PAH300・350S24-SERIES

TDK-Lambda

8

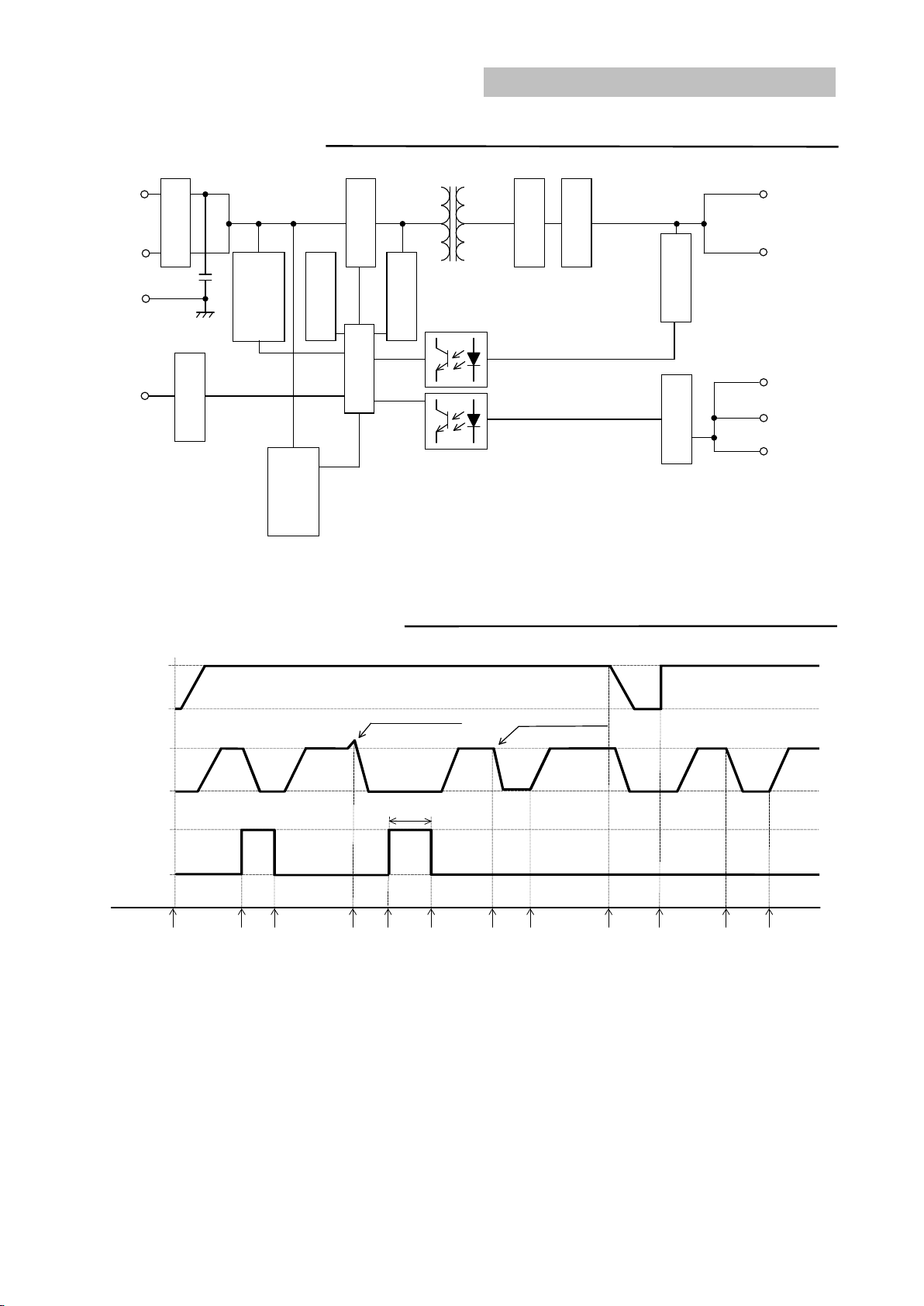

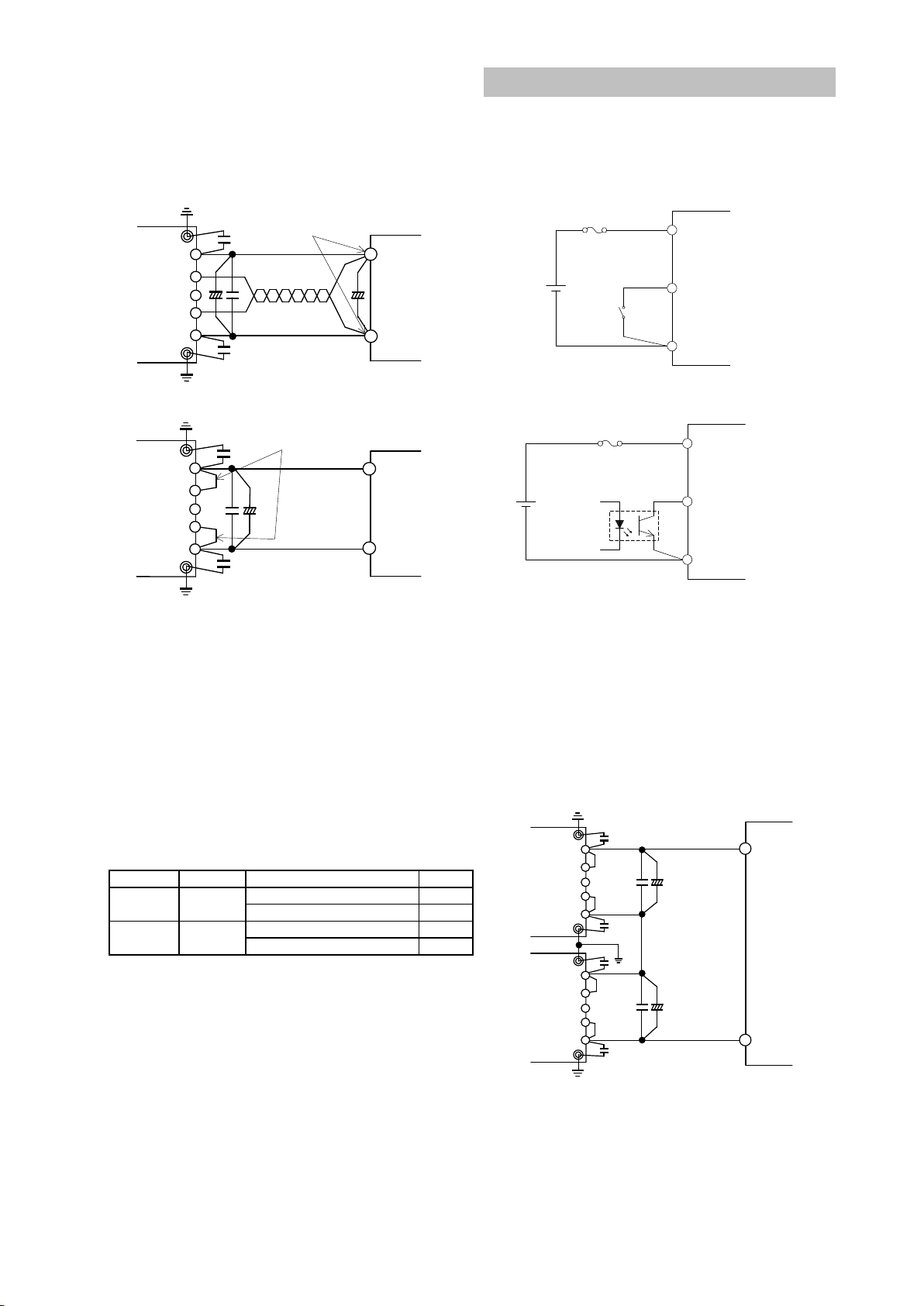

3. Maximum Ripple and Noise

Measured value according to the specified methods

based on JEITA-9141 (Clause 7.12 and clause 7.13)

which is described in the following.

Connect according to fig.3-1 and measure. Connect

capacitors (C2, C3: film capacitor or ceramic capacitor

0.022μF) between output terminals and the nearest

M3 threaded hole. Connect capacitors (C4: refer to

table 1-1 for electrolytic capacitor values, C5: ceramic

capacitor 0.1μF) at 50mm distance from the output

terminals. Measure at ceramic capacitor (C5) terminals

as shown in fig. 3-1 using coaxial cable with JEITA

attachment. Use oscilloscope with 100MHz frequency

bandwidth or equivalent.

Take note that output ripple voltage and output spike

noise may vary depending on PCB wiring design.

Generally, output ripple voltage and output spike

noise can be reduced by increasing capacitance value

of external capacitor.

JEITA Attachment

R:50Ω

C:4700pF

+

50mm

+V

-V

As short as possible

Coaxial Cable

1.5m 50Ω

C5

C4

R

C

C2

C3

Load

-S

+S

Fig.3-1 Measurement of Maximum Output Ripple &

Noise

4. Maximum Line Regulation

Maximum value of output voltage change when input

voltage is gradually varied (steady state) within

specified input voltage range.

5. Maximum Load Regulation

Maximum value of output voltage change when

output current is gradually varied (steady state) within

specified output current range.

When using at dynamic load mode, audible noise

could be heard from the power module and output

voltage fluctuation might increase. A thorough pre-

evaluation must be performed before using this power

module.

6. Over Current Protection (OCP)

This power module has built-in OCP function.

Output will recover when short circuit or overload

conditions are released. OCP setting value is fixed and

therefore, cannot be externally adjusted.

Also, take note that power module might be damaged

continuing output short circuit or over load conditions

depending on thermal conditions.

7. Over Voltage Protection (OVP)

This power module has built-in OVP function.

OVP set point is relative to the rated output voltage

value. OVP setting value is fixed and therefore, can not

be externally adjusted.

When OVP is triggered, output can be recovered by

turning input line off and then turning it on again after

lowering the input voltage below the voltage value

indicated below, or by manual reset of the CNT

terminal. Reset time for CNT terminal is 100ms or

longer.

OVP release input voltage value : 3VDC and below

When verifying OVP function by applying external

voltage at the output terminals, applied voltage value

should not exceed specified OVP maximum value.

Refer to specification table for OVP maximum value.

Avoid applying external voltage that exceeds OVP

maximum value because this will cause power module

damage.

8. Over Temperature Protection (OTP)

This power module has built-in OTP function.

This function operates and shuts down the output when

ambient temperature or internal temperature of power

module abnormally rises. OTP operates at 105℃ to

130℃ baseplate temperature. OTP can be released when

baseplate temperature drops down approximately to

within 80℃ to 95℃. However, take note that OTP will

operate again unless the cause of abnormal heat of the

power module is eliminated.

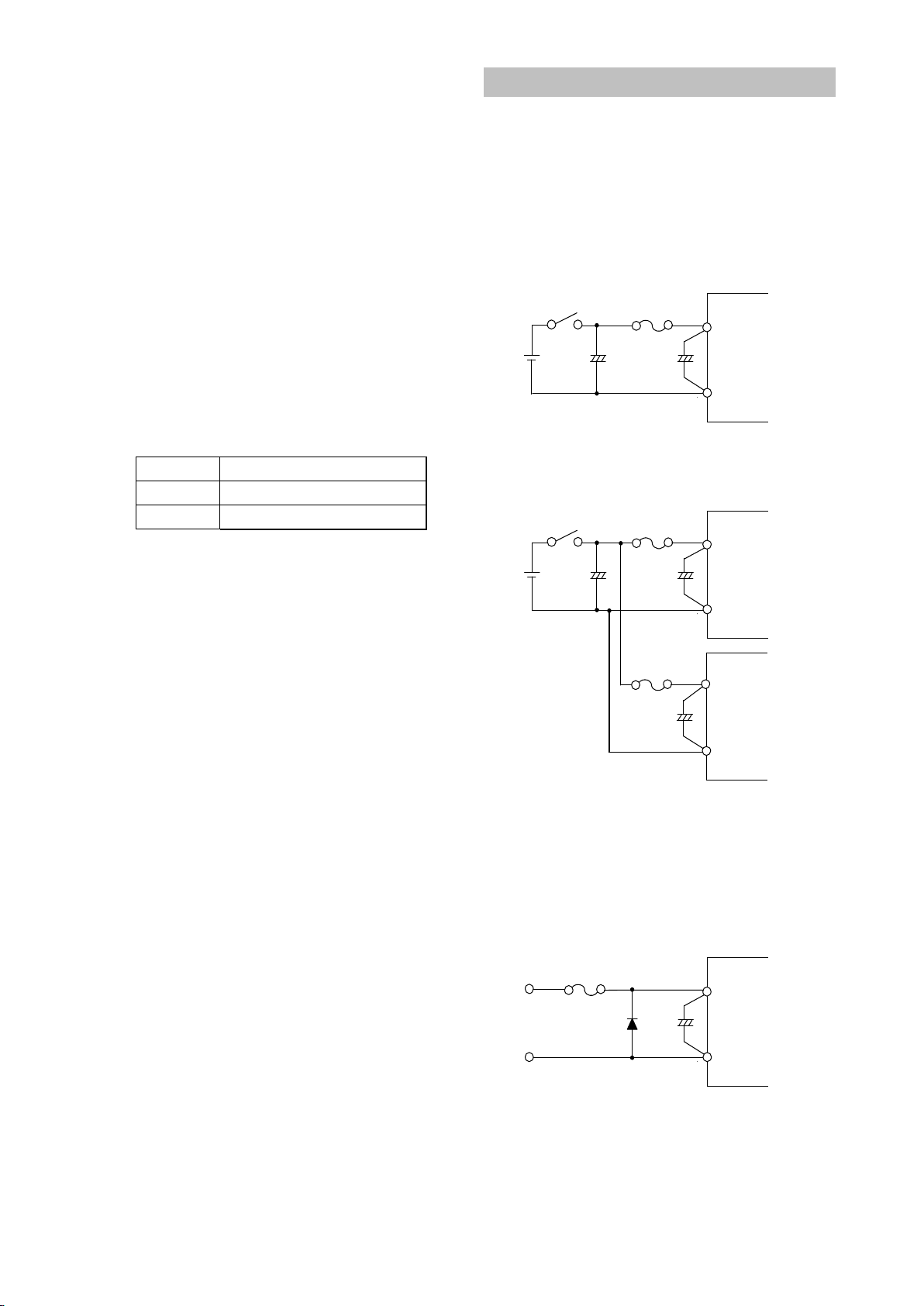

9. Remote Sensing (+S, -S terminal)

Remote sensing terminal is provided to compensate for

voltage drop across the wirings from the power module

output terminal to the load input terminal.

When remote sensing function is not used (local sensing),

short +S terminal to +V terminal and, –S terminal to –V

terminal.

Take note that voltage compensation range for line

drop (voltage drop due to wiring) is determined such

that output voltage at the output terminals is within

output voltage range and that voltage between –V and –

S terminals is within 2V or less. Even for remote

sensing case, use power module such that output power