2 of 3

GT1175 Telescopic, U19 Electric Lock Kit Instrucon Sheet www.NabcoEntrances.com

P/N C-00336 Rev 3-15-18

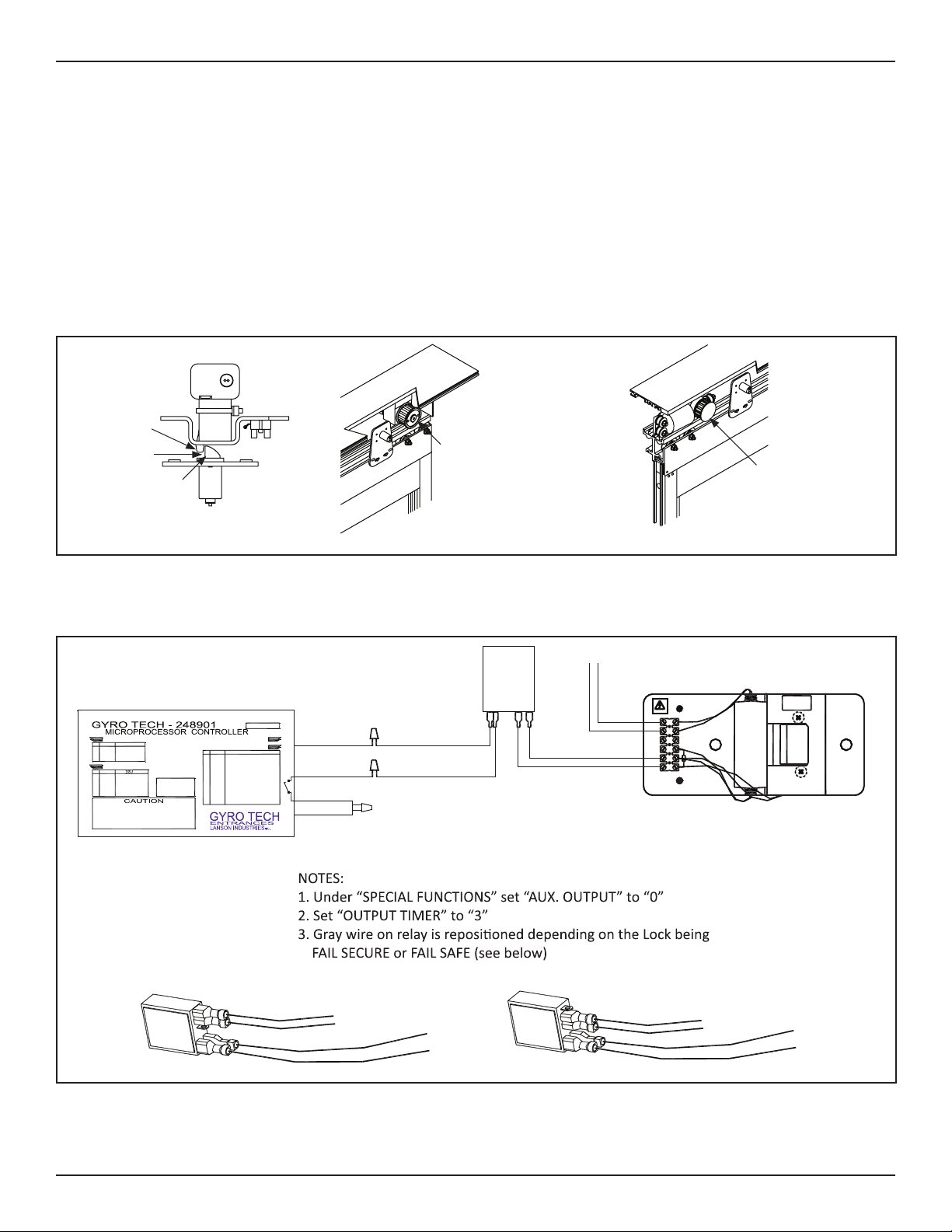

3. Mark and drill out (1) Retangle Hole and (4) Rivnut Holes onto the front face of the Box Beam according to the Template

located in CHAPTER 5.

4. Insert (1) 1/4-20 Rivnut into each Rivnut hole.

5. Insert the Electric Lock into the Cutout.

6. Ensure the Flat side of Latch faces the Strike on the Electric Lock.

7. Loosely secure the Electric Strike to the Box Beam with (4) 1/4-20 x 1” Screws and 1/4” Lock Washers.

8. Fully close the Slide door.

a. A slight gap must exist between the Latch and the Strike.

b. Ensure the Belt Clip does not hit the Speed Reducer Roller.

9. Fully Open the Slide Door. Ensure the Belt Clip does not hit the Drive Belt Roller.

10. Make adjustments if deemed necessary.

DN 1968

Slight Gap

Strike

Flat side of Latch

Speed Reducer Roller

Drive Belt Roller

Door Fully Closed Door Fully Open

Figure 2 Ensure Terminal Strip is Facing Strike Side of Slide Door

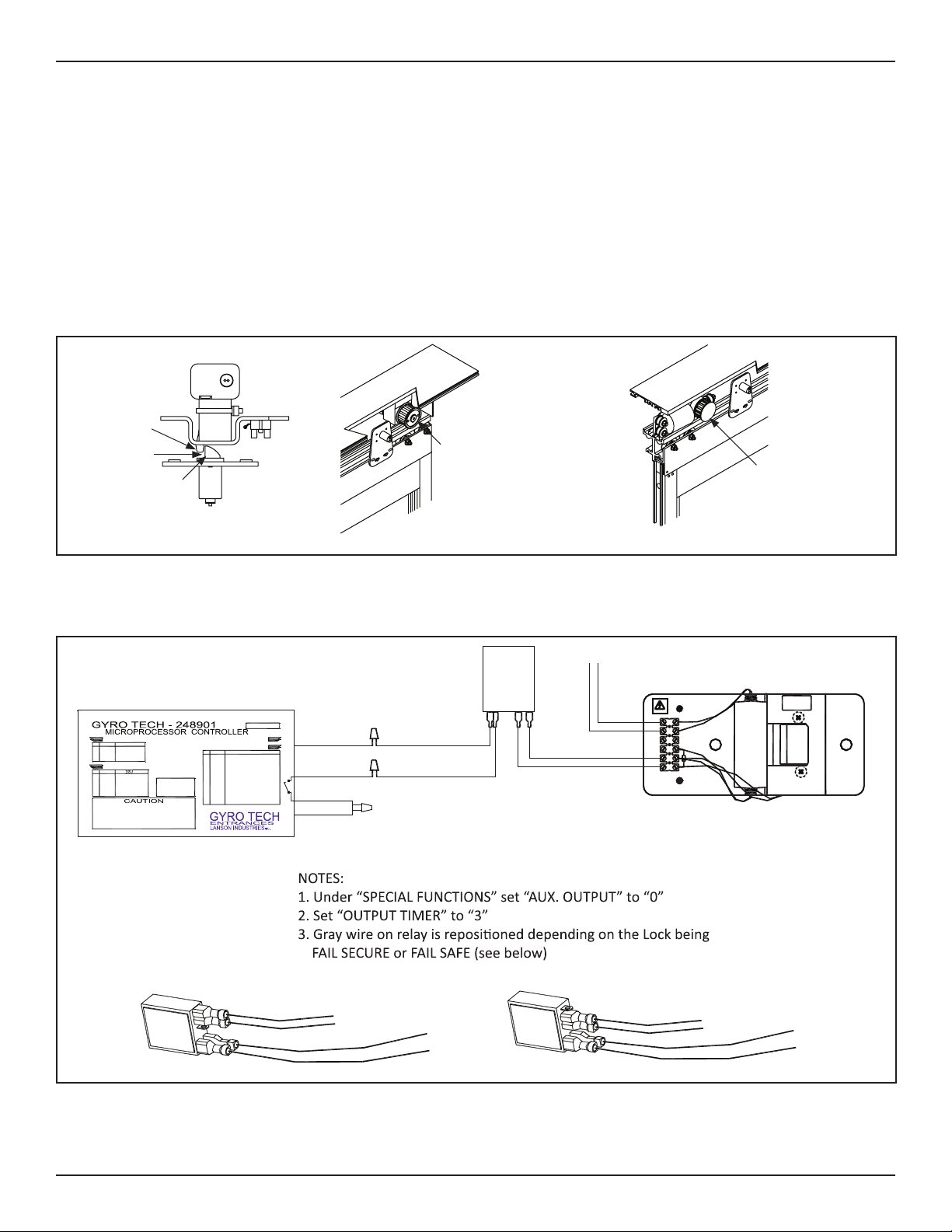

CHAPTER 3: GENERAL WIRING

Aenon: Electric Lock only works in One Way mode or Night Mode.

DN 1913

FAIL

SECURE

VIO

GRY

WHT

BLK

1

6

110V

Wire Nut

103125

BROWN 60"

VIOLET 60"

No.

HANDY TERMINAL (6P)

SENSOR (12P)

1.Please adjust this operator as per instruction manual.

2.Turn the power off, before opening the box.

3.Don't open this box except for replacing fuse.

Otherwise, the warranty will be terminated.

4.Repair of this unit except by Lanson Industries, Inc.

may cause software and hardware malfunction.

USE [SLIDER/SWINGER]

For continued protection

against fire, replace only

with same type and rating

of fuse.

WARNING

FUSE INSIDE

RATING:125V,4A

SIZE:5.2 x 20mm

COLOR

BROWN

RED

BLACK

WHITE

GREEN

ORANGE

ORANGE

ORANGE

YELLOW

BLUE

VIOLET

GRAY

7

61

6B

9DC12V

SYMBOL

H

M0

M1

62

BA

OUT +

OUT -

SQ

1

2

3

4

NO.

5

6

7

8

9

10

11

12

POWER SOURCE (4P)

OPERATOR (6P)

EMPTY

115VAC HOT

EMPTY

115VAC COMMONWHITE

BLACK

1

2

3

4

COLORNO.

MOTOR V PHASE

ENCODER 12VDC

ENCODER A PHASE

MOTOR U PHASE

ENCODER GND

ENCODER B PHASE

ORANGE

RED

BROWN

YELLOW

COLOR

BLUE

BLACK

1

2

3

4

5

6

NO.

OUT+

(VIOLET)

OUT-

(GRAY)

7 (RED)

9DC12V

(BROWN)

GREY 10"

VIOLET 10"

BROWN 60"

VIOLET 60"

GREY 10"

VIOLET 10" BROWN 60"

VIOLET 60"

GREY 10"

VIOLET 10"

FAIL SECURE RELAY WIRING FAIL SAFE RELAY WIRING

U-SERIES CONTROL

(U19 OR EARLIER)

RELAY

LOCK

TO 120VAC