TB Controls TC02 Manual

B U I L D I N G C O N F I D E N C E

TC02 Curtain heater controller

(Previously known as the mini-FCU)

Operations & Maintenance manual

©TBControls 2011

Operations & Maintenance Manual

Doc: TC02 O&M Page 2 of 20

Status: Final Issue: 11 ©TB Controls 2011

CONTENTS

1.........DOCUMENT MANAGEMENT ........................................................................... 3

1.1. Change Control 3

1.2. Document Review 3

1.3. Document Status 3

1.4. Document Ownership 3

2.........TC02 CONTROLLER ........................................................................................ 4

2.1. Design 4

2.2. Features 4

2.3. Connection terminals 5

2.4. Disposal 5

2.5. Engineering 6

2.5.1. Supply cables 6

2.5.2. Mounting the unit (if supplied without fan deck) 6

3.........WALL CONTROL PLATE UNIT........................................................................ 6

3.1. TC02 Connections 7

4.........MASTER / SLAVE............................................................................................. 8

4.1. Phased Start Sequence 8

4.2. Controller Start sequence 8

4.3. Error Messages 9

4.3.3. Master 9

4.3.4. Slave Messages 9

4.4. LCD Modes 9

4.4.5. LCD Set up Mode 9

4.4.6. Engineering Mode 10

4.4.7. User Mode 12

4.5. Final checks before Power UP 12

5.........CONTROL OPERATION SEQUENCES............................................................ 13

5.1.8. Sequence 1 13

5.1.9. Sequence 2 13

5.1.10. Sequence 3 13

5.1.11. Sequence 4 13

5.1.12. Graph settings 14

5.1.13. Graph settings 15

6.........TC02 DIP-SWITCH SETTINGS ......................................................................... 16

7.........OUTSIDE AIR TEMPERATURE SENSOR........................................................ 18

7.1. Fitting the sensor 18

8.........MODBUS PROTOCOL AND UNIT DATA......................................................... 19

9.........FAULT FINDING................................................................................................ 20

Operations & Maintenance Manual

Doc: TC02 O&M Page 3 of 20

Status: Final Issue: 11 ©TB Controls 2011

1. Document Management

1.1. Change Control

Ver.No.

Date of

Issue

Status

Changes

Description/Comment

1

8 Sept 04

Final

All sections

First Issue

2

13 Oct 04

Final

Changes relating to additional

air sensors

3

15 Oct 04

Final

All sections

Typographical amendments

Increased index references

4

16 Nov 04

Final

Section 7 added

Outside sensor fitting

5

20 Nov 06

Final

Name change & Various

updates

Mini-FCU changed to TC02

6

7 Feb 06

Final

Section 8 (fault finding)

added and various minor

text changes

Updates from Diffusion

7

24 May 07

Final

New mode to allow user

interface to be locked

Requested by Diffusion,

TC02 firmware V3.23

8

16 July 08

Final

MODBUS BMS interface

details. LON comms error

for slave device added.

Return air sensor now NOT

required on slave units if

fitted to master.

TC02 firmware V4.00

9

30 Sep. 09

Final

LON wire colour change to

match Diffusion drawings,

terminals 11 and 13 (black

and white).

Requested by Diffusion

10

22 Apr. 10

Final

Reverse sense option for

return air sensor. Disable or

setback heating when

sensor is below a set-point.

Requested by Diffusion for

New Look (firmware V4.10)

11

5 Apr. 11

Final

Set-point limits extended,

DIP 5 for New Look settings

Requested by Diffusion for

New Look (firmware V4.12)

1.2. Document Review

Reviewer.

Remit

Rob Boardley

Technical Accuracy

Kevin Byrne

Presentation

1.3. Document Status

FINAL

1.4. Document Ownership

Rob Boardley

Design & Development

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 4 of 20

Status: Final issue: 11 ©TB Controls 2011

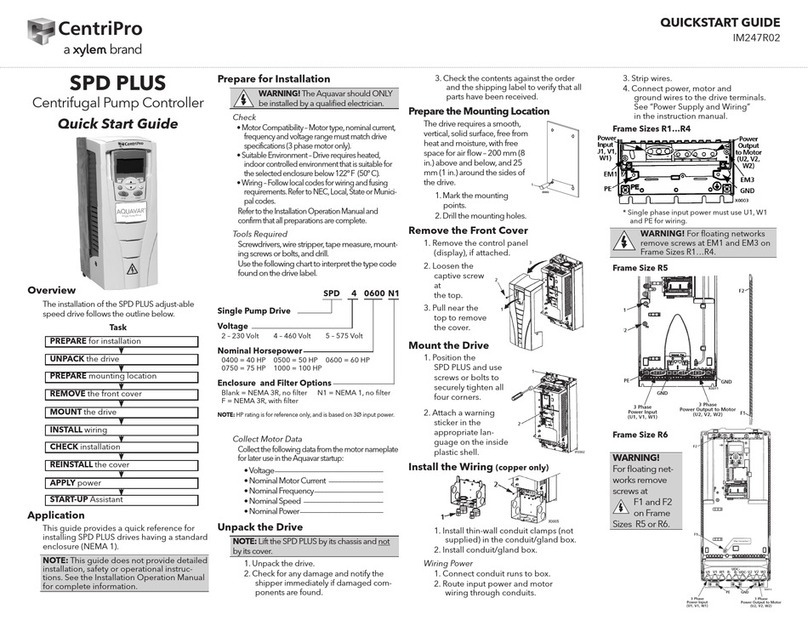

2. TC02 controller

2.1. Design

The TB Controls TC02 controller is designed to be a cost effective multi-purpose digital

control unit fulfilling the requirements for over-door curtain heaters and powerful fan coil

units such as the Ambassador. It will control both electric and water fed units (air and

water side types) or a combination of both.

The control system consists of a control board of 140 mm long by 70 mm wide by 35 mm

deep, mounted in the FCU and user display board of approximately 105 mm long by 60

mm wide. It is supplied on a standard 146 mm long by 81 mm wide electrical faceplate.

The user display board has an alphanumeric LCD display. It is connected to the controller

with a twin twisted pair cable.

2.2. Features

The curtain heater controller unit has the following features…

Powered from 12-24 volts AC or DC.

Four fan speed settings with silent fan speed switching. Controlled by four

snubberless triacs with heat sinks for increased current handling.

Direct PID control of valve actuators for water fed systems.

PID control of electric heating elements, with an external solid-state relay.

Selectable off-coil setpoint from the values of up to 70 C.

Master/slave control of fan speeds achieved with twin twisted pair between

controllers.

High precision digital temperature sensors, no cable length restrictions and

calibration unnecessary.

ELV Stat input to reduce or turn off heating when room temperature setpoint

exceeded in curtain heater systems.

On/off input for time clock or BMS control.

BMS control of fan speeds.

On/off input for occupancy sensor control. Settable run on time, default 15

minutes.

Fault indication input for overheat trip display.

Fault indicator output for BMS or panel display.

Figure 1 - LCD

Figure 2- TC02 Controller

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 5 of 20

Status: Final issue: 11 ©TB Controls 2011

Summer/Winter setting.

Return air temperature measurement in place of room stat for greater flexibility

Outside air temperature for fully automatic control.

RS485 network communications, MODBUS open protocol. Full BMS monitoring

and control.

Additional features (for room FCU control available, not supplied with curtain

heater controller)…

Silent PID control of two 24VAC heating and cooling actuators, or dampers,

controlled by four snubberless triacs. Selectable room temperature setpoint from

values of 17, 19, 21, 23 and 25 C.

Lamp output for over-door welcome or security. The two spare triac outputs in an

airside system can be used to drive 230 VAC lamps as in the Ambassador unit.

On board real time clock for timed operation and event log time stamping.

Log of the last 500 system events.

Fan speed monitoring input to detect fan motor failure.

DPS filter dirty input.

RS485 network communications.

LCD user display features for curtain heater…

Simple twin twisted pair connection to controller unit.

2 line 16-character LCD backlit display.

Three buttons for control, mode, plus and minus buttons.

Four fan speeds and off.

Summer Winter or Automatic mode.

Display of off coil temperature.

Engineering settings such as sensor offset and setpoint step.

2.3. Connection terminals

To avoid incorrect wiring, terminals that can be connected to AC 230 V (Fan speed and

Lighting) are physically separate from the other terminals.

2.4. Disposal

The controller contains electrical and electronic components and must not be disposed of

as domestic waste.

Current local legislation must be observed.

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 6 of 20

Status: Final issue: 11 ©TB Controls 2011

2.5. Engineering

2.5.1. Supply cables

The TC02 controller requires a 12 to 24 VAC supply. The valve actuators may be rated

between 24 VAC and 230 VAC. The controller does not supply actuators. Sizing and fuse

protection of 230 VAC supply cables depends on the total load and on local regulations.

2.5.2. Mounting the unit (if supplied without fan deck)

The controllers may be mounted in any orientation using metal Stand-offs, to suit the four

fixing holes, the minimum stand-off height is 5mm, 3 mm fixing screws are recommended.

Push over type plastic stand-offs may be used if it eases production.

The following points should be noted;

The controller should be freely accessible after mounting.

Adequate air circulation to dissipate heat generated during operation.

Easy access for service personnel.

Local installation regulations must be observed.

3. Wall control plate unit

The control plate for the TC02 is a second fix item. The following points should be noted;

back box to receive the plate must be a double unit and a minimum of 47 mm deep

Do not fix when plaster is wet

Use connectors supplied to terminate the unit

Follow the connection instructions with care

Use sleeving on the drain wire

Use shrink-wrap on the cable end to insulate foil

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 7 of 20

Status: Final issue: 11 ©TB Controls 2011

3.1. TC02 Connections

Connecting the field devices

Caution

There is no protection against accidental connection of 230 VAC to 24 VAC and data

connections.

Care must be taken to ensure connections for 230 VAC are made correctly and in

accordance with local regulations

Water control

option DIP switch

4 = ON

24VAC power

230VAC fan

control

LON data loop for

LCDs and slave TC02s

27

26

25

24

23

22

21

20

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

33

32

31

45

44

43

42

41

MODBUS RS485 network

RS485 red wire (A)

RS485 black wire (B)

RS485 shield in

RS485 shield out

RS485 jumper on shield out

24VAC feed

Actuator drive open

24VAC feed

24VAC common (0v)

Earth

Actuator drive closed

Fan speed common output

Fan speed 4 tap

Fan speed 3 tap

Fan speed 2 tap

Fan speed 1 tap

BMS / Time switch input

ground ref.

Return air sensor (data)

Sensor ground ref.

Overheat fault input

ground ref.

Occupancy PIR sensor or

BMS summer/winter input

ground ref.

BMS 0-10v ground ref.

BMS 0-10v fan speed input

LON +12v output (red wire)

LON L1 data (white wire)

LON L2 data (green wire)

LON 0v ground (black wire)

LON earth (shield)

Occupancy PIR +12v feed

Outside air sensor (data)

ground ref.

Heating SSR +ve

Heating SSR output -ve

Fault output ground ref.

Fault output (switch to gnd)

Off coil sensor (data)

Sensor ground ref.

40

39

38

37

36

35

34

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 8 of 20

Status: Final issue: 11 ©TB Controls 2011

4. Master / Slave

Where several controllers are operating in the same space, they must be synchronized via

the Master / Slave interface.

Up to 8 slaves may be used (further options available)

The operating parameters are passed via the data bus (LON)

Up to 8 control plates may be used.

Single Belden 8723 cable connects slaves and control plates

To set the unit to slave mode;

Switch Dipswitch 8 to ON

Master Unit will require Dipswitches 9 and 10 switched to ON and 8 to OFF

Dip Switch 9 and 10 are the Terminating resistors for the LON network on the

Belden 8723 cable

The Slave Address on the LON is set using Dip switches 1, 2, and 3 giving 8

combinations addresses 0 to 7. The switches are set using Binary, (see notes on

setting switches). Each slave unit in a group must have a different address.

The Slave will follow all settings of the Master

Each slave will report its faults to the Control Plate.

Any unit may be set to a Master to suit site conditions; this must be the only Master

unit of the group.

Return air and Off coil temperature sensors are local to each unit

Outside air temperature sensor is connected to the Master this input controls all

slave units.

BMS time switch control signal must be wired to the Master this input controls all

slave units.

4.1. Phased Start Sequence

The TC02 is designed for soft start, this avoids large numbers of fan decks switching on

simultaneously causing electrical overload or tripping of circuit breakers due to very large

starting currents, each unit has a delay of „x‟ mS. on power up.

The phased start is set using the Dipswitches 1 to 7. The switches are set using Binary,

(see notes on setting switches)

4.2. Controller Start sequence

The TC02 has a green LED on board. This LED will flash three times on power up and

afterwards will flash for 20mS every second. Three flashes, flash, flash, flash, indicates the

unit has self tested and is OK. Regular flashing indicates unit is running OK

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 9 of 20

Status: Final issue: 11 ©TB Controls 2011

4.3. Error Messages

4.3.3. Master

There are a number of possible error or operation messages; these will be displayed on

the LCD screen.

BMS or Time switch control when connected to the controller it will signal the controller

to turn off. The controller will shut down the heating then work through the fan run on

period, and then stop. The display will read; “BMS/Time Switch Unit OFF”

Overheat Stat A temperature fault will be displayed when the cut out switch signals the

controller. The display will read; “Over Temperature Trip”

Occupancy sensing enables the controller for a predetermined period for example 10

minutes; if no further signal is received in this period then the unit will shut down and await

a further occupancy signal. The display will read; “Unoccupied Unit OFF”

Where the Off Coil Temperature sensor fails the heating will be turned off. The display

will read; “Off Coil Sensor Fault”

Where the Return Air Temperature sensor fails the heating will still be functional. The

display will read; “Return Air Sensor Fault”

Where the Outside Air Temperature sensor fails the display will read; “Outside Air

Sensor Fault”

4.3.4. Slave Messages

Slave unit error messages will be displayed on the LCD unit with the Slave unit number.

BMS or Time Switch: “BMS/Time Switch....Slave X OFF”

Overheat stat: “Over Temperature.....Trip Slave X”

Occupancy sensor: “Unoccupied .......Slave X OFF”

Off Coil Sensor fault: “Off Coil Sensor.... Fault Slave X”

Return Air Sensor fault: “Ret Air Sensor.... Fault Slave X”

Slave comms connection fault: “Slave X Comms Fault”

4.4. LCD Modes

There are three modes in the LCD display unit these are outlined below.

4.4.5. LCD Set up Mode

To enter set up mode press and hold all three buttons for more than ten seconds, the unit

will display “LCD set up mode” there are two options; “module address x” and “backlight x”

The module address is the unique identity given to the unit to enable the Master unit to

determine with which unit data is exchanged.

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 10 of 20

Status: Final issue: 11 ©TB Controls 2011

To change address use outer buttons to increase or decrease the address number, a

maximum of 8 can be set in one group.

The LCD Backlight is the illumination property of the display; this allows the display to be

read in poor light conditions. To alter the Back light „on period‟ use the outer buttons, the

period can be from 1 to 25 seconds „on‟ or „off‟

4.4.6. Engineering Mode

To enter engineering mode press and hold „+‟ and „-„ buttons for more than ten seconds.

The „mode‟ label will appear with stars “*mode*”.

Pressing the mode button cycles through the readings and settings shown in quotes

below. Some settings are displayed or omitted according to which sensors are fitted.

Setpoints and outside temperature “OS xx C RS xx C RT xx C OT xx C”. Where OS

is Off coil Setpoint, RS is Return air Setpoint, RT is Return air Temperature, OT is Outside

Temperature. This temperature display will remain until the mode button is pressed, or the

- button is pressed, in which case the Temperature and duty cycle are displayed. Pressing

the mode button from this display will return to original display.

Summer Off Coil Setpoint is displayed as “Summer OC xx C”. Range 10 to 70 C.

Default 18 C

Winter Off Coil Setpoint is displayed as “Winter OC xx C”. Range 10 to 70 C. Default

40 C

Summer Return Air Setpoint / Trip is displayed as “Summer Ret xx C” Range -40 to 40

C. Default 16 C. When the temperature reaches this value the heater turns off or is

setback by the „Return Air Setback‟ value. A negative value reverses the action, eg -10

would turn off or setback the heating at +10C or below. The minus is ignored for

calculations. In New Look mode (DIP 5 on) default is 18C.

Winter Return Air Setpoint / Trip is displayed as “Winter Ret xx C” Range -40 to 40 C.

Default 25 C. When the temperature reaches this value the heater turns off or is setback

by the „Return Air Setback‟ value. A negative value reverses the action, eg -10 would turn

off or setback the heating at +10C or below. The minus is ignored for calculations. In New

Look mode (DIP 5 on) default is 18C.

Summer Outside Air Setpoint is displayed as “Summer Out xx C” Range -40 to 40 C.

Default 20 C. In New Look mode (DIP 5 on) default is 10C.

Winter Outside Air Setpoint is displayed as “Winter Out xx C” Range -40 to 40 C.

Default 15 C. In New Look mode (DIP 5 on) default is 0C.

Stat Offset or Return Air setback is the temperature setting in degrees, which the

controller will use to adjust the output when it receives a signal from the Thermostat (Stat).

Or return air sensor. “Ret Setback xx C” change steps using the +/- buttons. 0 C to 30C.

0C is off.

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 11 of 20

Status: Final issue: 11 ©TB Controls 2011

Occupancy is detected by the occupancy sensor, this signal will be used by the controller

to enable the fan and controls, the period for which it will work after detecting an occupant

is set using the Occupancy Timer; “Occupncy Tmr xxm” change steps using the +/-

buttons. 5 to 60 minutes in 5-minute steps.

PIR Contact normally open or normally closed setting facility ”PIR Contact – NC or NO”

Default N/O, closing to indicate occupancy

Fan Run On timer is the time for which the controller will allow the fan to run after the unit

has been switched off; this allows dissipation of residual heat on the heat exchanger. “Fan

Runon xxm” change steps using the +/- buttons. 0 to 15 minutes in 1-minute steps.

(Default 3 minutes)

BMS Contact, normally open or normally closed setting facility. ”BMS Contact – NC or

NO” Default N/O, closing to disable unit.

BMS Summer/Winter input, if enabled (ENA) the PIR contact input becomes a

summer/winter mode switch the "BMS S/W ip –ENA or DIS" Default DIS (disabled). The

input is open for Summer mode and closed for Winter mode.

BMS 0-10v fan input, if enabled (ENA) the fan speed is taken from a 0-10v signal on the

fan speed analogue input (see 3.1). The fan speeds are set as follows…

Fan Off: 0 volts (0v-2v)

Fan speed 1: 3 volts (2v-4v)

Fan speed 2: 5 volts (4v-6v)

Fan speed 3: 7 volts (6v-8v)

Fan speed 4: 9 volts (8v-10v)

P I D terms

“P Factor x” change steps using the +/- buttons. Change the Proportional value as

instructed by factory. (Default 75 for electric and 30 for water)

“I Factor x” change steps using the +/- buttons. Change the Integral value as

instructed by factory. (Default 9 for electric and 4 for water)

“D Factor x” change steps using the +/- buttons. Change the Differential value to suit.

(Default 10 for electric and 0 for water)

PWM Period adjustment, “PWM P fast or slow”. Default slow 12.75 seconds period.

Actuator travel time, hot water valve actuator travel time in seconds (default 150) used

when DIP switch 4 is on, water heating system.

Lock the user interface, “Lock UI –YES or NO”, once set to yes the user cannot change

any settings and pressing the buttons has no effect. The display shows Off coil

temperature (C), heater duty (0-100%), fan speed (Off,1,2,3,4) and mode

(Summer/Winter/Auto). The summer/winter setting and fan speed cannot be changed

without entering engineer mode (see 4.4.6).

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 12 of 20

Status: Final issue: 11 ©TB Controls 2011

Factory Reset returns controller to factory defaults pressing the + button will restore the

factory default settings. Pressing the –button restores the last power up settings. Displays

“*Factory Reset*”

Factory reset will invoke a system temperature sensor recount, and will alter the operating

parameters accordingly, ie if an outside air sensor is fitted or omitted.

Firmware Version, “Firmware V4.13”, This menu is only available on firmware V4.12 and

above. Displays the TC02 software version number.

MODBUS network address, “MODBUS add:1”, This menu appears only if the MODBUS

protocol option has been purchased. Sets the MODBUS open protocol RS485 network

address. This must be different for each unit on the network, range is 1 to 247.

MODBUS network baud rate, “MOD baud:19200”, This menu is only available on

firmware V4.13 and above. Sets the MODBUS open protocol RS485 network baud rate.

Default is 19200 baud, available baud rates are 2400, 4800, 9600, 19200, 38400, 57600,

115200.

Engineer mode exits automatically after 30 seconds of inactivity, ie no buttons pressed.

4.4.7. User Mode

User display mode default display when powered up will be Fan Status, it will read „Fan

Off‟ or „Fan Speed x‟ on the top line and Mode on the bottom. Change Fan speed using

the +/- buttons. If the user interface has been disabled the display is different see Lock the

user interface above.

The options are four speeds and Off. The unit will not turn the fan off if the heating has

been on, this allows for cooling of the element. Run on time may vary ask engineering for

the set time (normally 3 minutes).

The Summer / Winter mode is selected by pressing the Mode button; the unit will display

the status of the Heater “ Summer” or “Winter”. If an Outside temperature sensor is fitted

then selection is not possible and the display will read “Automatic”

The Duty Cycle display is selected by pressing the Mode button, the top line will display

“Tp xxC Dty xx%” this gives shows the Temperature at the grill „Tp‟ and the energy use as

a percentage of the total available from the heater. These values will change relative to the

temperature and the performance of the heater. “TP xxC Dty xx%” Temperature and

Power Duty cycle.

4.5. Final checks before Power UP

Check all connections

Fan

Solid State Relay / Actuator

Sensor / Sensors

BMS signals where present

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 13 of 20

Status: Final issue: 11 ©TB Controls 2011

Trip for overheat sensor

Room stat where present

Occupancy sensor where present / if not insert loop!

LCD Plate if used

Communications cable LON

Communications cable Loop

Mains transformer

DIP switch 4 ON for water heating actuator control OFF for electric heating

DIP switch 8 OFF, 9 and 10 ON for a Master unit

DIP switch 8 ON, 9 and 10 OFF for a slave unit

Setting the unit up with the network address and the Slave address is covered in the

following sections

5. Control Operation sequences

The unit may be fitted with up to three sensors combinations of which will result in varied

operation sequences.

5.1.8. Sequence 1

Off coil sensor only fitted will result in the temperature of the air leaving the supply grill

being controlled to the given set point for Summer or Winter modes

5.1.9. Sequence 2

Off coil and Return Air sensors only fitted will result in the temperature of the air leaving

the supply grill being controlled to the given set point for Summer or Winter modes,

however when the return air temperature reaches the appropriate setpoint trip the Off coil

temperature setpoint will be adjusted according to the setback parameter.

5.1.10. Sequence 3

Off coil, Return Air and Outside Air sensors fitted will result in the temperature of the air

leaving the supply grill being controlled to the given set point, automatically controlled

between the Summer and Winter setpoints, (see 5.1.12,13) however when the return air

temperature reaches the appropriate setpoint trip the Off coil temperature setpoint will be

adjusted according to the setback parameter. The return air trip setpoint is varied between

the Summer and Winter setpoints as shown in 5.1.12,13

5.1.11. Sequence 4

Off coil, Return Air and Outside Air sensors fitted will result in the temperature of the air

leaving the supply grill being controlled to the given set point, automatically controlled

between the Summer and Winter setpoints.

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 14 of 20

Status: Final issue: 11 ©TB Controls 2011

Default Set-points

Setpoints

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Outside temperature C

temperature C

off coil setpoint return air trip

5.1.12. Graph settings

summer

winter

off-coil

18

40

return air

16

25

outside

20

15

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 15 of 20

Status: Final issue: 11 ©TB Controls 2011

New Look Mode Set-points (DIP 5 on)

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

temperature C

Outside temperature C

Setpoints

off coil setpoint

return air trip

5.1.13. Graph settings

summer

winter

off-coil

18

40

return air

18

18

outside

10

0

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 16 of 20

Status: Final issue: 11 ©TB Controls 2011

6. TC02 dip-switch settings

12345678910

ON

MINI-FCU Dipswitch setting

Switch ON position

Switch Number

Table of Switches 1 to 8

Sw1 = 1, Sw2 = 2, Sw3 = 4, Sw4 = 8, Sw5 = 16

Sw6 = 32, Sw7 = 64, Sw8 = 128.

Using various combinations of switches to 'on' the requires address

up to a decimal value of 255 may be set see next illustration Dipswitch Settings

Switch ON position

Switch Number

12345678910

ON

Switches 9 and 10

Master Setting

both on

The above shows a Master

Controller setting with a

network address of 8

Master Dipswitch setting

Switch 8

Slave Setting

on

The above shows a Slave

Controller setting with a

network address of 4

Slave Dipswitch setting

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 17 of 20

Status: Final issue: 11 ©TB Controls 2011

Dipswitch settings from 0 to 17

D 8 H 8

12345678910

ON

12345678910

ON

D 0 H 0 D 2 H 1 D 2 H 2

D 3 H 3 D 4 H 4 D 5 H 5

D 6 H 6

D 9 H 9

D 12 H C

D 15 H F

D 7 H 7

D 10 H A

D 13 H D

D 16 H 10

D 8 H 8

D 11 H B

D 14 H E

D 17 H 11

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

12345678910

ON

For exampleNumber 4 switch has a

value of 8 in decimal. Therefore Unit

address 8 would be set as shown

Each switch has a Decimal and a

Hexadecimal value.

These values are shown as (D xx.) and

(Hxx)

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 18 of 20

Status: Final issue: 11 ©TB Controls 2011

7. Outside air temperature sensor

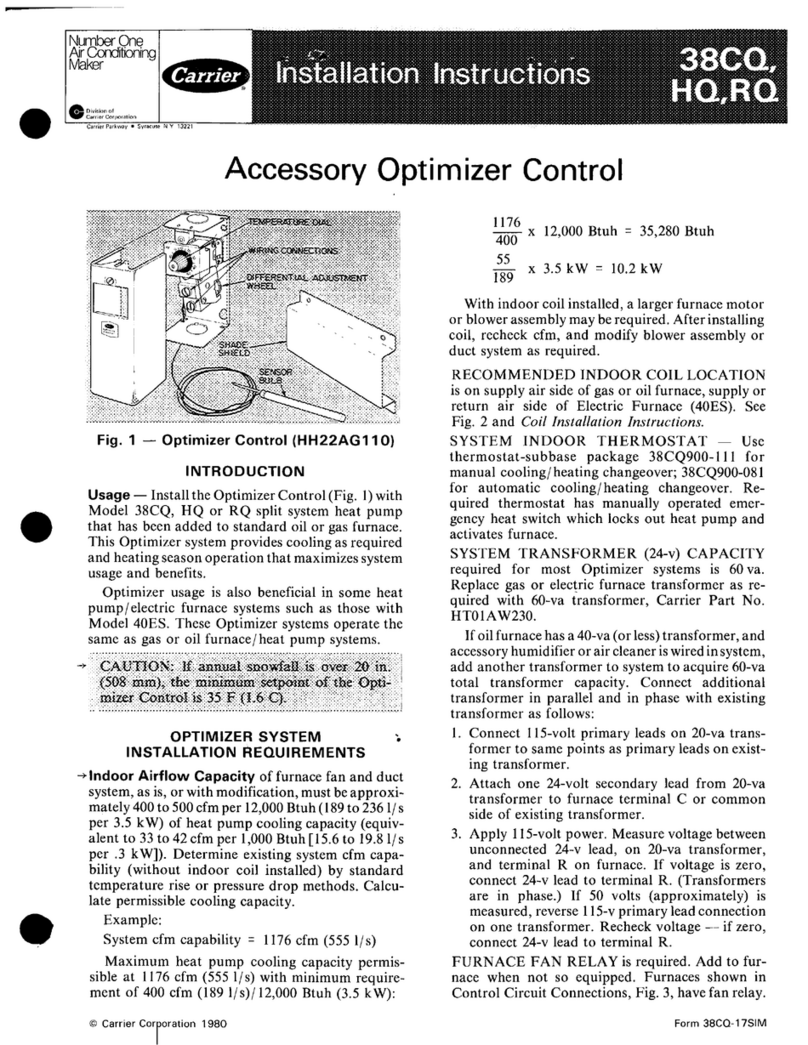

7.1. Fitting the sensor

For best results locate the sensor on the north side of the structure high under an eave. This

prevents incorrect readings due to direct sunlight and damage from the elements.

Mount vertically with the open end of the tube facing down to prevent the accumulation of dirt

or water.

North

Installation example

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 19 of 20

Status: Final issue: 11 ©TB Controls 2011

8. MODBUS protocol and unit data

The hardware interface is half duplex RS485 (single twisted pair) and we normally use a ¼ unit load driver chip

with +/-60 volt line protection (LT1785CN8).

There are four screw terminal connections on the board these are RS485 B, RS485 A, Shield In, and Shield

Out. Either or both Shield In and Shield Out can be connected to local ground via a jumper link. Normally only

the Shield Out is linked to local ground.

The open protocol is MODBUS RTU at 19200 baud (default), no parity, 8 data bits, and 1 stop bit. Each unit has

a network address ID from 1 to 247 (8bit) settable from the LCD interface.

The following MODBUS function codes are implemented…

Read Holding Registers (3)

Write Single Register (6)

The following data is available as 16bit signed integers…

Tag no.

0. Off coil temperature: in ¼ ºC

1. Return air temperature: in ¼ ºC (if fitted)

2. Outside air temperature: in ¼ ºC (if fitted)

3. Electric heater element duty: in % or hot water valve position in % open (0-100)

4. Fan speed: 0-4 (0=Off, 4=Maximum) (R/W)

5. Summer/Winter mode: 0=Summer, 1=Winter (R/W), 2=automatic (Read only)

6. Summer Off Coil Set-point: range 10 to 40ºC. Default 18ºC (R/W)

7. Winter Off Coil Set-point: range 40 to 70ºC. Default 40ºC (R/W)

8. Summer Return Air Set-point/Trip: range 10 to 40ºC. Default 16ºC (R/W)

9. Winter Return Air Set-point/Trip: range 10 to 40ºC. Default 25ºC (R/W)

10. Summer Outside Air Set-point: range 5 to 40ºC. Default 20ºC (R/W)

11. Winter Outside Air Set-point: range 5 to 40ºC. Default 15ºC (R/W)

12. Stat Offset or Return Air setback: 0ºC to 30ºC. 0ºC is off (R/W)

13. Occupancy Timer: time to keep the unit running after a occupancy signal is detected, 5 to 60 minutes

in 1-minute steps (R/W)

14. Fan Run On time: 0 to 15 minutes in 1-minute steps (Default 3 minutes) (R/W)

15-23 Error/Status bits readable from the master unit (15 master and 16-23 slave units 0-7)

Bit 0: BMS/Time Switch input active, Unit OFF (Remote disable)

Bit 1: Over Temperature Trip

Bit 2: Off Coil Sensor Fault

Bit 3: Unoccupied Unit OFF (PIR sensor inactive for Occupancy timer period)

Bit 4: Return Air Sensor Fault

Bit 5: Outside Air Sensor Fault (master only, tag 15 only)

Bit 6: Return air sensor setback active or Stat input trip

Bit 7: spare

Bit 8: Slave comms fault (16-23 only, occurs only when a slave has been connected)

Bit 9: Slave connected (16-23 only)

A master unit uses bits 8 and 9 in tag registers 16-23 to indicate if a salve is connected or has become

disconnected. Slave units can also be addresses on the MODBUS network with tag registers 0-15 available as

read only data and tag 15 having bits 0-4 and 6 available.

Tag registers marked (R/W) are Read and Write.

A temperature value of 396, equivalent to 99ºC indicates a sensor not fitted or sensor fault, the appropriate bit

will also bet set in the status register (tags 15-23) if this is a fault condition.

Operations & Maintenance Manual January 2002

Doc: TC02 O&M Page 20 of 20

Status: Final issue: 11 ©TB Controls 2011

9. Fault finding

Fault Indication: Check:

module add 0 The LCD has power but no data comms. Check wiring between LCD

wall plate and unit mounted control board. Refer to wiring diagrams.

Correct cabling has been used “Beldon

8723”.

No power @ LCD plate Wiring between LCD wall plate and unit mounted control board. Refer to

wiring diagrams.

Check main power supply into unit.

Check transformer fuse (2A) on 24VAC supply.

Check controller has 24VAC supply and 12VDC from controller.

Check remote LCD wall plate has been earthed.

Sensors Check connections @ unit mounted control board, also making sure

colours are correct to wiring diagram.

Overheat Cut-out Check fans are running. Check unit air inlet & discharge are not

blocked.

BMS Connections Should remote LCD plate read BMS/Time switch unit off, this may either

be the main BMS system holding the units off or the N/O or N/C may

need to be altered. The contacts can be altered by accessing the

engineering mode. Should units be master/slaved it will also inform

you of this.

PIR Contact Should the LCD plate read “unoccupied unit off” the PIR contact may

need to be altered, which can be accessed in the engineering mode or

the PIR sensor may not have been activated.

Slave X Comms Fault Should the LCD plate read “Slave XComms Fault” The Belden cable

between master and slave units has become damaged, disconnected or

shorted.

MODBUS network Check polarity of red and black wires at BMS connection, they may

need to be reversed for correct operation. Make sure all network cables

lengths have the shield wire connected to local earth at one end (jumper

link on TC02). An unconnected shielded cable is worse than an

unshielded cable!

Check network address with BMS system. Each TC02 controller that is

connected to the network must have a different MODBUS address

(default is 1).

Check baud rate, changeable from firmware V4.13 and above.

Table of contents

Popular Controllers manuals by other brands

CentriPro

CentriPro Aquavar SPD PLUS quick start guide

Exodraft

Exodraft EBC10v2 instructions

eltherm

eltherm 0620001 operating manual

TeeJet

TeeJet UniPilot Pro installation manual

rotork

rotork IQ3 Range Instructions for Safe Use, Installation, Basic Setup and Maintenance

Vacon

Vacon 20 CP Installation, Technical and Maintenance Manual