EU – 401N User’s manual v 1.1.3

- 10 -

IV.a) Accumulation tank

This menu enables the user to adjust all the parameters related to the tank (heat accumulator).

IV.a.1.) Pre-set temperature

This function is used to adjust the pre-set tank temperature. After reaching this temperature the

collector pump is deactivated.

IV.a.2) Maximum temperature of tank 1

Using this option, the user may declare the maximum acceptable safe temperature value which the

tank can reach in case of collector overheat.

If the collector reaches its alarm temperature (overheat), the pump is activated automatically in order

to cool down the heated collector, regardless of the pre-set temperature. The pump operates until the

tank maximum temperature is reached or until the collector temperature drops by the value of the

alarm hysteresis (see: SERVICE MENU > Solar collector> Alarm hysteresis).

IV.a.3) Minimum temperature of tank 1

Using this parameter, the user may declare the minimum acceptable temperature value which the tank

can reach. Below this temperature the pump is not activated in collector defrosting mode.

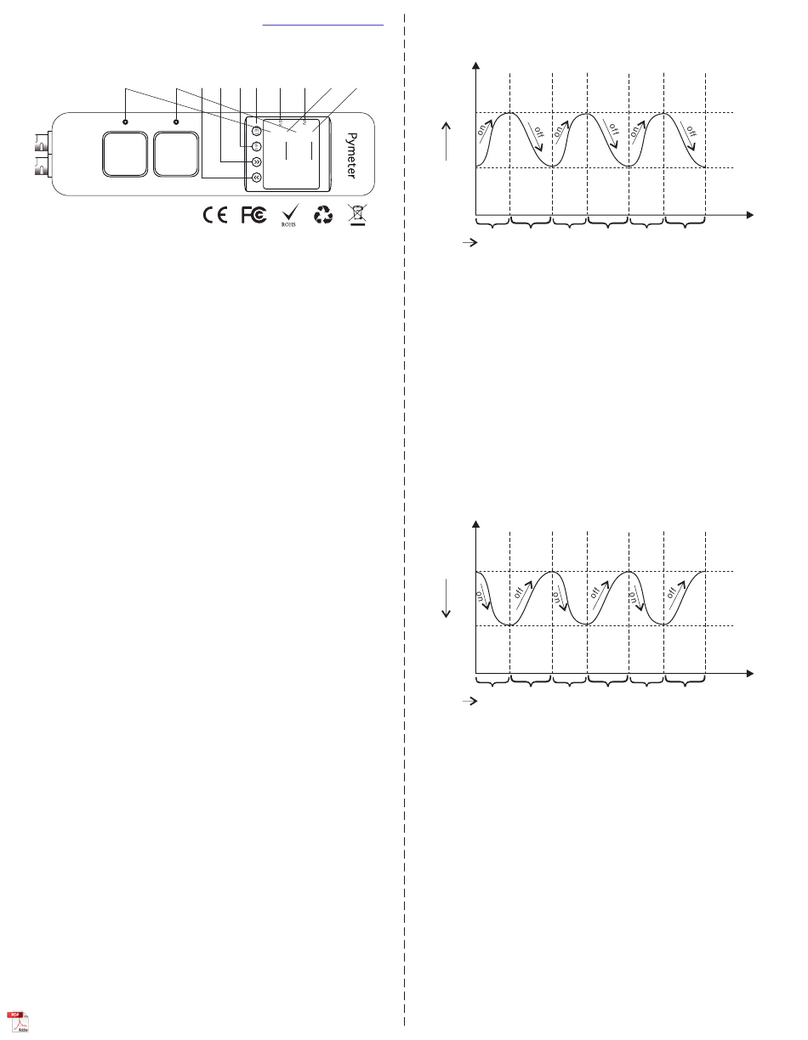

IV.a.4) Tank hysteresis

Using this function, the user declares the tank hysteresis value. If the tank reaches the pre-set

temperature and the pump is deactivated, it will be activated again after the tank temperature drops

below the pre-set value by the value of this hysteresis.

IV.a.5) Cooling to pre-set temperature

When the collector reaches the overheat temperature, the pump is activated in emergency mode to

cool it down. In this case, the heat is transferred to the tank until the maximum temperature is reached.

To prevent the accumulation of too hot water in the tank, Cooling to pre-set temperature function

should be activated. Once activated, when the collector temperature drops below the temperature of

the tank, the pump is activated in order to cool down the tank until it reaches the pre-set temperature.

IV.a.6) Holiday delta

This function is active only in Holiday mode. This parameter determines how many °C before reaching

the collector overheat temperature the pump is activated in order to cool it down. The pump is

deactivated after the collector temperature drops by at least 5°C.

IV.b) Solar collector

These parameters enable the user to configure solar collector operation.

IV.b.1) Overheat temperature

It is acceptable alarm temperature of the solar collector at which the pump is forced to activate in order

to cool down the solar panels. The discharge of warm water will take place regardless of the tank pre-

set temperature. The pump will operate until the tank temperature drops below the alarm temperature

by alarm hysteresis value (Service Settings > Solar collector > Alarm hysteresis) or until the tank

reaches the maximum acceptable temperature (Service settings > Accumulation tank > Maximum

temperature).

IV.b.2) Minimum heating temperature

It is the collector threshold temperature. If the collector temperature is higher and starts to drop, the

controller disables the pump when the minimum heating temperature is reached. When the collector

temperature is below this threshold and starts to increase, the pump is activated when the minimum

heating temperature plus hysteresis ( 3°C ) is reached. The threshold heating temperature is not active

in the emergency mode, manual mode or collector defrosting.