Technisonic Industries Limited TiL-91-DE/8.33 User manual

VHF/AM BASE STATIONS

MODEL TiL-91-DE/8.33

7 WATT SYSTEM NO. 920607, Opt.8.33 (TBS-150/8.33)

15 WATT SYSTEM NO. 910815, Opt.8.33 (TBS-250/8.33)

25 WATT SYSTEM NO. 910825, Opt.8.33 (TBS-350/8.33)

Installation and

Operating Instructions

Til Document No.

02RE304

Rev. N/C

October, 2002

Technisonic Industries Limited

240 Traders Blvd., Mississauga, Ontario L4Z 1W7 Tel:(905)890-2113 Fax:(905)890-5338

www.til.ca

A Page

WARNING

Do not make physical contact with antenna when transmitter is on. This unit can produce up to 30 watts of

power (depending on configuration) when operated in high power mode.

CAUTION

This unit contains static sensitive devices. Wear a grounded wrist strap and/or conductive gloves when

handling printed circuit boards.

WARRANTY INFORMATION

The Base Stations, Model 91-DE/8.33 series and Model Til 90-6R/8.33 series are under warranty for one

year from date of purchase. Failed units caused by defective parts, or workmanship should be returned to:

Technisonic Industries Limited

240 Traders Blvd.

Mississauga, Amherst, NY, USA

Ontario L4Z 1W7

Tel: (905) 890-2113 Tel: (716) 691-0669

Fax: (905) 890-5338

i

TABLE OF CONTENTS

Paragraph Title Page

iSECTION 1 GENERAL DESCRIPTION

1.1 Introduction ........................................................... 1-1

1.2 Description ........................................................... 1-1

1.2.1 Transceivers - Models Til-91-DE/8.33, Til-90-6R/8.33 ......................... 1-3

1.2.2 Power Supply Modules - Models SPG-007, SPG-015, SPG-025 ................ 1-3

1.2.3 RF Amplifier Modules - Models PA-15, PA-25 ............................... 1-3

1.2.4 DistributionBoard-MarkIISeries ........................................ 1-3

1.2.5 RemoteControlBoards-MarkIISeries .................................... 1-4

1.2.6 Microphone P/N 861902 ................................................ 1-4

1.2.7 Antenna ............................................................. 1-4

1.3 Modes of Operation .................................................... 1-5

1.3.1 Transmit/Receive Modes (Local Mode) .................................... 1-5

1.3.2 Local/RemoteOperation ................................................ 1-5

1.3.3 AC and DC Operation .................................................. 1-6

1.4 TechnicalSummary.................................................... 1-6

SECTION 2 PREPARATION FOR USE AND STORAGE

2.1 Introduction ........................................................... 2-1

2.2 Disassembly/Assembly ................................................. 2-1

2.2.1 Remove/ReplaceCoverAssembly ........................................ 2-1

2.2.2 Remove/Replace Microphone ............................................ 2-1

2.2.3 Remove/ReplaceTransceiver ............................................ 2-2

2.2.4 Remove/Replace Power Supply .......................................... 2-4

2.2.5 Remove/Replace RF Power Amplifier Module ............................... 2-4

2.2.6 Remove/ReplaceDistributionBoard ....................................... 2-5

2.2.7 Remove/ReplaceControlBoard .......................................... 2-5

2.3 RemoteOperationSetUp-LineInterfaceBoards(MarkIISeries)............... 2-6

2.3.1 Two Wire Line Interface board P/N 923051-1 (TLI-203) . . ..................... 2-7

2.3.2 Two Wire Line Interface board P/N 943180-1 (TLI-180) . . ..................... 2-7

2.4 Loudspeaker, Headphone Installation .................................... 2-12

2.4.1 External Loudspeaker ................................................. 2-12

2.4.2 Headset ............................................................ 2-12

2.5 Operational Check .................................................... 2-12

2.6 Storage ............................................................. 2-12

ii

TABLE OF CONTENTS (Continued)

Paragraph Title Page

SECTION 3 TRANSCEIVER SET UP and OPERATING INSTRUCTIONS

Index to Section 3 ...................................................... 3-1

LIST OF TABLES

Table No. Title Page

1-1 BaseStationConfigurations ............................................. 1-1

1-2 Base Station Leading Particulars ......................................... 1-7

2-1 9-Pin "D" Type Remote Connector Functions ............................... 2-6

2-2 9-Pin Positronics Type Remote Connector Functions ......................... 2-7

LIST OF ILLUSTRATIONS

Figure No. Title Page

1-1 BaseStations ......................................................... 1-2

2-1 BaseStationAssembly/Disassembly ...................................... 2-3

2-2 Line Interface/Control Board, P/N 923051-1 (TLI-203) . . . .................... 2-10

2-3 Line Interface/Control Board, P/N 943180-1 (TLI-180) . . . .................... 2-11

(Refer to Index to Section 3, Page 3-1 for Illustrations located in Section 3)

1-2

SECTION 1

GENERAL DESCRIPTION

1.1 INTRODUCTION

Sections 1 and 2 of this publication provide general information on Technisonic VHF/AM Base

Station Systems, Item No.'s TBS-100/150, TBS-200/250 and TBS-300/350. All of the systems

described in this publication include the 8.33kHz spacing option and are designated with an /8.33

suffix. Information for models indicated on the front cover can be found in Section 3.

The /8.33 Base Station Systems consist of a simplex transceiver complete with microphone,

operating over the frequency range of 117.975 to 138.000 MHz with both 8.33 and 25kHz channel

spacing. The Base Station Systems are intended for base station operation in an air traffic

environment. These systems can operate from AC power or external DC power in local and

remote operating modes.

TABLE 1-1 BASE STATION CONFIGURATIONS

System Transceiver Power Supply RF Amplifier Remote

Control

TBS-150/8.33

91-DE/8.33, 7W Base

Station

System No. 920607

w. Option 8.33

Model 91-DE/8.33

P/N 901006

w. Option 8.33

SPG-007

P/N 921020-1

Not Required Optional in

all Units

P/N's

923051-1

943180-1

TBS-250/8.33

91-DE/8.33, 15W

Base Station

System No. 910815

w. Option 8.33

Model 91-DE/8.33

P/N 901006

w. Option 8.33 and

Option 1

SPG-015

P/N 911018-1

PA-15

P/N 912025-1

TBS-350/8.33

91-DE/8.33, 25W

Base Station

System No. 910825

w.Option 8.33

Model 91-DE/8.33

P/N 901006

w. Option 8.33 and

Option 1

SPG-025

P/N 911019-1

PA-25

P/N 922062-1

TBS-100/8.33

90-6R/8.33 7W

Base Station

System No. 920707

w. Option 8.33

Model 90-6R/8.33

P/N 861605

w. Option 8.33

SPG-007

P/N 921020-1

Not Required

TBS-200/8.33

90-6R/8.33, 15W

Base Station

System No.910915

w. Option 8.33

Model 90-6R/8.33

P/N 861605

w. Option 8.33

Option 1

SPG-015

P/N 911018-1

PA-15

P/N 912025-1

TBS-300/8.33

90-6R/8.33, 25W

Base Station

System No. 910925

w. Option 8.33

Model 90-6R/8.33

P/N 861605

w. Option 8.33

Option 1

SPG-025

P/N 911019-1

PA-25

P/N 922062-1

1-2

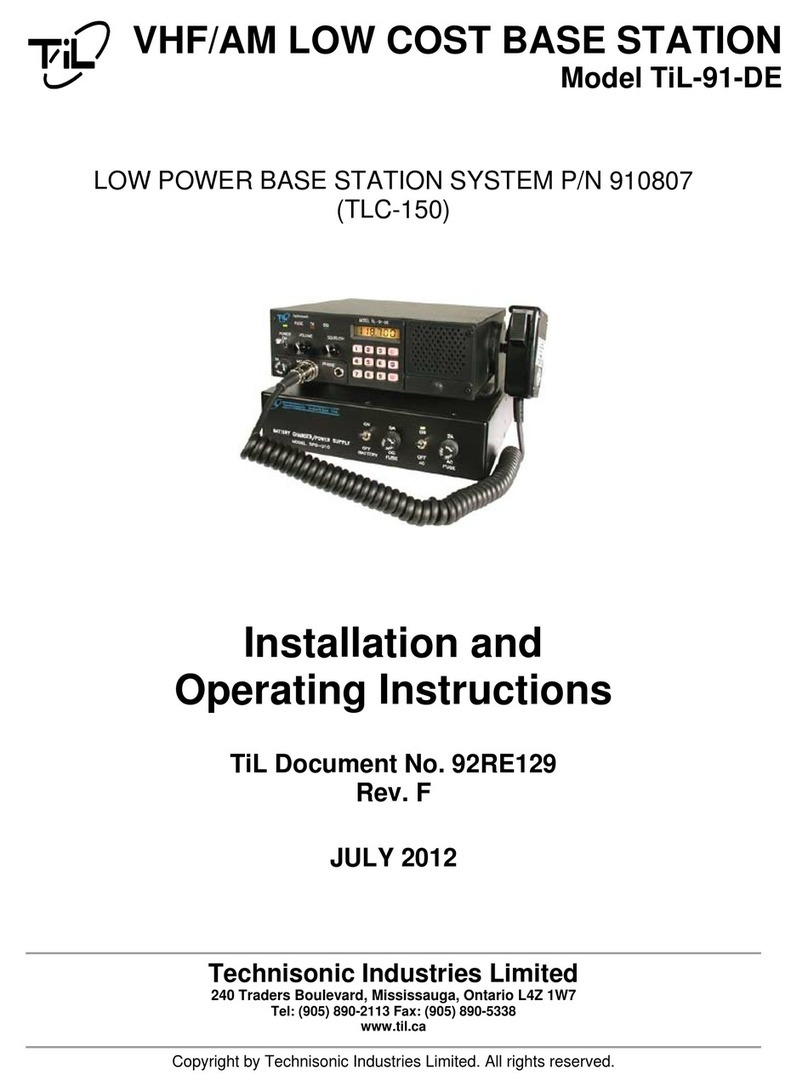

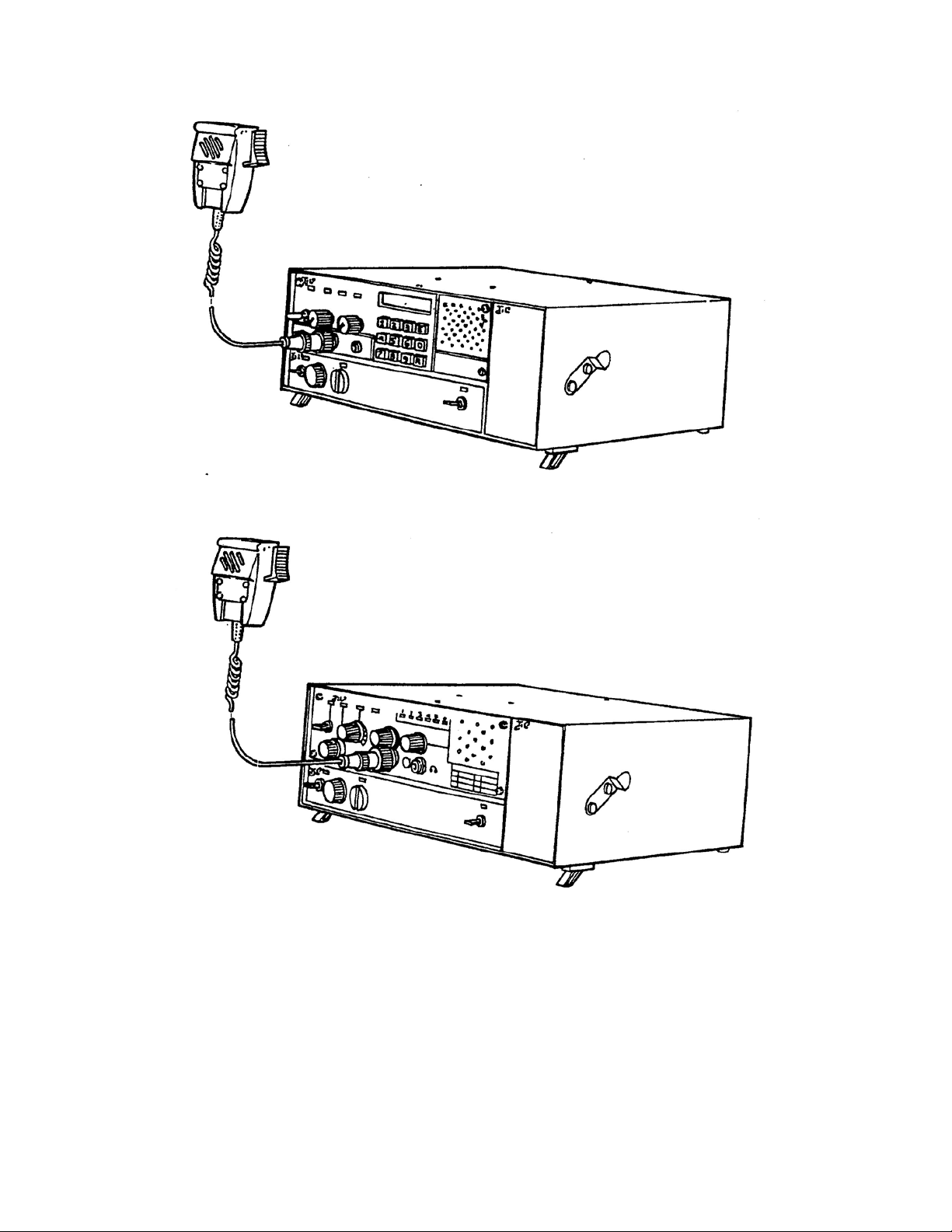

Til-91-DE/8.33 SERIES BASE STATIONS

Til-90-6R/8.33 SERIES BASE STATIONS

Figure 1-1 TBS-Series ase Stations

1-3

1.2 DESCRIPTION

The six base station configurations are based on either the LCD with keypad entry transceiver (TiL

91-DE/8.33) or six channel (TiL 90-6R/8.33) pre-programmable transceiver configured for 7 Watt, 15

Watt or 25 Watt operation. All systems are configured for use of optional Line Interface/Control boards

for remote operation. Each base station consists of a Transceiver, Power Supply Module, RF Amplifier

Module, Microphone and Control Board (optional). Refer to Table 1-1 for system configuration details.

To improve the rejection of interfering signals, dual conversion receiver technology has been

incorporated on the Transmitter/Receiver (Module A1) board used in Technisonic VHF/AM base

stations. The second IF is 455kHz using a ceramic filter, which is immune to high energy

ringing. The dual conversion module also has a second local oscillator, second mixer and

ceramic filter. The first local oscillator is the original VCO.

The dual conversion receiver board, P/N 003494-1 was implemented into TBS and TSC series base

stations starting in January 2001. An option label on the chassis will indicate OPTION 94 if the dual

conversion board is installed. It is possible to retro-fit the dual conversion receiver/transmitter board

into older TSC/TBS series base station employing the single conversion board. Please contact

Technisonic for availability of an exchange board. Note:

If a new A1 Module has been retrofitted the squelch circuit must be aligned for the receiver

squelch to operate correctly.

The dual conversion receiver’s squelch knob must be rotated significantly more clockwise (4

o’clock position) to obtain the same squelch setting (3uV) as a single conversion receiver’s

squelch knob set to the 12 o’clock (straight up) position.

If the dual conversion receiver’s squelch knob is set to the 12 o’clock position, signals with a

level greater than 0.5uV will open the squelch. At most airports this will not be an adequate level

of squelch. Please be aware of this squelch knob adjustment variance when setting and/or

comparing squelch levels of dual conversion vs. single conversion base stations.

1.2.1 Transceivers - Models TiL-91-DE/8.33 and TiL-90-6R/8.33

The basic model of each transceiver is required for the 7 Watt Base Stations. Option 1 indicates that

the basic transceiver has a DC to DC convertor (Module A6) installed to facilitate operation with the

RF Amplifier Module. Refer to Section 3 for specific details on the Transceiver unique to the systems

indicated on the front cover of this document.

1. Transceiver Model TiL-91-DE/8.33, P/N 901006-2 with Option 8.33

Transceiver Model Til-91-DE/8.33, Part Number 901006-2 with Option 8.33, is a microprocessor

controlled, 7 watt VHF/AM transceiver operating over the entire band of 117.975 to 138.000 MHz in

25 or 8.33 kHz steps. The transceiver will store (25) user selected frequency channels in addition to

the resident emergency channel of 121.500 MHz. Frequency Selection, Storage, Recall, Channel

Scan, Search, and Toggle modes are all selected by the 12 key keypad. Current operating frequency

is displayed on a backlit liquid crystal display (LCD).

2. Transceiver Model TiL-90-6R/8.33, P/N 861605-2 with Option 8.33

Transceiver Model 90-6R/8.33, Part Number 861605-2 with Option 8.33, is a 7 watt VHF/AM

transceiver which operates in simplex on six preprogrammable, frequency synthesized channels, with

25 or 8.33 kHz channel spacing in the frequency range 117.975 MHz to 138.000 MHz.

1.2.2 Power Supply Modules - Models SPG-007, SPG-015, SPG-025

The Power Supply Modules provide the DC supply voltage to the Transceiver and Linear Amplifier,

and houses a battery charger which can provide charging and trickle charging to external

rechargeable batteries. Model SPG-007 is for use in the 7 Watt configurations, Model SPG-015 is for

use in the 15 Watt configurations, Model SPG-025 is for use in the 25 Watt configurations.

1-3

1.2.3 RF Amplifier Modules - Models PA-15 and PA-25

The RF Amplifier modules provide 15 Watt (Model PA-15) or 25 Watt (Model PA-25) power output

when the front panel switches are set to High. The RF Amplifiers are fed by the 7 Watt RF output

from the transceiver. An internal mounted RF relay bypasses the RF Amplifier in receive and low

power transmit modes.

1.2.4 Distribution Board

The Distribution Board provides all interconnection between the External DC connector, RF Amplifier

Module, Power Supply/Charger, Remote Control Board (optional), and Transceiver. The optional Line

Interface/Remote Control Boards are mounted on the Distribution Board. The distribution board

provides a 9-pin D connector and RJ-11 (2-wire audio available only) telephone style jack for access

to signals provided by the remote control board. The Line Interface/Remote Control boards indicated

in Table 1-1 are available for use with this distribution board.

1-4

1.2.5 Remote Control Boards - Mark II Series

1. Line Interface Board P/N 923051-1 (TLI-203)

Provides remote control transceiver operation on 2 wire or 4 wire 600 ohm lines. This board can be

configured to key the transmitter using a 2175 Hz* continuous tone (see below), plus/minus DC

Voltages, ground keying and internal or external DC (15 mA) current loop keying. Transmit and

Receive audio is user selectable for two wires or four wires. *Crystals for tone frequencies other than

2175 Hz may be obtained by special order (ie/2380 Hz). An adjustable (30-300 second) Tx time out

function is provided on this board.

2. Line Interface Board P/N 943180-1 (TLI-180)

Provides remote control transceiver operation on 2 wire dedicated 600 ohm lines utilizing the EIA

multi-tone keying format found in the Land Mobile Industry. A high level 2175 tone followed by a 1950

Hz guard tone and then a low level 2175 Hz continuous tone is utilized to key the transceiver. The

943180-1 board can also be jumper strapped for standard aeronautical 2175 Hz continuous tone

operation. DC (15mA) current loop and ground keying is also supported. However this board does

not support 4 wire operation. An adjustable (30-300 second) Tx time out function is provided on this

board.

NOTE P/N 923051-1 is the default board supplied in all units. The EIA multi-tone board

P/N 943180-1 must be special ordered. To determine which remote card your TBS-series

base station has installed, the Configuration label on the back of the chassis should be

consulted.

1.2.6 Microphone P/N 861902-1

An illustration of the Microphone Assembly Part Number 861902-1, is included in Figure 1. The

Assembly P/N 861902-1 consists on microphone P/N 861901-1 and microphone retaining bracket P/N

863905-1. The unit is a rugged hand-held microphone housed in a high impact plastic case. The

dynamic microphone is a noise cancelling type with a two- stage preamplifier, press-to-talk switch,

and a retractable three-core cable terminated by a three-pin, male contacts, connector which mates

with the MIC/PTT connector located on the front panel of the transceiver. The microphone dc supply

for the microphone is supplied by the transceiver. The microphone bracket can be mounted on the

left or right side of the Base Station as required.

1.2.7 Antenna

This unit is designed for use with a 50 ohm impedance antenna (not supplied). A 50 ohm RF N type

connector (BNC available as an option) is provided on the rear of the unit for interfacing with an

antenna.

1-5

1.3 MODES OF OPERATION

Refer to Section 3 for additional operating modes.

1.3.1 Transmit/Receive (Local Mode)

The transceiver may be operated in either of two modes; transmit or receive, as selected by the

Press-to-Talk (PTT) switch on the microphone.

(1) TRANSMIT MODE - When the PTT switch on the microphone is pressed, the transceiver

operates in the transmit mode. The PTT signal line is grounded by the microphone PTT

switch via the microphone lead and the MIC/PTT connector to the transceiver. The Tx ON

amber LED will go ON, indicating that the transmitter is activated.

Transmission will occur on the channel frequency indicated on the front panel. Refer to

Section 3 for transceiver details

(2) RECEIVE MODE - When the PTT switch on the microphone is released, the transceiver

operates in the receive mode. The Tx ON amber LED will go OFF, indicating that the

transmitter is inhibited.

The setting of the SQUELCH CONTROL determines the squelch threshold level. When

the SQUELCH CONTROL is rotated in the counter-clockwise direction, the SQUELCH

INDICATOR green LED will go ON, indicating that the squelch circuit is connecting the

demodulated audio to the VOLUME CONTROL. The setting of the VOLUME CONTROL

determines the audio level produced from the internal speaker. When the VOLUME

CONTROL is adjusted in the clockwise direction, the audio level will increase.

NOTE

When the connector of the external loudspeaker or

head phone is connected to the SPEAKER/PHONE

jack, the internal loudspeaker is disconnected and the

VOLUME CONTROL will control the audio level of the

external loudspeaker or headphone.

1.3.2 Local/Remote Operation

Base Stations which employ the TiL-90-6R/8.33 or TiL-91-DE/ 8.33 transceiver operate in local

and remote modes simultaneously. (The Model TiL-91-DE/8.33 transceiver can be operated in Local

or Remote modes as selected by a front panel switch, upon special request.)

1. LOCAL OPERATION - In local operation, voice audio, and keying (PTT) functions are

routed from the microphone to the transceiver. Receive audio is routed to the internal

loudspeaker.

2. REMOTE OPERATION - In Remote operation, transmit audio, keying (PTT), and receive

audio functions are routed over land lines to the 600 ohm remote input. Internal jumpers

can be set for ±DC, ground transmitter keying, tone keying or current loop keying,

depending on the line interface/remote control board utilized.

1-6

1.3.3 AC and DC Operation

The unit can be operated by external 120 VAC (220 VAC operation available) or external 28

VDC (13.7 VDC for 7W configurations).

1. AC OPERATION - During AC operation, the unit can charge and trickle charge external

batteries via the External DC connector mounted on the rear panel of the Base Station.

Refer Table 1-2 for details.

2. DC OPERATION - The unit can be operated from an external DC supply within the range

of 21.6 Vdc to 30 Vdc for 15 watt and 25 watt configurations and within the range of 11.5 Vdc

to 15.0 Vdc for 7 watt configurations. A DC connector is mounted on the rear of the Base

Station which mates with DC Power Cable P/N 863701-1 (Not Supplied) to facilitate external

DC operation.

The following battery back-up kits are also available for TBS-series base stations:

P/N 989978-1, 24 Volt Battery Back-up Kit (7.2 AH)

For use with 15watt/25watt TBS-series Base Stations. Provides a minimum of 4 hours back-up

for 25 watt unit with 20% Tx and 80% Rx duty cycle. Note: Back-up time for 15 watt unit is

approximately 40% longer.

Kit includes:

qty. (1) p/n 987370-3, DC mating cable with battery connectors.

qty. (2) p/n LCR 12V7.2P, 7.2 amp hour sealed lead acid batteries.

qty. (1) p/n 987246-2, battery interconnect cable.

qty. (1) p/n 968211, battery hook-up instructions.

P/N 989979-1, 12 Volt Battery Back-up Kit (7.2 AH)

For use with 7 watt TBS-series Base Stations. Provides a minimum of 6.5 hours back-up for 7

watt unit with 20% Tx and 80% Rx duty cycle.

Kit includes:

qty. (1) p/n 987370-3, DC mating cable with battery connectors.

qty. (1) p/n LCR 12V7.2P, 7.2 amp hour sealed lead acid battery.

qty. (1) packing log/ instructions.

1.4 TECHNICAL SUMMARY

A summary of electrical, operational, mechanical and physical characteristics of the Base Station are

provided in Tables 1-2 and 3-1.

1-7

TABLE 1-2 BASE STATION SYSTEM LEADING PARTICULARS

POWER REQUIREMENTS:

7 Watt Base Stations

AC Input Voltage/Current ........................... 100 to 132 VAC @ 1.0 Amp

AC Input Voltage/Current (Available) ................. 190 to 250 VAC @ 0.5 Amp

DC Input Voltage/Current ...................... 11.5VDCto15VDC@3.5Amp

15 Watt Base Stations

AC Input Voltage/Current ........................... 100 to 132 VAC @ 1.5 Amp

AC Input Voltage/Current (Available) ................. 190 to 250 VAC @ 0.8 Amp

DC Input Voltage/Current ...................... 21.6VDCto30VDC@4.0Amp

25 Watt Base Stations

AC Input Voltage/Current ........................... 100 to 132 VAC @ 2.0 Amp

AC Input Voltage/Current (Available) ................. 190 to 250 VAC @ 1.0 Amp

DC Input Voltage/Current ...................... 21.6VDCto30VDC@7.5Amp

POWER OUTPUT:

7WattBaseStations .................................................. 5-10Watts

15WattBaseStations(Low/High) ................................... 5-10/10-20Watts

25WattBaseStations(Low/High) ................................... 5-10/20-30Watts

Microphone Compression Range .....................................................35dB

Battery Charger Voltage & Current (15 & 25 watt configurations) ........... 27.5Vdc,3.5AmpsMAX

OPTIONAL REMOTE CONTROL BOARDS - P/N 923051-1

Remote Audio Input ............................... 2or4wire(selectable),balanced600 Ωlines

Remote Tx Timeout ..................................................... 30to300 seconds

Tone Keying:

Impedance ............................................. 600 Ωfloating with respect to ground

TxControlTone..............................................Selectable1800 Hz to 3000 Hz

Tx Tone Input Level .......................................................... 0to-40dBm

Tx Tone Control Response Time ............................................<12milliseconds

DCKeying .....................................................................±48Vdc

Loop Resistance ............................................................. 10KΩMAX

Ground Keying ......................................................... ClosuretoGround

Loop Resistance .............................................................. 4KΩMAX

Remote RX:

Range ......................................... +10dBmto-15dBm(Factorysetto-10dBm)

Impedance ............................................. 600 Ωfloating with respect to ground

RX/TX Interface Signals:

Squelch Signal ................................................ Ground, Open circuit for Mute

TX RF Output Signal ....................................RFON=Ground,RF OFF=Open Circuit

AGC Signal Output ..................................................... Linear 0 to +6 Vdc

Temperature & Humidity:

Operating Temperature Range .......................... -25EC(-13EF) to +55EC(+131EF)

Storage Temperature Range ........................... -55EC(-67EF) to +65EC(+149EF)

RelativeHumidity ........................................................... 100%

Dimensions & Weight:

Width ...................................................... 305 mm (12.0 in) MAX

Height(includingfeet) .......................................... 166 mm (6.5 in) MAX

Depth ..................................................... 274 mm (10.75 in) MAX

Weight ....................................................... 5.5Kg(12lbs)MAX

* Refer to Section 3 for Transmitter and Receiver Leading Particulars

2-1

SECTION 2

PREPARATION FOR USE AND STORAGE

2.1 INTRODUCTION

This section provides the information required for custom configuration of the base station, and

storage. Custom system configuration includes customizing remote control set up, and removal

and replacement of Power Amplifier Module, Transceiver, and Power Supply.

Refer to Section 3 for Channel/Frequency configuration.

Remote set up instructions for Mark II series Line Interface boards P/N's 923060-1, 923051-1,

923051-2 and 923082-1 are provided in paragraph 2.3 of this section.

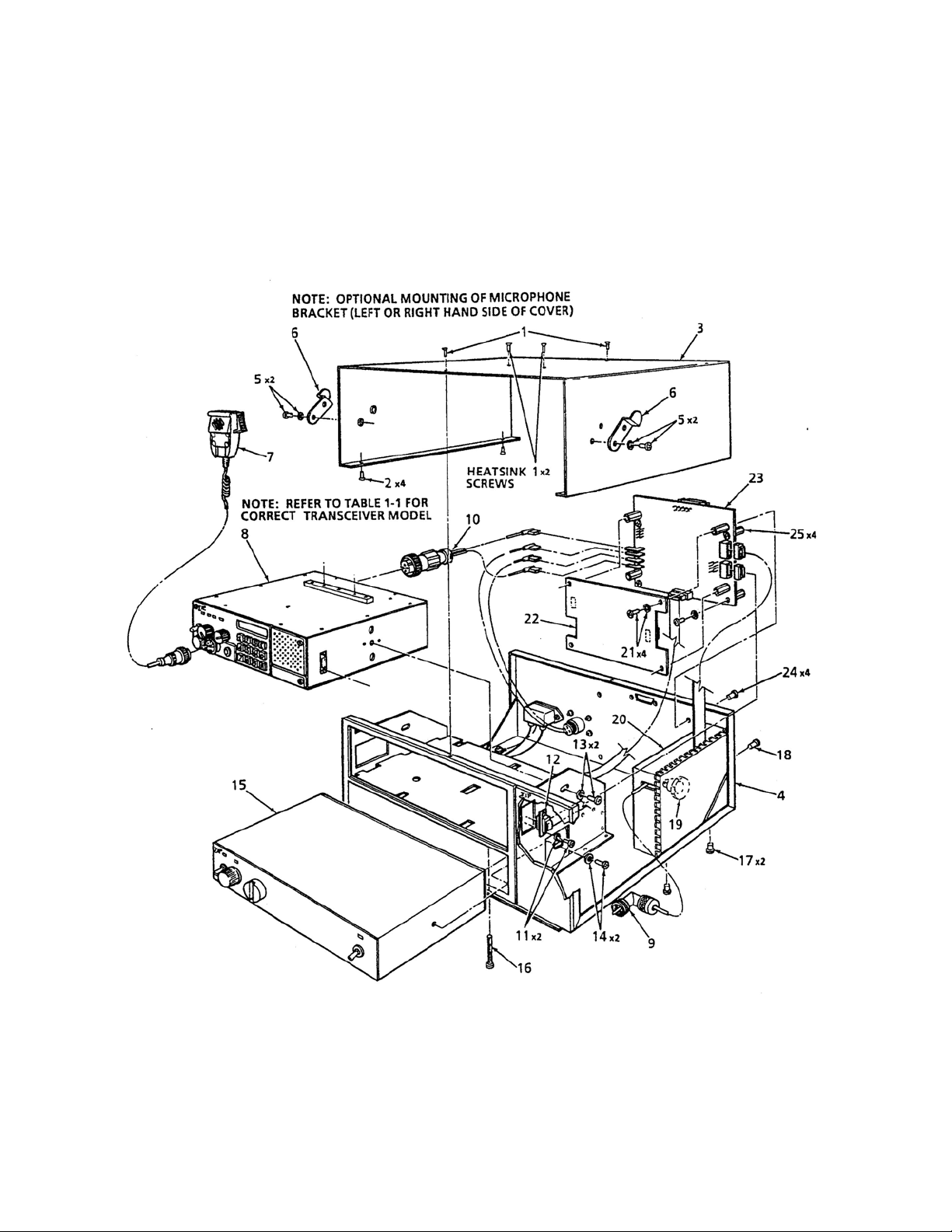

2.2 DISASSEMBLY/ASSEMBLY (Refer to Figure 2-1)

2.2.1 Remove Replace Microphone

REMOVAL

(1) Disconnect microphone (item 7) from front panel of transceiver (item 8). Slide microphone

clear of bracket (item 6).

(2) Remove and Retain two screws (item 5) securing microphone bracket (item 6) to cover

(item 2).

REPLACEMENT

(1) Secure microphone bracket (item 6) to left or right side of cover (item 3) as required

with two screws and two washers (item 5).

(2) Connect microphone (item 7) to front panel connector on transceiver (item 8). Slide

microphone onto bracket (item 6).

2.2.2 Remove/Replace Cover Assembly

NOTE

It is necessary to first remove Microphone Bracket

before removing Cover.

Remove screws securing Heat Sink to cover last, after

removing all other top and bottom screws.

2-2

REMOVAL

(1) Remove and retain two top screws (item 1) securing cover (item 3) to chassis (item 4).

(2) Remove and retain four bottom screws (item 2) securing cover to chassis.

(3) Remove and retain the two heatsink screws.

(4) Slide cover forward or backward to lift cover clear of chassis.

REPLACEMENT

(1) Slide cover (item 3) forward or backward onto chassis (item 4), positioning screw access

holes on cover over chassis threaded inserts.

(2) Secure heatsink to cover with two screws.

(3) Secure cover to chassis with four bottom screws (item 2), then with two top screws

(item 1).

2.2.3 Remove Replace Transceiver

REMOVAL

(1) Remove Cover as described in paragraph 2.2.2.

(2) Disconnect coaxial connector (item 9) from rear of transceiver (item 8).

(3) Disconnect DC connector (item 10) from rear of transceiver.

(4) Remove and retain two screws and two washers (item 11) securing flat cable (item 12)

to transceiver. Disconnect flat cable from transceiver.

(5) Remove and Retain two screws and two washers (item 13) securing transceiver to

chassis bracket.

(6) Slide transceiver toward rear of chassis. Lift transceiver clear of chassis.

REPLACEMENT

(1) Slide transceiver from rear of chassis into top window of Base Station front panel.

(2) Secure transceiver to chassis bracket with two screws and two washers (item 13).

(3) Connect flat cable (item 12) to transceiver. Secure flat cable to transceiver with two

screws and two washers (item 11).

(4) Connect DC connector (item 10) to rear of transceiver.

(5) Connect coaxial connector (item 9) to rear of transceiver.

(6) Replace Cover as described in paragraph 2.2.2.

2-3

Figure 2-1 Base Station Assembly/Disassembly

2-4

2.2.4 Remove Replace Power Supply

REMOVAL

(1) Remove Cover as described in paragraph 2.2.2.

(2) Loosen two screws and two washers (item 14) securing Power Supply (item 15) to

chassis (item 3).

(3) Remove and Retain one screw (item 16) securing Power Supply to bottom of

chassis.

(4) Slide Power Supply forward through window using partially loosened screws (item

14). Remove and retain two screws and two washers and remove Power Supply from

chassis.

REPLACEMENT

(1) Slide Power Supply (item 15) part way into lower front panel window until screw

inserts are visible through chassis bracket holes.

(2) Partially install screws and washers (item 14).

(3) Grasp two screws (item 14) with fingers to position Power Supply into chassis

mounted connectors. Press into position from front panel.

(4) Secure Power Supply to chassis with one screw (item 16) on bottom of chassis.

(5) Tighten screws (item 14)

(6) Replace Cover as described in paragraph 2.2.2.

2.2.5 Remove Replace RF Power Amplifier Module

REMOVAL

CAUTION

Do not adjust nut or shaft (item 19) protruding from

RF Power Amplifier Module. This is a Power

Transistor Mounting Stud.

(1) Remove Cover as described in paragraph 2.2.2.

(2) Disconnect coaxial connector (item 9) from Transceiver (item 8).

(3) Disconnect Flat Cable from Distribution Board (item 23).

(4) Remove and retain two bottom screws (item 17) and one rear screw (item 18) securing

RF (15W) Power Amplifier (item 20) to chassis (item 4). Note: 25W RF Power Amplifier

has four bottom screws (item 17) securing it to the chassis.

2-5

REPLACEMENT

(1) Secure RF Power Amplifier (item 20) to chassis with bottom screws (item 17) and

one rear screw (item 18).

(2) Connect UHF Connector (item 9) to Transceiver and flat cable to distribution board.

(3) Replace Cover as described in paragraph 2.2.2.

2.2.6 Remove Replace Distribution Board

REMOVAL

(1) Remove Cover as described in paragraph 2.2.2. Disconnect flat ribbon cables.

(2) Remove and retain four screws (item 25) securing the distribution and control

boards (item 23,24) to the rear of chassis (item 4).

REPLACEMENT

(1) Secure Distribution Board and Control Board (item 23) to the rear of chassis (item 4)

with four screws (item 25).

(2) Reconnect flat ribbon cables and replace Cover as described in paragraph 2.2.2.

2.2.7 Remove Replace Control Board

REMOVAL

(1) Remove Cover as described in paragraph 2.2.2.

(2) Remove Distribution Board as described in paragraph 2.2.6.

CAUTION

Care must be taken when removing or replacing

Control Board to avoid damage to Distribution Board

Pins.

(3) Remove and retain four screws (item 21) securing Control Board (item 22) "piggy

back" to the Distribution Board (item 23). Remove Control Board from Distribution Board.

REPLACEMENT

(1) Align the two female connectors on the control board with the male connectors on

the Distribution Board using the four mounting holes and standoffs as a guide.

(2) Secure control board "piggy back" to the distribution board (item 23) with four

screws (item 21).

(3) Replace Distribution Board as described in paragraph 2.2.6 and replace Cover as

described in paragraph 2.2.2.

2-6

2.3 REMOTE OPERATION SET UP - Line Interface Boards

The Procedures listed below enable the user to custom configure the unit for external remote

control hardware. Refer to Table 2-1 for connector pin details on Remote Control D Connector

located at rear of Base Station or Table 2-2 for connector pin out on the special order Positronics 9-

pin connector. Position jumpers on Line Interface Board as indicated Figures 2-2 or 2-3 as required.

Verify Remote Control operation in accordance with manufacturers instructions.

TWO WIRE SETUP - In two wire operation, a single balanced 600 ohm pair is provided for

transmit and receive audio. The transmitter can be keyed on the same pair or externally.

FOUR WIRE SETUP - In four wire operation, separate balanced 600 ohm pairs are provided for

transmit and receive audio. The transmitter can be keyed on the Tx audio pair or externally.

DC KEYING - In ± DC keying, a positive voltage between +10 Vdc and +48 Vdc or negative

voltage between -10 Vdc and -48 Vdc will key the transmitter. A DC voltage between -5 Vdc and +5

Vdc will not key the transmitter.

TONE KEYING - In Tone keying a tone of 2175 Hz or 2380 Hz (Optional) can be used to key

the transmitter. Tone sensitivity is adjustable from -40 dBm to 0 dBm.

GROUND KEYING - In Ground Keying the transmitter is keyed by shorting the control point

(landline or External Keying) to chassis ground

CURRENT LOOP KEYING - In Current Loop keying, an internal or external current source (15

mA) is used to key the transmitter

EIA TONE KEYING - The EIA multi-tone keying format is found in the Land Mobile Industry.

A high level 2175 Hz tone followed by a 1950 Hz guard tone then a low level 2175 Hz continuous

tone is utilized to key the transceiver.

TABLE 2-1 9-Pin "D" TYPE CONNECTOR FUNCTIONS

PIN

NO

Two Wire Line Interface Boards

P/N 943180-1

PIN

NO

Four/Two Wire Line Interface Board

P/N 923051-1

8,9

6

2

7

3

1

4,5

2 Wire Remote TX/RX Audio(600Ω)

Ground

RF Indicator

Squelch

External PTT

AGC

Not Connected

8,9

4,5

6

2

7

3

1

4 Wire Remote TX Audio or

2 Wire Rx/Tx Audio (600Ω)

Remote RX Audio Line (600Ω)

Ground

RF Indicator (Optional)

Squelch

External PTT

AGC

NOTE: A modular RJ-11 Jack is also provided on the rear of the chassis (on later units) for quick

connection to the 2 wire, Tx/Rx Audio. The red and green wire connections (centre pins) on the RJ-11 are

connected parallel to pins 8 and 9 on the 9 pin connector. This RJ-11 jack CANNOT be used if the remote

control card is set to 4-wire operation as it does not have the necessary connections.

2-7

TABLE 2-2 9-Pin POSITRONICS TYPE CONNECTOR FUNCTIONS

PIN

NO

Two Wire Line Interface Board

P/N's 943180-1

PIN

NO

Four/Two Wire Line Interface Board

P/N 923051-1

A,B

J

H

F

K

E

D,C

2 Wire Remote TX/RX Audio(600Ω)

Ground

+12 Vdc Output

Squelch

External PTT

Not Connected

Not Connected

A,B

D,C

J

H

F

K

E

4 Wire Remote TX Audio Line or

2 Wire Rx/Tx Audio (600Ω)

4 Wire Remote RX Audio (600Ω)

Ground

+12 Vdc Output

Squelch

External PTT

Not Connected

2.3.1 Two/Four Wire Remote Control Board P/N 923051-1

Provides remote control base station operation on 2 wire or 4 wire, 600 ohm lines. This board can

be configured to key the transmitter using a 2175 Hz tone (2380 Hz upon request), plus/minus DC

Voltages, ground keying and internal or external current loop keying. Transmit and Receive audio

is user selectable for two wires or four wires. Crystals for tone frequencies other than 2175 Hz or

2380 Hz may be obtained by special order.

See Table 2-3 for jumper settings and their functions. See Figure 2-3 for location of jumpers

referred to in the Table 2-3. Pins are numbers increase as you go from top to bottom or left to

right on the connector.

2.3.2 Two Wire Remote Control Board P/N 943180-1

Provides remote control Base Station operation on 2 wire 600 ohm lines. Two wire Line Interface

board with EIA multi-tone, standard 2175Hz continuous tone, DC keying of ground keying over

audio lines. The multi-tone keying format consists of a high level 2175 tone followed by a 1950 Hz

guard tone and then a low level 2175 Hz continuous tone is utilized to key the transceiver. This

board will also support 15mA current loop or ground keying. Refer to Figure 2-4 for jumper

locations to set functions and line level adjustments for this board. Summary of jumper settings

follow. Pins are numbers increase as you go from top to bottom or left to right on the connector.

Set J1 for ST (standard 2175Hz continuous) Tone keying or

for EIA (multi-tone keying format).

Set J2 for Tone keying function ON (left jumper position) or OFF (right jumper position).

Set J3 for Time out timer OFF (left jumper position) or ON (right jumper position).

See Table 2-4 for jumper settings and their functions. See Figure 2-3 for location of jumpers and

left/right orientation referred to in the Table 2-4.

2-8

TABLE 2-3 REMOTE CONTROL BOARD P/N 923051-1 SETTINGS

CONTROL FUNCTION

J1 Jumper Pin 1 and Pin 2 for DC Current Loop Keying

Jumper Pin 2 and Pin 3 for ± DC Keying or Ground Keying.

Note: SW2 must be in position 2 if Pin 2 and Pin 3 are jumpered.

J2

J3

J7

J6

SW1

SW2

Y1,Y2

R7

R22

R25

R44

R10

Jumper Pin 1 and Pin 2 for Ground Keying (Land Line).

Jumper Pin 1 and Pin 4 for ± DC Keying (Land Line).

Jumper Pin 2 and Pin 3 for Ground Keying (Single Key Line).

Jumper Pin 3 and Pin 6 for ± DC Keying (Single Key Line).

Jumper Pin 2 and Pin 5 for No Function.

Jumper Pin 1 and Pin 2 for ± DC or Ground Keying.

Jumper Pin 4 and Pin 5 for Tone Keying.

Note: Both Options may be selected.

Jumper Pin 2 and Pin 3 for No Function.

Jumper Pin 5 and Pin 6 for No Function.

Jumper Pin 1 and Pin 2 to enable Timeout Timer.

Jumper Pin 2 and Pin 3 to disable Timeout Timer.

Jumper Pin 1 and Pin 2 to for Internal Current Loop Keying.

Jumper Pin 2 and Pin 3 to for External Current Loop Keying.

Position 1 Selects 2 Wire Operation.

Position 2 Selects 4 Wire Operation.

Position 1 Selects Normal (Land Line Keying).

Position 2 Selects Local (Single Line Keying).

Determines Keying Tone Frequency.

Sets Tx Audio IN Level (Range -18 dBm to +10 dBm).

Sets Key Tone Level (Range -40 dBm to 0 dBm).

Sets Rx Audio OUT Level (Range -15 dBm to +10 dBm).

Sets Timeout Timer (Range 30 to 300 Seconds).

Sets Receive Audio Output Balance.

Other manuals for TiL-91-DE/8.33

1

This manual suits for next models

3

Table of contents

Other Technisonic Industries Limited Accessories manuals