teching Craftsman Galileo Pendulum Clock DM35 User manual

Galileo PendulumClock

Clock Series

Metallic MechanicalAssemblyModel

ck

ide +

Product name: Galileo pendulum clo

Product model: DM35

Main materials: anodic aluminum ox

stainless steel

Assembly difficulty: ★★

Quality grade: A

Assembly Instructions for Teching Craftsman

◆Perform assembly rigorously and orderly, keep the tabletop tidy, look at drawings carefully, and pay attention to safety;

◆If you have any doubt when adjusting any assembly clearance or tightness after the completion of assembly, please refer to our

website or WeChat public account;

◆The user is encouraged to modify part defects or fitting clearances, and apply lubricant under adult supervision to further

improve assembly;

◆The user is encouraged to use simple material removal tools (file, sandpaper, etc.)under adult supervision;

◆The user is encouraged to modify or generally refit parts of this product to enter the refitting stage as early as possible;

◆The user may disassemble this product and put it in the package again according to the parts list attached hereto;

◆If any part is lost, please inquire of or purchase it from us (Teching store on www.taobao.com);

◆The product structure is subject to continual improvement.If the real object differs fromthe instruction manual, please refer to

our latest assembly information.

If you are willing to share with us, after completing product assembly tasks of different difficulty levels at different stages,

you will receive corresponding gifts, and have a chance to win our special medals and take part in relevant events.

“Teching Craftsman” is a metallic assembly model other than a toy for playing only. It serves to improve hands-on

skills of children and youngsters, and let them learn common industrial knowledge mainly. By keeping using our

products, the user can reach the goal of assembly –refitting –creation in stages.

The requirements for product assembly are as follows:

•1. Some safety awareness is required to use this product, and improving safety awareness is also one of the functions of this

product;

•2. This product is not intended for children below 8 years, and adult guidance on assembly is recommended for children

below 10 years;

•3. Use assembly tools rationally, assemble the parts in strict conformity with the instruction manual, and avoid forcible

handling to avoid scratches;keep sharp points of tools or parts away from the eyes to avoid contusions;

•4. This product is made up of metallic parts mainly, and has a certain level of hardness and a certain weight; please place it

properly to avoid bodily injuries;

•5. During mechanical movement, do not put a finger or any other part of the body within the movement range to avoid

contusions;

•6. When any mechanical part is turning, do not put a finger or any other part of the body beside it to avoid entanglement and

contusions;

•7. Wire connectors must be connected according to the marks specified in the instruction manual to avoid short-circuit or

failure arising from wrong connection;

•8. Charge,discharge and place the battery as required;it is advised to replace the battery when it has not been used for3

months or more;

•9. Do not prevent any part fromrunning forcibly in any form;to do this, turn off the power directly;

•10. The charging cable of the product is a 5V dedicated cable (USB). Do not use any other charging cable to avoid damaging

the circuit.

•11. To refit this product, please pay attentionto the relevant part parameters, and avoid using any high-power electric part

that may result in an accident.

Safety Tips

Contents

Assembly of top cap

Assembly of main

board

Assembly of pendulum

Assembly of base

Assembly of rope

1

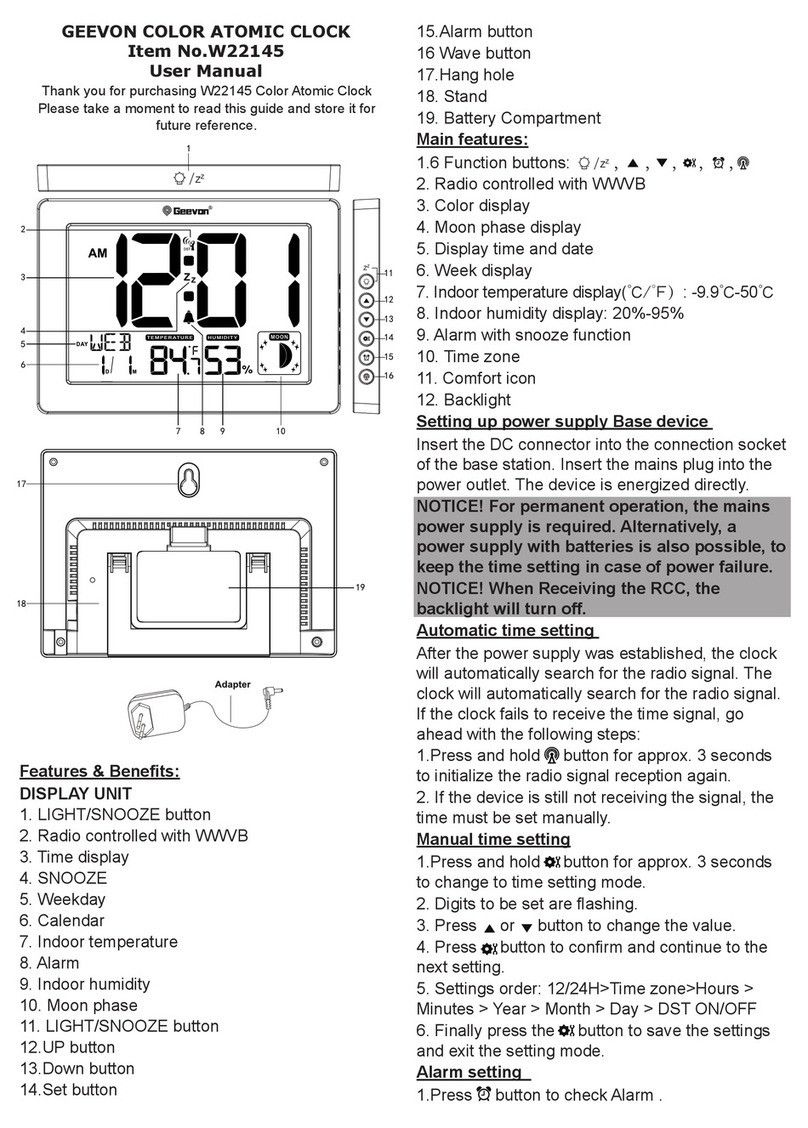

Right Wrong

2. Mounting sequence of screws

Mount the screws diagonally in

order of number.

Teching Craftsman®

Basic knowledge on standard parts assembly

1. Mounting of screws 3. Mounting of snap ring

Right Wrong

Push in thesnap

ring in parallel. Push in the snap

ring obliquely

4. Lubricant mark

Where this mark is shown, it is recommended to apply

create to improve mechanical performance.

Teching Craftsman®

2

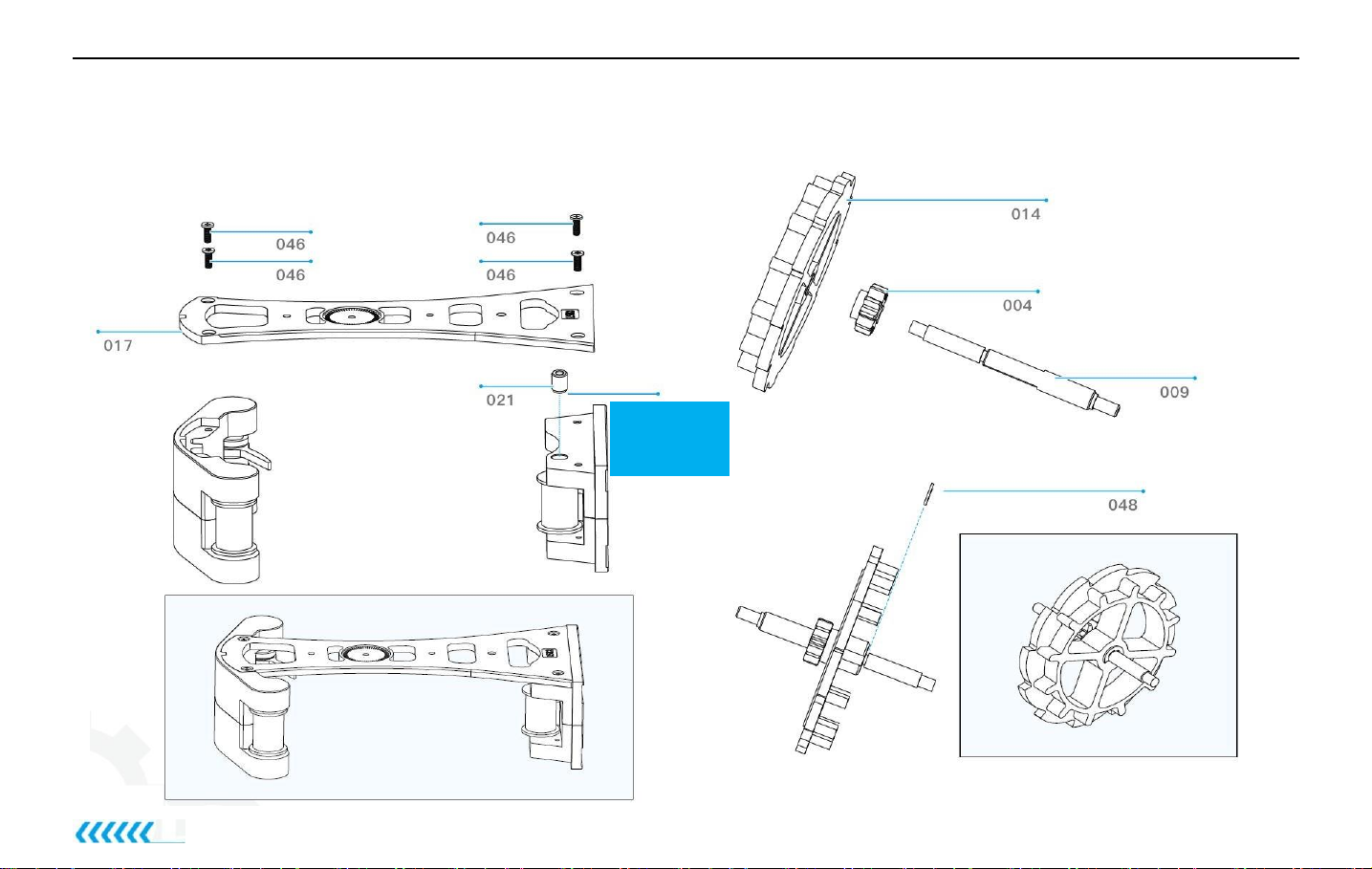

1. Assembly of top cap

1.1 Mounting of pulley

The slot of the ratchet pawl

should hang on this boss.

1.3 Mounting of ratchet pawl

1.2Assembly of rope pulley and

front top cap

1.4Assembly of ratchet pawl and front top cap

Teching Craftsman®

3

1.5 Mounting of swing arm 1.6Assembly of swing arm and front top cap

The eyelet faces

downward when

this swing armis

placed

horizontally.

Level

The eyelet

faces the front.

Flat and

facingupward

Teching Craftsman®

4

1.7 Assembly of front and rear top caps 2. Assembly ofbase

2.1 Mounting of pulley

2.2Assembly of pulley and front base

Teching Craftsman®

5

2.4Assembly of front and rearbases2.3 Mounting of cylindrical pin and front base

Teching Craftsman®

6

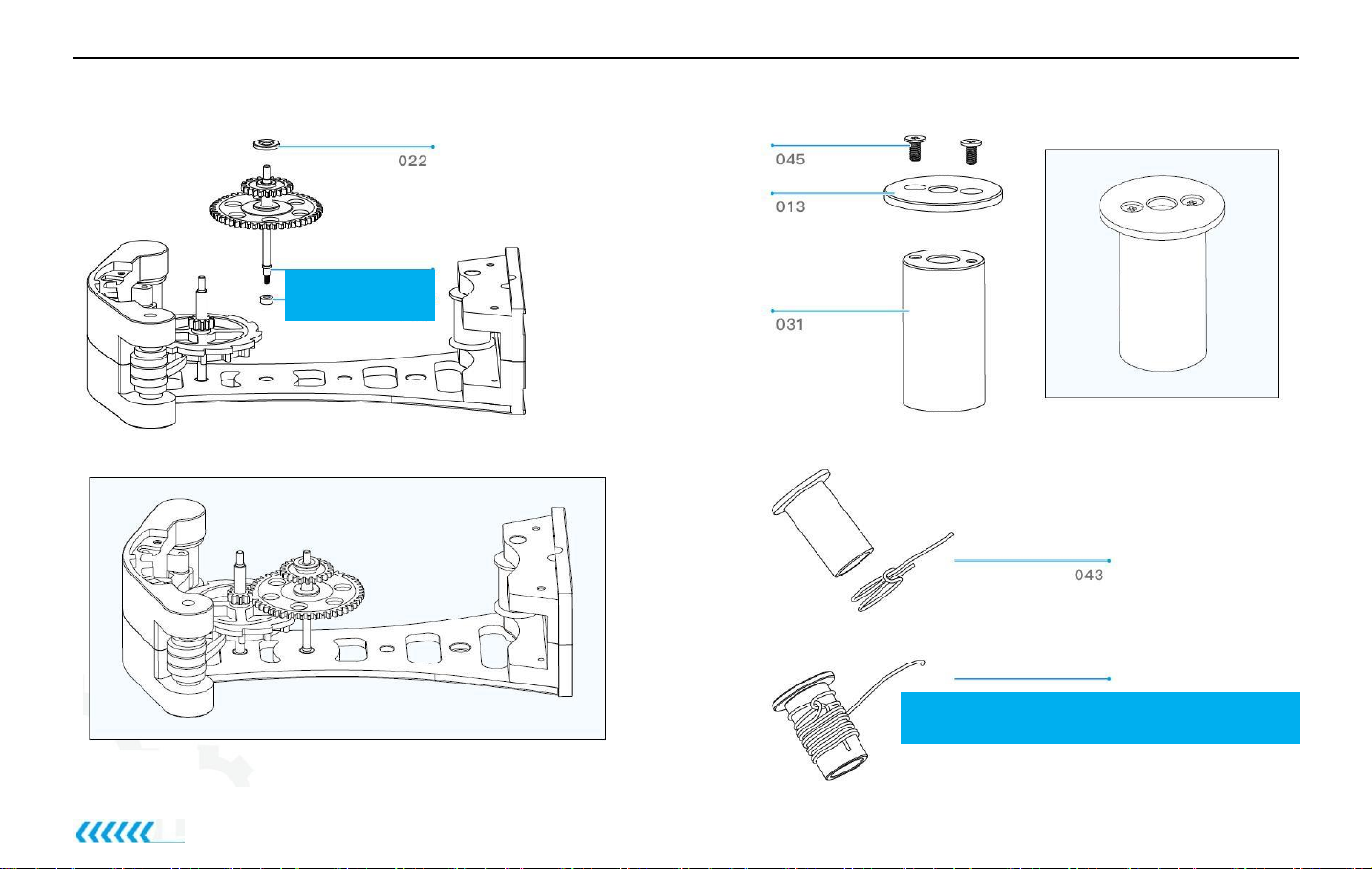

3 Assembly of main board

3.1 Mounting of front main board, top cap and base 3.2 Mounting of ratchet

The small

end faces

downward.

Teching Craftsman®

7

3.3 Mounting of ratchet and front main board 3.4 Mounting of Shaft II and gear

Teching Craftsman®

8

3.5 Combination of Shaft II, gear and front main

board

Wind the rope reversely and tightenen the

rope end to prevent the knot from loosening.

3.6 Mounting of rope pulley

3.7 Winding of knot

The threadfaces

downward.

Teching Craftsman®

9

3.8 Mounting of rope pulley, rope pulley shaft and gear 3.9 Mounting of rope pulley and front main board

Run the rope through the inside

of the pulley.

Teching Craftsman®

10

3.10 Mounting of Shaft I and gear 3.11Assembly of Shaft I, gear and front main board

The long end is

the direction of

the bull gear.

Teching Craftsman®

11

3.12 Mounting of rope pulley and bearing

The small

end faces

downward.

3.13 Mounting of rear main board

Teching Craftsman®

12

3.14 Mounting of rear main board and bearing 3.15 Fixation of rear main board

Teching Craftsman®

13

3.16 Mounting of rear main board and shaft cap 3.17 Mounting of foot pad Remove the sealing

sticker during

mounting.

Teching Craftsman®

14

4. Assembly of rope

4.1 Mounting of rope and pulley

Wind the rope end

reversely by one turn, and

then tighten the lock screw

to prevent the knot from

loosening.

Step 1:

Wind the rope up from the

bottom of the pulley.

4.2 Mounting of rope in drop hammer cap

This is a X5

schematic view of

winding of PointA.

Step 3:

Run the rope through the

center hole of the drop

hammer cap.

Step 2:

Wind the rope from inside the

pulley.

Table of contents

Other teching Clock manuals