AC-501X

User’s Manual

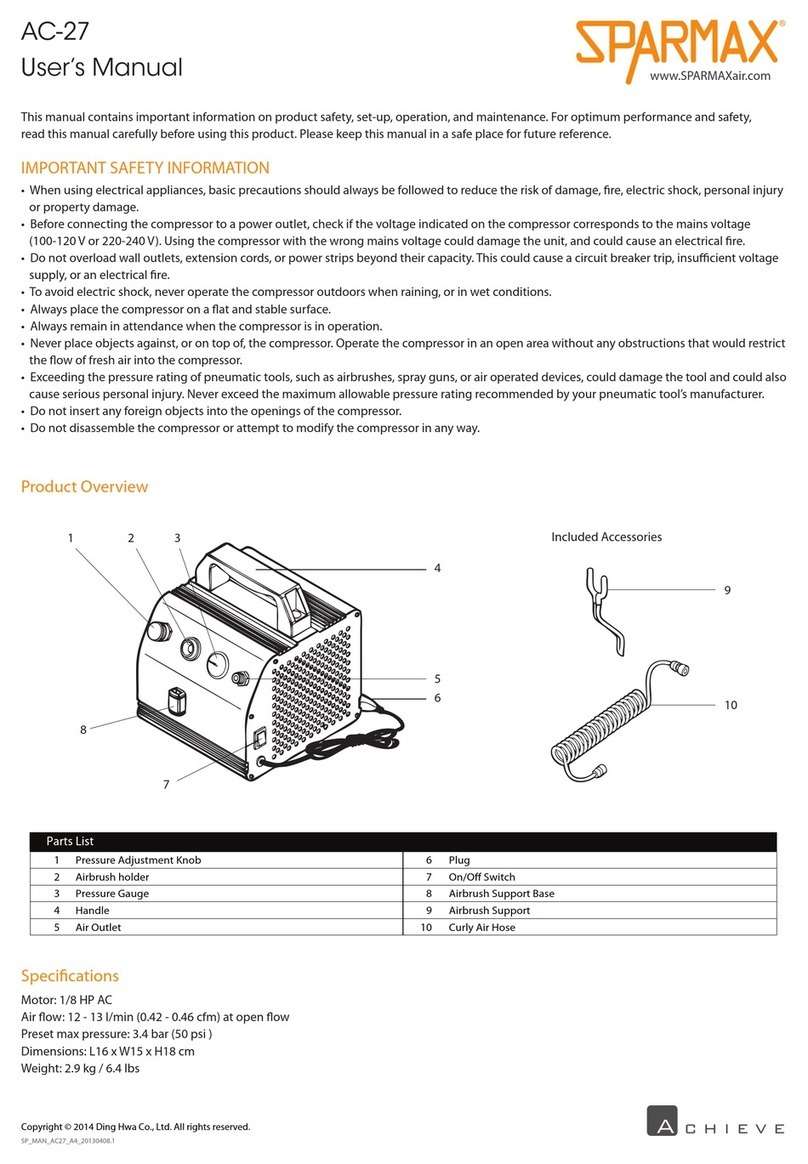

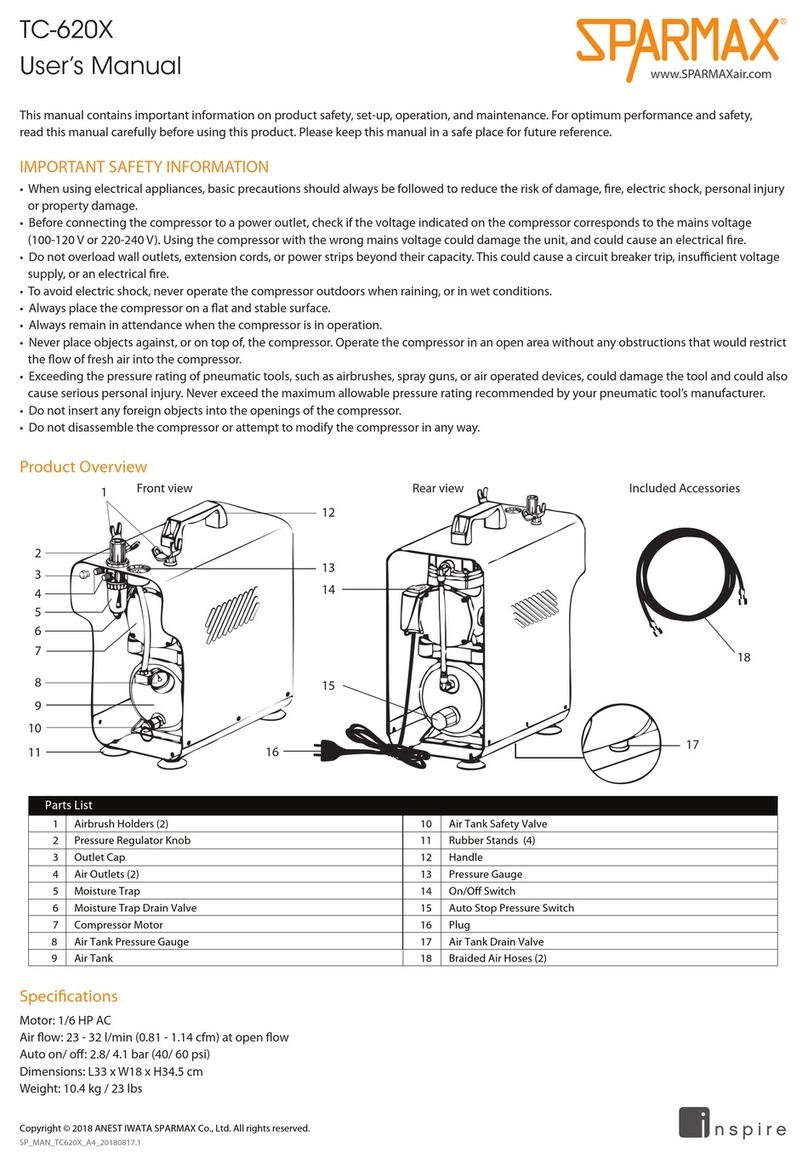

Product Set Up

Copyright © 2018 ANEST IWATA SPARMAX Co., Ltd. All rights reserved.

SP_MAN_AC501X_A4_20180817.1

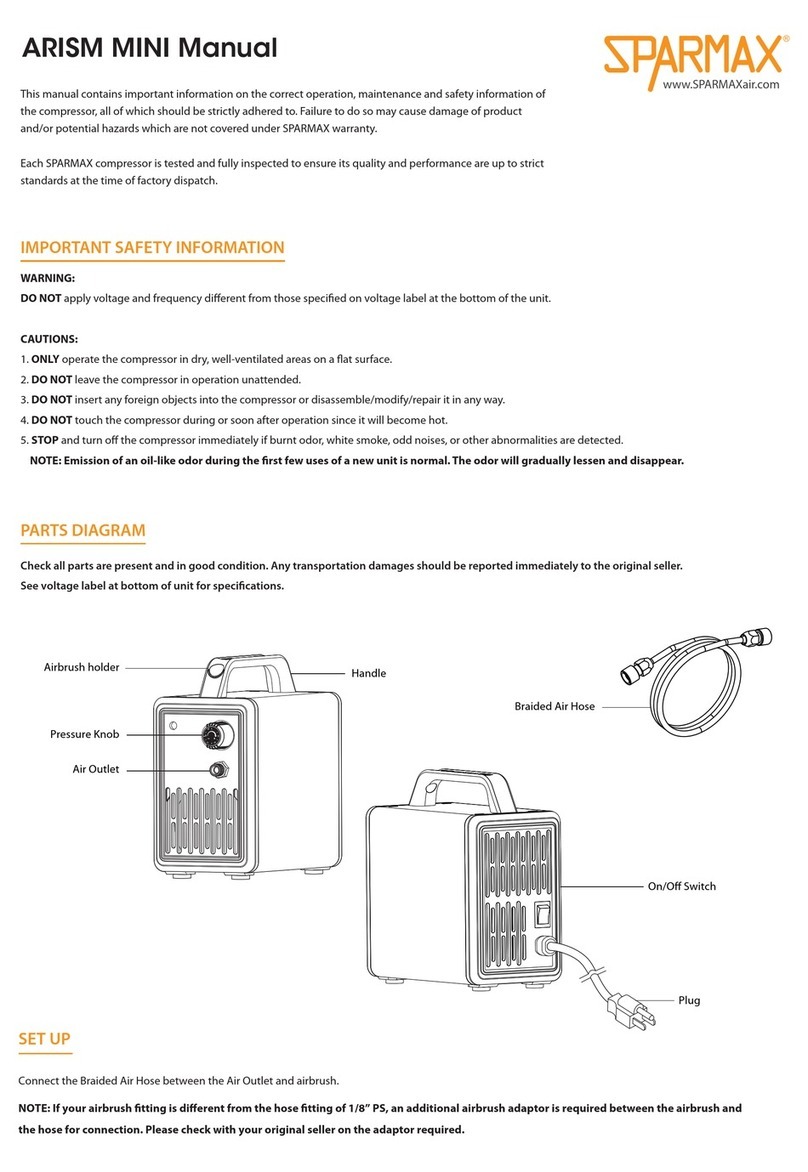

1. First use: Carefully unpack the unit, verify that all parts listed in the “Parts List” are present, and visually inspect for damage. If there are any

signs of damage or if any parts are missing, do not use the product. Contact your retailer or supplier immediately.

2. Locate the compressor in a clean, dry, and well-ventilated area that has adequate air circulation.

3. Screw one end of the Braided Air Hose onto the compressor’s Air Outlet located below the Pressure Regulator Knob, and the other end of the

hose to the Silver Bullet™ Air Inlet.

4. Place the airbrush holder in the designated area.

5. Screw your airbrush into the Silver Bullet™ Air Outlet. NOTE: Different adaptors may be required for different airbrush brands and models.

If your airbrush needs an adapter, please contact your local retailer or supplier.

Product Operation

www.SPARMAXair.com

1. Plug the compressor into a power outlet. Turn the compressor on by pressing the On/Off Switch.

2.

4.

5.

3. The Pressure Gauge connected to the Pressure Regulator gives continuous, real-time readings of current air pressure delivery.

When condensation forms in the Silver Bullet™, push on the Silver Bullet™ Drain Valve to release built-up

moisture. Perform this operation as often as needed – with greater frequency the higher the humidity.

SUGGESTION: When pushing on the drain valve, hold a paper towel under the drain to collect water released

from the drain.

6. When the airbrush is not in use, it may be placed into the Airbrush Holder.

To adjust air pressure, pull up on the black Regulator Knob until you hear

a “click.” Turn the knob clockwise to increase air pressure (“+”sign), or

counter-clockwise to decrease air pressure (“–”sign). When the desired

pressure is reached, push down on the knob to lock it in place.

NOTE: Adjust pressure only when the compressor is turned on and connected

to an airbrush, with trigger depressed.

Troubleshooting

If airflow is not sufficient …

• Check for air leaks where air can be heard escaping, or apply a soap and water solution on all connections. Resulting bubbles indicate an air leak.

Tighten fittings where necessary.

• PTFE seal tape is recommended for all threaded connections.

• Replace the Air Hose if the hose is torn or damaged.

If compressor shuts off frequently, the motor fails to come up to full speed or becomes hotter than usual during operation …

• Disconnect other appliances that are using the same power outlet.

• Avoid using extension cords.

If problems arise which you cannot solve with the information provided above, please contact your retailer or supplier for assistance. Do not

attempt to fix the device yourself. Improper operation and/or dismantling of the device may damage the compressor. If any parts/accessories are

damaged, please contact your retailer or supplier for replacement or repair.

7. Do not touch any exposed metal parts on the compressor during, or immediately after, operation. The compressor will remain hot for several

minutes after operation.

8. It is recommended that the compressor run continuously for no more than one hour with the auto stop in action. After one hour of continuous

operation, use the On/Off Switch to turn off the unit. Allow the unit to cool for 10 to 15 minutes before turning the compressor back on.

9. The compressor has a thermal safety switch which automatically ceases compressor operation when the compressor becomes too hot. If this

happens, use the On/Off Switch to turn off the compressor. Allow the unit to cool for 10 to 15 minutes before turning the compressor back on.

After each use, make sure to disconnect the hose from the regulator outlet and allow the compressor to run for 2~3 minutes, such that the air

passage within the compressor can be air-dried. Then, turn off and unplug the unit.

10.

With a dual-action airbrush attached, but not in use, the Auto Stop Pressure

Switch automatically stops the compressor when the pressure reaches 60 psi,

and will automatically re-start the compressor when the airbrush trigger is

pushed down and the pressure drops to 40 psi. Do not attempt to remove the

Auto Stop Pressure Switch. In the rare instance that the switch malfunctions,

do not allow the compressor to operate above 80 psi, and run the compressor

continuously no more than 40 minutes.