TDI TURBOTWIN T30ML User manual

FromTech Development

6800 Poe Ave. Dayton OH 45414

Tel: (937) 898-9600 Fax: (937) 898-8431

Website: www.tdi-turbotwin.com

Publication T3-906

Dated: January 8, 2016

INSTALLATION AND OPERATING

MANUAL

T30ML

T

URBO

T

WIN

Air Motor

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page: i

Publication T3-906

Issued January 8, 2016

TABLE OF CONTENTS

Section Subject Page

1.0 General Information……………………………………1

2.0 Orientation of the Motor……...………………………..1

3.0 Installing the Motor……………………………………..2

4.0 Motor Operation……………………………………….. 3

5.0 Warranty……….………………………...................... 4

6.0 Operator’s Troubleshooting Guide…………………...5

LIST OF ILLUSTRATIONS

Figure Title Page

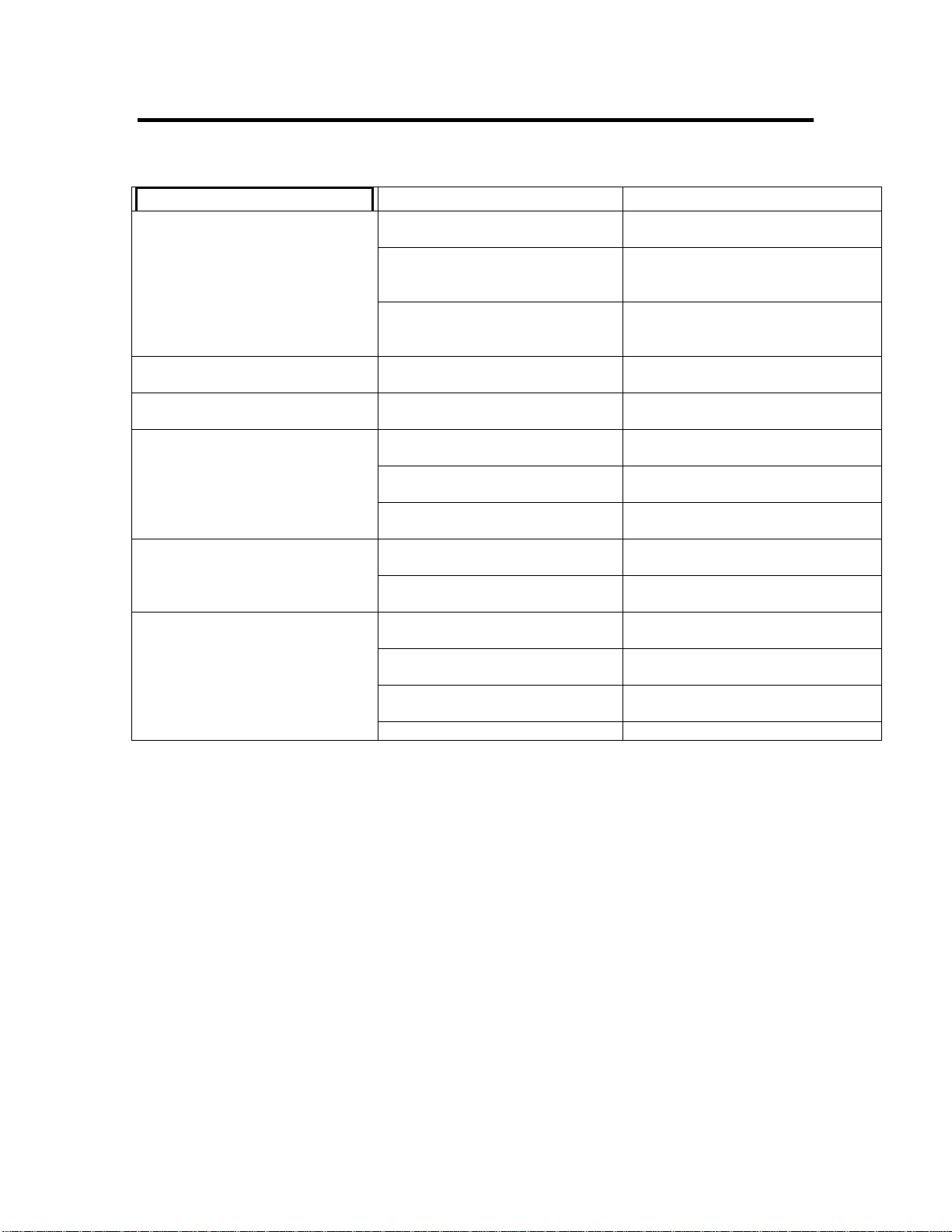

1 T30ML Air Motor w/Pump Envelope Drawing……….6

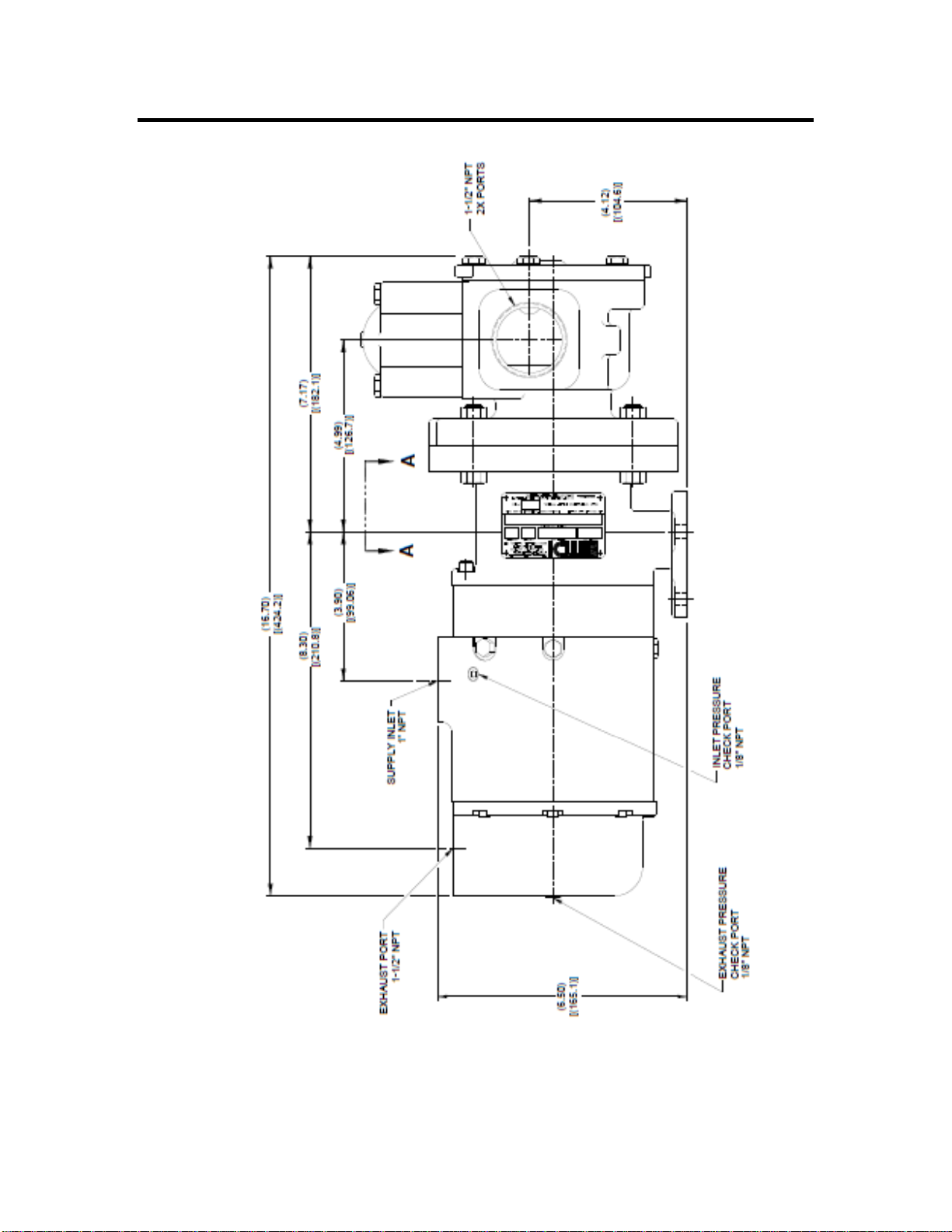

2 T30ML Air Motor Envelope Drawing......................... 7

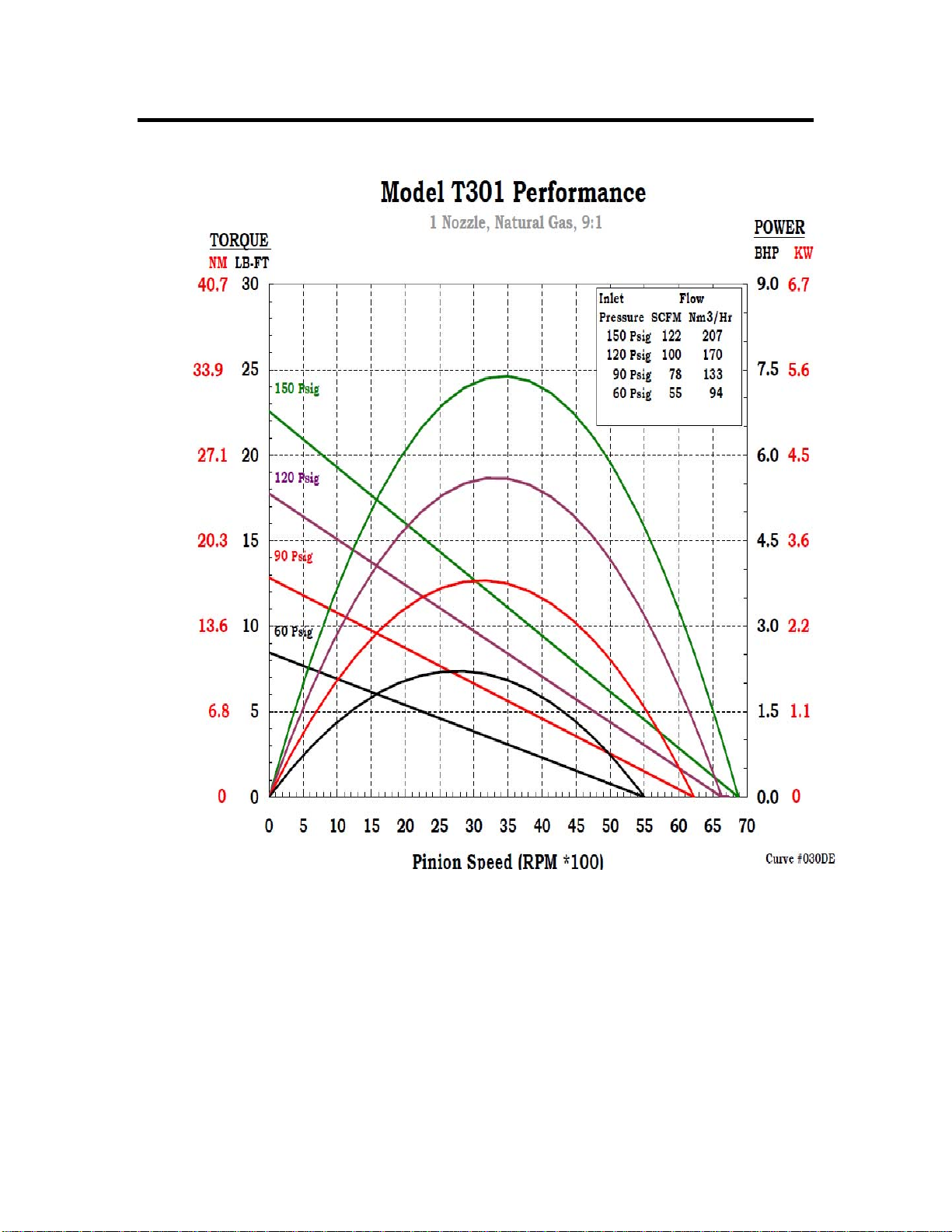

T301 Performance Curves (Gas)……………............8

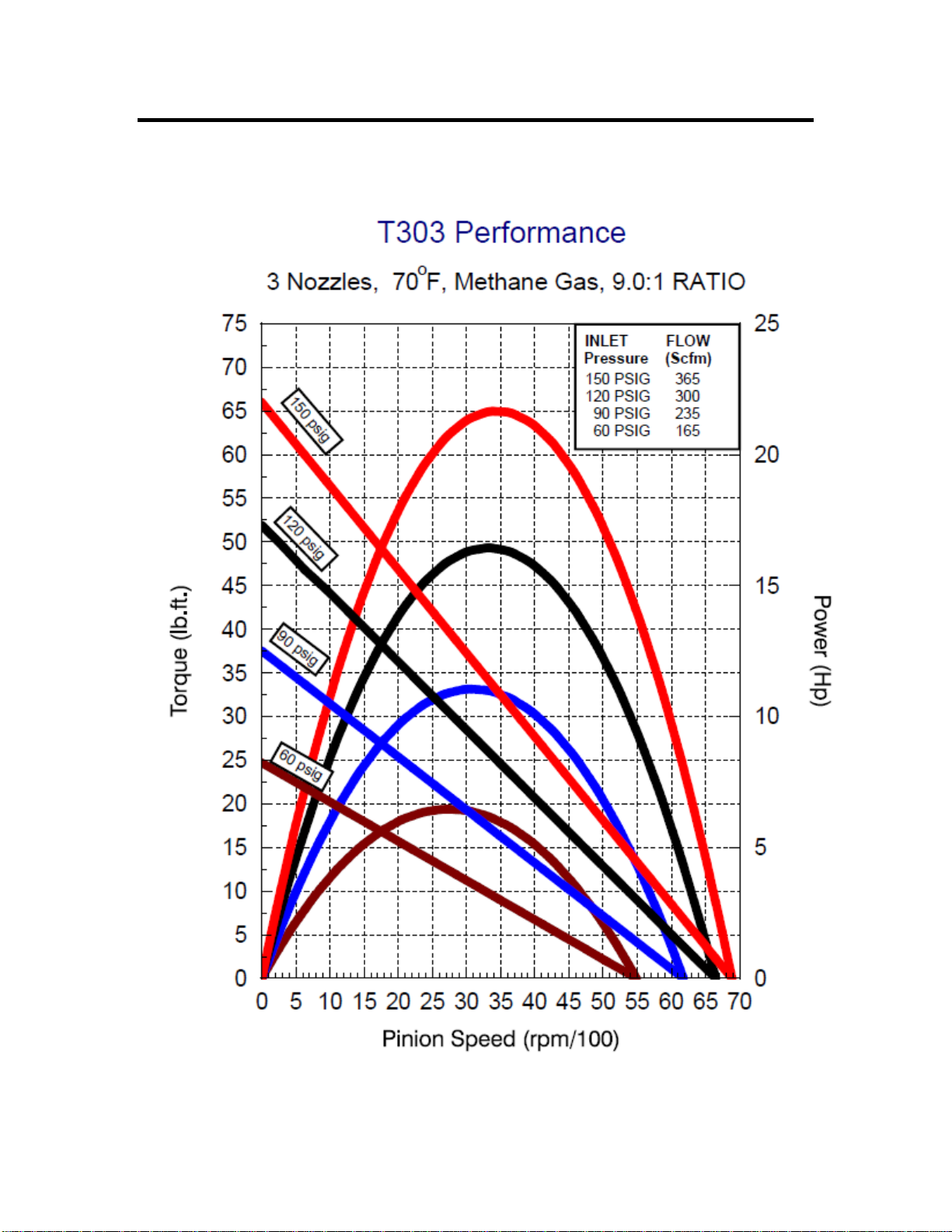

T303 Performance Curves (Gas)……………………. 9

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T30-906 Page 1

Issued January 8, 2016

1.0 GENERAL INFORMATION

This manual provides instructions for the

installation and operation of the TDI

TurboTwin™ Model T30 ML air motors. If

there are questions not answered by this

manual, please contact your TDI

TurboTwin™ distributor or dealer for

assistance.

The T30 ML is a turbine driven air motor

with a .625” diameter keyed output shaft.

The T30 ML is designed for installation on

an oil pump with D-type mounting flange.

The T30 Series motors are suited to operate

within a wide range of inlet air pressures and

ambient temperatures.

A pressure regulator installed within 10 feet

of the motor can be used to adjust pressure

to the motor.

The T30 Series motors are designed for

operation with compressed air or natural

gas. Moderate amounts of foreign matter or

liquid in the air stream will normally not

adversely affect T30 Series motors.

As with all other TDI TurboTwin™ models,

no lubrication is required in the supply air.

You need to review the rest of this manual

before installing your TDI TurboTwin™ T30

Series motor.

1.1 WARNINGS, CAUTIONS, & NOTES

Throughout this manual, certain types of

information will be highlighted for your

attention:

WARNING - used where injury to

personnel or damage to the

equipment is possible.

CAUTION - used where there is the

possibility of damage to the

equipment.

NOTE - used to point out special

interest information.

1.2 INSTALLATION and SERVICE

The TDI TurboTwin™ T30 Series motors

provide distinct advantages of size and

efficiency compared to electric motors,

vane-type, or other turbine-type air motors.

It is important to properly install the motor to

receive full benefit of these advantages.

Repair technicians or service organizations

without turbine motor experience should not

attempt to repair this machine until they

receive factory approved training from TDI,

or its representatives.

Proper operation of your TDI TurboTwin™

T30 Series motor will assure continued

reliable and superior performance for many

years.

WARNING

The TDI TurboTwin™ T30 Series motors

must be installed and operated in

accordance with the instructions given in

this manual. Failure to properly install the

motor or failure to operate it according to

these instructions may result in damage to

the motor, the engine, or cause personal

injury.

NOTE

THIS MOTOR IS TO BE SERVICED ONLY BY

AUTHORIZED TDI TURBOTWIN™ DISTRIBUTORS,

DEALERS, AND REPAIR STATIONS. DO NOT

OPERATE THIS MOTOR UNLESS IT IS PROPERLY

INSTALLED ON AN ENGINE.

2.0 ORIENTATION OF THE

MOTOR

The factory orientation of the motor’s

mounting flange is ideally configured for

most applications and does not required

reorientation.

2.1 MODEL T30-I ORIENTATION

Determine the required orientation of the

optional exhaust port if installed.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 2

Publication T30-906

Issued January 8, 2016

2.1.1 Exhaust Housing Orientation

If this unit has an optional exhaust housing

remove the seven (if a 90⁰elbow) or eight (if

a straight exhaust) socket head cap screws

connecting the exhaust to the turbine

assembly. Rotate the exhaust housing to

the desired position relative to the inlet port.

Reinstall the seven or eight socket head cap

screws. Torque to 61 Lbs.-In. (6.89 Nm)

CAUTION

Ensure the O-ring on the exhaust housing

remains in position and is not cut.

3.0 INSTALLING THE MOTOR

The T30ML air motor is configured with a

footed section on the gearbox housing for

installing onto the engine or appropriate

mounting bracket. The air motor and

optional 7 or 30 GPM oil pump if attached to

motor should be mounted in a horizontal

position as shown.

The piping illustrated may vary in shape, but

there must at least be a start initiation

switch, air supply, and a motor relay valve to

correctly install and operate a T30 Series

motor.

NOTE

Installing the air piloted relay valve on the

motor is preferred in installations where the

space is available.

TDI recommends mounting the air piloted

relay valve no more than 3 meters (10 feet)

from the motor’s inlet port, and as close to

the motor as possible. If the motor is being

installed on a vehicle where the air tank is

within 3 meters (10 feet) of the motor, then

the relay valve may be mounted on the tank.

A turbine driven motor does not require

lubrication in the supply air. Therefore, if a

vane-type motor is being replaced, TDI

recommends that all lubrication devices and

lines be removed to minimize flow

restrictions.

WARNING

If a fuel (pulse) lubricator is installed in the

system, disconnect and plug the line to

eliminate spraying diesel fuel on the

engine.

After mounting the motor to the engine,

attach the supply air line from the tank

including any control air lines, air piloted

relay valve and solenoids.

TDI recommends installation of a “Glad

Hand” / quick disconnect for auxiliary

pressurization of the air tank.

Because turbine motors are sensitive to flow

restrictions, care must be taken to use

uniform sized hose or tubing and fittings for

connection of the supply air line. Tees,

elbows, and line length must be kept to a

minimum.

TDI recommends that hose or flex couplings

be installed to eliminate possible leakage

caused by strain on the supply air line.

Normally an air strainer is not required. In

dirty environments, use of a #40 mesh

Y-strainer is recommended.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T30-906 Page 3

Issued January 8, 2016

Only type approved metallic hose

assemblies are approved in permanently

pressurized compressed air lines of motors.

Non-metallic hose assemblies are allowed

only in case the piping system will be

emptied after the starting procedure.

Pipe unions must be type approved by GL.

Downstream of the pressure regulator a

pressure relief valve is to be provided.

WARNING

Recheck all connections for tight fit to

eliminate leakage.

Fill the air system tank. The T30 Series

motor is now ready to operate.

4.0 MOTOR OPERATION

The maximum operating pressure limit is

that pressure measured at the motor inlet

pressure check port during the run cycle. In

order to check the motor inlet pressure, a

1/8" NPT pipe tap connection is provided

just below the main inlet for attaching a

pressure gauge. Refer to Figure 1. IN NO

CASE SHOULD INLET OPERATING

PRESSURE EXCEED 10.3 BAR (150

PSIG).

WARNING

Do not operate the TDI TurboTwin T30

Series air motor with air pressure greater

than the pressure rating on the nameplate.

This pressure should be measured at the

motor inlet while the motor is operating.

The static supply pressure will always be

higher than the operating pressure. As a

guideline, the maximum pressure limit (proof

pressure) that the T30 Series motor may be

subjected to is 600 PSIG (41.4 Bar).

System pressure that exceeds the maximum

operating limit must use a pressure regulator

to ensure operating pressure limit to the T30

Series motor is maintained.

System pressure that exceeds the 600 PSIG

(41.4 Bar) limit must, in addition to a

pressure reducer device, incorporate a

pressure relief valve, set below 600 PSIG

Bar (41.4) in the supply air line.

All appropriate local pressure codes and

pressure limitations on other system

components must be adhered to and

supersede guidelines given in this manual.

If the motor fails to function properly when

first operated, or its performance

deteriorates with use, refer to the Operator’s

Trouble Shooting Guide, Section 6.0. If you

cannot solve the problem, or repair is

necessary, contact your local TDI

TurboTwin™ distributor or dealer.

CAUTION

The grease used in the planetary system

has a shelf life of 2 years. Therefore, if the

motor is NOT installed and operated on the

engine for 2 years after the motor is

manufactured, the grease should be

replaced prior to motor operation. The

manufactured date is reflected in the motor

serial number. (Ex: 0602-0567 has a

manufactured date of February 2006).

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 4

Publication T30-906

Issued January 8, 2016

5.0 WARRANTY

Tech Development (TDI) warrants to the original user of the TDI TURBOTWIN™ air motors to be

free from defects in material and workmanship for a period of one year. The warranty period shall

not extend beyond two years from the date the unit was manufactured. (i.e.: a unit with a

manufactured date of July 1999 (SN: 9907-101) will not be covered under warranty after July

2001). The conditions of this warranty are: a) TDI is notified within this period by return of such

product to TDI or its authorized distributor/dealer, transportation prepaid by user; b) the motor has

been installed according to TDI’s specifications; c) the motor has not been misused, abused, or

improperly maintained by user; d) the defect is not the result of normal wear and tear; e) the

motor has been repaired with parts manufactured or authorized by TDI; and f) TDI installation

and repair procedures as outlined in the appropriate manual were properly followed.

Tech Development will repair, or at its option, replace the unit during the warranty period at no

charge to the customer, provided it is returned to TDI with the proper return procedure.

Tech Development makes no other warranty, and implied warranties including any warranty or

merchantability or fitness for a particular purpose are hereby disclaimed.

This warranty constitutes the entire obligation of Tech Development relating to the sale and use

of such product, and TDI’s maximum liability is limited to the purchase price of such product at

the date of purchase. In no event shall TDI be liable for incidental, indirect, consequential, or

special damages of any nature arising from the sale or use of such engine motor product.

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T30-906 Page 5

Issued January 8, 2016

6.0 OPERATOR’S TROUBLESHOOTING GUIDE

TROUBLE PROBABLE CAUSE SOLUTION

1. Air always flow through

exhaust A. Relay valve improperly

installed. A. Check typical installation

diagram and correct

B. Relay valve not sealing

properly. B. Check for damaged sealing

ring, replace relay valve or

damaged parts.

C. Control valve not sealing,

pressure remains in APP port of

relay valve.

C. Check control valve and replace

if necessary.

2. Motor does not run, small air

flow from turbine exhaust. A. Nozzle blockage. A. Remove blockage or obstruction

from nozzles.

3. Motor does not run. Normal

air flow from exhaust. A. Excessive bends in the

supply line. A. Shorten length or straighten

supply air line.

4. Motor runs but pump rotates

slowly or not at all. A. Air pressure too low A. Increase air pressure to 40 -150

psig.

B. Excessive back pressure. B. Increase inlet pressure or

reduce back pressure.

E. Nozzle blocked or damaged. D. Remove blockage or replace

damaged parts.

5. Motor continues to operate

after start button is released. A. Control valve is not sealing

correctly. A. See 1C. above

B. Relay valve is not sealing

correctly. B. See 1B. above

6. Air tank pressure decays after

extended shut down. A. Air connections are too tight. A. Tighten loose fittings. Repair or

replace damaged fittings.

B. Damaged air lines: crushed,

frayed, kinked. B. Replace damaged lines.

C. Relay valve is not sealing

correctly. C. See 1B. above

D. Control valve is stuck open. D. See 1C. above

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 6

Publication T30-906

Issued January 8, 2016

Figure 1. T30ML TurboTwin Air Motor w/Pump Envelope Drawing

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T30-906 Page 7

Issued January 8, 2016

Figure 2. T30ML TurboTwin Air Motor Envelope Drawing

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Page 8

Publication T30-906

Issued January 8, 2016

TDI TURBOTWIN

FROM TECH DEVELOPMENT

Publication T30-906 Page 9

Issued January 8, 2016

Table of contents

Other TDI Engine manuals