) DEEP

1”

(25 mm)

FACEPLATE

c.

d.

OUTLINE

DOOR JAMB PREPARATION

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

8

4 PREPARE DOOR JAMB AND INSTALL STRIKE PLATE

Door Jamb hole dimensions

a. 3/32” (2.5 mm)

b. 1” (25 mm)

c. 1-1/8” (28 mm)

3/4” (19 mm) SCREWS

HIGH SECURITY

STRIKE PLATE

3”(76 mm) SCREWS

a.

b.

c.

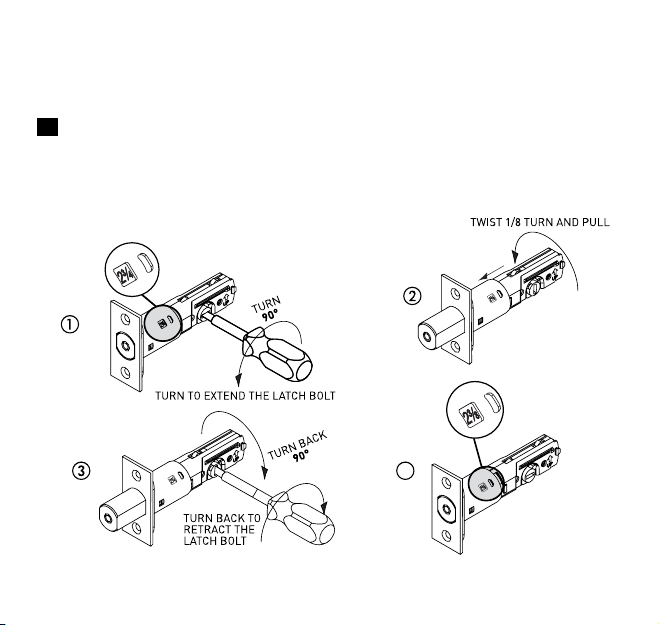

INSTALLATION

1a LATCH BACKSET ADJUSTMENT

Latch backset adjustment only needs to be made if your door needs

a 2-3/8” (60 mm) backset. Please follow diagrams below as reference.

Skip this if your door has a 2-3/4” (70 mm) backset

9

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

4

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

10

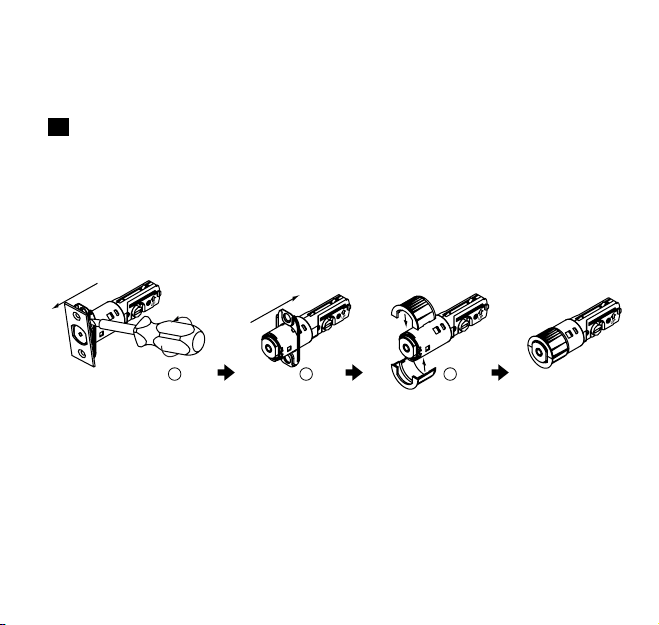

INSTALLATION

1b DRIVE-IN COLLAR or FACEPLATE ADJUSTMENT

In addition to 2-3/8” (60 mm) or 2-3/4” (70 mm) adjustable backset,

you may change the faceplate to drive-in collar. (If your door is not

a drive-in latch type, please skip this step)

Note: Reverse the above steps if you need to change

the drive-in collar to the faceplate.

COMBINE

REMOVE

REMOVE

1 2 3

11

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

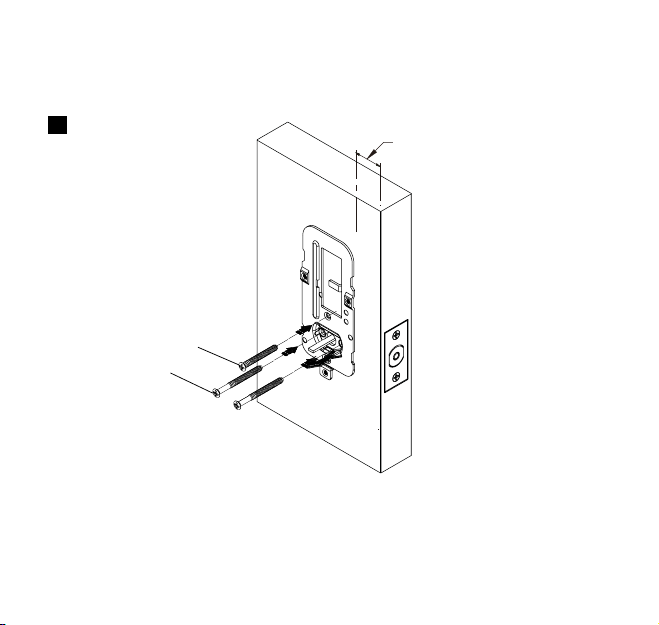

INSTALLATION

2 INSTALL LATCH IN MORTISED AREA OR INSTALL DRIVE-IN LATCH

If the backset of your door is 2-3/8” (60 mm), please install it now.

If your door is set up to use a standard type latch, please install it

with the 3/4” (20 mm) screws that are provided. If you use the

drive-in type latch, please tap it in place.

BACKSET

FACEPLATE

3/4” (20 mm) WOOD SCREWS

OR

DRIVE-IN LATCH TAP

LATCH

FLUSH

WOOD BLOCK

(NOT INCLUDED)

(SEE PAGE 10 BEFORE

INSTALLATION OF

DRIVE-IN LATCH)

INSERT

CYLINDER

TORQUE BLADE

IN HORIZONTAL

POSITION

THE LATCH

BOLT SHOULD

BE IN THE

UNLOCKED

POSITION

THREAD THE CABLE

THROUGH THE HOLE AND

UNDER THE LATCH

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

12

INSTALLATION

FOR INSTALLATION INTO 1-1/2” (38 mm)

BORE HOLE:

1. Remove adapter collar by releasing

cylinder mounting screw and top

mounting post.

2. Once adapter collar is off, reinstall

cylinder mounting screw.

CYLINDER MOUNTING SCREW

ADAPTER COLLAR

3

IMPORTANT

13

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

INSTALLATION

4

THE BULGED PART OF THE MOUNTING

PLATE MUST FACE TOWARD THE DOOR

SLIDE CABLE THROUGH THE

NOTCH OF THE MOUNTING PLATE

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

14

INSTALLATION

5 KEEP PARALLEL TO THE

EDGE OF DOOR

AA

BB

SECURE MOUNTING PLATE WITH 1-1/4” SCREW (1) AND 2-1/8” MOUNTING SCREWS (2)

(1-1/4” SCREW NOT REQUIRED FOR 1-1/2” BORE HOLE)

6 REMOVE THE INTERIOR COVER BY PUSHING THE THUMBTURN

THROUGH

15

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

INSTALLATION

INTERIOR GASKET (OPTIONAL)

INSTALLATION

7

CONNECT THE CABLE INTO

CONNECTOR PORT FIRMLY

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

16

OR

INSTALLATION

8 THE CABLE MUST BE ARRANGED

AS SHOWN IN THE DIAGRAM

17

® REGISTERED TRADEMARK OF TAYMOR INDUSTRIES LTD.

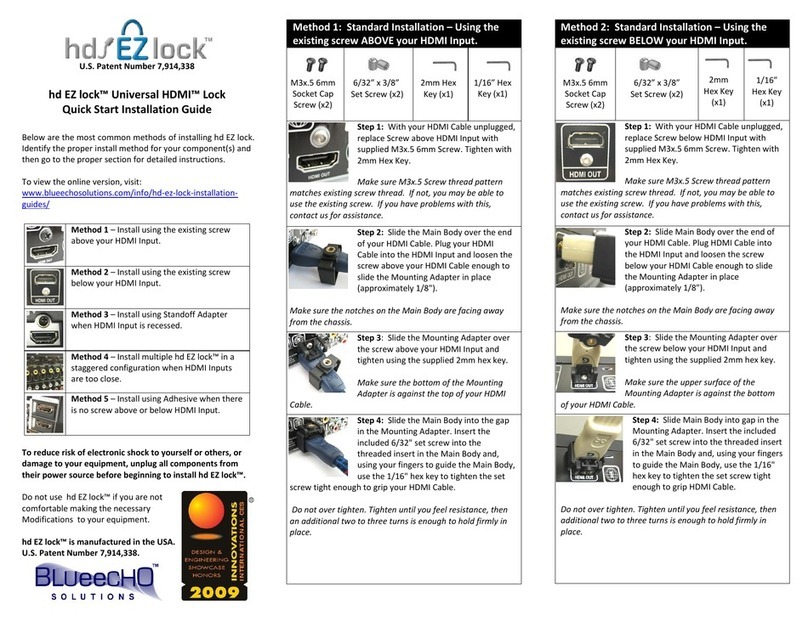

Table of contents

Other Taymor Lock manuals

Popular Lock manuals by other brands

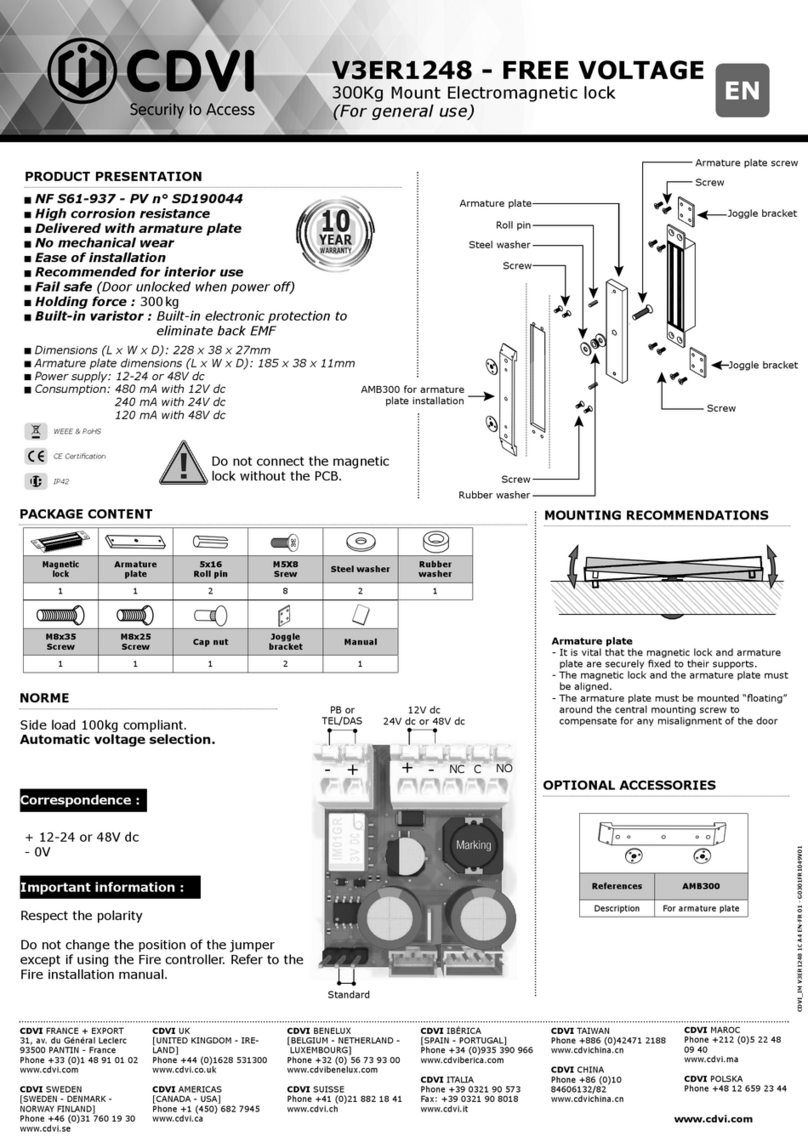

CDVI

CDVI V3ER1248 quick start guide

Gianni Industries

Gianni Industries EB-200N Specifications

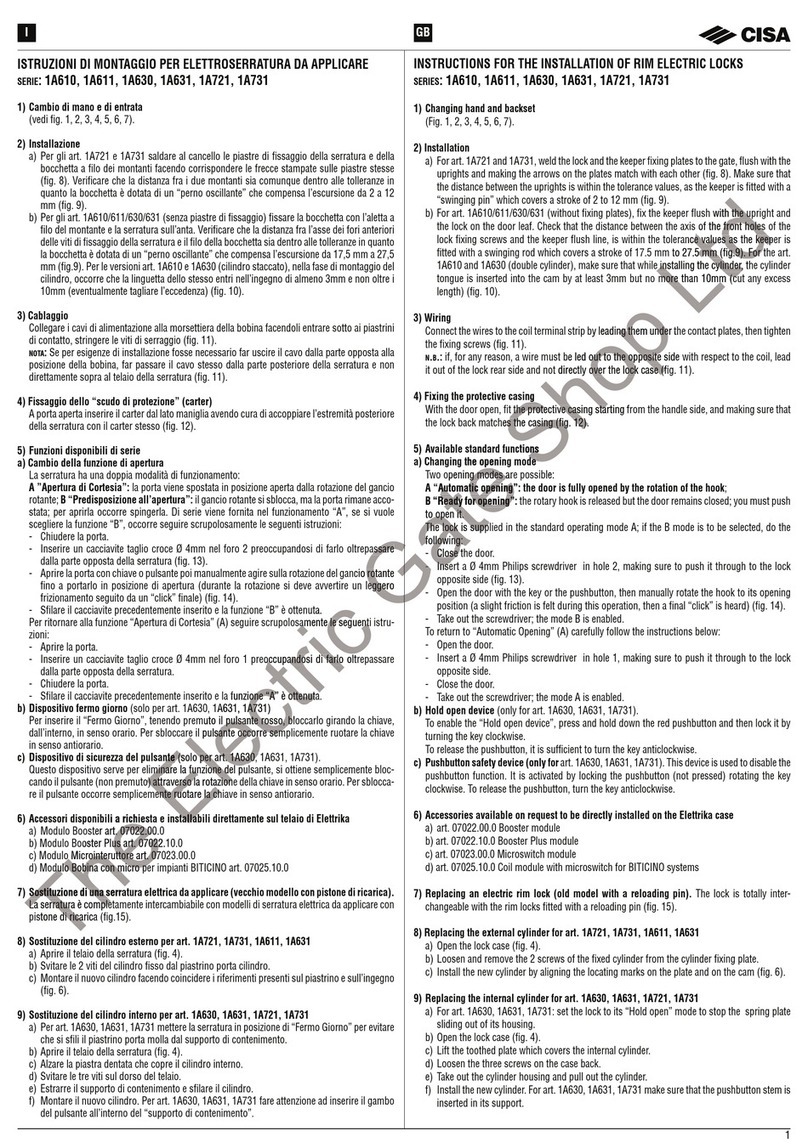

CISA

CISA 1A610 Series Instruction for the installation

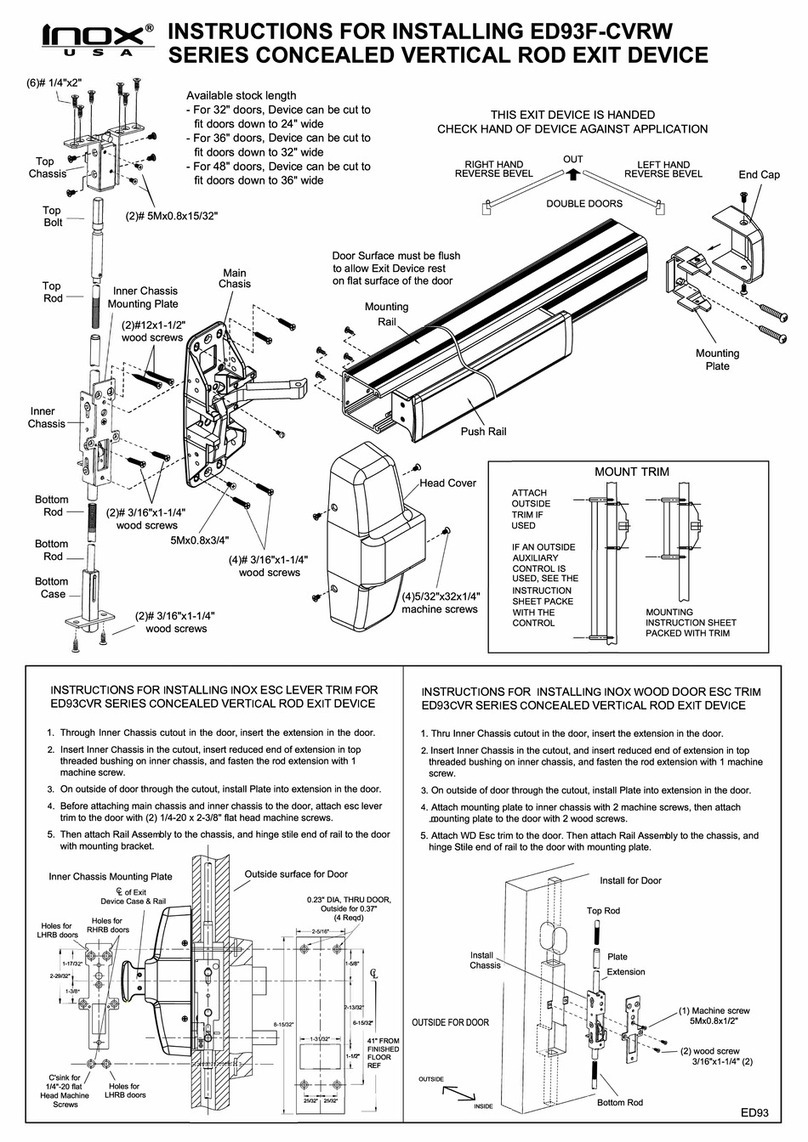

INOX

INOX ED93F-CVRW Series Instructions for installing

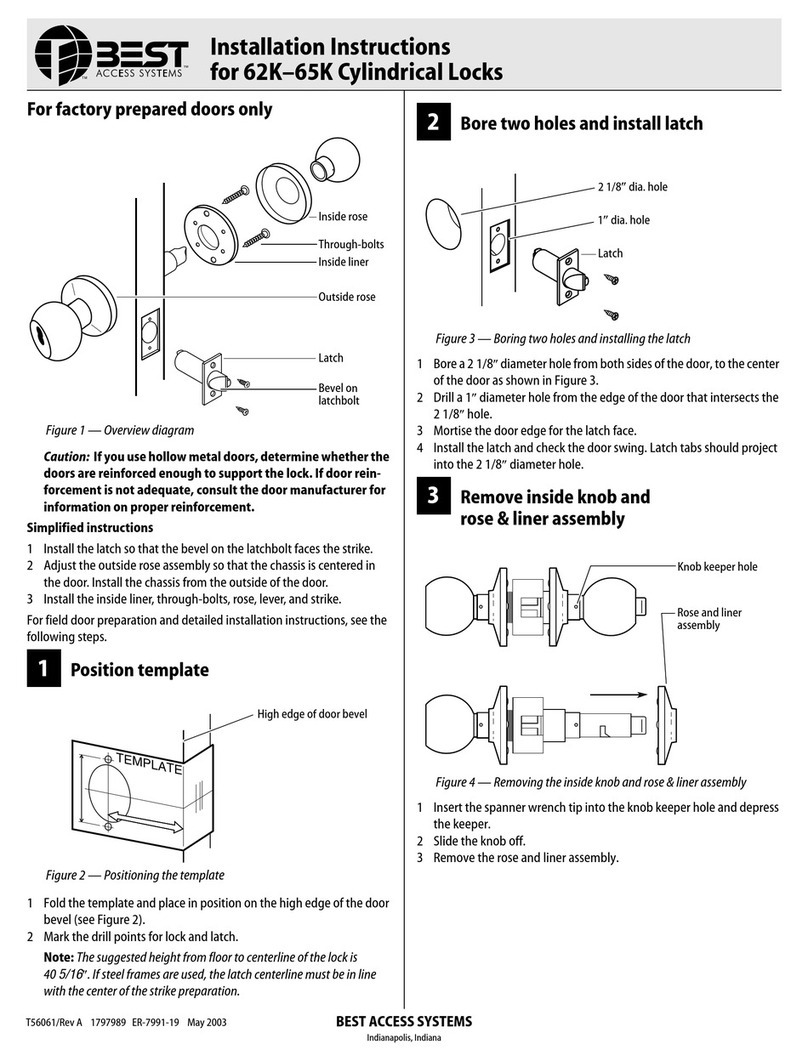

BEST ACCESS SYSTEMS

BEST ACCESS SYSTEMS 62K installation instructions

Simons Voss Technologies

Simons Voss Technologies SmartHandle WP Instruction leaflet