CONNECTING YOUR

LP

GAS

TANK

NOTICE:

A FIRE EXTINGUISHER FOR CLASS

A,

B, C & D FIRES SHOULD BE READILY

AVAILABLE AT ALL TIMES.

WARNING:

FAILURE TO FOLLOW THE ABOVE

PRECAUTIONS COULD RESULT

IN

A FIRE CAUSING

DEATH OR SERIOUS INJURY OR PROPERTY DAMAG

E.

NOTICE:

FOR YOUR SAFETY. ONLY USE THE

REGULATOR AND HOSE ASSEMBLY PROVIDED

WITH YOUR GRILL OR,

IF

REPLACEMENT PARTS

ARE NECESSARY, USE ONLY TEC-SPECIFIED

REPLACEMENT PARTS.

WARNING: A MINIMUM OF

12

INCHES OF

CLEARANCE MUST BE MAINTAINED ON ALL

SIDES OF THE UNIT TO THE LP GAS SUPPLY

TANK WHEN USING THE REGULATOR WITH

HOSE ASSEMBLY. KEEP THE FUEL SUPPLY HOSE

AWAY FROM HEATED SURFACES. THE LP GAS

SUPPLY TANK MUST BE LOCATED IN A SAFE

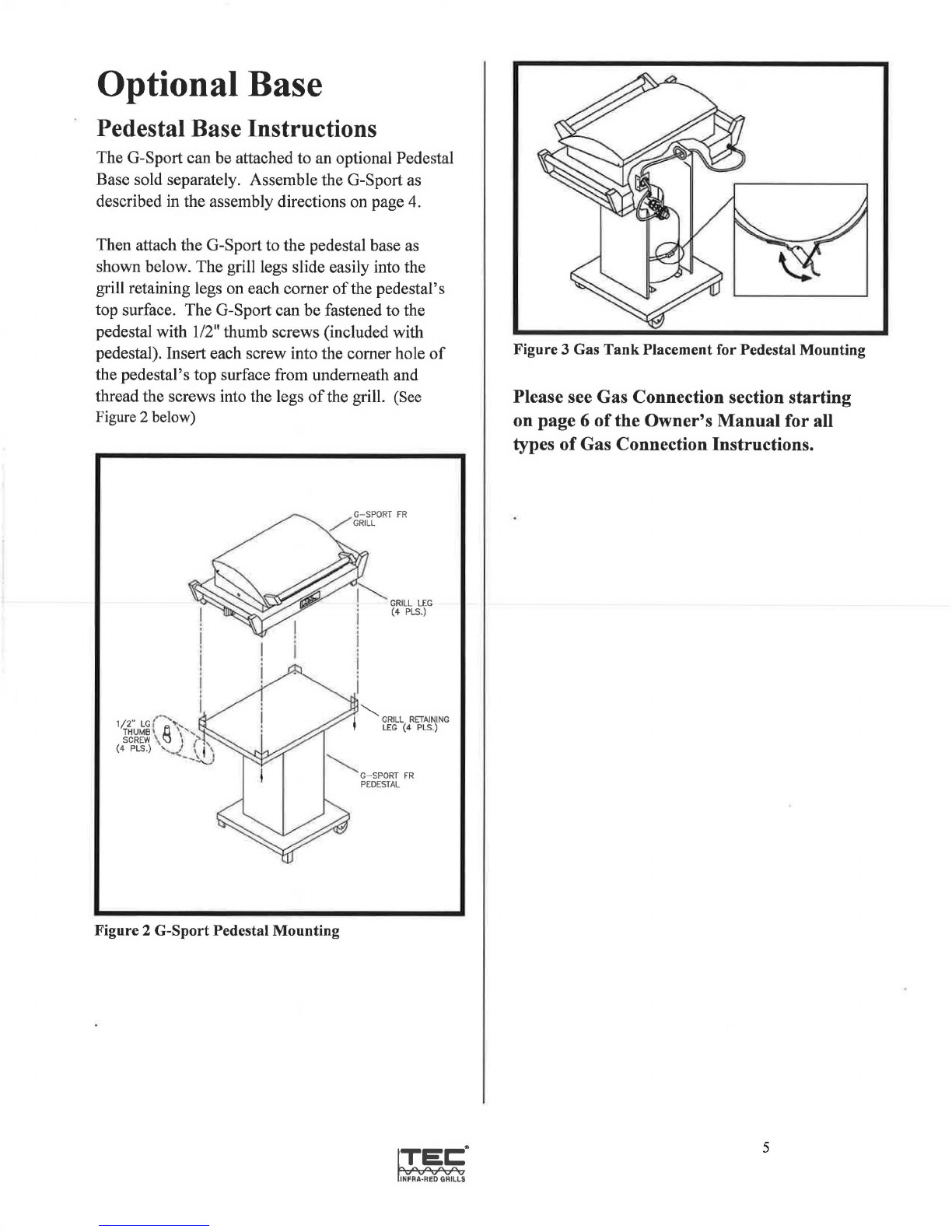

POSITION TO PREVENT TIPPING. (See Figures 5 and

6)

NOTICE:

THE GAS MUST BE TURNED OFF AT

THE SUPPLY TANK AND THE GAS TANK MUST

BE DISCONNECTED FROM THE REGULATOR

WHEN THE GRILL

IS

NOT IN USE.

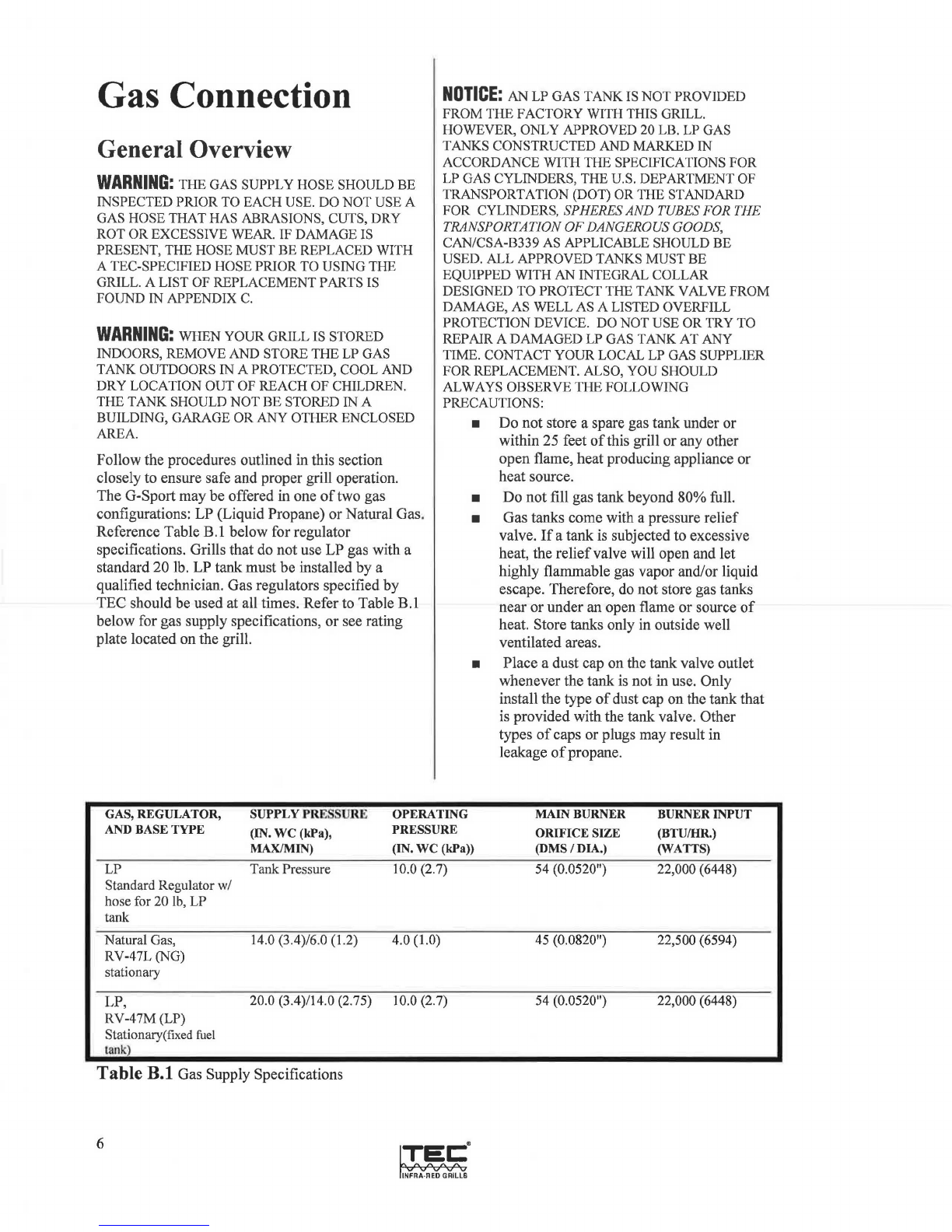

Procedure

for

20

lb.

LP

Tank

Connection:

1.

Inspect the Grill to make sure the Burner Control

Knob

is

in the "OFF" position and Grill is on a level

surface.

2. Make sure the valve

of

the

LP

Gas

Tank

is

fully

closed; tum the Hand Wheel clockwise until it stops.

3. Check tank valve to insure it has proper external

mating threads; must be TYPE 1

to

match TEC

supplied regulator.

4. When using the grill

as

a Portable or Tabletop

model, place the

LP

Gas

Tank

in

a safe and upright

position maintaining

12

inches

of

clearance on

aU

sides and locating the tank and hose

in

a position to

prevent tipping. (See Figure 5) When using the grill

with the optional base attached, place the tank in the

space provided in the base and secure the tank with

the tank strap latch assembly.

5.

Remove the protective cap from the Tank Valve

Outlet on the

LP

Gas

Tank.

Inspect the entire

valve assembly for any damage, dirt or debris.

Remove dirt or debris or replace LP Gas Tank

if

the

valve assembly is damaged. (See Figure 4

Regulator/LP Tank Assembly)

6.

Inspect the Coupling Nut and Nipple

of

the Grill

Regulator

with

Fuel

Supply Hose for any damage,

dirt or debris. Remove dirt or debris or replace the

Regulator with Fuel Supply Hose,

if

damaged, with

a TEC specified replacement part. (See Figure 4)

7.

Remove the protective cover from the Grill

connection at the back

of

the grill. For Portable and

Tabletop use, attach the hose end

of

the regulator to

the grill using the Quick Disconnect Instructions

found on Page 8. When attaching the grill to the

optional Pedestal Base, place the fuel supply hose

through the LP Hose Support Bracket on the back

of

the Pedestal just above the tank taking care to avoid

all contact with the drip tray. (See Figure 6) Then

place the hose through the hole

in

the right side

of

the Pedestal and attach the hose end

of

the regulator

to the appliance connection at the back

of

the grill

using the Quick Disconnect Instructions found on

Page

8.

8.

With the Grill

Regulator

with Fuel supply Hose in

your hand, insert the Nipple into the Tank Valve

Outlet. Make sure the Nipple is centered

in

the Tank

Valve Outlet. Tighten the Coupling Nut by hand,

making sure not

to

cross-thread the connection.

Please note that when you connect your tank

to

the

grill, you will feel the nipple seal when there

is

slight resistance. Turn until the Coupling Nut will

turn no further (about one-halfto three-quarters

of

a

turn)

to

complete the connection. Tighten only by

hand;

do

not use tools.

If

you cannot complete the

fmal connection, disconnect the Coupling Nut and

repeat step

7,

above.

Ifyou

are still unable to

complete the connection, replace the appropriate

parts.

9.

Open tank valve fully by turning the Hand Wheel

counterclockwise. Use a soapy solution to check all

connections for leaks before lighting grill.

If

a leak

is

found, turn tank valve

off

by turning the Hand

Wheel clockwise and do not use grill until repairs

can be made by qualified LP Gas technician.

~VALVE

OULET

COUPUNG

NUT

Figure 4 Regulator/LP

Tank

Assembly

7