Advance Data Sheet: FReta iEB Series –Single Output Eighth Brick Bus Converter

©2004-2007 TDK Innoveta Inc.

10/29/2007

9/12

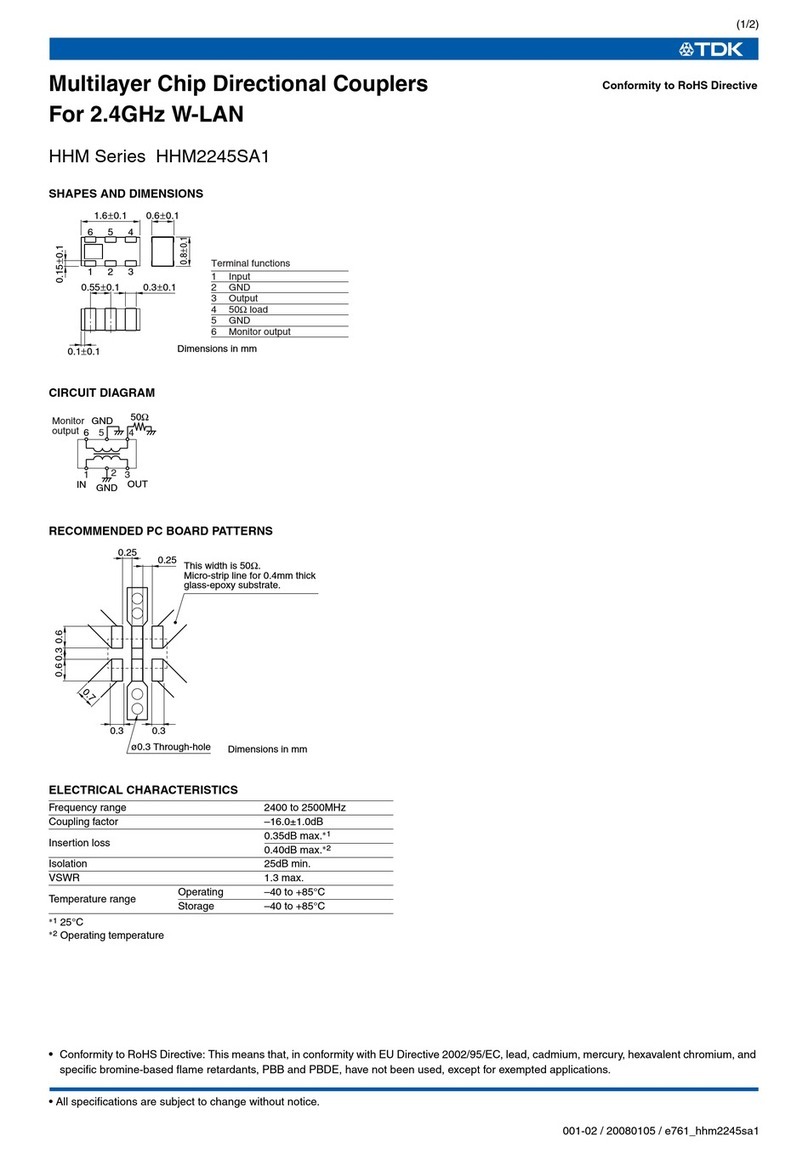

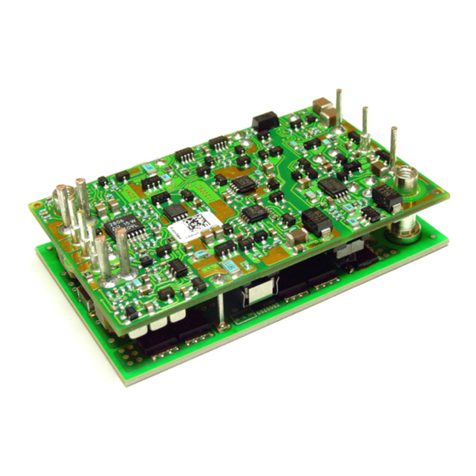

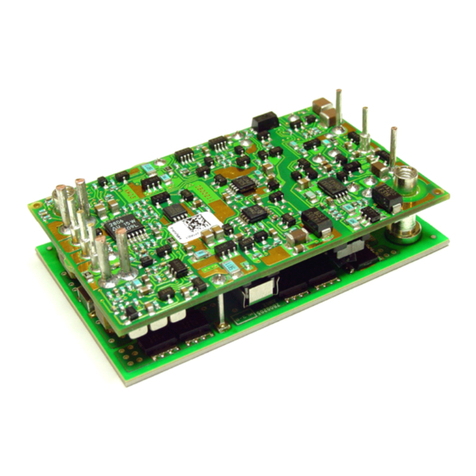

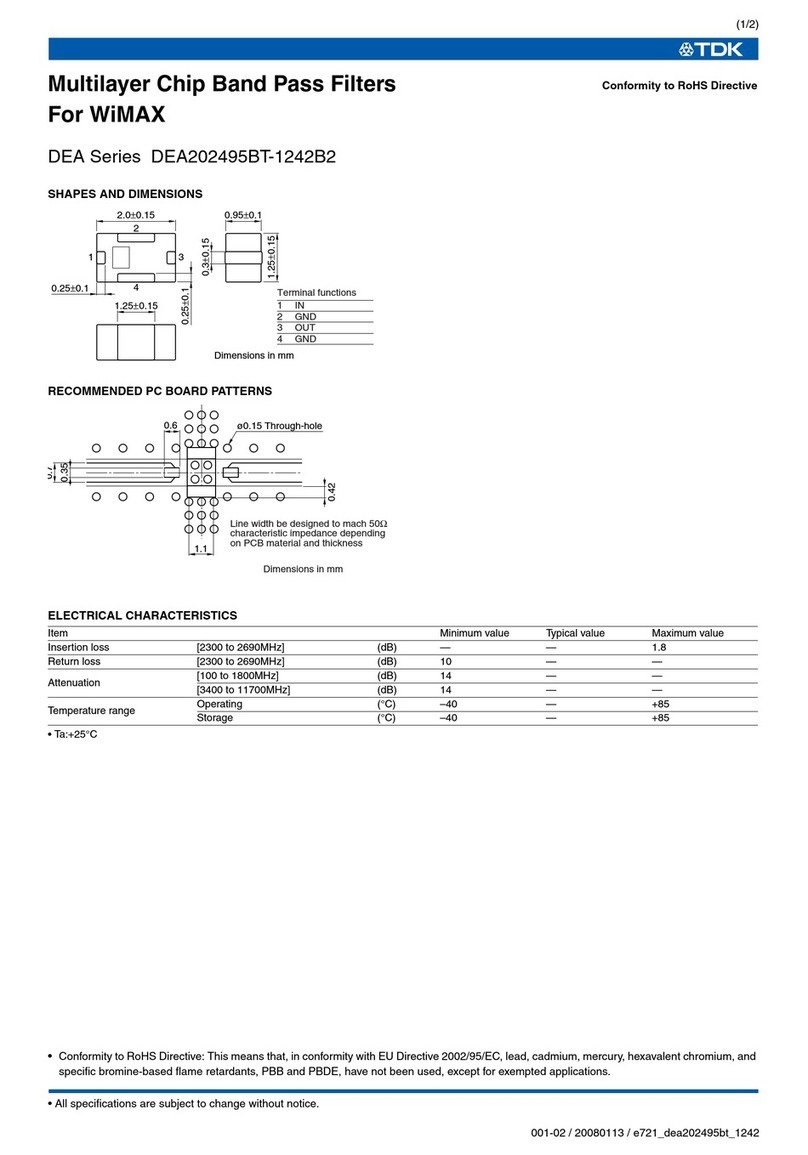

Wind Tunnel Test Setup Figure

Dimen ion are

in millimeter and (inche ).

Thermal Management:

An important part of the overall y tem

de ign proce i thermal management;

thermal de ign mu t be con idered at all

level to en ure good reliability and lifetime

of the final y tem. Superior thermal de ign

and the ability to operate in evere

application environment are key element

of a robu t, reliable power module.

A finite amount of heat mu t be di ipated

from the power module to the urrounding

environment. Thi heat i tran ferred by the

three mode of heat tran fer: convection,

conduction and radiation. While all three

mode of heat tran fer are pre ent in every

application, convection i the dominant mode

of heat tran fer in mo t application .

However, to en ure adequate cooling and

proper operation, all three mode hould be

con idered in a final y tem configuration.

The open frame de ign of the power module

provide an air path to individual

component . Thi air path improve

convection cooling to the urrounding

environment, which reduce area of heat

concentration and re ulting hot pot .

Test Setup: The thermal performance data

of the power module i ba ed upon

mea urement obtained from a wind tunnel

te t with the etup hown in the wind tunnel

figure. Thi thermal te t etup replicate the

typical thermal environment encountered in

mo t modern electronic y tem with

di tributed power architecture . The

electronic equipment in networking, telecom,

wirele , and advanced computer y tem

operate in imilar environment and utilize

vertically mounted PCB or circuit card in

cabinet rack .

The power module, a hown in the figure, i

mounted on a printed circuit board (PCB)

and i vertically oriented within the wind

tunnel. The cro ection of the airflow

pa age i rectangular. The pacing

between the top of the module and a parallel

facing PCB i kept at a con tant (0.5 in).

The power module’ orientation with re pect

to the airflow direction can have a ignificant

impact on the module’ thermal

performance.

Thermal Derating: For proper application of

the power module in a given thermal

environment, output current derating curve

are provided a a de ign

guideline on the Thermal Performance

ection for the power module of intere t.

The module temperature hould be

mea ured in the final y tem configuration to

en ure proper thermal management of the

power module. For thermal performance

verification, the module temperature hould

be mea ured at the component indicated in

the thermal mea urement location figure on

the thermal performance page for the power

module of intere t. In all condition , the

power module hould be operated below the

maximum operating temperature hown on

the derating curve. For improved de ign

margin and enhanced y tem reliability, the

power module may be operated at

temperature below the maximum rated

operating temperature.

AIRFLOW

Air Velocity and Ambient

Temperature

Mea urement Location

I

F

L

O

W

12.7

(0.50)

Module

Centerline

Air Pa age

Centerline

Adjacent PCB

76 (3.0)