PPI HumiTherm Ultra User manual

HumiTherm Ultra User Manual

Temperature + Humidity (%RH)

Control & Recording System

with 8 / 16 Mapping Inputs

User Manual

HumiTherm Ultra

PPI

HumiTherm Ultra

Touch Operation Panel

HumiTherm Ultra User Manual

CONTENTS

1. MOUNTING & ELECTRICAL CONNECTIONS : HMI (TOUCH PANEL) 1

2. MOUNTING & ELECTRICAL CONNECTIONS : microPLC 4

3. MOUNTING, ELECTRICAL CONNECTIONS & JUMPER SETTINGS : MAPPING 7

4. BASIC OPERATION & PARAMETERS ORGANIZATION 11

5. OPERATOR LEVEL PARAMETERS 20

6. SUPERVISORY LEVEL PARAMETERS 22

7. FACTORY LEVEL PARAMETERS 26

APPENDIX-A : DC LINEAR SIGNAL INTERFACE 47

APPENDIX-B : COMPRESSOR SETTING PARAMETERS 50

APPENDIX-C : STANDBY SENSORS 53

APPENDIX-D : STANDBY CONTROL GADGET 55

APPENDIX-E : DOOR LOCK 58

APPENDIX-F : DIGITAL INPUT & OUTPUT 59

1

HumiTherm Ultra User Manual

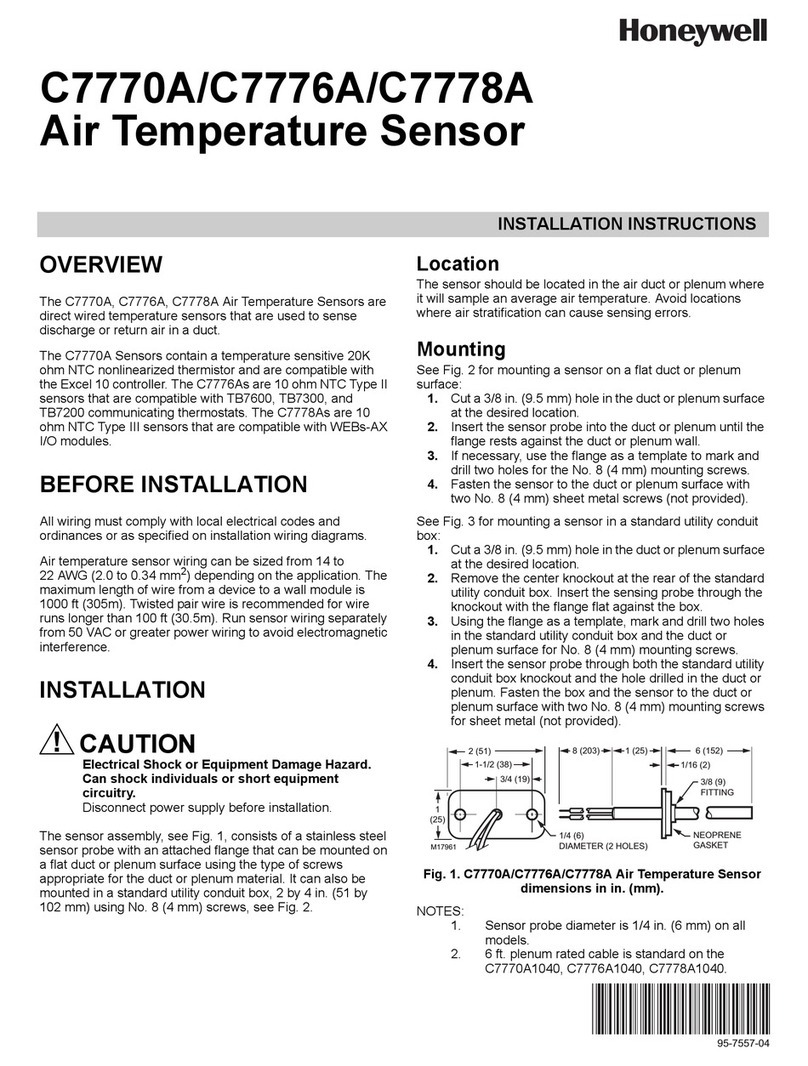

4.3” Mounting

Dimensions

Overall

Panel Cutout

128(W) X 102(H) X 55(D), mm

121(W) X 95(H), mm

Table 1.1

128 mm

102 mm

Figure 1.1

95 mm

(Panel Cut)

55 mm

5 mm

121 mm

(Panel Cut)

12

3

4.3” Electrical Connections

Section 1

MOUNTING & ELECTRICAL CONNECTIONS : HMI (TOUCH PANEL)

Figure 1.2

2

HumiTherm Ultra User Manual

199 mm

(Panel Cut)

206 mm

136 mm

129 mm

44 mm

6.5 mm

(Panel Cut)

Dimensions

Overall

Panel Cutout

206(W) X 136(H) X 44(D), mm

199(W) X 129(H), mm

7” Mounting

Table 1.2

Figure 1.3

3

HumiTherm Ultra User Manual

7” Electrical Connections

Figure 1.4

1

2

3

3-Pin Male / Female Connector (5.08 mm pitch)

Supply Voltage : 20 to 28 VDC (24 V Nominal)

9 (4.3” HMI) / 15 (7” HMI) Pin D Type Connector

RS485 Serial Communication with microPLC &

Mapping Unit

6 Pin PS/2 Connector

RS232 Serial Communication with PC

24VDC FG

+-

COM2 ETHERNET

COM1 USB

HOST SD-CARD

3

1 2

RESET

PULL

Battery Cover

15 Pin

Table 1.3

9 Pin

4

HumiTherm Ultra User Manual

Mounting (Base / Wall Mounting)

microPLC Electrical Connections

Stby Set Select

525150494847464544

Alarm ACK

1 2 3 4 5 6 7 8 9 10 11 12 13 22 2314 15 16 17 18 19 20 21

Power Fail

Door Open

Thermostat

Thermostat

Water Level

Water Level

Heater

Humidifier

Compressor

Alarm

Main Set Select

Heater

Humidifier

Compressor

Main

RS485

mA

Pt100

V

mA

Pt100

V

Stability Control

mA

V

mA

V

43424140393837363534333231302928

Main

27262524

Door Lock

Standby

Digital Inputs

Digital Outputs

HMI

Temperature

Humidity Temperature

Humidity

microPLC

Stby

Standby

Main

18~32VDC

Supply 5VDC

Exc

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+-

+-

+-

+-

+-

+-

+-

+-

Figure 2.2

Figure 2.1

Section 2

MOUNTING & ELECTRICAL CONNECTIONS : microPLC

179mm

100mm

8mm

8mm

ø5mm Mounting Hole

ø5mm Mounting Hole

77mm

5

HumiTherm Ultra User Manual

DESCRIPTIONS

The connections are described as under:

0/4~20mA

78 9

mA

Figure 2.3 (b)

0/1~5V, 0~10V

7 8 9

V

Figure 2.3 (a)

Humidity Transmitter with DC Voltage (V) Output

The Figures 2.3(a) depicts wiring connections for voltage output transmitter. The Excitation Voltage

can be obtained from an external source or from the controller (5 VDC).

Humidity Transmitter with DC Current (mA) Output

The Figures 2.3(b) depict wiring connections for current output transmitter. Note that terminals 8 & 9

should be shorted. The Excitation Voltage can be obtained from an external source or from the

controller (5 VDC).

Main Humidity (%RH) Transmitter Input (Terminals : 7,8, 9)

The Controller accepts DC Current (mA) / DC Voltage (V) as Humidity input. The connections are

described below.

Figure 2.4 (a) Figure 2.4 (b) Figure 2.4 (c)

Main Temperature (°C) Sensor / Transmitter Input (Terminals : 10, 11, 12, 13 )

The Controller accepts RTD Pt100 (3-wire / 2-wire) or DC Current (mA) / DC Voltage (V) as Temperature input. The

connections are described.

0/1~5V, 0~10V

V

10 11 12 13

RTD Pt100

10 11 12 13

0/4~20mA

mA

10 11 12 13

RTD Pt100, 3-wire

Connect single leaded end of RTD bulb to terminal 10 and the double leaded ends to terminals 11 & 12 as shown in Figure

2.4(a). Use copper conductor leads of very low resistance ensuring that all 3 leads are of the same gauge and length. Avoid

joints in the cable.

Temperature Transmitter with DC Voltage (V) Output

The Figures 2.4(b) depicts wiring connections for voltage output transmitter. The Excitation Voltage can be obtained from an

external source or from the controller (5 VDC).

Temperature Transmitter with DC Current (mA) Output

The Figures 2.4(c) depict wiring connections for current output transmitter. Note that terminals 12 & 13 should be shorted. The

Excitation Voltage can be obtained from an external source or from the controller (5 VDC).

5 VDC Excitation Voltage (Terminals : 4, 5)

The Controller is supplied with inbuilt 5VDC Excitation Voltage as standard. The Excitation Voltage can be used to power

external Temperature and/or RH Transmitters.

The ‘+’ and ‘-’ terminals are for voltage ‘Source’ and ‘Return’ paths, respectively.

6

HumiTherm Ultra User Manual

2 Pole

Isolating Switch

Fuse

1

DC Power

Source

+

-

+

2-

Mains

Earth 3

Figure 2.5

[Optional] Standby Humidity (%RH) Transmitter Input (Terminals : 14, 15, 16, 17)

[Optional] Standby Temperature (°C) Sensor / Transmitter Input (Terminals : 18, 19, 20, 21)

The Control Unit optionally supports Inputs for Standby (redundant) Humidity & Temperature sensor / transmitter. The

Connection detail are the same as for main sensor / transmitter described above.

[Optional] Door Output (terminals : 24, 25)

[Optional] Standby Set Select Output (terminals : 26, 27)

[Optional] Main Set Select Output (terminals : 28, 29)

[Optional] Standby Compressor Output (terminals : 30, 31)

[Optional] Standby Humidifier Output (terminals : 32, 33)

[Optional] Standby Heater Output (terminals : 34, 35)

Main Compressor Output (terminals : 36, 37)

Main Humidifier Output (terminals : 38, 39)

Main Heater Output (terminals : 40, 41)

Alarm Output (terminals : 42, 43)

All the above control & alarm outputs are Voltage pulses (12VDC @ 40mA) for driving external SSR or Relay. The ‘+’ and ‘-’

terminals are for voltage ‘Source’ and ‘Return’ paths, respectively.

The Optional Outputs are fitted only if Controller is ordered with Standby Control Outputs.

[Optional] Standby Thermostat Digital Input (Terminals 44, )46

[Optional] Standby Water Level Digital Input (Terminals 45, )46

Main Thermostat Digital Input (Terminals 47, )46

Main Water Level Digital Input (Terminals 48, )46

Alarm Acknowledge Digital Input (Terminals 50, )49

Power Fail Digital Input (Terminals 51, )49

Door Open Digital Input (Terminals 52, )49

(Terminals 46 & 49 are Common)

Potential-free contact closure input terminals are provided as digital inputs. An ‘Open’ or ‘Close’ switch position is detected as

input.

For reliable noise free communication, use a pair of twisted wires inside screened cable. The wire should have less than 100

ohms / km nominal DC resistance (Typically 24 AWG or thicker). Connect the terminating resistor (Typically 100 to 150 ohm)

at one end to improve noise immunity.

HMI (Terminals 22, 23) COMMUNICATION PORT

POWER SUPPLY 1(Terminals , 2, 3)

As standard, the is supplied with power connections suited Module

for to V C . The accuracy / p formance of the 18 32 D power source er

Module is not affected by the variations in the supply within sp cified e

limits of to 3 VDC. Use well-insulated copper conductor wire of 18 2

the size not smaller than 0.5mm² for power supply connections

ensuring proper polarity as shown in Figure . The is not 2.5 Module

provided with fuse and power switch. If necessary, mount them

separately. Use a blow fuse rated for 0.5A current. slow

For safety and enhanced electrical noise immunity, it is highly recommended to connect Main Power Supply ‘Earth’

to terminal 3.

7

HumiTherm Ultra User Manual

Section 3

MOUNTING, ELECTRICAL CONNECTIONS & JUMPER SETTINGS : MAPPING

Figure 3.2

Mounting (Base / Wall Mounting)

Mapping Electrical Connections

Figure 3.1

210mm

110mm

ø5mm Mounting Hole

ø5mm

Mounting Hole

8mm

5mm

205mm

88mm

SUPPLY

COMM PORT

B BB B

52 53 54 55

1 2 346 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

5

mV / V

mA

%RH

MAP 1

°C %RH

MAP 2

°C %RH

MAP 3

°C %RH

MAP 4

°C %RH

28293031323334353637383940

4142

43

44

45

46

47

48495051

MAP 8

%RH °C

MAP 7

%RH °C

MAP 6

%RH °C

MAP 5

%RH °C

UniMap

4 / 8 Points

Mapping Module

25

84 ~ 264

VAC

26 27

LN

Sr. No.:

PPI

°C

RTD

mV / V

mA

A1 A2 A3 B1 B2 B3

B1B2

B3 A1A2

A3

B1 B2 B3

A1 A2 A3

B1 B2 B3 A1 A2 A3 B1 B2 B3 A1 A2 A3 B1 B2 B3 A1 A2 A3

A1A2

A3 B1B2

B3 A1A2

A3 B1B2

B3 A1A2

A3 B1B2

B3

8

HumiTherm Ultra User Manual

Map Inputs

Each of the °C and %RH inputs are identical from wiring connection viewpoint. The descriptions below apply to all the inputs

with no deviations.

Make sure that proper jumper settings are made for each input for the selected input type as described later in this ection.s

RTD Pt100, 3-wire

Connect single leaded end of bulb to and the double leaded ends to terminals and (interchangeable) as shown RTD A1 A2 A3

in Use copper conductor leads of very low resistance ensuring that all 3 leads are of the same gauge and length. Figure 3.3(a).

Avoid joints in the cable.

DC Linear Voltage (mV / V) & Current (mA)

Use a shielded twisted pair with the shield grounded at the signal source for connecting mA / mV / V source. Connect common

(-) to and the signal (+) to , as shown in A2 / B2 A1 / B1 Figure 3.3(a) & (b).

POWER SUPPLY

Figure 3.4

As standard, the controller is supplied with power connections suited for 8 to 264 VAC line supply. Use well-insulated copper 5

conductor wire of the size not smaller than 0.5mm² for power supply connections. Connect Line (Phase) supply line to terminal

26 and the Neutral (Return) supply line to terminal 27 as shown in Figure . . The controller is not provided with fuse and 3 4

power switch. If necessary, mount them separately. Use a time lag fuse rated 1A @ 240 VAC.

Line

Neutral

26 (L)

27 (N)

2 Pole

Isolating Switch

Fuse

Power Supply

Terminal

Figure 3.3(b)Figure 3.3(a)

RTD

A1 A2 A3

°C

mV / V / mA

A1 A2 A3

%RH

mV / V / mA

B1 B2 B3

9

HumiTherm Ultra User Manual

SERIAL COMMUNICATION PORT

Figure 3.5

The wiring connections for interfacing the HMI with mapping unit is shown in the figure 3.5.

Mapping

HMI

RS485 Port

OUT

IN

RS485

Port

To microPLC

INPUT TYPE : JUMPER SETTINGS

The Mapping Unit (UniMap) is supplied with 8 ( ) or 16 ( T + 8RH) s. Each can be user configured for a 4T + 4RH 8 Map Input Input

variety of input types which requires appropriate parameters settings and jumper settings on . The figure shows UniMap 3.6

the locations of jumper setting arrangements for each . input

Figure 3.6

3

2

1

4

1

2

34

°C

MAP 1

%RH

MAP 4

°C

MAP 5

%RH

MAP 8

10

HumiTherm Ultra User Manual

The jumper setting arrangement comprises of as shown in the figure below. The figure also depicts Pins & Shorting-Link 3.7

how to mount the Shorting-Link for a particular jumper setting.

Shorting Link

Placed

Shorting Link

Parked

Pins Shorting

Link

Figure 3.7

The figures below show the jumper settings for different input types.

321

4

Place Shorting

Link on Pins 1 & 2

RTD Pt100 (3-wire)

321

4

Place Shorting

Link on Pins 2 & 3

0-20mA, 4-20mA

321

4

Park Shorting Link

0-50mV, 0-200mV, 0-1.25V,

0-5V, 1-5V, 0-10V

11

HumiTherm Ultra User Manual

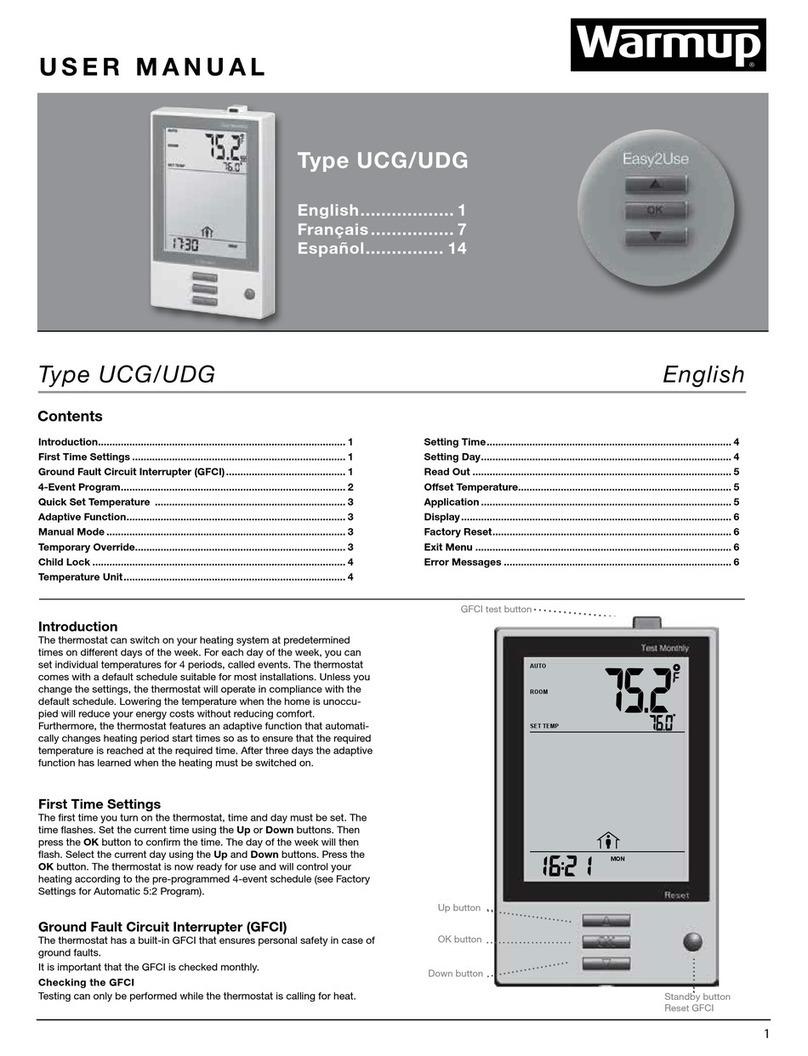

BASIC OPERATION & PARAMETER ORGANIZATION

Section 4

ALARM INDICATOR

This icon appears if one or more process alarms are active. The Alarm Relay gets activated whenever any alarm becomes

active. The user can acknowledge the alarm (de-activate the relay) by touching this icon.

BATTERY INDICATOR

This icon appears if the Mains power has failed and the controller is currently powered through an auxiliary power source like

Battery or Inverter.

COMM ERROR INDICATOR

This icon appears if the HMI communication link with the Control Unit, Mapping Unit or GSM Module is broken. Upon touching

this icon a message window pops up showing which communication link(s) is broken.

CALENDER DATE & CLOCK TIME

These two fields show the current date (DD/MM/YY) & time (HH:MM:SS, 24 Hours format), respectively.

TEMPERATURE VALUE & %RH VALUE

These two fields show the Temperature & %RH Process Values in 0.1 °C / %RH resolution. In case of errors the field shows

OPEN (Sensor Open), OVER (Process Value above Max Range), UNDR (Process Value below Min Range). The Process

Values are shown in Black color under normal condition. The Error Messages are shown in Red color.

TEMPERATURE SETPOINT & %RH SETPOINT

These two fields show the Temperature & %RH Set Values (SP) in 0.1 °C / %RH resolution. If enabled, these values can be

edited by touching the respective field. Upon touching a Numeric Keypad pops up for setting.

TUNE STATUS INDICATOR

This text appears if the controller is self tuning the temperature and / or %RH control loop.

STATUS VIEW BUTTON

This a touch button that enables navigation through various process status screens. The Screens are shown below.

Clock Time

Calendar Date

Alarm Indicator

%RH Value

Temperature Value

%RH Setpoint

(Optional Touch Button)

Set-up Mode Button

Temperature Setpoint

(Optional Touch Button)

Status View Button

Map View Button Door Open Button

Battery Indicator

Tune Status Indicator

Comm Error Indicator

Tuning

Upon Power up to the HMI, after a few initialization screens, the Main (Home) screen is displayed. This is the screen that shall

be used most often and is described below in details.

12

HumiTherm Ultra User Manual

Process Status Screen

This screen shows various rocess Alarm status and the information regarding working / fa ure of p il various Main and Standby

Sensors (Temperature & %RH) & Control Gadgets (Air Heater, Boiler Heater & Compressor). The contents on this screen are

dependent on whether Standby Sensors and / or Standby Control Gadgets are installed or not. Accordingly the following four

variants of this screen exist:

1. Alarm Only

2. Alarm + Standby Sensor

3. Alarm + Standby Control

4. Alarm + Standby Sensor + Standby Control

Alarm + Standby Sensor + Standby Control

Alarm + Standby Control

Alarm + Standby Sensor

Touch Button to go to

Next Screen

Touch Button to

Acknowledge Alarm

Touch Button to go to

Home (Main) Screen

Touch Button to go to

Previous Screen

Alarm Only

13

HumiTherm Ultra User Manual

Record Status

Th rage capacity, numbers of current stored records and available free space.is screen shows the total record sto

Output Status

This screen shows :

wHeating & Humidification % output power

wOn-Off Status for Main & Standby (if installed) Air Heater, Boiler Heater (Humidifier) & Compressor

wAlarm Relay Status

5000

1

4999

SMS Status

This screen shows the status related to GSM Module (if installed).

14

HumiTherm Ultra User Manual

MAP VIEW BUTTON

This is a touch button that opens up screen(s) to view process values for mapping s. The installed mapping s could input input

be 8 (4 Map Points : 4T + 4RH) or 16 (8 8T + 8RH) and accordingly 1 or 2 screens displayed. Note that this Map Points : are

touch button is not available if no mapping inputs are installed. The Screens are shown below.

Appears for both 8 & 16 Map Inputs Appears for 16 Map Inputs only

25.0

59.6

24.7

60.2

25.2

60.8

25.3

60.1

22.0

57.5

24.8

61.2

25.1

60.8

27.2

62.3

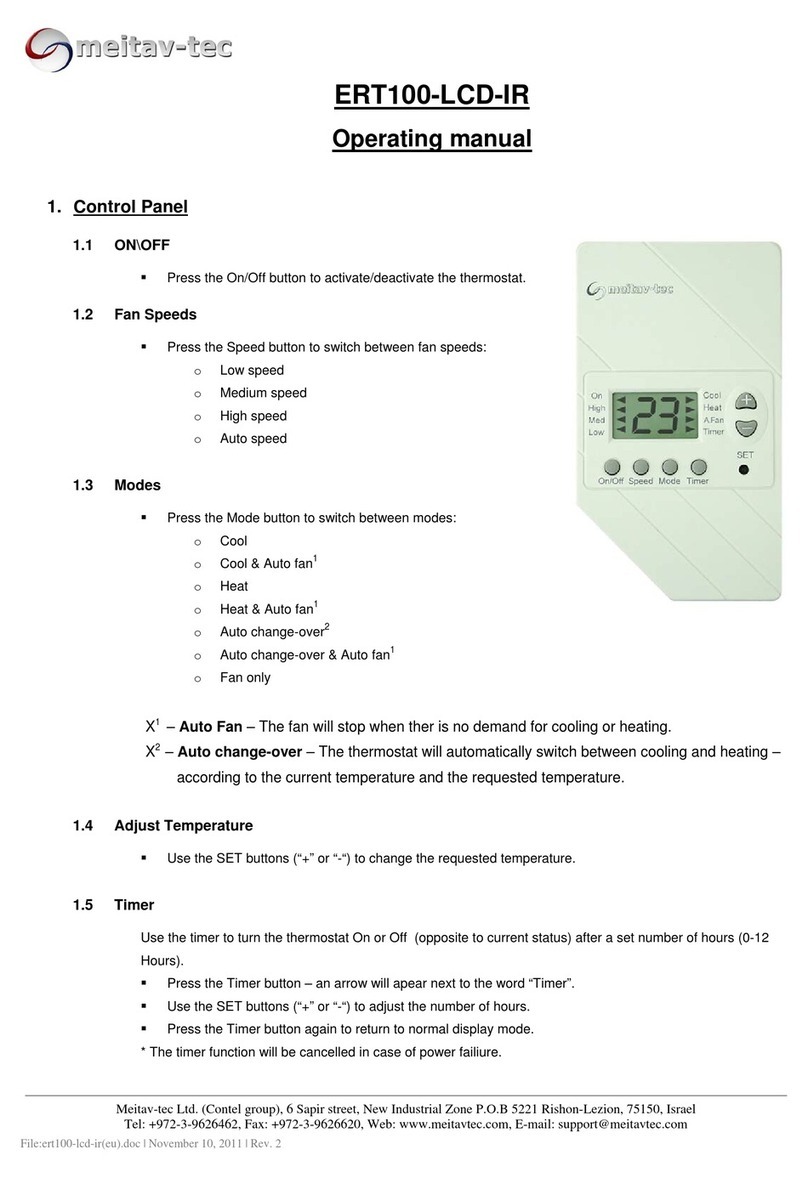

DOOR OPEN BUTTON

If the Humidity cabinet is equipped with Door Lock, this touch button opens a screen that allows password entry for unlocking

the cabinet door by authorised person. Also the authorised person’s identity is logged for audit purpose.

Access Level Default Password

Operator 0000

Supervisory 0001

Factory 0002

SET-UP MODE BUTTON

This touch button opens a screen that allows access to Operator, Supervisory or Factory Level parameter settings through

appropriate password entry. 4 character

The Factory default passwords are as below :

15

HumiTherm Ultra User Manual

Upon touching one of the levels, a keyboard for password entry pops-up as shown below.

Text Screen

The user must touch the text screen to make it

editable. Upon touch the text screen shows a blue

band as shown below.

****

Non Editable

Editable after touch

Password entry on

editable text Screen

****

While the screen is editable, type 4 character password & then press ENTER Key. If the password is correct, the parameter

setting screen opens up. Use ESC key (in case password is not known) to pop down the key pad.

Once an access level is entered, the user can change the password for that level as shown below as an example for operator

level.

0005

25.0

2.0

2.0

60.0

2.0

2.0

16

HumiTherm Ultra User Manual

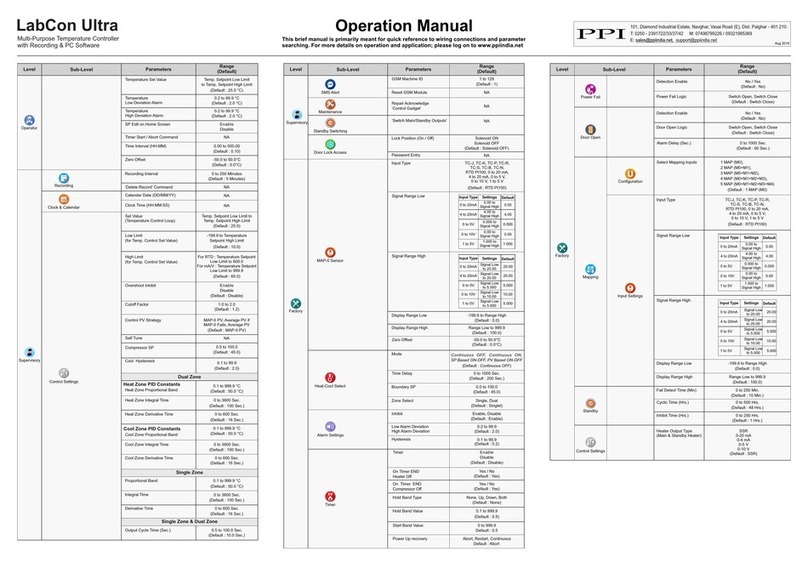

Each access level may have sub levels for convenient parameter grouping. The Table . lists various parameters with levels 4 1

and sub levels.

Sub-Level Parameters

Level

Operator

Supervisory

Recording

Clock & Calendar

Door Lock Access

Maintenance

Standby Switching

Temperature

Set Value

Low Deviation Alarm

High Deviation Alarm

%RH

Set Value

Low Deviation Alarm

High Deviation Alarm

SP Edit on Home Screen

Recording Interval

‘Delete Record’ Command

Calendar Date (DD/MM/YY)

Clock Time (HH:MM:SS)

Lock Position (On / Off)

Password Entry

Repair Acknowledge ‘Control Gadget’

Repair Acknowledge ‘Input Sensor’

‘Switch Main / Standby Outputs’

‘Switch to Standby Sensors’

Table 4.1

GSM Machine ID

Reset GSM Module

SMS Alert

SMS

Temperature

Control Settings

Alarm Settings

Input Settings

Control Settings

Alarm Settings

Input Settings

%RH

Input Type,

Signal Range Low, Signal Range High,

Display Range Low, Display Range High,

Zero Offset

Inhibit (Yes / No),

Low Alarm Deviation, High Alarm Deviation,

Hysteresis

Heat Zone PID Constants,

Cool Zone PID Constants,

Output Cycle Time (Sec.),

Control SP

Setpoint Low Limit, Setpoint High Limit

Self Tune

Input Type,

Signal Range Low, Signal Range High,

Display Range Low, Display Range High,

Zero Offset

Inhibit (Yes / No),

Low Alarm Deviation, High Alarm Deviation,

Hysteresis

Factory

Heat Zone PID Constants,

Cool Zone PID Constants,

Output Cycle Time (Sec.),

Control SP

Setpoint Low Limit, Setpoint High Limit

Self Tune

17

HumiTherm Ultra User Manual

Sub-Level Parameters

Level

Factory

Compressor

Water Level

Door Open

Power Fail

Mode (ON, OFF, PV Based, SP Based),

Boundary SP or Compressor SP,

Time Delay, Hysteresis

Zone Select (Single, Dual)

Detection Enable (Yes / No),

Door Open Logic (Open / Close),

Alarm Delay (Sec.)

Detection Enable (Yes / No),

Power Fail Logic (Open / Close)

Float

Detection Enable (Yes / No),

Low Level Logic (Open / Close)

Thermostat

Detection Enable (Yes / No),

Low Level Logic (Open / Close)

Common Boiler (Yes / No)

Control Gadgets

Standby

Sensor Inputs

Sensor Fail Detection Limits

Fail Detect Time (Min)

Cyclic Time (Hrs.)

Inhibit Time (Hrs.)

Mapping

Configuration

Temperature

%RH

Select Mapping Inputs (4T + 4RH, 8T + 8RH)

Alarm Settings

Input Settings

Low Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

High Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

Input Type,

Range Low, Range High,

Zero Offset

Alarm Settings

Input Settings

Low Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

High Alarm (Common for all Inputs)

Set Value, Hysteresis, Inhibit

Input Type,

Range Low, Range High,

Zero Offset

18

HumiTherm Ultra User Manual

PARAMETER SETTINGS

There are 3 types of parameters; Numeric, String Option and Commands. The setting methods for different types are

described below.

Numeric Parameters

This type of parameter has 2 fields; & as shown in the figure. The value for this type of parameter is set Name Field Value Field

using a Numeric keypad that pops up upon touching the for the parameter. The value can be edited using numeric Value Field

keys & other functional keys as shown in the figure. Use ENT key for storing the new value or use ESC key to revert without

changes. Touching ENT or ESC key, the keypad automatically collapses.

Name Field Value Field

Note that if the modified value falls outside the Minimum or Maximum limits specified for the

parameter value then the parameter retains the old value.

Selected Option

Unselected Options

String Option Parameters

This type of parameter has 2 or more fixed options to choose from. All the options are shown in rectangular boxes with

appropriate texts as shown in the figure. Only one of the several options can be selected. The selected option box is shown in

bright ( ) color, while all other unselected options are shown in dark ( ) color. For selecting the desired option. just touch

the box and wait for a while until the color changes from unselected to selected.

Table of contents

Other PPI Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Middleby Marshall

Middleby Marshall 37626 Installation, programming and troubleshooting instructions

THORLABS

THORLABS MTD415T datasheet

NPI

NPI TC-10 operating instructions

Warmworld

Warmworld Dataterm IHC user guide

Crow

Crow SH-TEMP-PRB-XT instruction manual

Honeywell

Honeywell C7776A installation instructions