7

Gas Connection

General Overview

WARNING:

THE GAS SUPPLY HOSE SHOULD BE

INSPECTED PRIOR TO EACH USE. DO NOT USE A

GAS HOSE THAT HAS ABRASIONS, CUTS, DRY ROT

OR EXCESSIVE WEAR. IF DAMAGE IS PRESENT, THE

HOSE MUST BE REPLACED WITH A TEC-SPECIFIED

HOSE PRIOR TO USING THE GRILL. LISTS OF

REPLACEMENT PARTS ARE FOUND IN APPENDIX C

AND D.

WARNING:

WHEN YOUR GRILL IS STORED

INDOORS, REMOVE AND STORE THE LP GAS

CYLINDER OUTDOORS IN A PROTECTED, COOL AND

DRY LOCATION OUT OF REACH OF CHILDREN. THE

CYLINDER SHOULD NOT BE STORED IN A BUILDING,

GARAGE OR ANY OTHER ENCLOSED AREA.

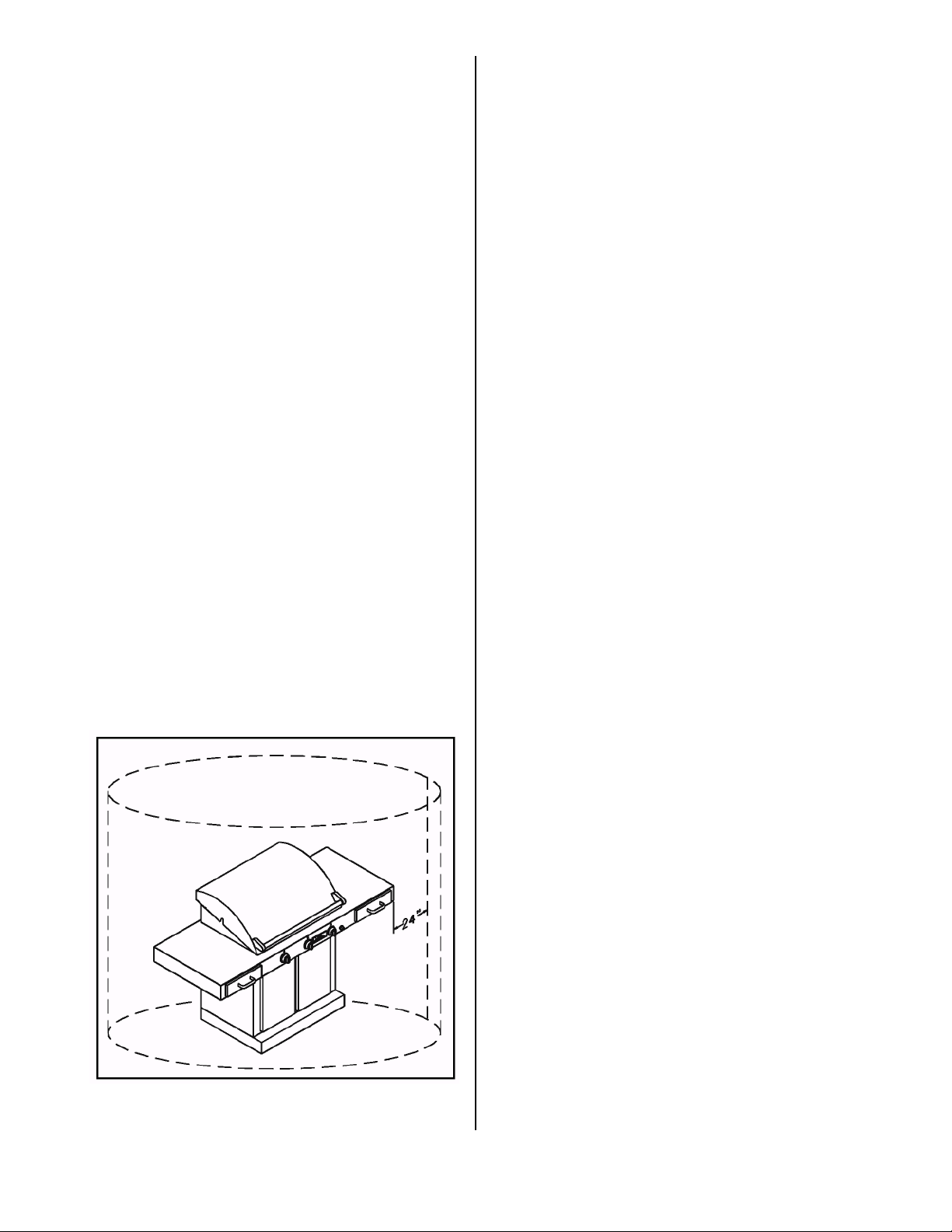

Follow the procedures outlined in this section closely to

ensure safe and proper grill operation. The Sterling FR

and the Sterling G-Series grills are offered in one of two

gas configurations: LP (Liquid Propane) or Natural gas.

Reference Table A.1 below for regulator specifications.

Grills that do not use LP gas with a standard 20 lb. LP

cylinder must be installed by qualified personnel. This

includes all Natural gas and permanently installed units

as well as LP Bulk Tank installations. Gas regulators

specified by TEC must be installed and used at all times.

Refer to Table A.1 below for gas supply specifications,

or see rating plate located on the grill.

LP Gas Cylinder Safety

WARNING:

WHEN PURCHASED FOR USE WITH LP

GAS, THE STERLING AND STERLING G-SERIES

GRILLS COME WITH A REGULATOR ASSEMBLY

THAT USES A TYPE 1 CYLINDER CONNECTION

DEVICE. THIS DEVICE MUST BE USED WITH A TYPE

1 VALVE CYLINDER CONNECTION.

NOTICE:

AN LP GAS CYLINDER IS NOT PROVIDED

FROM THE FACTORY WITH THIS GRILL. HOWEVER,

ONLY APPROVED 20 LB. LP GAS CYLINDERS

CONSTRUCTED AND MARKED IN ACCORDANCE

WITH THE SPECIFICATIONS FOR LP GAS

CYLINDERS OF

THE U.S. DEPARTMENT OF TRANSPORTATION

(D.O.T) OR NATIONAL STANDARD OF CANADA,

CAN/CGA-B339, CYLINDERS, SPHERES AND TUBES

FOR THE TRANSPORTATION OF DANGEROUS

GOODS; AND COMMISSION, AS APPLICABLE

SHOULD BE USED. ALL APPROVED CYLINDERS

MUST BE EQUIPPED WITH AN INTEGRAL COLLAR

DESIGNED TO PROTECT THE CYLINDER VALVE

FROM DAMAGE, AS WELL AS A LISTED OVERFILL

PROTECTION DEVICE. DO NOT USE OR TRY TO

REPAIR A DAMAGED LP GAS CYLINDER AT ANY

TIME. CONTACT YOUR LOCAL LP GAS SUPPLIER

FOR REPLACEMENT. ALSO, YOU SHOULD ALWAYS

OBSERVE THE FOLLOWING PRECAUTIONS:

gDo not store a spare gas cylinder under or within 15

feet of this grill or any other open flame, heat

producing appliance or heat source.

gDo not fill your gas cylinder beyond 80% full.

gGas cylinders come with a pressure relief valve. If a

cylinder is subjected to excessive heat, the relief

valve will open and let highly flammable gas vapor

and/or liquid escape. Therefore, do not store gas

cylinders near or under an open flame or source of

heat. Store cylinders only in outside well ventilated

areas.

gPlace a dust cap on the cylinder valve outlet

whenever the cylinder is not in use. Only install the

type of dust cap on the cylinder that is provided with

the cylinder valve. Other types of caps or plugs may

result in leakage of propane.

WARNING:

FAILURE TO FOLLOW THE ABOVE

PRECAUTIONS COULD RESULT IN A FIRE CAUSING

DEATH OR SERIOUS INJURY OR PROPERTY

DAMAGE.

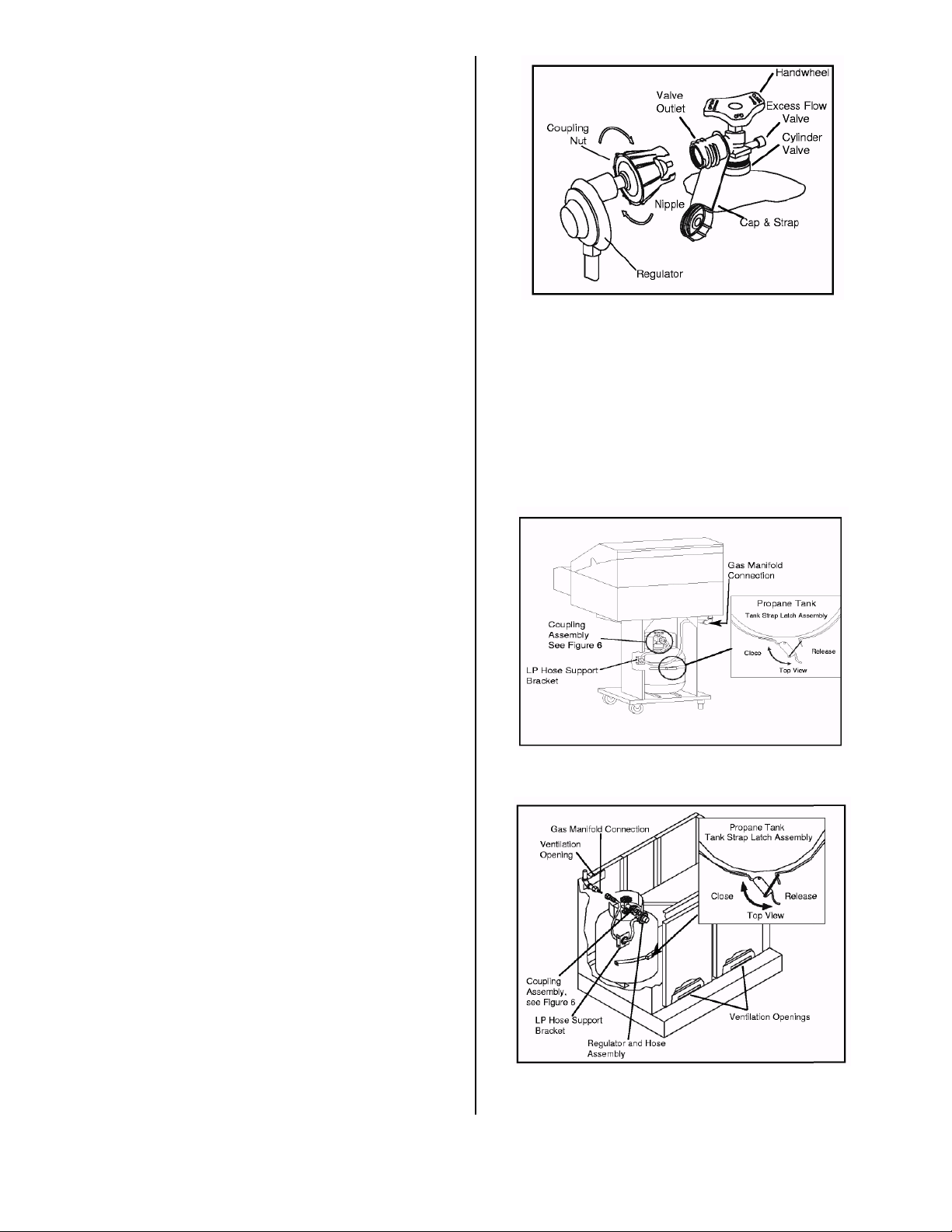

Installing Your LP Gas

Cylinder

NOTICE:

FOR YOUR SAFETY, ONLY USE THE

REGULATOR AND HOSE ASSEMBLY PROVIDED AS

ORIGINAL EQUIPMENT WITH YOUR GRILL OR, IF

REPLACEMENT PARTS ARE NECESSARY, USE ONLY

TEC-SPECIFIED REPLACEMENT PARTS.

GAS, REGULATOR AND

BASE TYPE

SUPPLY PRESSURE

(IN. WC (kPa),

MAX/MIN)

OPERATING

(kPa)

MAIN BURNER

ORIFICE SIZE

(DMS/DIA.)

BURNER INPUT

(BTU/HR. (W)/EA.)

Natural model RV-

stationary 14.0 (3.4)/5.0 (1.2) 4.0 (1.0) 49 (0.0730") 17,000 (4,983)

LP model RV-47L (LP)

stationary (LP Bulk Tank) 14.0 (3.4)/12.0 (3.0) 10.0 (2.7) 56 (0.0465") 16,000 (4,983)

LP (20 lb Tank) 125 psi (861), max 10.0 (2.7) 56 (0.0465") 16,000 (4,983)

Table A.1. Gas Supply Specifications