TDI 56A User manual

AN 96-429 From Tech Development

6800 Poe Ave. •Dayton OH 45414

Tel: (937) 898-9600 •Fax: (937) 898-8431

Website: www.tdi-turbotwin.com

Publication 56-711, Rev. 5

Dated: February 27, 2015

INSTALLATION AND OPERATING

MANUAL

MODELS: 56A / 56B / 56G / 56S

Gas Turbine Engine

Air Starter Motors

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 1

1.0 GENERAL INFORMATION

This manual provides instructions for the

installation and operation of the TDI TURBOSTART

Model 56 series air starters. If there are

questions not answered by this manual, please

contact your TDI distributor or dealer for

assistance.

The 56 series models are turbine driven air

starters with a sprag-type over-running clutch.

They are best suited for use with industrial gas

turbine engines. Model 56A and 56K are

designed for installation on engines which use an

AND 20002 Type XII-S engine accessory drive

pad. Model 56B has a mounting flange per MS

3332-2(AS) with a Type G grooved pilot and a

splined output shaft per MS 3335(AS). The 56G

has a mounting flange and output spline shaft

that mates with the accessory drive assembly

starter mounting pad on General Electric LM1600

& LM2500 engines. Model 56S is designed for

use on the Solar Saturn starter mount pad.

The 56 Series air starters are suited to operate

within a wide range of inlet pressures and

ambient temperatures. These starters are

designed for operation with either compressed air

or natural gas; materials used are compatible

with "sour" natural gas and marine environments.

Small amounts of foreign matter or liquid in the

air stream will normally not adversely affect 56

Series air starters. As with all other TDI air starter

models, no lubrication is required in the supply

air.

The 56 Series air starters are normally supplied

for use within a dedicated start monitoring

system. Some models may be equipped with the

TDI Automatic Trip Valve (ATV) to shut off air to

the starter when a predetermined cranking speed

is reached. This prevents excessive cranking

speeds, which could damage the starter.

NOTE

Throughout this manual, the term "air" is used to

denote the starter drive medium. Unless

otherwise stated, "air" means either compressed

air or natural gas.

Please review the rest of this manual before

installing your TDI TURBOSTART 56 Series

starter.

1.1 WARNINGS, CAUTIONS, & NOTES

Throughout this manual, certain types of

information will be highlighted for your attention:

WARNING - used where injury to personnel or

damage to the equipment is likely.

CAUTION - used where there is the possibility

of damage to the equipment.

NOTE - used to point out special interest

information.

2.0 ORIENTATION OF THE

STARTER

If the factory orientation of the starter's turbine

housing assembly does not fit your engine

installation, this component can be re-oriented.

Determine the required orientation of the turbine

housing assembly and gearbox housing

assembly. The turbine housing assembly can

be rotated to six different positions relative to

the gearbox housing assembly.

CAUTION

The gearbox housing assembly must always be

installed so the oil drain is at the bottom (6

o'clock) position. This assures that the oil level

check plug is also in the correct position.

Remove the oil drain plug to assure that all oil is

drained from the gearbox housing.

Remove the six turbine housing assembly to

gearbox housing assembly socket head cap

screws.

Rotate the turbine housing assembly to the

desired position and reinstall the six cap

screws. Torque the six screws to 14 Lb.-Ft

(19.2 Nm).

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 2

CAUTION

All screw threads are treated at the factory with a

fastener retention compound. Every screw and tapped

hole must be clean and have a drop of Loctite 290

applied to the threads before being reinstalled.

CAUTION

Ensure that the O-ring on the gearbox housing

assembly remains in position and is not cut.

Install the oil drain plug.

Remove the oil level check plug on the side of

the gearbox housing and the oil fill plug at the

top of the gearbox housing. Add oil to the

gearbox housing until it starts to run out of the oil

level check port. Install the oil fill plug and oil

level check plug.

3.0 INSTALLING THE STARTER

3.1 A turbine driven starter does not require

lubrication in the supply air. Therefore, if a

vane-type starter motor is being replaced,

TDI recommends that all lubrication devices

and lines be removed to minimize flow

restrictions.

WARNING

If a fuel (pulse) lubricator has previously been

installed in the system, disconnect and plug the

line to eliminate spraying diesel fuel on the

engine.

3.2 Liberally grease the starter's splined shaft

with chassis lube and then mount the 56

Series starter on the engine. Tighten all

mounting hardware as appropriate.

WARNING

The starter is shipped from the factory without oil

in the gearbox. Oil must be added before

operating the starter.

Remove the oil level check plug on the side of

the gearbox housing and check the oil level in the

gearbox housing.

NOTE

Use of a turbine engine oil conforming to

MIL-L-7808H, or equal, is recommended for -use

in the gearbox.

If oil needs to be added, remove the oil fill plug

at the top of the gearbox housing. Add oil to

the gearbox housing until it starts to run out of

the oil

level check port. Install the oil fill plug and oil

level check plug.

After adding oil to the starter, attach the supply

air line and all system monitoring and

shutdown devices.

3.3 Natural Gas Operation

Proper control of natural gas is a major

consideration when used in the starter system.

3.3.1 The turbine exhaust must be plumbed

away from the starter area and vented to

atmosphere. 3" NPT and 4" NPT exhaust

fittings are available from TDI; refer to

Section 4.6.

CAUTION

When an exhaust fitting and line are used, the

line must be supported to prevent load transfer

back to the starter and engine mounting pad.

3.3.2 There is a turbine housing natural gas

vent port that is plugged for compressed

air use. Remove this 3/8" NPT plug and

install a line to carry gas away from the

starter area and vent to atmosphere.

CAUTION

Do not connect the turbine housing vent line to the

turbine exhaust line; exhaust line gas can

pressurize the turbine housing.

3.3.3 If used, the oil fill vent stand pipe (1/2"

NPT) must be removed and a line installed

to locate this vent away from the

immediate vicinity of the starter system

monitors.

3.4 Because turbine starters such as the 56

Series are sensitive to flow restrictions,

care must be taken to use uniform hose or

tubing and fittings for connection of the

supply air line. Tees, elbows, and line

length must be kept to a minimum. TDI

recommends that hose or flex couplings

be installed to eliminate possible leakage

caused by strain on the supply air line.

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 3

3.5 Normally an air strainer is not required. In

dirty environments, use of a #40 mesh

Y-strainer is recommended.

WARNING

Recheck all connections for a tight fit.

Fill the air system tank. The 56 Series starter is

now ready to operate.

4.0 STARTER OPERATION

The maximum operating pressure limit is the

inlet pressure when measured at the starter

inlet pressure check port and reflects all

supply air pipe and valving losses. In order to

check the starter inlet pressure, a %" NPT

pipe tap connection is provided in the inlet

housing to attach a pressure gauge; refer to

Figures 1 and 2. IN NO CASE Should INLET

OPERATING PRESSURE EXCEED 10.3

BAR (150 PSIG).

WARNING

Do not operate the TDI Turbostart 56 Series

air starter with air pressure greater than the

pressure rating on the nameplate. This

pressure is to be measured at the starter

-inlet while the starter is running.

The static supply pressure will always be

higher than the operating pressure. As a

guideline, the maximum pressure limit (proof

pressure) that the 56 Series air starter may

be subjected to is 600 PSIG (41.4 Bar).

System pressure that exceeds the maximum

operating limit must use a pressure reducer

device to ensure that the operating pressure

limit to the 56 Series air starter is maintained.

System pressure that exceeds the 600 PSIG

(41.4 Bar) limit must, in addition to a

pressure reducer device, incorporate a

pressure relief valve, set below 600 PSIG

(41.4 Bar), in the supply air line.

All appropriate local pressure codes and

pressure limitations on other system

components must be adhered to and would

supersede the guidelines given in this manual.

4.1 Follow the engine manufacturer's instructions

for starting the engine.

4.2 If a start is aborted before a successful

engine start, a restart may be attempted after

the starter turbine and engine have come to

rest. Refer to the Engine Operator's Manual if

the system continues to shut down before a

successful start.

4.3 If an Automatic Trip Valve (ATV) is used and

the ATV happens to trip before a successful

engine start, a restart may be attempted after

the starter turbine and engine flywheel have

come to rest. If the ATV continues to trip, it

indicates that the supply line pressure is too

high. Refer to the Operator's Trouble

Shooting Guide, Section 6.0.

4.4 If the starter fails to function properly when

first operated, or its performance deteriorates

with use, refer to the Operator's Trouble

Shooting Guide, Section 6.0. If you cannot

solve the problem, or repair is necessary,

contact your local TDI Turbostart distributor

or dealer.

4.5 Gearbox housing lubricant should be

checked every six months. Lubricant should

flow out of the oil level check port when the

plug is removed. If lubricant needs to be

added, remove the gearbox housing oil fill

plug / stand pipe and add lubricant until it

starts to flow from the oil level check port;

refer to Section 3.2.

4.6 Accessories

DESCRIPTION KIT P/N:

3" Marman inlet flange 55-119

6" Marman exhaust flange 55-120

3" NPT exhaust fitting 52-419

3" NPT exhaust elbow 52-403

4" NPT exhaust fitting 52-418

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 4

5.0 WARRANTY

TDI TURBOSTART ENGINE STARTER WARRANTY

Tech Development (TDI) warrants to the original user of the TDI Turbostart 56 Series air starters that the starter and

related components manufactured by TDI will be free from defects in material and workmanship for a period of One (1)

Year from date of purchase by such user. The conditions of this warranty are: a) TDI is notified within this period by

return of such product to TDI or its authorized distributor or dealer, transportation prepaid by user, b) such product has

been installed according to TDI's specifications; c) such product has not been misused, abused or improperly

maintained by user, d) the defect is not the result of normal wear and tear, and e) such starter product has not been

repaired with parts not manufactured or authorized by TDI and that TDI installation and repair procedures as outlined in

the appropriate manual were properly followed.

Tech Development shall, at its option, either repair or replace, without charge, any such starter product found upon

TDI's examination to be so defective, or by mutual agreement, refund the user's purchase price in exchange for such

starter product. Repairs or replacements under this warranty are warranted for the remainder of the original warranty

period.

Tech Development makes no other warranty, and IMPLIED WARRANTIES INCLUDING ANY WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

This warranty constitutes the entire obligation of Tech Development relating to the sale and use of such product, and

TDI's maximum liability is limited to the purchase price of such product at the date of purchase. In no event shall TDI

be liable for incidental, indirect, consequential or special damages of any nature arising from the sale or use of such

engine starter product.

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 5

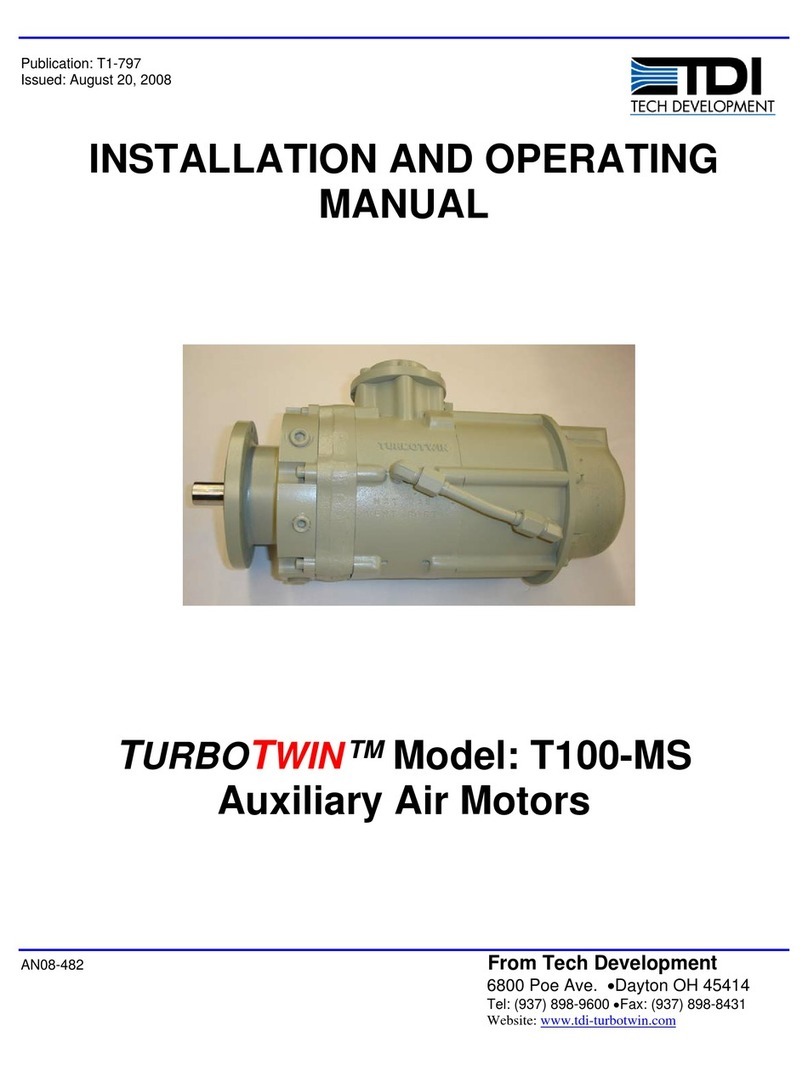

56-A Gas Turbine Air Starter

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 6

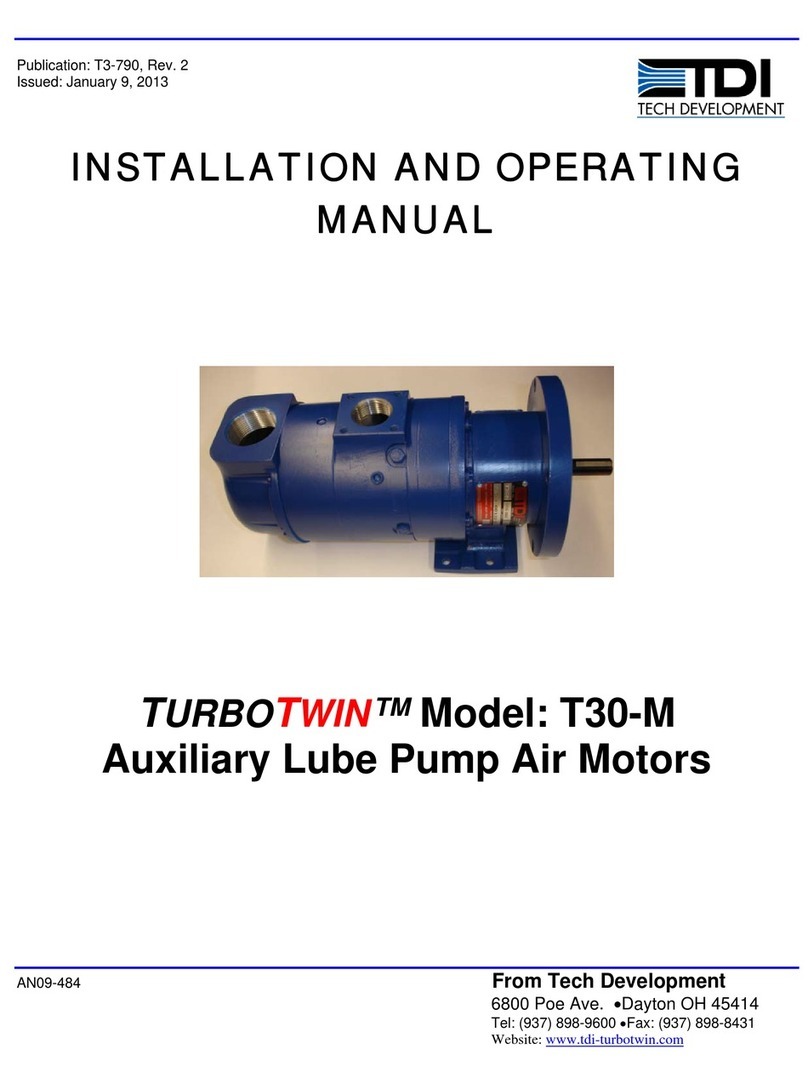

56-B Gas Turbine Air Starter

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 7

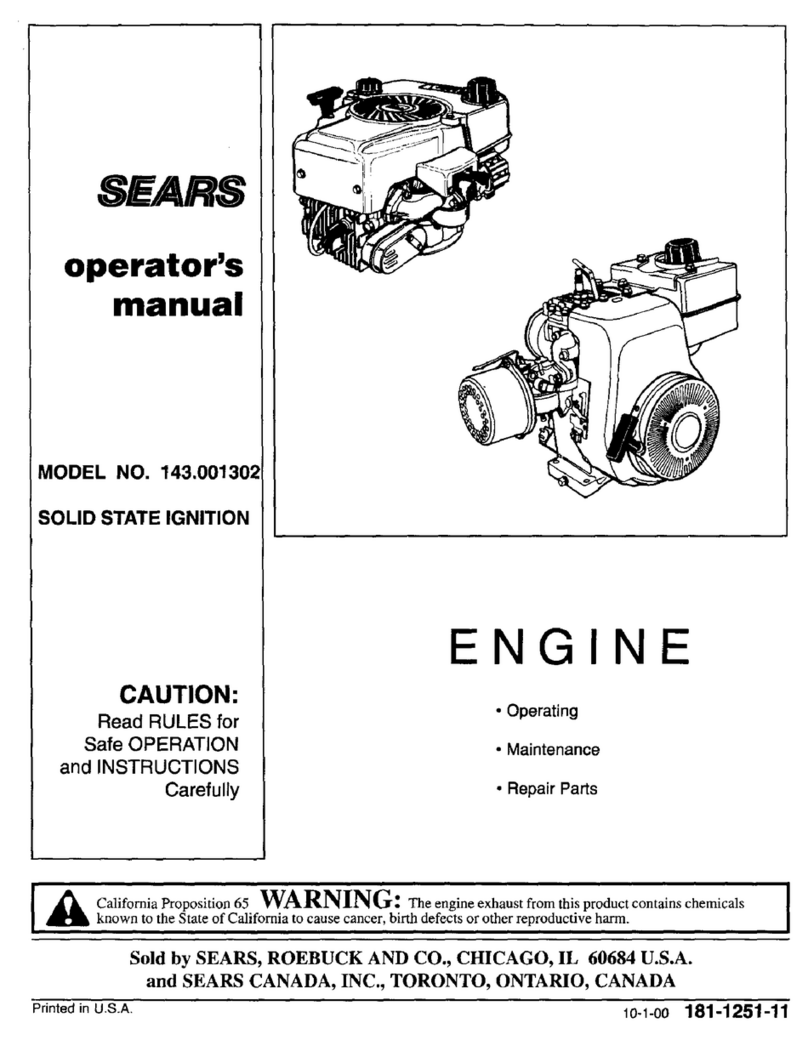

56-G Gas Turbine Air Starter

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 8

56A Performance Curves

21 Nozzles, Methane Gas, 11.4 Gear Ratio

0 5 10 15 20 25 30 35 40 45

0

50

100

150

200

250

300

350

400

450

500

550

0

20

40

60

80

100

120

140

160

180

200

220

150psig

120psig

90 psig

60psig

68

136

272

340

408

476

204

Nm

LB-FT

TORQUE

544

612

680

0

15

30

45

60

75

HP KW

POWER

120

90

105

748

135

150

165

56A Performance Curves

21 Nozzles, Compressed Air, 11.4 Gear Ratio

0 5 10 15 20 25 30 35 40 45

0

50

100

150

200

250

300

350

400

450

500

550

0

20

40

60

80

100

120

140

160

180

200

220

150psig

120psig

90psig

60 psig

68

136

272

340

408

476

204

Nm

LB-FT

TORQUE

544

612

680

0

15

30

45

60

75

HP KW

POWER

120

90

105

748

135

150

165

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 9

56B Performance Curves

21 Nozzles, Methane Gas, 9.0 Gear Ratio

0 5 10 15 20 25 30 35 40 45

0

50

100

150

200

250

300

350

400

450

500

550

0

20

40

60

80

100

120

140

160

180

200

220

150psig

120psig

90psig

60psig

68

136

272

340

408

476

204

Nm

LB-FT

TORQUE

544

612

680

0

15

30

45

60

75

HP KW

POWER

120

90

105

748

135

150

165

56B Performance Curves

21 Nozzles, Compressed Air, 9.0 Gear Ratio

0 5 10 15 20 25 30 35 40 45

0

50

100

150

200

250

300

350

400

450

500

0

20

40

60

80

100

120

140

160

180

200

150psig

120psig

90psig

60psig

68

136

272

340

408

476

204

Nm

LB-FT

TORQUE

544

612

680

0

15

30

45

60

75

HP KW

POWER

120

90

105

135

150

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 10

56G Performance Curves

21 Nozzles, Methane Gas, 7.5 Gear Ratio

0 5 10 15 20 25 30 35 40 45 50 55

0

50

100

150

200

250

300

350

400

450

500

550

0

20

40

60

80

100

120

140

160

180

200

220

150psig

120psig

90psig

60psig

68

136

272

340

408

476

204

Nm

LB-FT

TORQUE

544

612

680

0

15

30

45

60

75

HP KW

POWER

120

90

105

748

135

150

165

56G Performance Curves

21 Nozzles, Compressed Air, 7.5 Gear Ratio

0 5 10 15 20 25 30 35 40 45 50

0

50

100

150

200

250

300

350

400

450

0

20

40

60

80

100

120

140

160

180

150psig

120psig

90psig

60psig

68

136

272

340

408

476

204

Nm

LB-FT

TORQUE

544

0

15

30

45

60

75

HP KW

POWER

120

90

105

135

612

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 11

56S Performance Curves

7 Nozzles, Methane, 9.0 Gear Ratio

0 5 10 15 20 25 30 35 40 45 50

0

20

40

60

80

100

120

140

160

0

10

20

30

40

50

60

70

80

150psig

60psig

27

54

108

135

162

189

81

Nm LB-FT

TORQUE

216

0

8

15

22

30

38

HP KW

POWER

60

45

52

120psig

90psig

56S Performance Curves

7 Nozzles, Compressed Air, 9.0 Gear Ratio

0 5 10 15 20 25 30 35 40 45 50

0

20

40

60

80

100

120

140

160

0

10

20

30

40

50

60

70

80

150psig

60psig

27

54

108

135

162

189

81

Nm

LB-FT

TORQUE

216

0

8

15

22

30

38

HP KW

POWER

60

45

52

120psig

90psig

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 12

TDI TURBOSTART™

FROM TECH DEVELOPMENT

Page 13

This manual suits for next models

3

Table of contents

Other TDI Engine manuals

Popular Engine manuals by other brands

Chang Fa

Chang Fa ZS1115G Operation manual

Pelikan Daniel

Pelikan Daniel RAY G3 manual

Generac Power Systems

Generac Power Systems GTV-760 owner's manual

O.S. engine

O.S. engine MAX-91SX-HRING C Spec PS VIPER Owner's instruction manual

Isuzu

Isuzu 4BG1 instruction manual

Vertilux

Vertilux VTi 35 Series Programming instructions

Nissei

Nissei F2 Series installation manual

O.S. engine

O.S. engine GF40 Owner's instruction manual

Daihatsu

Daihatsu CB-20 Workshop manual

Robin America

Robin America EH72 Instructions for use

Mitsubishi Electric

Mitsubishi Electric meiki series instruction manual

Briggs & Stratton

Briggs & Stratton 12L800 Series Illustrated parts list