TDI TurboTwin T30-M User manual

AN09-484 From Tech Development

6800 Poe Ave. Dayton OH 45414

Tel: (937) 898-9600 Fax: (937) 898-8431

Website: www.tdi-turbotwin.com

Publication: T3-790, Rev. 2

Issued: January 9, 2013

INSTALLATION AND OPERATING

MANUAL

TURBOTWIN™Model: T30-M

Auxiliary Lube Pump Air Motors

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 1

TABLE OFCONTENTS

SECTION SUBJECT PAGE

1.0 General Information …. ………………………………………………………. 2

1.1 Description & Advantages ... ………………………………………………… 2

1.2 Basic Operation ...……………………………………………………………… 2

1.3 Product Identification ...………………………………………………………. 3

1.4 Motor Performance & Output ….……………………………………………... 3

2.0 Installing the Motor …………………………………………………………… 5

2.1 Proper Installation and Setup ….…………………………………………….. 5

2.2 Supply & Exhaust Line Installation ……..…………………………………… 5

2.3 Motor Controls ………………………………………………………………… 6

2.4 Inlet Pressure Check Port. ……………………………………………………. 6

2.5 Matching Motor Output to Load ………………………………………………. 7

2.6 Adjusting Motor Output Speed ...…………………………………………….8

3.0 Motor Operation ……………………………………………………………….. 7

4.0 Trouble Shooting Guide ………………………………………………………. 8

5.0 TURBOTWIN Warranty ………………………………………………………….. 9

FIGURES ILLUSTRATIONS PAGE

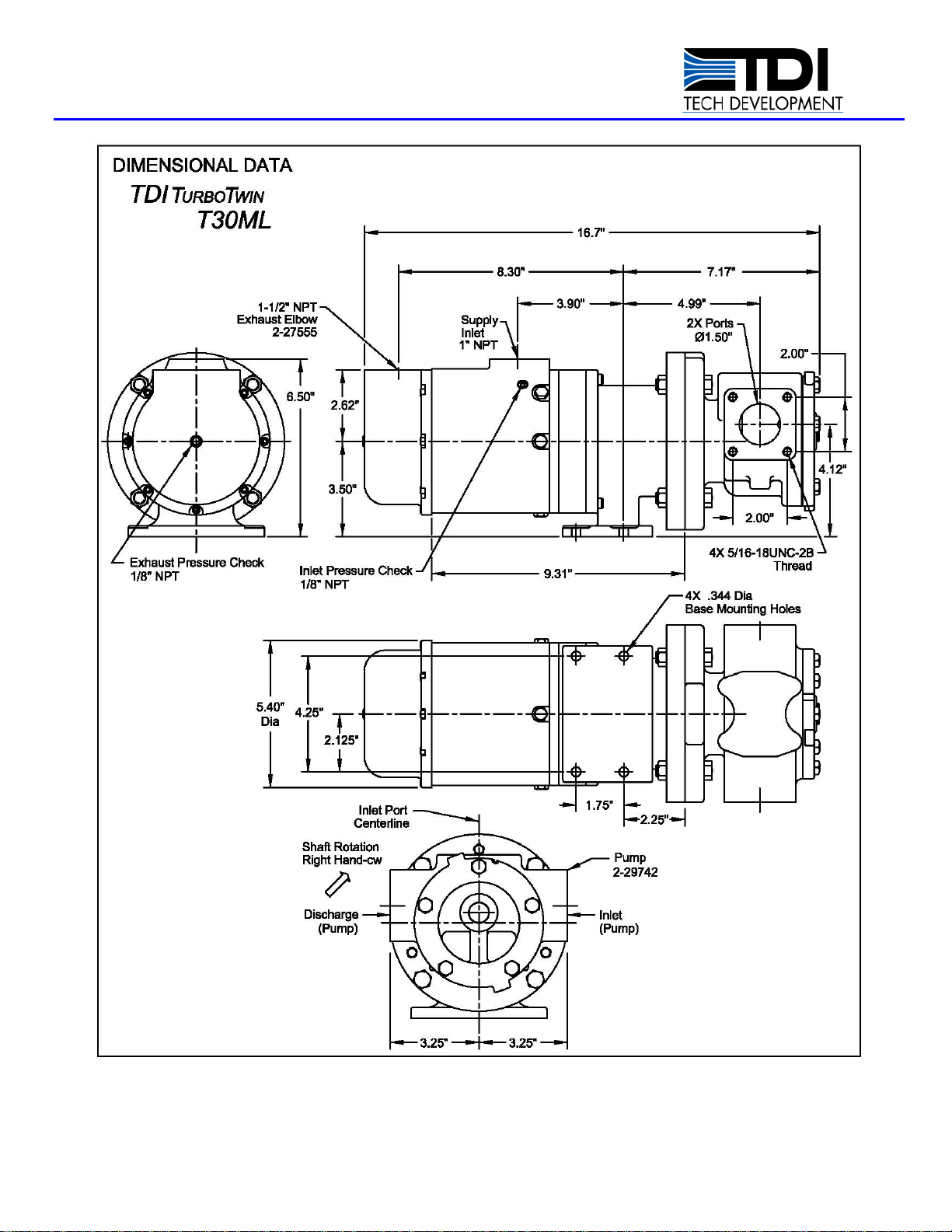

1 T30-M Lube Pump Motor ........................................................................... 10

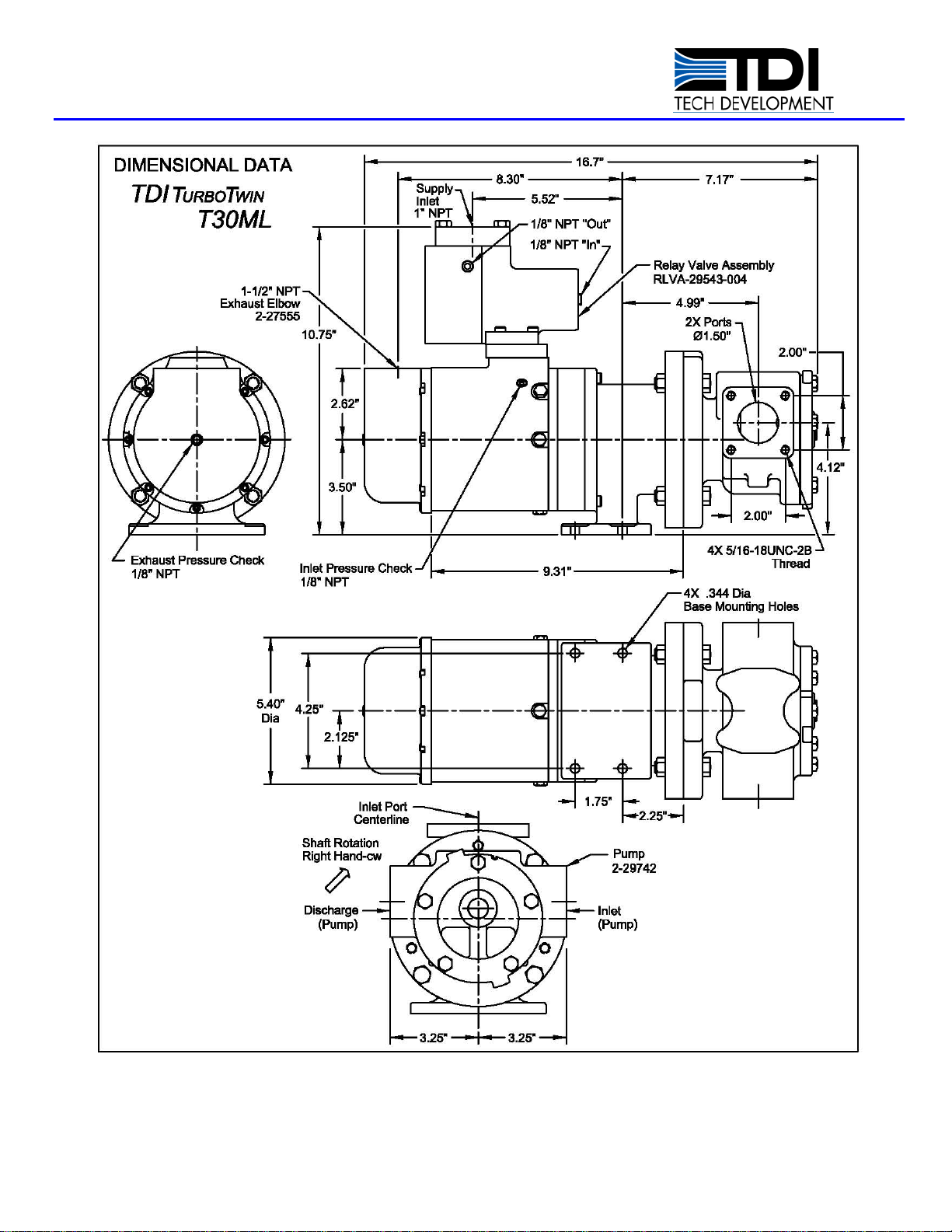

2 T30-M Lube Pump Motor w/Integral Relay Valve (Pneumatic) …………… 11

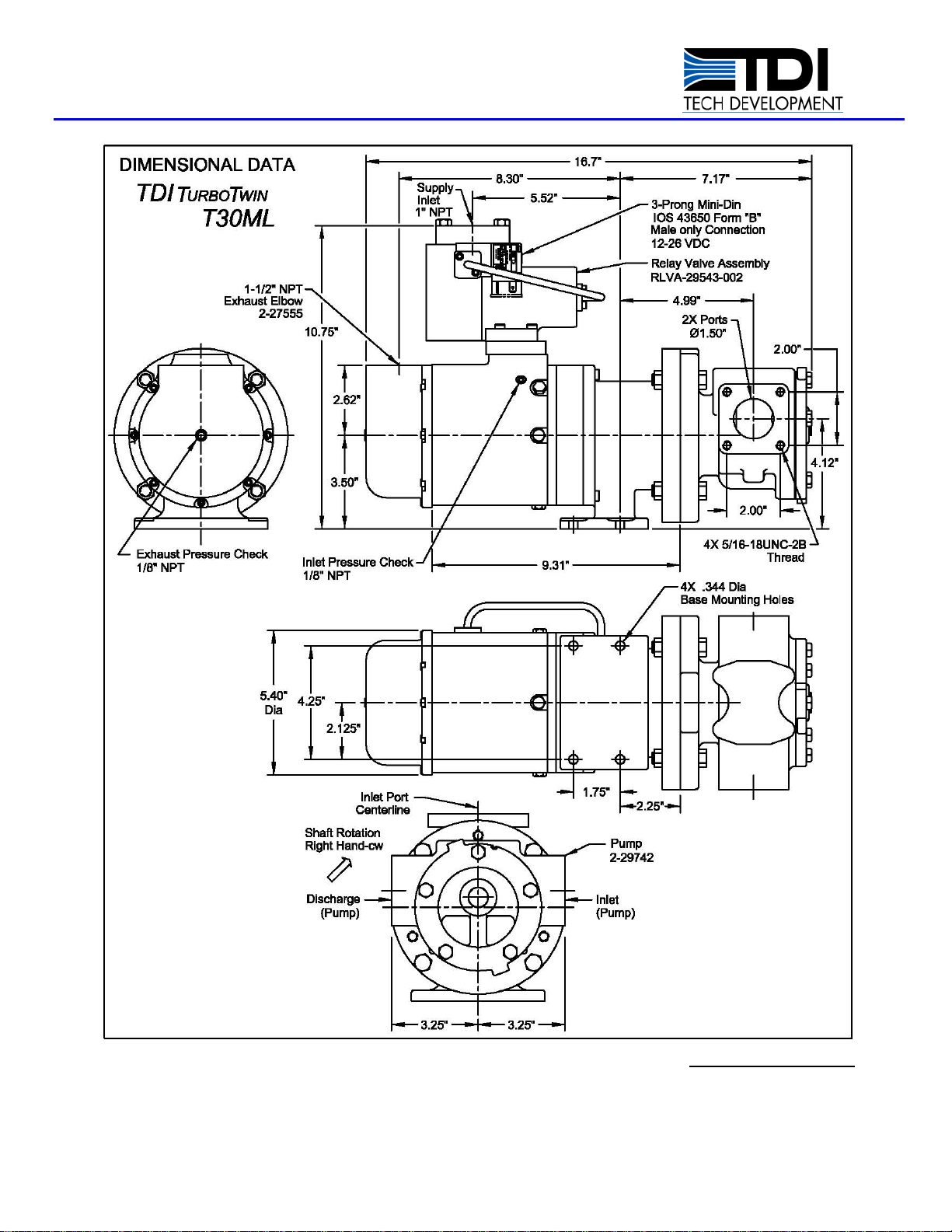

3 T30-M Lube Pump Motor w/Integral Relay Valve (Solenoid) ………………12

4 T30-M Lube Pump Motor w/Modified NEMA 56C Mounting Flange ………13

5 T30-M Lube Pump Motor w/ NEMA 56C Mounting Flange ………………...14

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 2 Publication: T3-790, Rev. 2

Issued January 9, 2013

1.0 GENERAL INFORMATION

This manual contains Instructions for installation,

operation and maintenance of TDI TURBOTWIN™

Model T30-M Air Motors used as auxiliary drives for

Pre & Post Lube Oil Pumps. These are supplied by

OEMs and can also be obtained in the aftermarket as

motor upgrades.

Review this manual before installing or operating T30-

M Air Motors. For Questions, ContactyourAuthorized

TDI Distributor, OEM or TDI directly.

WARNINGS, CAUTIONS AND NOTES

Certain types of information are highlighted in this

manual for your attention:

WARNINGS: - used wherein NON-

COMPLIANCE will likely result in injury to

personnel or damage to the equipment.

CAUTIONS: - used where there is possibility

of damage to the equipment.

NOTES/IMPORTANT: - used to cite special

information for “optimum” use & care.

1.1 DESCRIPTION & ADVANTAGES

T30-M Air Motors are similar to the design used in T30

AirStarters. T30-M featuresvariousinterfacesallowing

the motors to be fitted with couplings or directly to

different model mechanical (oil) pumps. T30-M Air

Motors are superior to other types of drive motors in:

oDurability- Very tolerant of contamination

(liquid or fine solids) in the air/gas supply.

oCost Effectiveness – costly supply air/gas

filtration, drying, lubrication are generally not

required.

oEfficiency - Low air/gas consumption per

unit of power produced.

oCooler Running – greater expansion allows

motor to run cooler on extended duty cycles.

oApplication Flexibility – Variable operation

(output power & RPM). Suitability for use at

much lower air/gas supplies to 10 psig.

oOwnership Cost - Sealed bearings and

gear train require no maintenance or

external lubrication.

oEase of Compliance - Exhaust is cleaner,

since motor produces no (fugitive) oily mist

emissions.

NOTE

THIS MOTOR IS TO BE SERVICED ONLY BY AUTHORIZED TDI

TURBOTWIN™ DISTRIBUTORS, DEALERS, AND REPAIR

CENTERS. DO NOT OPERATE THIS MOTOR UNLESS IT IS

PROPERLY ATTACHED TO AN ENGINE.

oTURBOTWIN T30-M Air Motors are designed

for operation on either compressed air or

natural gas.

oTURBOTWIN T30-M Air Motor materials are

compatible with “sour” natural gas and marine

environments.

oTURBOTWIN T30-M Air Motors are ATEX

certified (where indicated in certain OEM

applications).

oTURBOTWIN Air Motors do NOT require mist-

type or injection-type lubrication of the air/gas

supply. These are not fitted on OEM

applications and should be removed when

upgrading from vane-type air motors.

NOTE

Throughout this manual, the term “air” designates the

Motor drive medium. Unless otherwise stated, "air"

means either compressed air or natural gas. UNITS

WITH INTEGRATED CONTROLS as SUPPLIED BY

TDI, ARE NOT OPERABLE ON NATURAL GAS.

OEM applications, may be supplied with gas

compatible controls, and which meet various

agency requirements as specified.

1.2 BASIC OPERATION

NOTE

T30-M Air Motors are designed for intermittent duty

cycles, NOT continuous duty cycles.

TURBOTWIN T30-M Air Motors are two-stage turbine

driven, gear reduced air motors, with the following key

differencesvs. other typesofmotorscommonly usedin

similar (pump) drive applications:

Unlike electric Motors, power output and

operating speed can vary greatly depending

on the dynamic operating pressures supplied

to the motor inlet and the loads imposed.

(See performance data).

Unlike vane-type (positive displacement) or

electric motors, turbine-type air motors, if

unloaded/under-loaded, will operate at much

higher free-speeds (or over-speed).

Turbine type motors should be properly

selectedand regulatedto operate efficiently at

a required load & speed… rather than over a

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 3

wide range of inlet supply pressures, loads &

speeds.

BASIC OPERATION:

Pressurized air or natural gasenters themotor through

the inlet port. Air/gas expands through the two-stage

turbine and is exhausted to atmosphere. The turbine

drives through a gearbox (speed reduction) to the

output shaft. Indicated motor output (torque, HP,

RPM) is as measured at the shaft end.

Motor rotation is indicated “as viewed” on theshaft end

of the motor; as either RH-CW (clockwise) & LH-CCW

(counter-clockwise).

IMPORTANT

To attain maximum product life, it is important to

properly match the Motor inlet supply pressure,

power output and Motor speed to a specific load.

Regulate (if necessary) Motor supply air

pressure to the lowest possible setting

required to drive the load (pump). No more.

There are two pressure check ports on the

Motors (at inlet & exhaust) that allow users to

check the dynamic inlet supply pressure &

exhaust (back) pressure applied to the Motor.

Motor exhaust back pressure exceeding 10

psig may reduce the life of the Motors’ rear

seals & bearings.

Dynamic pressures aremeasured while Motor

is running at indicated pressure check ports

(inlet & exhaust) on the Motor housings.

1.3PRODUCT IDENTIFICATION

The identification nameplate(s) attached to Motor

housing should indicate the following information:

Model Designation - T30-M

P/Ns (OEM &/or aftermarket p/ns) may be

present on the Motor data tag(s).

Serial Number (date manufactured code)

Maximum Operating (Inlet) Supply Pressure

Direction of Rotation

NOTE

Direction of Rotation - either left hand LH (CCW) or

right hand RH (CW) is designated from output shaft

end of the Motor.

CAUTION

Exceeding the Maximum Operating Pressure rating

shown on Motor nameplate or continued operation

above the Recommended RPM Range (speed)

indicated may result in damage to the Motor or

damage to the driven equipment (pump).

NOTE

Maximum Operating Pressure as indicated on the

nameplate can be verified at the pressure check port

below Motor inlet port, and set dynamically as

described in Section 1.2.

IMPORTANT

DO NOT RUN UNLOADED or UNDERLOADED

Optimum (correct) Operating Supply Pressure is not

necessarily the Motor supply pressure observed in

your application or the Max rated Operating Pressure.

Motor supply pressure optimization, per application,

has been proven to maximize the service life and

reliability of the Motor(s) in most applications.

NOTE

TheProof Pressureshownon thenameplateindicates

the maximum static pressure rating at which Motor

turbine Motor housing(s) will not burst in operation.

1.4MOTOR OUTPUT AND

PERFORMANCE

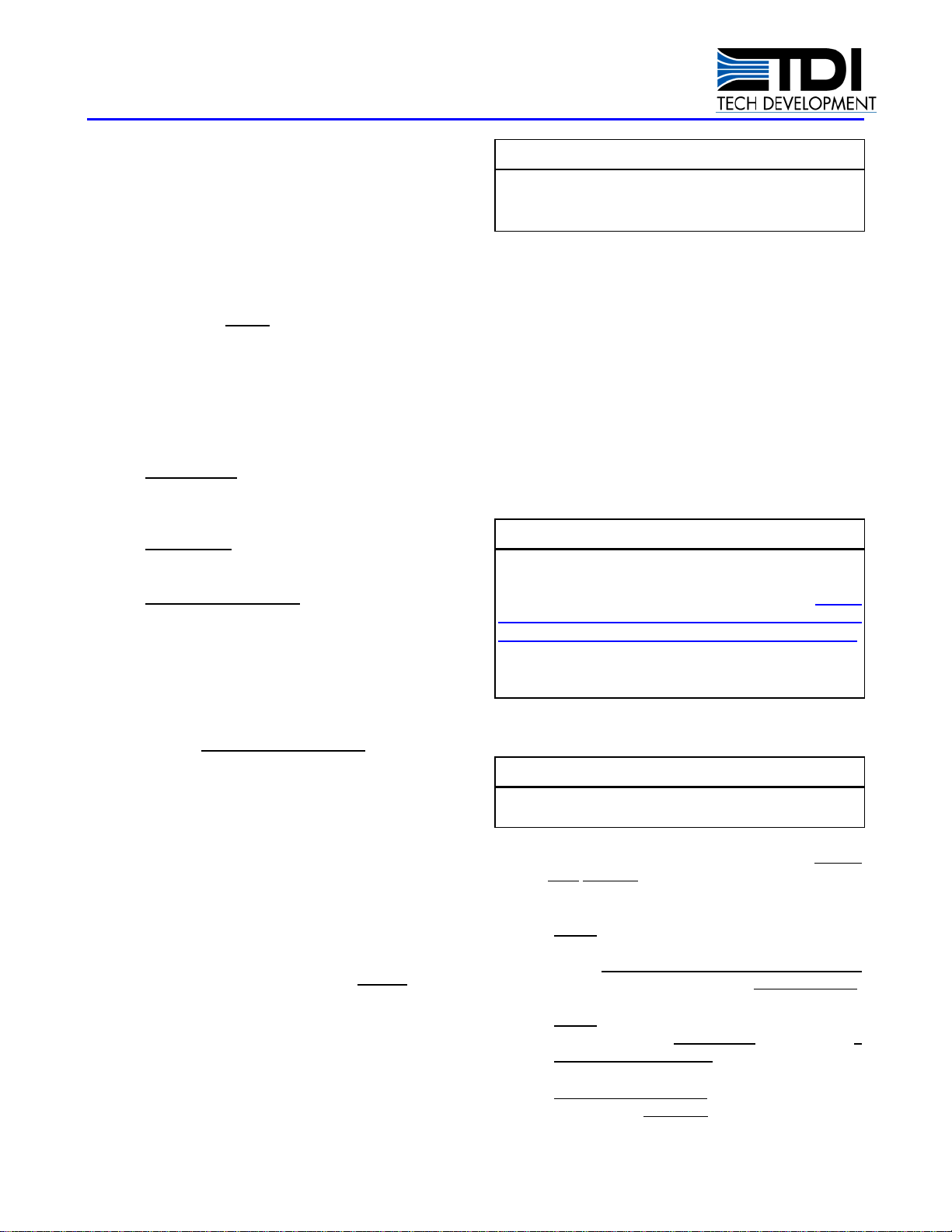

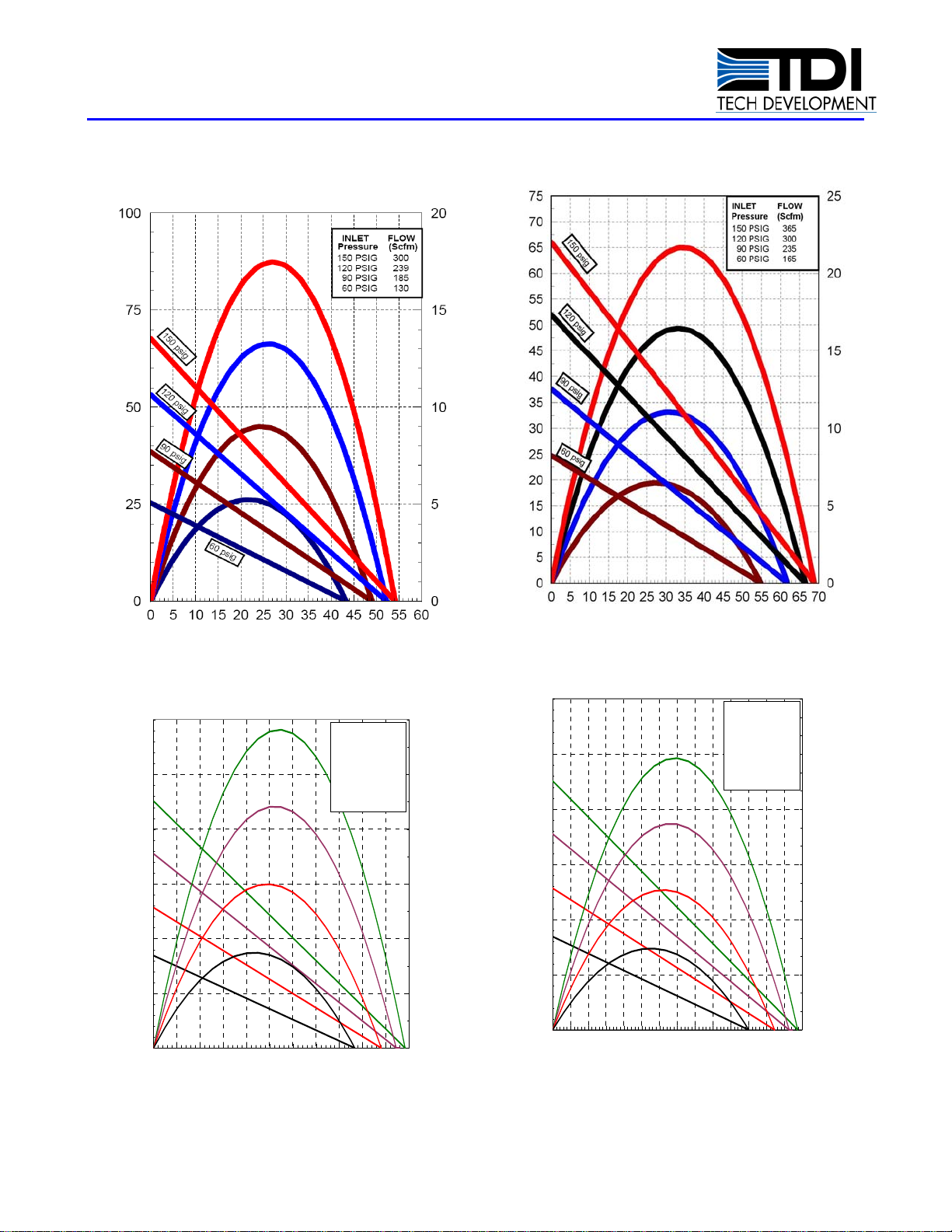

Please refer to Performance Graphs which illustrate:

Motor Output (shaft HP/Torque) over a range

of dynamic supply pressures & at speeds

(RPM) from stall to maximum free speed is

indicated on the performance graphs of each

Motor model.

Air Consumption Rates over a range of

dynamic supply pressures (consumption is

constant at a given dynamic inlet pressure)

and is therefore cited in a separate table on

the Performance Graphs for a Motor model.

Operating speed varies by approximately

+25% when motor is run on methane gas.

Supply pressure should be adjusted

accordingly to prevent excessive Motor/pump

speed (over-speed) on gas.

Performance assumes exhaust is to

atmosphere or where Motor exhaust system

piping minimizes back pressure, to less

than 10 psig.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 4 Publication: T3-790, Rev. 2

Issued January 9, 2013

T303-M Performance Curve

(Compressed Air)

Output Speed (shaft)/100

Output Speed (Shaft)/100

T303-M Performance Curve

(Methane Gas)

Output Speed (shaft)/100

Output Speed (Shaft)/100

Power

(

HP

)

Power

(

HP

)

Tor

q

ue

(

lb.ft

)

0

5

10

15

20

25

30

0 5 10 15 20 25 30 35 40 45 50 55

0.0

1.0

2.0

3.0

4.0

5.0

6.0

Inlet Flow

Pressure SCFM Nm3/Hr

150 Psig 100 170

120 Psig 80 135

90 Psig 62 105

60 Psig 43 74

150 Psig

120 Psig

90 Psig

60 Psig

0

5

10

15

2

0

2

5

3

0

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70

BFT

0.0

1.5

3.0

4.5

6.0

7.5

9.0

150 Psig

120 Psig

90 Psig

60 Psig

Inlet Flow

Pressure SCFM Nm3/Hr

150 Psig 122 207

120 Psig 100 170

90 Psig 78 133

60 Psig 55 94

T301-M Performance Curve

(Methane Gas)

T301-M Performance Curve

(

Compressed Air

)

Torque

(lb.ft)

Torque (lb.ft)

Power

(

HP

)

Tor

q

ue

(

lb.ft

)

Power

(

HP

)

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 5

2.0 INSTALLING THE MOTOR

TDI T30-M Motors feature a turbine type air

Motor that does not require lubrication in the

supply air.

If a vane-type Motor is being replaced by a

TDI turbine type Motor, TDI recommends

removal of in-line or mist type lubricators to

minimize Motor supply flow restriction,

eliminate oily exhaust residue and reduce

maintenance.

2.1 PROPER INSTALLATION & SET-UP

WARNING

Do not operate this Motor unless it is properly

connected to a load (see below).

Motor & oil pump must be installed in a

location that prevents unloaded or under-

loaded operation.

T30-M Lube Pump Motor w/optional exhaust muffler

There are two main causes for the oil pump to become

unloaded or under-loaded:

1) Cavitation - air in the oil suction line to the pump.

This can be prevented by insuring the oil supply

(suction) line to the pump inlet, is below the oil sump

level of the equipment/engine. This is referred to as a

“flooded” location, as it insures oil will always be

present at the pumps suction port. This is VERY

IMPORTANT when up-fitting aTDIpumppackage that

uses the T30-M motor, or installing a T30-M motor

replacement on an existing oil pump. Take steps

necessary to prevent accumulation of excessive air in

the oil system. Utilize check valves and vent lines in

accordance with equipment/engine manufacturer’s

guidelines.

2) Excessive Motor Output

Excessive Motor (Horsepower) results in pump over-

speed. Excessive HP output will drive the mechanical

oil pump to a speed higher than recommended (most

are rated at 1200-1750 RPM for maximum life).

Oil pump over-speed does not always produce

excessive or higher (indicated) oil pressures (on a

panel or gauge) because most machines and/or oil

pumps have a pressure bypass. Even pumps with a

pressure bypass, if operated at excessive speed, may

fail bearings and/or seals prematurely.

AdjustingT30-M Motoroutputis accomplishedsimply

by reducing (or increasing if needed) the dynamic

motor supply air/gas pressure. Matching the motor

output speed to the same optimum range as that ofthe

oilpump (1200-1750RPM)will provide maximumT30-

M Motor life

2.2 SUPPLY & EXHAUST LINE

INSTALLATION

WARNING

Be sure to either bleed the pressurized air reservoir

and/or safety the system such as closing all air/gas

supply valves prior to installing Motor or a new

supply line.

The T30-M Motors come standard with a 1.0 inch NPT

female pipe thread connection at the inlet. A 1.5 inch

or 2.0” exhaust adapter is standard.Supplied adapters

are sealed with Viton O-rings.

The Motor supply line consists of the line from the

air/gas supply source (via a pressure regulator when

necessary) through filters, manual and/or automatic

relay valves to the Motor inlet.

The exhaust line consists of the line from the Motor

exhaust to a “safe” location. Turbine exhaust (gas) is

typically plumbed away from the engine area.

Hard piping may be used on supply/exhaust lines. A

section of flexible tubing (gas approved where

required) is recommended, between Motor

inlet/exhaust outlets, to the hard piping. This can

prevent leaks or “wobble” out due to piping weight &

vibrationand ease offieldmaintenance/replacementof

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 6 Publication: T3-790, Rev. 2

Issued January 9, 2013

the Motor(s).

Motor supply & exhaust lines and components should

be dry-fitted for proper alignment /location prior to final

assembly.

All pipe threaded joints should be sealed with Loctite

Pipe Thread Sealant (TDI P/N 9-94085) or equivalent,

for leak tight joints prior to final assembly. Be sure to

tighten all joints to proper torque after final assembly.

The installation of the Motorusing naturalgas issimilar

to the air installation except all fittings, piping, valves

and regulators must be compatible with natural gas

and gas industry regulations.

WARNING

When using natural (or combustible) supply gas

(e.g.methane gas)mustbe pipedtoa safelocation,

routed and terminated according to industry codes

and local regulations.

NOTE

On low pressure applications, if the supply line is

longer than 40 feet, piping size may need to be

increased to minimize dynamic flow losses through

piping and ensure specified output. Similarly, exhaust

piping length & diameter must not induce back

pressure above 10 psig

On higher supply pressures, a regulator or manual

valve may be used to limit dynamic operatingand drive

motor speed (RPM). See Motor Performance Chart

WARNING

Be sure that any/all piping &/or tubing used, meets

applicable requirements and that no leaks are

present following line installation or thereafter.

CAUTION

There is often weld slag, grindings, thread shavings,

hardened compounds and other heavy debris in new

packagepiping &atnew siteinstallations. Therefore,

atcommissioning TDIrecommendsa purgeor“blow-

down” of Motor supply lines to prevent damage to the

Motor. While T30-M TURBOTWIN Motors are highly

tolerant of moisture & fine contamination, Motor life

can be increased by use of a coarse #40 mesh

strainer upstream in the motor supply line

NOTE

Expensive moisture abatement (air/gas drying) is not

required, as this has no effect on the Motors.

2.3 MOTOR CONTROLS

Preferred Motor supply control valve isa pilot-operated

type,which ispneumaticallyor electricallyactuated. A

manual valve may also be used.

CAUTION

SET UP – Motor supply pressure “matching” will

control motor speed and is recommended on all

installations of the T30-M. Do Not use Motor’s (data

plate)Max Operating Pressure rating as the default

supply pressure setting. (also See Section 2.5)

Motor supply pressure (flow restriction) or a pressure

regulator is required:

Where Motor supply pressure exceeds

dynamicMotor operatingpressure(measured

at the inlet port while motor is running. (Over-

pressure).

Where “default” Motor supply pressure (e.g.

engine fuel gas pressure or starting pressure)

producesMotor outputspeedsbeyondwhat is

specified for the application. (Over-speed).

Where motor over-speed, occurs even when

Motor is operated (dynamically) at a pressure

below the Motor’s Maximum Operating Max.

Over-pressure & Over-speed reduce life of Motor &

driven equip (oil pump) & wastes supply air/gas

(increases operating costs).

2.4 INLET PRESSURE CHECK PORT

(checking dynamic operating pressures)

A 1/8" NPT port is located on the Motor housing, at

the air inlet. This port is used to check the dynamic

supply pressure (at the Motor when the Motor is

operating). To check dynamic pressure, remove the

1/8" NPT pipe plug and save for later use. Install a

pressure gauge to read at this port. Using Loctite Pipe

Thread Sealant or equivalent, replace 1/8” NPT pipe

plug upon completion of pressure check.

This pressure monitoring gauge may also be

permanently installed. Alternately, a pressure

transducer may be installed at the pressure check port

and electrical lines routed to a digital display or panel

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 7

at the operator's station.

2.5 MATCHING MOTOR OUTPUT (SPEED)

TO LOAD – OIL PUMP/MOTOR LOCATION

It is recommended T30-M Motors be installed to

operate at an RPM between 1200-1750 RPM.

Where possible, a hand held tachometer

should be used to double-check Motor/pump

output speeds.

Motor supply pressure should be set at the

minimum pressure required to insure the

Motor runs the speed/load required by the

pump application.

Depending on where indicated/monitored, oil

pressure may not indicate excessive motor

speed since an oil bypass (relief valve) may

reduce this to a indicate a “normal” oil

pressure reading by the operator.

Oil Pump discharge pressure (taken at the oil

pump discharge port) is the best indicator of

pump speed. Followthepumpmanufacturer’s

recommendations.

Do not apply or select the maximum Motor supply

pressure by default, (e.g. “same as” fuel gas pressure

or starting air pressure on the package). Motor speed

& output must account for:

Varying starting or fuel gas pressures.

Varying oil pump models, oil viscosity, oil

temperatures (loads).

Varying site conditions (temperatures, etc…).

Varying oil pressure & cycle times required.

2.6 ADJUSTING MOTOR OUTPUT SPEED

Set multi-meter to measure frequency (Hz).

Connect the two multi-meter leads to the

speed pick-up connector attached to the air

motor.

To identify the speed on the multi-meter,

multiply the frequency times 3 as shown on

the tag affixed to the air motor.

Apply the supply pressure to the motor and

slowly increase the pressure until the desired

output speed is achieved. DO NOT EXCEED

1750 RPM.

NOTE

Motor over-speed: Where motor & pump output

pressure or RPM, exceed that needed for an

application:

Reducing Motor supply pressure;

or

Increasing size of oil pump supply/discharge lines,

will correct this condition.

3.0 MOTOR OPERATION

WARNING

Do not operate the TDI TURBOTWIN Motor at

dynamic supply pressures greaterthan the pressure

rating on the nameplate. This dynamic pressure is

measured at Motor inlet while Motor is running.

Static (non-flowing) supply pressure will

always behigher than theoperating(dynamic)

pressure. The maximum pressure limit (proof

pressure) that the TDI TURBOTWIN Motor

housings may be subjected to is 600 PSIG

(42 BAR).

Where system static pressuremay exceedthe

600 PSIG (42 BAR) limit, in addition to

pressure reducing device, a pressure relief

valve (set below 600 PSIG [42 BAR], should

be used.

Speed Pick-up

Connector

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 8 Publication: T3-790, Rev. 2

Issued January 9, 2013

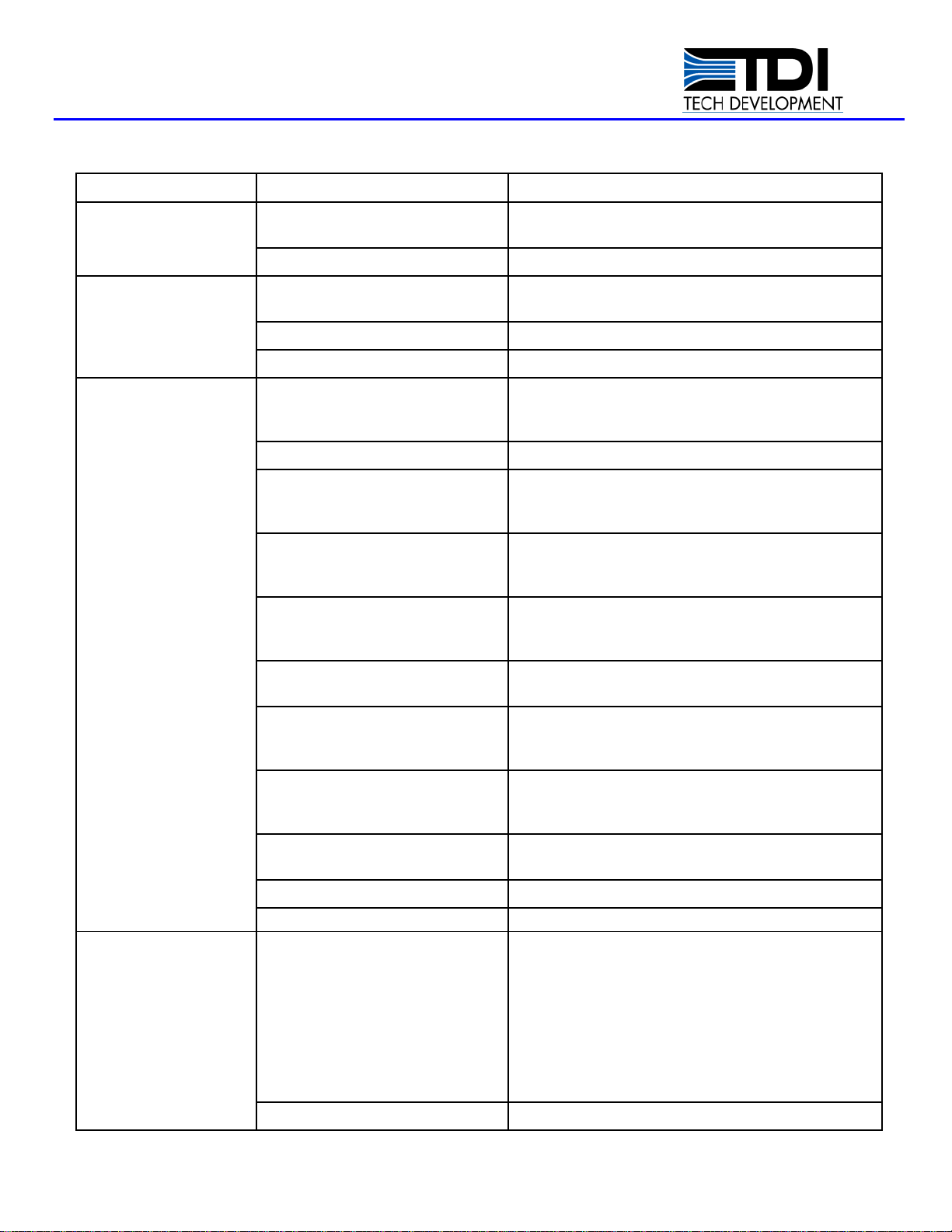

4.0 TROUBLESHOOTING CHART

TROUBLE PROBABLE CAUSE

SOLUTION

1. Motor does not run;

small air flow from

exhaust.

A. Y-Strainer or filter in supply line

clogged. A. Clean strainer.

B. Nozzle blockage. B. Remove blockage or obstruction from nozzles.

2. Motor does not run;

(rotate) but normal air

flow from exhaust.

A. Broken/damaged turbine

rotor(s). A. Replace all damaged parts.

B. Broken gear train. B. Repair or replace gear train.

C. Seized Load (e.g. oil pump) C. Repair or replace pump (or driven device)

3. Reduced Motor

output power (will not

carry load).

A. Motor inlet air pressure/flow

insufficient to produce required

Motor output.

A. Check dynamic operating pressure at Motor inlet.

Increase air pressure in 10 PSIG increments; DO

NOT EXCEED OPERATING LIMIT.

B. Damaged turbine nozzle. B. Replace turbine nozzle.

C. Inlet supply piping or

components too small. C. Check dynamic operating pressure at Motor inlet.

Supply piping size (lengths/diameters) must match

dynamic flow requirements.

D. Pressure regulator orifice too

small. D. Check dynamic operating pressure at Motor inlet.

Increase orifice size or replace pressure regulator to

one that matches pressure/flow requirements.

E. Inlet supply line valve (ball,

gate, relay, plug) too small. E. Check dynamic operating pressure at Motor inlet.

Install valve that matches flow/pressure

requirements for application.

F. In line lubricator installed in

supply line restricting flow. F. Check dynamic operating pressure at Motor inlet.

Remove lubricator.

G. Control Valve or Regulator not

fully open. G. Check dynamic operating pressure at Motor inlet.

Repair or replace control valve or regulator as

needed.

H. Excessive back pressure;

exhaust restricted. H. Check dynamic operating pressure at Motor

exhaust port. Clean exhaust piping or increase size

to length/diameter required for application.

J. Wrong rotation Motor. J. Check rotation (direction) Replace with Motor of

proper rotation if necessary.

K. Wrong size Motor. K. Check Application Specification for correct Motor.

4. Motor & Pump turns

too fast. Excessive oil

pump output/pressure.

OR

Validate with a hand

tachometer if necessary.

A. Motor Inlet air pressure too

high. A. Check dynamic operating pressure at Motor inlet

Decrease air pressure in 10 PSIG (0.6 BAR)

increments.

OR

If there is a manual shut-off valve in the supply line,

partially close it to restrict dynamic Motor supply

pressure.

OR

Install a restriction orifice in the inlet supply line.

B. Wrong size Motor. B. Check Application Specification for correct Motor.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 9

5.0 WARRANTY

Tech Development (TDI) warrants to the original user of the TDI TURBOTWIN™ air starters to be free from defects in material

and workmanship for a period of one year from the date of installation. The warranty period shall not extend beyond two years

fromthe datetheunit wasmanufactured. (i.e.: aunit witha manufactured dateof July 1999 (SN:9907-0101)willnot be covered

under warranty after July 2001). The conditions of this warranty are: a) TDI is notified within this period by return of such

product to TDI or its authorized distributor/dealer, transportation prepaid by user; b) the starter has been installed according to

TDI’s specifications; c) the starter has not been misused, abused, or improperly maintained by user; d) the defect is not the

result of normal wear and tear; e) the starter has been repaired with parts manufactured or authorized by TDI; and f) TDI

installation and repair procedures as outlined in the appropriate manual were properly followed.

TechDevelopment willrepair,or atitsoption, replacetheunit duringthewarranty period atnochargeto thecustomer,provided

it is returned to TDI with the proper return procedures.

Tech Development makes no other warranty, and implied warranties including any warranty or merchantability or fitness for a

particular purpose are hereby disclaimed.

This warranty constitutes the entire obligation of Tech Development relating to the sale and use of such product, and TDI’s

maximum liability is limited to the purchase price of such product at the date of purchase. In no event shall TDI be liable for

incidental, indirect, consequential, or special damages of any nature arising from the sale or use of such engine starter

product.

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 10 Publication: T3-790, Rev. 2

Issued January 9, 2013

Figure 1. T30-M Lube Pump Motor

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 11

Figure 2. T30-M Lube Pump Motor w/Integral Relay Valve (Pneumatic)

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 12 Publication: T3-790, Rev. 2

Issued January 9, 2013

Figure 3. T30-M Lube Pump Motor w/Integral Relay Valve (Solenoid) for Air Only Operation

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Publication: T3-790, Rev. 2

Issued: January 9, 2013 Page 13

Figure 4. T30-M Lube Pump Motor w/Modified NEMA 56C Mounting Flange

TDI TURBOTWIN™

FROM TECH DEVELOPMENT

Page 14 Publication: T3-790, Rev. 2

Issued January 9, 2013

Figure 5. T30-M Lube Pump Motor w/NEMA 56C Mounting Flange

Table of contents

Other TDI Engine manuals

Popular Engine manuals by other brands

Sirius Satellite Radio

Sirius Satellite Radio SEM5 XS316 User & installation manual

Mercury

Mercury 4.3 TKS series Operation & maintenance manual

RCGF

RCGF 21CC-Twin Operator's manual

MTU

MTU 12V2000M93 operating instructions

Wacker Neuson

Wacker Neuson WM 80 Repair manual

Volvo Penta

Volvo Penta IPS 350 Installations