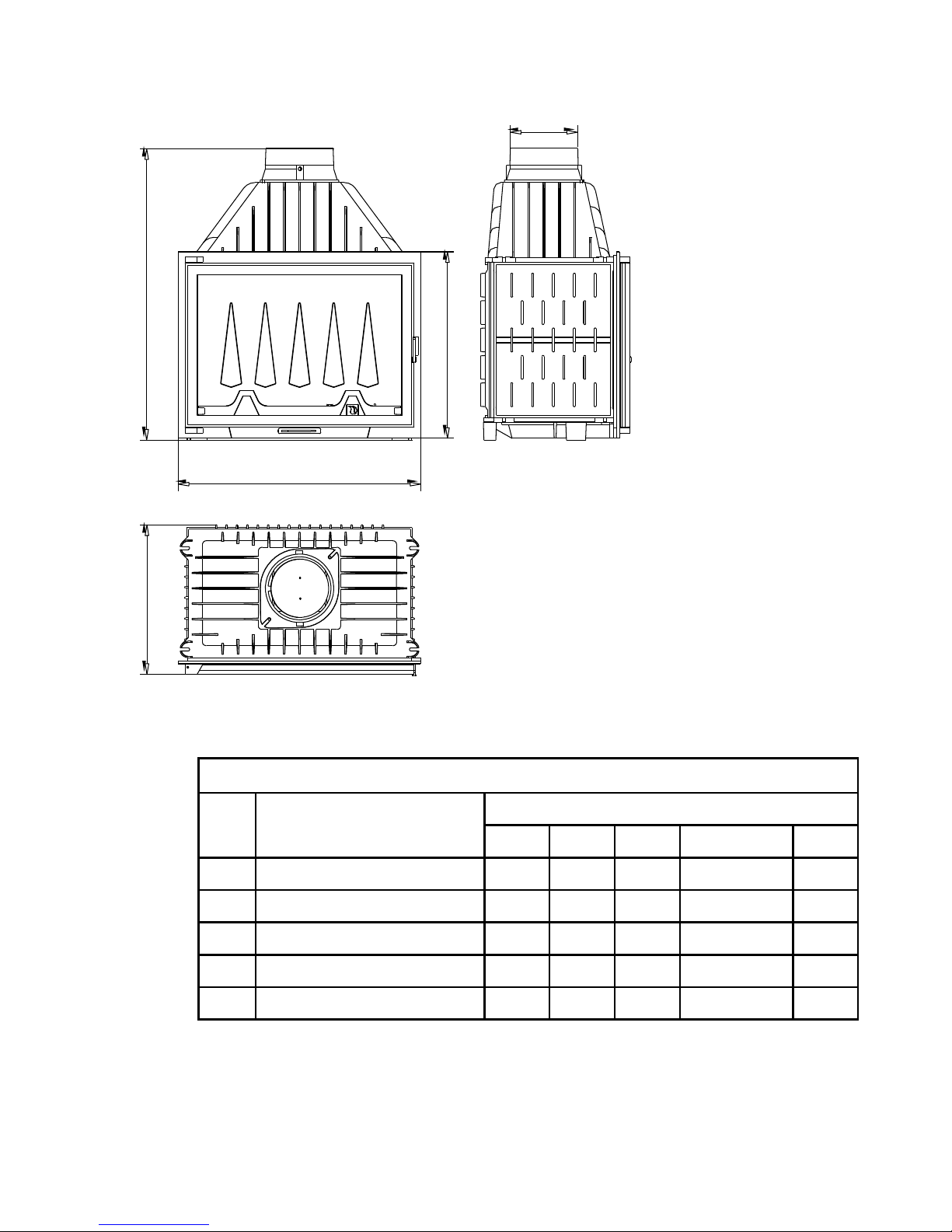

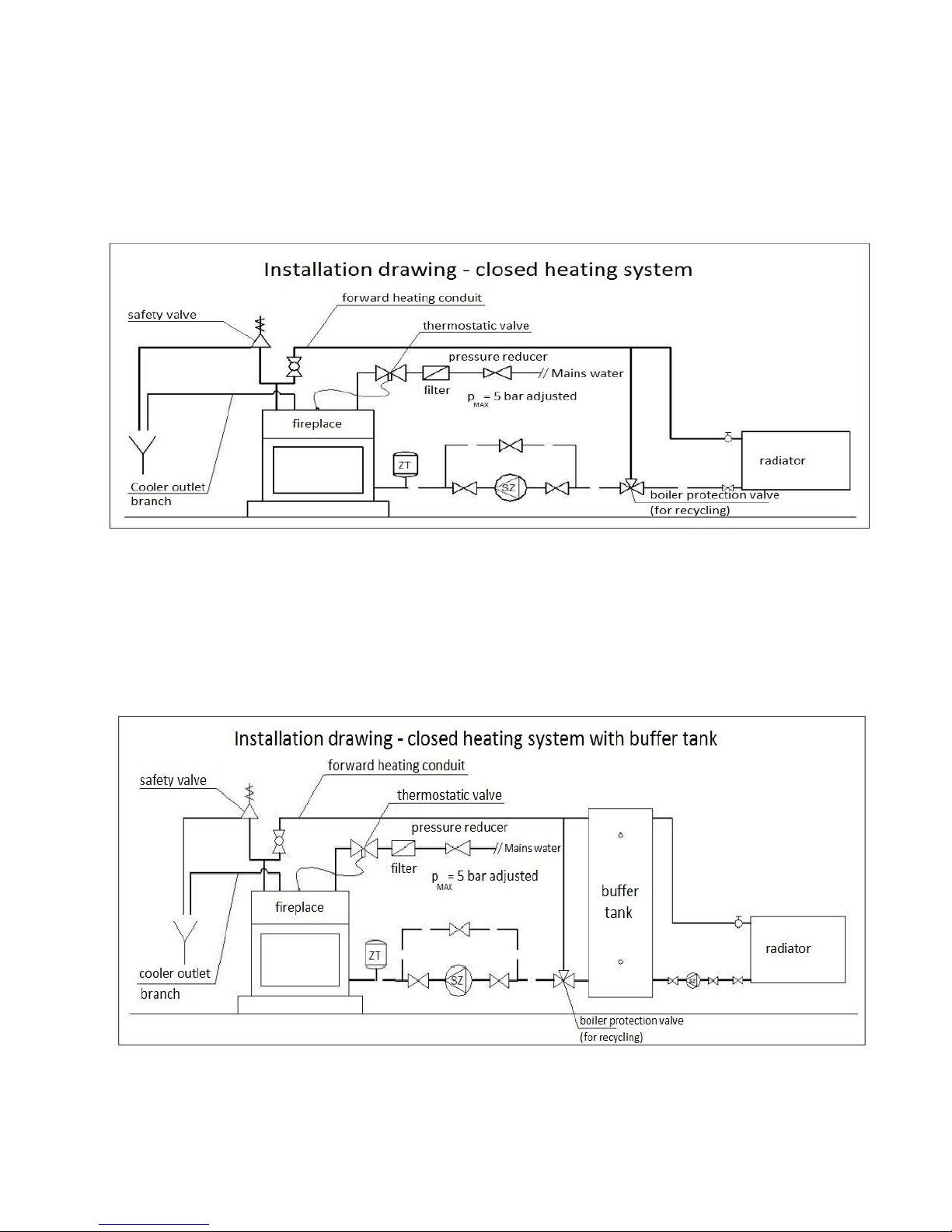

Technical PanTherm PT80 User manual

This manual suits for next models

23

Table of contents

Popular Indoor Fireplace manuals by other brands

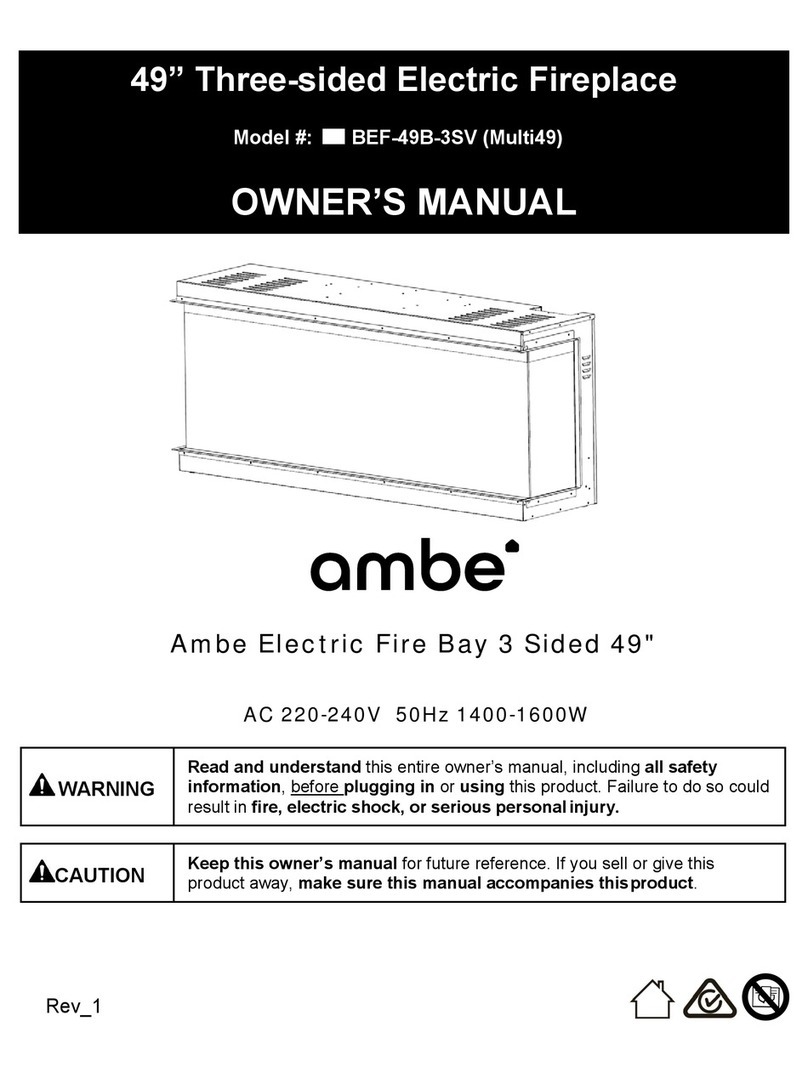

ambe

ambe Multi49 owner's manual

Valor

Valor 1200EAN Installation and configuration

Nordpeis

Nordpeis Panama installation manual

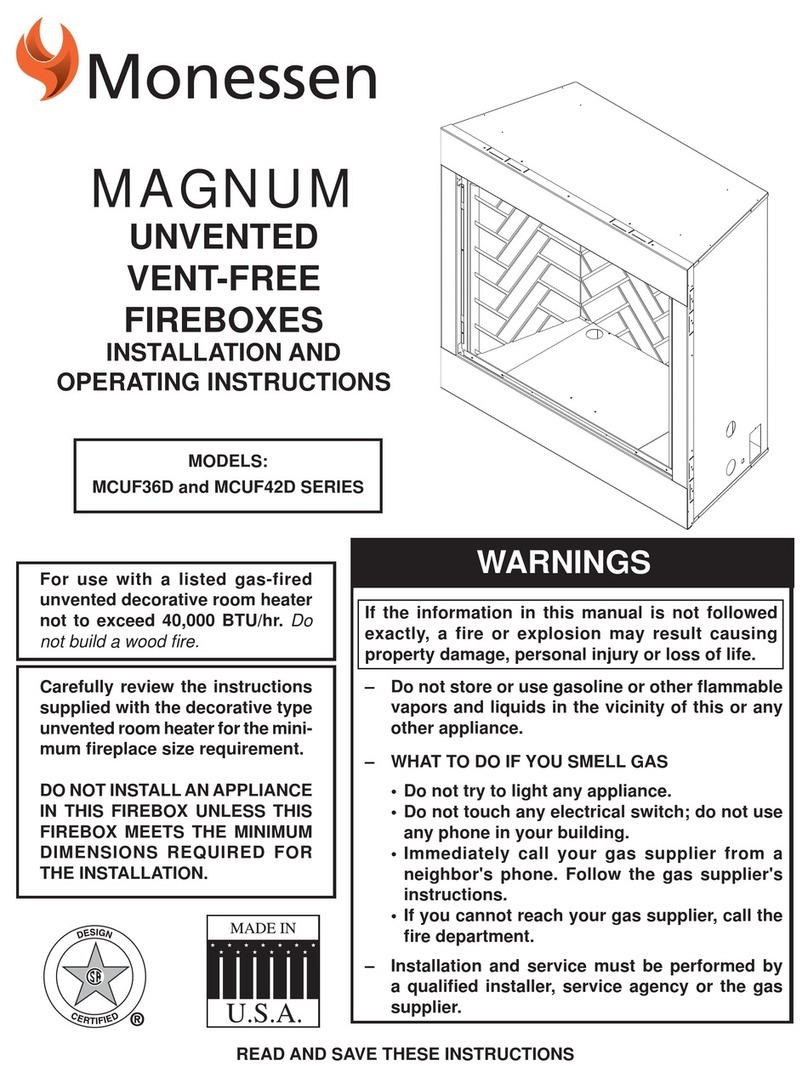

Monessen Hearth

Monessen Hearth Magnum Unvented Vent-Free Fireboxes MCUF42D... Installation and operating instructions

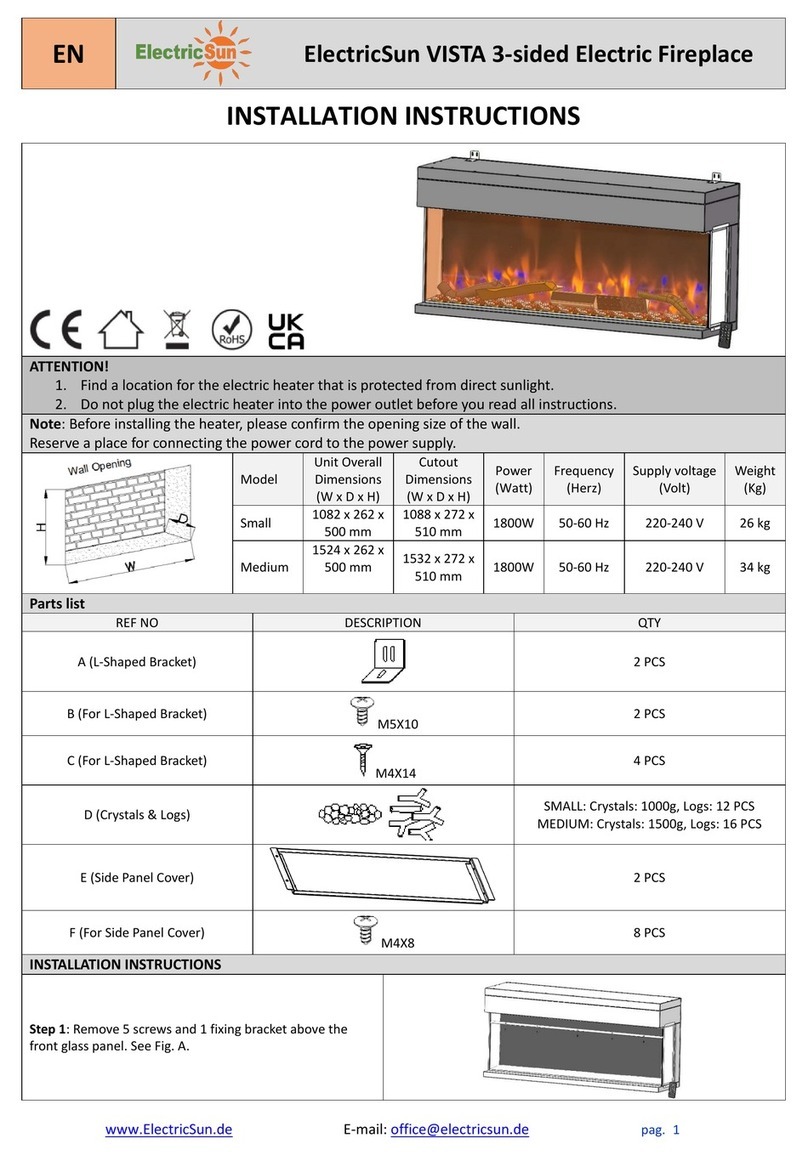

ELECTRICSUN

ELECTRICSUN VISTA installation instructions

Valcourt

Valcourt ANTOINETTE FP7CB Quick install guide

AFLAMO

AFLAMO Fort BB owner's manual

Plamen International

Plamen International Vesta Installation and operating instructions

Jetmaster

Jetmaster DROP IN 1020 Installation and operation instructions

Sirocco

Sirocco Streamline 3 Installation and user instructions

pleasant hearth

pleasant hearth LH-24 operating instructions

Ecoflam

Ecoflam MAX GAS 40 P operating instructions

Twin-Star International

Twin-Star International 18EF023GRA manual

Rinnai

Rinnai Evolve RHFE950ETRN installation guide

Archgard

Archgard OPTIMA 22 User's installation, operation and maintenance manual

Desa

Desa Vanguard VI33PR OWNER'S OPERATION AND INSTALLATION MANUAL

Majestic

Majestic JADE42IN owner's manual

Flamerite Fires

Flamerite Fires Luma Series Installation, Precautions & Servicing