Tech West ELITE Series Manual

2625 N. Argyle Ave. • Fresno, CA 93727

(559) 291-1650 • (800) 428-7139 • FAX (559) 348-9677

T

ECH

W

EST

I

NC.

Manufacturers of Dental Vacuum

and Air Systems

ELITE SERIES

ROCKY COMPRESSOR

INSTALLATION

AND SERVICE

MANUAL

Revised 12-18

ELITE SERIES

ROCKY COMPRESSOR

INSTALLATION AND SERVICE MANUAL

This manual is for the installation and service of Tech West’s Elite Series Rocky Compressors.

CONTENTS

Installation

Location Requirements 2

Figure 1: Wire and Breaker Sizes 2

Elite Series Rocky Installation Steps 3

Elite Series Rocky Compressor Connections 4

Elite Series Rocky Start Up 5

Elite Series Rocky Maintenance 6

Elite Series Rocky Compressor Motor Assembly Breakdown 7-8

Coalescing Filter Assembly Breakdown 9

Tank Breakdown 10

Desiccant Dryer Parts Breakdown 11

Gauge and Moisture Indicator Assembly Breakdown 12

Wiring Diagram, 115V 13

Wiring Diagram, 230V 14

Dual Elite Series Rocky Compressor Assembly 15

TROUBLE SHOOTING

Dual Rocky Compressor Trouble Shooting 18-19

Air Line Sizing Chart 22

Maintenance Schedule 23

Maintenance/Service and notes 24-25

1

ELITE SERIES ROCKY COMPRESSOR

INSTALLATION

1. ROCKY COMPRESSOR LOCATION REQUIREMENTS

The Elite Series Rocky Compressor location should be level, accessible and well ventilated.

If the Elite Series Rocky Compressor will be located in a confined space, provide adequate ventilation.

Electrical

(1) Line voltage must be within the limits of Figure 1 below. (Install a “buck-boost

transformer” if line voltage is not between these values.) Circuit breaker switches must

be 20 amp voltage.

(2) Local code may require you to provide a quick disconnect (safety switch) for the

compressor.

(3) See Figure 1 below for breaker size and line voltage.

CAUTION - Voltage must be 208/240 V or motor damage may occur.

CAUTION - Voltage must be 110/120 V or motor damage may occur.

2

Figure 1: Recommended Wire and Breaker Size

Dual Head Compressors

Model Voltage Amperage Wire Size Recommended

(Gauge) Breaker Size

ACOR2D1 110/120 11 12 20

ACOR2D2 208/230 7.6 12 20

ACOR2D1Q 110/120 11 12 20

ACOR2D2Q 208/230 7.6 12 20

ELITE SERIES ROCKY COMPRESSOR

INSTALLATION

2

2. INSTALLATION STEPS

This dental compressor should only be installed by qualified personnel. Should any questions arise

during the installation, call Tech West Technical Support between the hours of 7:00 a.m. to 4:00 p.m.

(Pacific Standard Time).

Place the compressor in a clean, dry, well ventilated area, on a solid, level surface. Consider sound

level and insulate as needed. Be sure that adequate ventilation is available as the compressor is air

cooled. Ambient temperature in the equipment room should be within the temperature range of 40

degrees Fahrenheit minimum to 104 degrees Fahrenheit maximum.

(a) Check the shipping carton for damage. This could detect damage to the unit which might

otherwise be overlooked. Remove cardboard shipping carton.

(b) Remove the Oilless Compressor from its shipping skid. Inspect the unit for damage.

Oilless Compressors are shipped bolted to a pallet. This pallet is intended for shipping only

and should be discarded.

(c) Remove installation kit attached to pallet. It should contain the following:

(4) Isolation Feet

(1) Alternate Air Hookup Hose

(1) 5’ Flexible Air Hose

(d) Install isolation feet on tank legs.

(e) Move compressor into place and make sure it is completely level.

(f) Wiring instructions:

(1) Have all electrical connections made by qualified personnel only. All connections

should be in accordance with local codes.

(2) Use the chart on page 1 to help determine the proper line and breaker size for

the unit that is being installed.

(g) Install the air line from the compressor tank to the building supply.

(h) Install the 1” flex alternate air hose from the compressor to a fresh air supply.

3

4

ELITE SERIES ROCKY COMPRESSOR

INSTALLATION

2

3. CONNECTIONS

Figure 2

Dryer Purge

Connection

Electrical Connection to

disconnect and electrical panel

(110 v / 220 v)

Alternate Air

Connection

to fresh air supply

Air Out

Connection to building

supply line

5

ELITE SERIES ROCKY COMPRESSOR

INSTALLATION

2

4. SAFETY PRECAUTIONS

• Keep fingers, foreign objects and clothing free from rotating parts and do not touch hot surfaces.

• Never attempt to service an operating unit.

• Isolate unit from system pressure and relieve backpressure before servicing

• Disconnect all power before servicing. The thermal protector in single phase motors

automatically starts motor when device resets.

USE OF THIS PRODUCT IN OR NEAR EXPLOSIVE ATMOSPHERES, OR FOR

PUMPING MIXTURES OTHER THAN ATMOSPHERIC AIR MAY CAUSE AN

EXPLOSION OR FIRE, RESULTING IN PERSONAL INJURY OR DEATH.

2

5. START-UP STEPS

(a) Make sure the shut-off valve from the compressor tank is closed.

(b) Turn the breaker from the panel to the “ON” position.

(c) Turn power “ON” from the toggle switch on the compressor. Compressor should run quietly

and vibration free. The storage tank should start to build pressure.

(d) The compressor will run until the pressure gauge reads 105 psi. The compressor then will

automatically shut off and the dryer will purge with a quick blast of air.

(e) Using soapy water, check the compressor plumbing hook ups for leaks. Repair leaks if needed.

(f) Pressure test the entire plumbing system for leaks. Use the storage tank pressure gauge to

monitor a pressure drop. After the plumbing system has been pressurized for 30 minutes,

re-check the gauge for pressure drop. If there is a drop in pressure, find and repair all leaks

in the office plumbing.

(g) Complete and mail in the warranty card for the compressor within ten days of installation.

AIR LEAKS ARE THE MAIN CAUSE OF COMPRESSOR FAILURES.

6

7. PERIODIC SERVICING

MONTHLY SERVICING

(a) Remove the purge bucket and empty as needed

(b) Crack the drain petcock on the bottom of the storage tank to check for water and drain if needed.

(c) Check moisture indicator to see that it is still “BLUE”. If it is pink, it is time to service the air dryer.

(d) Check pump-up times of the compressor.

(e) Check intake air supply filters. Replace filters as needed.

YEARLY SERVICING

(a) Repeat all of the monthly servicing.

(b) Replace the alternate air filter. (Part #: TIF-100)

(c) Check the coalescing filter and change if needed. (Part #: CFEO-375)

ELITE SERIES ROCKY COMPRESSOR

INSTALLATION

2

6. GENERAL SERVICE INFORMATION

For parts and service on Rocky series products contact the nearest authorized Tech West distributor. To

expedite appropriate service, be prepared to provide the unit model number, identification number,

and serial number found on the nameplate located on the front of the unit switch plate.

Component life operating at continuous duty & maximum pressure will shorten the life of the rings

and skirts. It is difficult to predict due to many conditions which directly influence wear. Some of

these conditions may include ambient air temperature, air cleanliness, operating pressure, piston

stroke on the particular model being utilized, duty cycle, maintenance of filters, etc.

Because of these various factors it is appropriate to generalize on component wear life and choose

some conservative estimates for most standard applications.

With these conditions in mind, we recommend the following preventative maintenance schedule.

RECOMMENDED MAINTENANCE

FOR ROCKY MODELS

Minor Service Kits, Piston Cups & Valves, Skirts, Etc.

Major Replacement Kit, Piston & Rod Assemblies

Replace inlet Filter

HOURS

Cont. Duty

Maximum Pressure

8,000 Hours

12,000 Hours

4,000 Hours

TIME

Based on 100%

Duty Cycle

12 months

18 months

6 months

9

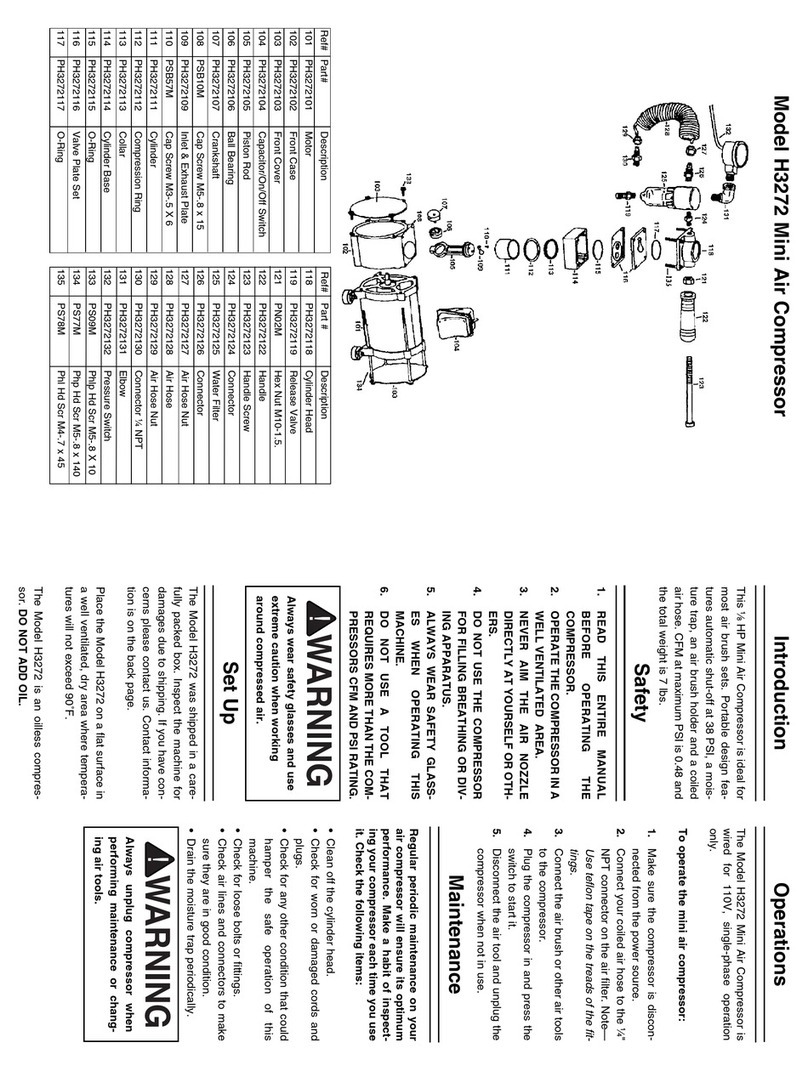

ROCKY FILTER ASSEMBLY

1

2

3

KEY PART NO. DESCRIPTION UNIT

1 CFAO-375 COALESCING FILTER ASSEMBLY 3/8 1

2 CFEO-375 COALESCING FILTER ELEMENT 3/8 1

3 CFBP-375 COALESCING FILTER BOWL 1

10

ROCKY REAR VIEW TANK ASSEMBLY AND PARTS LIST

KEY PART NO. DESCRIPTION UNIT

1 EDT-100 REPLACEMENT DESICANT CARTRIDGE - ELITE 1

2 EPT-100 ELITE PURGE TANK 1

3 ETAR-R ELITE TANK ANGLE ROCKY - REAR 1

4 ETHR ELITE TANK HANDLE ROCKY 2

5 EPCB ELITE PRECOOLER BRACKET 2

6 CFB-P COALESCING FILTER BRACKET 1

7 CFAO-375 COALESCING FILTER ASSEMBLY 1

8 ERPCM ELITE ROCKY PRECOOLER MOUNT 1

9 DPC-1E ELITE PRECOOLER - SINGLE 1

10 ETAR-F ELITE TANK ANGLE ROCKY - FRONT 1

11 ERMM ELITE ROCKY MOTOR MOUNT 1

12 CF-115-230E ELITE COOLING FAN - DUAL VOLTAGE 2

13 EAAR ELITE ALTERNATE AIR - ROCKY 1

1

3

2

4

5

7

8

9

6

10 11

12

13

11

ROCKY DESICCANT AIR DRYER ASSEMBLY

KEY PART NO. DESCRIPTION UNIT

1 DSV-115 115V PURGE SOLENOID VALVE 1

2 DSV-230 230V PURGE SOLENOID VALVE 1

3 AS-500 1/2 FILTER ASSY 1

4 EDC-100 REPLACEMENT DESSICANT TANK 1

5 MV-250 METERING VALVE 1

6 SN-250-CL STAINLESS STEEL NIPPLE 1/4 3

7 FE-4-6 FLAIR FITTING 1/4 X 3/8 1

8 BV-250 BALL VALVE 1/4 1

9 BT-250 BRASS TEE 1/4 2

10 FPH-375 CLEAR PURGE HOSE PER FOOT

11 MSD-100 MOLECULAR-SIEVE 1 LB 2LBS

12 MSD-200 ACTIVATED ALUMINA 1 LB 2LBS

13 CV-250D 1/4 CHECK VALVE 1

4

3

5

12

11

INSIDE

TANK

ELEMENT

12

KEY PART NO. DESCRIPTION UNIT

1 CPG-250 COMPRESSOR GAUGE 1

2 BV-250-FM 1/4” BALL VALVE 1

3 MI-100 MOISTURE INDICATOR 1

4 FA-4-4 1/4” FLARE HOSE FITTING 1

5 POVA-100 POP OFF VALVE 125 PSI ASME 1

6 SSN-375-CL STAINLESS STEEL NIPPLE 3/8” CLOSED 1

7 ATM ALUMINUM TANK MANIFOLD 1

8 FE-4-4 BRASS FLARE ELVOW 1/4” X 1/4” 1

ELITE ROCKY GAUGE AND CUT-OFF ASSEMBLY

1

3

4

6

5

7

2

8

TOGGLE

13

ELITE ROCKY WIRING DIAGRAMS

WIRING DIAGRAM WITH SOUND COVER AND 24v SWITCH 115V

15

KEY PART NO. DESCRIPTION UNIT

1 FPH-500R INTAKE HOSE REINFORCED 8” 65’

2 SBHA-11-375 STEEL BRAID HOSE ASSEMBLY 2

3 SBHA-13.5-375 STEEL BRAID HOSE ASSEMBLY 1

4 SBHA-27-375 STEEL BRAID HOSE ASSEMBLY 1

5 HA-7.5-250 HOSE ASSEMBLY 1

6 HA-18-250 HOSE ASSEMBLY 2

7 HA-25-250 HOSE ASSEMBLY 1

8 FPH-500R INTAKE HOSE REINFORCED 25” 2.42’

9 DSV-115 PURGE VALVE SOLENOID VALVE 115V 1

10 DSV-230 PURGE VALVE SOLENOID VALVE 230V 1

11 CFAO-375 COALESCING FILTER 3/8 1

12 CFEO-375 COALESCING FILTER ELEMENT ONLY 1

13 DPB-100 DRYER PURGE BUCKET 1

14 RIC-GAST RUBBER MOUNTING FEET 8

15 EPT-100 COMPRESSOR PURGE TANK 1

16 EDT-100 REPLACEMENT DESICCANT CARTRIDGE 1

17 CV-250D 3/8 CHECK VALVE 2

18 TOM-075R-115 OILLESS MOTOR 3/4 HP 115V 2

19 TOM-075R-230 OILLESS MOTOR 3/4 HP 230V 2

20 RFV-100 RUBBER MOUNTING FEET 4

21 PSC-250E PRESSURE SWITCH 1

DUAL ELITE SERIES ROCKY COMPRESSOR

1

16

15

910

DUAL ELITE SERIES ROCKY COMPRESSOR

2

2

1

3

4

6

6

7

8

11

12

14

17

18

19

20

21

18

DOES AIR

COMPRESSOR

RUN?

Does compressor run

for a few seconds,

“chugs”, then stops?

Does compressor pres-

surize from 80 to 100

psi in less than 2

minute with no air

being used?

Does compressor

cycle with no air

being used?

YES NO YES

NO

GO ON TO

THE NEXT

PAGE.

Are there leaks in

compressor or in

office piping system?

Does air

bleed out

the purge

valve when

unit is

running?

Clean

or

replace.

Replace

intake

filter.

NO

NO

Check voltage at

the valve and

make sure valve is

closed.

Does

unloader

valve pres-

sure switch

or float

assembly

seat while

running?

NO

YES

Trouble Shooting Chart

Dual Elite Series Rocky Compressor

Dual Elite Series Rocky Compressor

YES

Is the moisture

indicator pink?

YES

Is intake

filter

clogged?

Is there sufficient

pressure build-up

with head

discharge line

removed?

YES

NO

Defective

head,

contact

Tech West.

Note: Close

shut off valve.

Pump up tank to

100 psi. If pres-

sure is main-

tained for 15-20

min., leak is in

office lines.

YES

Locate and

repair.

NO

NO

Does

purge valve

system

function

properly?

YES

Does com-

pressor run

too hot or too

frequent?

NO

Check for proper

voltage. Use buck-

boost if needed.

NO

1. Locate and repair

leaks.

2. Ventilate if room is

above

100 deg. F.

3. Contact compressor

may be undersized.

YES

YES

Service dryer and

replace moisture

indicator.

YES

Check voltage

supplied to the

compressor.

YES

Defective

head,

contact

Tech West.

YES

NO

Does air leak

from unloader

valve or the

purge muffler

continuously

until unit cycles

again?

Make sure that the

dryer valve is clos-

ing properly.

19

CHECKFOR:

1. Broken or loose

wire.

2. Defective pressure

switch.

3. Defective ON/OFF

switch.

4. Excessive voltage

drop across power

lines.

NOTE: Voltage

should be + or -

10% of rating.

Is there sufficient

voltage at motor

terminals while

motor tries to start?

GO ON TO

THE NEXT

PAGE.

COMPRESSOR

DOES NOT RUN

OR RUNS FOR

ONLY A FEW

SECONDS.

YES

Does head

run with dis-

charge line

disconnected?

NO

Is there suffi-

cient voltage

at disconnect

box?

Blockage in

air line locate

& repair.

YES

Install

Tech West

transformer.

NO

YES NO

YES

Is there

resistance

rise across

the capaci-

tors?

YES

Replace

defective

capacitors.

NO

Turn power off.

Remove fan guard.

Try turning fan by

hand. If it doesn’t

turn, contact head

may be frozen.

NOTE:

Short capacitor

leads. Check resis-

tance rise. If no

resistance rise,

replace.

Dual Elite Series Rocky Compressor

Maintenance & Service Supplies

Service scheduled for: Service items needed:

22

23

2625 N. Argyle Ave. • Fresno, CA 93727

(559) 291-1650 • (800) 428-7139 • FAX (559) 348-9677

T

ECH

W

EST

I

NC.

Manufacturers of Dental Vacuum

and Air Systems

This manual suits for next models

5

Table of contents

Other Tech West Air Compressor manuals