Teba therm TP-05 User manual

Installation and User Manual

Model

TP-05 / TP-06 / TP-07 / TP-08/ TP-09

TP-10 / TP-11

Pellet Stove

Tested according to DIN EN 14785

E

N

TABLE OF CONTENTS

1. INTRODUCTION..............................................................................................................................................................3

2. FEATURES.......................................................................................................................................................................3

3. WARNING ......................................................................................................................................................................3

4. INSTALLATION AND CONNECTION ................................................................................................................................4

4.1 GENERAL..................................................................................................................................................................4

4.2 SAFETY .....................................................................................................................................................................4

4.3 ELECTRICITY .............................................................................................................................................................5

4.4 FLUE PIPE CONNECTION ......................................................................................................................................5

4.5 MINIMUM SAFETY DISTANCES ..........................................................................................................................10

5. CONTROL PANEL..........................................................................................................................................................11

5.1. ERROR CODE AND EXPLANATION.........................................................................................................................12

5.2. MENU FUNCTIONS................................................................................................................................................13

5.2.1 COMBUSTION FUNCTIONS MENU..................................................................................................................13

Level;........................................................................................................................................................................13

Auger Calibration;....................................................................................................................................................13

Fan Calibration;........................................................................................................................................................13

5.2.2. HEATING MANAGEMENT ..................................................................................................................................13

5.2.4. CHRONO MENU.............................................................................................................................................14

5.2.5. LOADING MENU............................................................................................................................................15

5.2.6. TIME AND DATE MENU..................................................................................................................................15

5.2.7. LANGUAGE MENU .........................................................................................................................................15

5.2.8. ENTRANCE MENU ..........................................................................................................................................15

5.2.9. SYSTEM (PARAMETERS) MENU .....................................................................................................................15

6. CLEANING AND MAINTENANCE...................................................................................................................................16

6.1 FLAME PIPES CLEANING.........................................................................................................................................18

6.2. COMBUSTION POT CLEANING ..............................................................................................................................18

6.3 ASH TRAY 1 AND ASH TRAY 2 CLEANING...............................................................................................................19

7. GENERAL WARRANTY AND POLICIES...........................................................................................................................19

1. INTRODUCTION

Pellet stoves are easy-to-use domestic heating appliances. They are fully automatic and

can be used inside the house. These indoor heating units combines pleasure with a

fireplace view.

You have a stove with European Standards Quality Certificate.

Please read the user manual, carefully.

It includes information on product functions and easy-to-use information.

Use of these informations increases the product quality and extend its life. You can

properly protect the fuel and the environment.

Warranty of the product depends on the right use of installation and instructions as

described in the guide.

We recommend you to keep this guide in order to reach the information about the correct

use of the stove at the beginning of every winter.

2. FEATURES

TECHNICAL

FEATURES

TP-05

TP-06

TP-07

TP-08

TP-09

TP-10

TP-11

Power (kW)

8

9

9,8

10

10

10

18

Flue pipe

diameter

80 mm

80 mm

80 mm

80 mm

80 mm

80 mm

80 mm

Pellet

storage

capacity

15 KG

15 KG

15 KG

15 KG

10 KG

20 KG

20 KG

Efficiency

89,4 %

88,1 %

88,1 %

92 %

90 %

89,5 %

93 %

Electric

230 V-

50Hz

230 V-

50Hz

230 V-

50Hz

230 V-

50Hz

230 V-

50Hz

230V-

50Hz

230 V-

50Hz

Weight

73 kg

75 kg

78 kg

128 kg

101 kg

148 kg

207 kg

3. WARNING

●USE ONLY 6MM NATURAL PELLETS MANUFACTURED ACCORDING TO DIN PLUS

STANDARTS.

●DO NOT USE 8MM OR 10 MM PELET, OLIVE SEEDS, CHERRY SEEDS, HAZELNUT

SHELL ETC.

●CLEAN THE FIRE POT EVERYDAY.

●AT THE END OF THE WINTER, GENERAL MAINTENANCE AND CLEANING MUST BE

CARIED OUT AND THE FUEL STORAGE MUST BE EMPTIED.

●DAMAGES CAUSED BY USING INAPPROPRIATE PELLET AND NON-REGULAR

CLEANING ARE NOT COVERED BY WARRANTY.

●SMOKE AND SMELL IS NORMAL AT FIRST USING. JUST VENTILATE THE ROOM.

●DO NOT TOUCH PAINTED PARTS DURING OPERATION TO AVOID DAMAGING ON

PAINT.

●THE PROBLEMS CAN BE OCCURED IN CASE WRONG/LOW QUALITY PELLET

USING AND CLEANING IS NOT MADE, ARE NOT COVERED BY THE WARRANTY.

4. INSTALLATION AND CONNECTION

4.1 GENERAL

All the inspections for the pellet stove are done according to the stipulated standards. It

complies with the prescribed parameters related to combustion efficiency and flue gas

emissions. The product mentioned in this manual has been tested by the approved bodies

according to EN 14785 Standard.

The packaging of the stove protects the product from damage in the best possible way.

However, the stove or its accessories may still be damaged during transport. Therefore,

after removing the stove from the package, check whether it is complete and undamaged.

In case of any damage, notify your dealer. If dealer or manufacturer are not informed

about the damage and not presented the proof, the damages are not covered by the

warranty.

4.2 SAFETY

* Product must be installed by an authorized person.

* Before installing the product, it should be determined whether the bearing capacity of

the floor to be installed is durable to the product. In case of insufficient bearing capacity,

appropriate measures should be taken. If the floor where the stove is to be installed is

flammable or heat-sensitive, you should place a base (eg marble or glass base).

* Care must be taken to ensure that the ventilation conditions of the place where the

product is installed.

* The pellet stove can operate in conjunction with the existing multiple chimneys. In

addition, the stove should not be connected at places such as the aspirator chimney and

ventilator.

* Chimney must be cleaned at least twice a year.

* Product needs to be connected to the chimney with a shortest distance.

* In order to get better heat efficiency and extend the life of the product, qualitative pellet

and wood fuel should be preferred. Do not use moist or wetted pellet, sawdust, coal etc.

* Since the pellet stoves are designed according to the interior spaces and give heat to the

environment, they should not be installed in places such as bathrooms, shelter, cellar.

And they should not be used for cooking.

4.3 ELECTRICITY

The electricity must be 230V / 50 Hz 10A.

Our company is not responsible for any damage that may occur in case of any voltage

drop or rise. We recommend taking necessary measures as it does not include the

warranty.

4.4 FLUE PIPE CONNECTION

We recommend the use of twin(double) wall or twin(double) wall insulated system for

chimney connection.

•In the interior spaces, by using twin wall chimney system, exhaust gas can be throughed

out to the outside, at the same time fresh air provided to inside. Twin insulated chimney

should be used on the outside.

•In the interior spaces, by using twin wall insulated chimney system, exhaust gas can be

throughed out to the outside. In this case, you can provıde fresh air by additional pipe

and elbow.

•To provide fresh air easily, a vent should be used on the nearest window where stove is

installed.

•Chimney or twin wall insulated chimney, should be at least 80 cm higher than the highest

point of the roof.

•Use rain cap or wind cowl at the end of the chimney to avoid to come inside

anything(bird,etc…). Distance between raincap and chimney end should be 30-40 cm.

•The pellet stove can operate in conjunction with the existing multiple chimneys. In

addition, the stove should not be connected at places such as the aspirator chimney

and ventilator.

•The chimney can be given directly out of the pellet stove at a short distance, or it

can be connected to the existing chimney at short distance.

ATTENTION !!!

THE PIPE AND ELBOWS USED UP TO THE CHIMNEY OUTPUT AND INPUT NEEDS TO BE THE SAME

DIAMETER. BY THE INPUT OF THE CHIMNEY A REDUCTION MUST BE USED. MAXIMUM 4 METERS

PIPES AND 2 ELBOWS NEEDS TO BE USED. PIPE JOINTS SHOULD BE TAPED TO CONNECTOR OR

ALUMINUM BAND.

ROOM THERMOSTAT

CONNECTION POINT

TP-05 / TP-06 / TP-07

TP-08

TP-09

TP-10

TP-11

4.5 MINIMUM SAFETY DISTANCES

A50 cm from rear wall

B40 cm from lateral wall

C100cm from front side

Flammable materials and

furniture should not be

placed at a distance of 100

cm in the radiation area

(C) of the flame

monitoring cover.

While installing the stove, the fire regulations and chimney’s instructions must be complied.

For any related questions please ask the chimney provider. Minimum distances to be

observed in flammable or heat-sensitive materials (eg furniture, wallpaper, wood panels)

(see diagram above) are:

This distance can be reduced to 40 cm when the protection panel is placed between the

stove and the materials that are likely to burn.

Minimum distances for flammable materials and furniture are indicated on the product

label and must not be exceeded. If the floor where the stove is to be installed is flammable

or heat-sensitive, you should place the product on the ground protection plate (eg marble

or glass base).

5. CONTROL PANEL

FUNCTIONS

BUTTONS

DESCRIPTION

S

EXIT

Use P1 to exit from menu or submenu and to

return previous menu

P1

ON- OFF

Wait for 3 seconds by touching the P2 to

switch on and off

P2

RESET

(Er05) Wait for 3-4 seconds by touching the P2

to reset the error code

MENU

ENTRANCE

Use the P3 to access the menus

P3

SUBMENU (

ENTRY )

Use the P3 to enter a submenu in the current

menu.

SAVE

Use the P3 to save data or values in the

current submenu.

MENU

CHANGE

Use the P4 and P6 s to switch between menus,

submenus data and values. When the P6 is

touched on the home screen the chimney

temperature - room temperature - air speed -

the chimney fan, auger speed will be shown.

P4

P6

SUB MENU

CHANGE

TIME SLOT

ACTIVATION

After the adjustment of time, the selected

time slot will be activated by P5.

P5

5.1. ERROR CODE AND EXPLANATION

NOTE: When you encounter the error codes, firstly be sure stove and parts don’t work.

You will see “BLOCK”on the screen. After checking and correcting the following

connection, parts and values according to the error code, the error code must be

cleared by -pressing the P2 for 3 seconds. When the error code is erased, contact your

dealer for any malfunctions that persist.

Error

code

Explanation

Solution

Er01

Safety limit thermostat error -

overheating of fuel chamber

(over 90°)

In the first screen when the stove display starts

to work, ER01 may be encountered. Push

button to delete the error code. Check the

sanitary valves and pump. Push the black tip of

the safety limit thermostat inside, which is on

the back side of the boiler.(see pg.9)

Er02

Chimney emmission safety

switch error

Check chimney connections and chimney

emmission. Be sure chimney and second ash

tray is clean

Er03

Chimney outlet temperature

drop or auger failure

Check if there is fuel in the combustion

chamber and whether the fuel is supplied by

the coil.

Er05

Chimney outlet over

temperature error / flue

temperature sensor error or

cleaning error

This error occurs when the calibration values

are increased or when the general cleaning

time is reached. Please give a general cleaning

of the product.

Er07

Chimney emmission fan motor

error

Check that your chimney is not clogged and

reset it. Be sure chimney and second ash tray is

clean. If the error still persists, contact your

dealer.

Er08

Chimney emmission fan motor

encoder error

Reset the product, contact your dealer if the

error still persists.

Er11

Date and Time Error

Check the date and time

Er12

Ignition failure error

This error can occur due to pot pullution or

resistanse, check the resistance and clean the

pot.

Er15

Safety Low Voltage

Check voltage fluctuation

Er16

Display - Motherboard

connection error

Check the display and the cable between

display and control board.

5.2. MENU FUNCTIONS

Touch the P3 button to enter the user menu. The following menus will appear on

the screen.

Combustion Management

Heating Management

Remote control

Chrono

Loading

Press P3 for 3 seconds to enter the input menu, the following menu will appear on the

screen.

Input settings

Home menu

System menu

Use the P4 and P6 buttons to switch between menus. Use the P3 button

to access the desired menu.

5.2.1 COMBUSTION FUNCTIONS MENU

Touch the P3 button to enter the submenu. You can enter the Combustion

Management menu again with the P3 button. In the Combustion Management menu, there

are Level, Auger Calibration and Fan Calibration menus.

Level;

In this menu, the pellet combustion speed can be changed with the help of P4 and P6 buttons.

Ex: 1 - 2 - 3 - 4 - 5 –6 - A (A = Auto) Use P3 to save.

Auger Calibration;

Enter the pellet loading speed settings with P3. Use P4 and P6 to slow the pellet

loading speed or adjust the acceleration values in the display ( +7…0…-7 ). Use P3 to save.

Use P1 ESC to exit the menu.

Fan Calibration;

Enter with the P3 button for fan speed control. Use P4 and P6 to slow down the chimney fan

speed or set acceleration values in the display ( +7…0…-7 ). Use P3 to save. Use P1 ESC to exit

the menu.

5.2.2. HEATING MANAGEMENT

Press the P3 button to enter the submenu. You can enter the Heating Management menu

again with the P3 button. Boiler thermostat, heating power and summer-winter menus

are avaliable in the Heating Management menu.

5.2.3 REMOTE CONTROL MENU

Remote control is not available

5.2.4. CHRONO MENU

Press the P3 button to enter the menu. The display shows the chrono management

menu. Enter the modality menu by touching the P3 button. The

screen on the right-up will appear. In the chrono menu, the daily /

weekly / weekend time settings are usually switched on / off. When

turned on, the display will show the time in the left corner and nothing

will be visible in the closed position. When the P2 button is pressed in

the modality menu, the timer can be set to ON or OFF. To select daily, weekly or weekend

programming and to set the clock, the timer menu must be entered with the P3 button.

When programming needs to be done, the steps in the table below should be followed. 3

time slot opening and 3 time slot shutdowns can be programmed for each day. To set each

time slot, use the P3 menu button to flash the time slot on the display and the P4 and

P6 buttons to increase or decrease the time.

After choosing the time slot selection, activate it with P5 button (when it becomes

actived, there will be a “√” sign on the right side. Use P3 menu button to save and

use P1 ESC to exit each step.

Example: DAILY PROGRAMMING

Daily

Monday

Monday

Weekly

Tuesday

OPEN CLOSE

Weekend

Wednesday

09.30 11.15 √

Thursday

00.00 00.00

Friday

00.00 00.00

Example: WEEKLY PROGRAMMING

Daily

Monday- Sunday

Weekly

OPEN CLOSE

Weekend

09.30 11.15 √

00.00 00.00

00.00 00.00

Example: WEEKEND PROGRAMMING (MONDAY-FRIDAY OR SATURDAY- SUNDAY

Daily

Monday- Friday

Monday - Friday

Weekly

Saturday- Sunday

OPEN CLOSE

weekend

10.00 12.15 √

14.00 16.00 √

00.00 00.00

OFF

Daily

Weekly

Weekend

5.2.5. LOADING MENU

Press the P3 button to enter the submenu. It will manually load the pellet when it

is turned ON with the P4 button. Pellet loading will stop by selecting OFF mode. Use

P1 ESC to exit. (This is only a process to fill the pot and accelerate the ignition during the

first burning phase when the product is in the OFF mode.

5.2.6. TIME AND DATE MENU

Press the P3 button to enter the submenu. The time setting menu appears first.

Press the P3 button again to set the current time. The numbers will flash and use

P4 and P6 to change the digits. After setting, press the P3 button. Use the

P4 button to move to the minute setting side. Login with the P3 button for the

current minute setting. The numbers will flash. Use P4 and P6 to change

numbers. After setting, save it with P3. After the time setting is completed, P4

button changes to day / month / year. Press P3 to enter. The display will flash. Use

P4 and P6 to change numbers. Press P3 to set the time according to the

order in the setup menu. Use P1 ESC to exit.

5.2.7. LANGUAGE MENU

Press the P3 button to enter the submenu. The P4 and P6 buttons are the

preferred language. Sample; Turkish P3 button to save. Use P1 ESC to exit.

5.2.8. ENTRANCE MENU

Press the P3 button to enter the submenu. The following screen will appear

Contrast

Used to adjust the screen sharpness.

Minimum Light

Login Address

Network List

Acoustic Alarm

Used to adjust the display illumination

Not used

Not used

Not used

5.2.9. SYSTEM (PARAMETERS) MENU

FOR AUTHORIZED SERVICE.

OUR COMPANY IS NOT RESPONSIBLE FOR ANY DAMAGES İN CASE USER ENTERS IN

SYSTEM MENU AND CHANGE THE PARAMETERS

6. CLEANING AND MAINTENANCE

TP-05 / TP-06 / TP-07

TP-08

TP-09

TP-10

TP-11

Sections to clean

Cleaning Frequency

Flame Transmission Channels

Cleaning

Average 15 days

Firepot Cleaning

Daily

Ash tray 1 Cleaning

Daily

Ash tray 2 Cleaning

Average 20-30 dyas

6.1 FLAME PIPES CLEANING

For the cleaning of the flame transmission channels, the combustion wall behind the

firepot should be removed by taking screws out. Clean the flame channels and put the

part where its place.

6.2. COMBUSTION POT CLEANING

Open the door and be careful about ashes not come out. Be sure stove is cold and closed.

You can clean the firepot with vaccum cleaner firstly and use brush later. You should

clean it daily.

6.3 ASH TRAY 1 AND ASH TRAY 2 CLEANING

The ashtray 1 and ashtary 2 which is placed under or behind(according to the model) the

firepot is easy-to-replace. When you pull them, they will be moved out easily. You should

clean ash tray 1 daily, ash tray 2 once in 20 days.

7. GENERAL WARRANTY AND POLICIES

ARAL MAKİNA MADENİ EŞYA SAN. VE TİC.LTD. ŞTİ provides warranty to the buyer

within the framework of legal provisions. 2 (two) year warranty period starts from the

actual delivery date. An invoice must be presented for inclusion in the warranty.

In case of any damage related to production in our product, our company will try to repair

this damage as soon as possible within the warranty period or it will replace the

problematic part. Only spare parts approved or supplied by the manufacturer must be

used.

After the warranty period, our company will continue to serve you in the necessary

conditions.

You are kindly requested to inform the relevant dealer where you have purchased the

product from with the model number printed on the label on the back of the product.

The company reserves the right to make changes to the product after publication of this

manual.

Malfunctions resulting from the use of the product contrary to the matters stated in the

user manual are not covered by the warranty

Glass, cast irons, electric current high/low voltage resulted to a digital card failure,

user errors are not covered by the warranty.

Our company is not responsible for any damages during transport, in case dealer or

manufacturer are not informed about itand not presented the proof.

Our company is not responsible for any damage that may occur in case of any voltage

drop or rise.

Our company is not responsible for any damages in case user enters in system menu and

change the parameters.

The damages can be occured in case cleaning and maintenance are not made are not

covered by the warranty.

PRODUCER

AUTHORIZED

Company Name : Aral Makina

Madeni Eşya San. Ve Tic.Ltd. Şti

Address : Organize Sanayi Bölgesi

8.Cad. No: 16 Melikgazi / KAYSERİ

Tel : +90 0 352 321 28 11

Fax : +90 0 352 321 28 14

Sign / Stamp

Company Name

Address :

Tel :

Fax :

E- posta :

Sign / Stamp

User Informations

Name –Surname

Address

Tel

E-posta

Model

Barkod / Seri No

Warranty

2 Years

Starting Date of Warranty

This manual suits for next models

6

Table of contents

Other Teba therm Stove manuals

Popular Stove manuals by other brands

Bronpi

Bronpi Londres-V instruction manual

Harman Home Heating

Harman Home Heating MARK III Installation and operating manual

MCZ

MCZ SUITE COMFORT AIRMATIC 12 M3 CORE installation guide

Napoleon

Napoleon Arlington GDS20N Installation and operating instructions

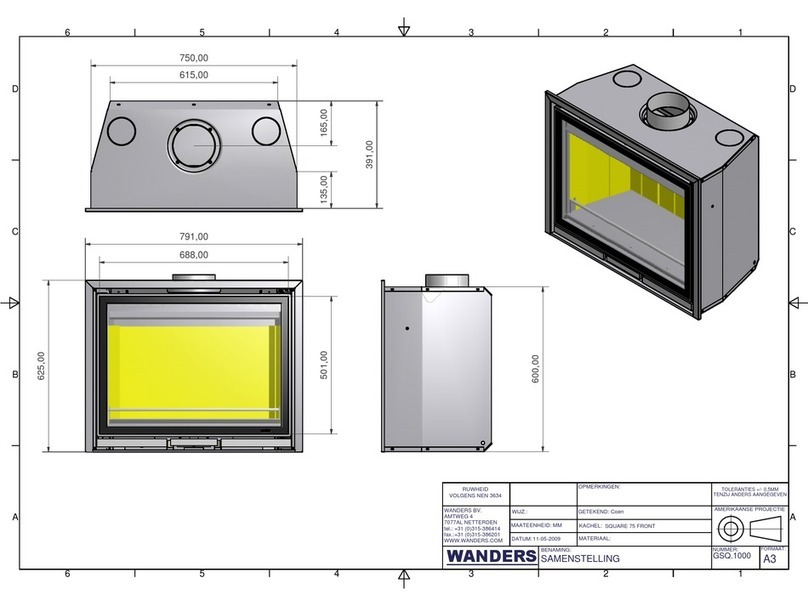

WANDERS

WANDERS SQUARE 75 manual

Bilberry Stoves

Bilberry Stoves 5kW Stove Installation & operating instructions