Techno CNC Systems HD II Tabletop User manual

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 1

HD II Tabletop Manual

NK105G2

Techno CNC Systems, LLC ©2018

This document will provide a quick guide to the set up and operation of the Techno HD II Tabletop

CNC Router equipped with the NCstudio controller.

Tabletop CNC

Router Manual

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 2

HD II Tabletop Manual

NK105G2

TABLE OF CONTENTS

Safety Instructions .............................................................................................................................................................. Page 3

Colleting Guidelines .............................................................................................................................................................. Page 4

l HD II Tabletop Quick Setup .......................................................................................................................................... Page 5

Control Panel Functions and Enabling the Machine...........................................................................................Page 6

II HD II Tabletop Start Up .......................................................................................................................Page 7

Functions of the Keys ......................................................................................................................................... Page 8

Shift Commands / Combination Keystrokes ......................................................................................... Page 9-11

III Operating Tutorials

3.0- Switching Movement to Step or Jog

3.1- Jogging the Machine and Changing from High/Low Jog Speed

3.2- Stepping the machine .............................................................................................. Page 12

3.3- Modifying the Jog Speed and Step Size

3.4- Feedrate Override ................................................................................................................... Page 13

3.5- Adjusting the XYZ Position/WCS/User Origin .................................................................... Page 14

3.6-LoadingaG-codele ...................................................................................................................Page15

3.7- Running a G-code File ............................................................................................... Page 15

IV Advanced Tutorials

4.1- Alternating between Override Page .................................................................Page 16

4.2- Programmed Feedrates .................................................... Page 16

4.3- How to use all 6 work coordinates ............................................................................................. Page 17

4.4- How to use select line number function ......................................................................... Page 18

Using the 4th Axis .............................................................................................................................................. Page 19

SettingOverridespeedforaG-codele....................................................................................Page20

NotesontheG-codeleAccelerationSet.....................................................................................................Page21

Appendix

HD II Tabletop Settings ................................................................................................................................................ Page 21- 26

Machine Lubrication ................................................................................................................................................................ Page 27

Maintenance / Problem/Solutions ............................................................................................................................. Page 28

Controller Diagram .................................................................................................................................................................... Page 29

Warranty ...................................................................................................................................... Page 30

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 3

HD II Tabletop Manual

NK105G2

1. Keepngers,hands,andallotherobjectsawayfrom

machine while power is on.

2. Disconnect power to all system components when

not in use, when changing accessories, and before

servicing.

3. Do not loosen, remove, or adjust machine parts or

cables while power is on.

4. Exercise care with machine controls and around

keyboard to avoid unintentional starting.

5. Make sure voltage supplied is appropriate to

specicationsofcomponents.

6. Machines must be plugged into three-pronged

grounded outlets. Do not remove the grounding

plug or connect into an ungrounded extension

cord.

7. Keep cables and cords away from heat, oil, and

sharp edges. Do not overstretch or run them

under other objects or over work surfaces.

8. Useproperxturesandclampstosecurework.

Never use hands to secure work.

9. Do not attempt to exceed limits of machine.

10. Do not attempt to use machine for purposes other

than what is intended.

11. Use machine only in clean, well-lit areas free from

ammableliquidsandexcessivemoisture.

12. Stay alert at all times when operating the machine.

13. Always wear safety goggles.

14. Donotwearloose-ttingclothingwhenoperating

machine. Long hair should be protected.

15. Always maintain proper balance and footing when

working around the machine.

16. Maintain equipment with care. Keep cutting

tools clean and sharp. Lubricate and change

accessories when necessary. Cables and cords

should be inspected regularly. Keep controls

clean and dry.

17. Before using, check for damaged parts. An

authorized service center should perform all

repairs. Only identical or authorized replacement

parts should be used.

18. Remove any adjusting keys and wrenches before

turning machine on.

19. Do not operate the machine unattended.

20. Follow all safety instructions and processing

instructions in the MSDS for the material being

processed.

21. Use proper precautions with dust collection

systemstopreventsparksandrehazards.

22. Makesuretohaveproperreextinguishing

equipment on hand at all times.

WARNING: IMPROPER OR UNSAFE OPERATION OF THE MACHINE WILL RESULT IN

PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE OPERATING MACHINE. DO

NOT OPERATE MACHINE IF YOU ARE UNFAMILIAR WITH THESE SAFE OPERATING

INSTRUCTIONS. DO NOT OPERATE MACHINE WITHOUT KNOWING WHERE THE

EMERGENCY STOP SWITCH IS LOCATED.

PREVENT FIRE HAZARDS by using the proper feeds, speeds, and tooling while operating your

Techno machine. For example, setting feeds and speeds too low and/or using dull tool bits creates

friction at the material.The friction generates heatwhich can result in a re that can be drawn

through the vacuum table or dust collector without warning. Fire hazard from friction heating caused

by dull tools is possible when cutting certain materials, especially composite material such as wood

composites, MDF and Particleboard. © 2012

Safety Instructions

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 4

HD II Tabletop Manual

NK105G2

WARNING!

THE SPINDLE WILL BE DAMAGED

IF UNBALANCED EQUIPMENT IS USED.

AIR SUPPLY MUST BE FILTERED AND DRY.

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 5

HD II Tabletop Manual

NK105G2

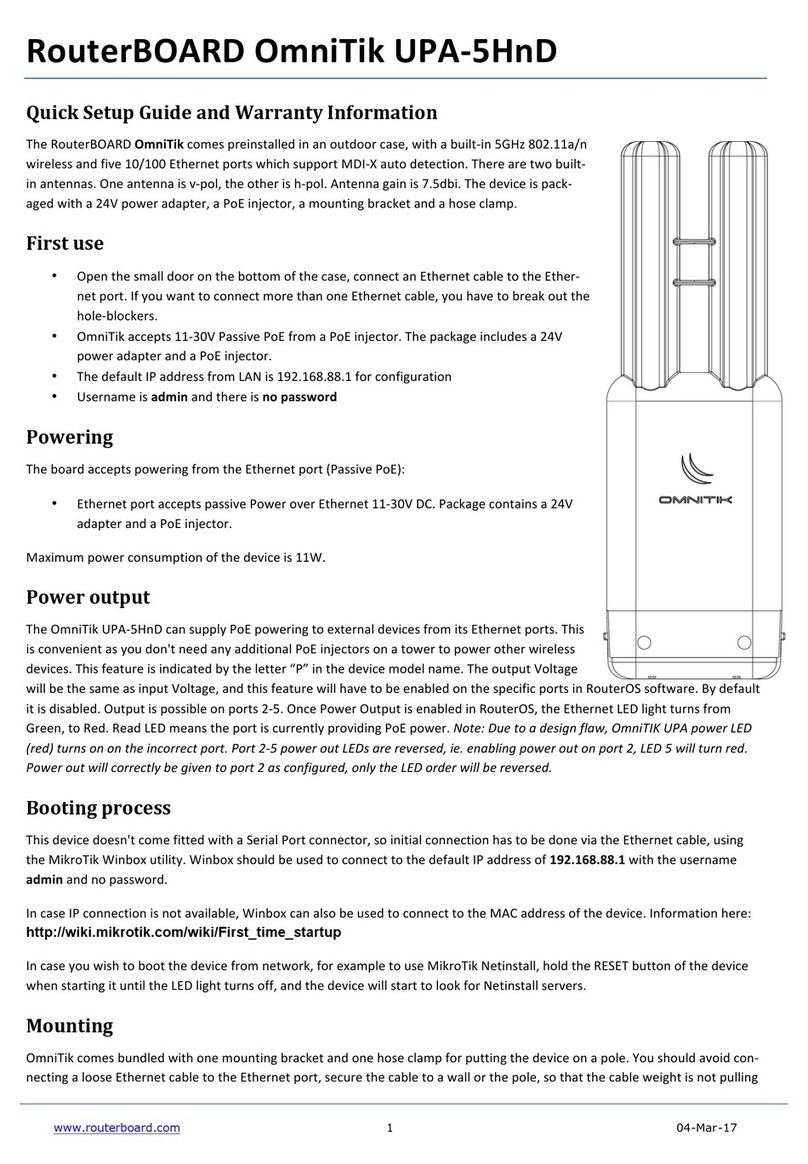

1.1 - The electronics are housed in the

controller cabinet located at the back of the

machine displayed in Figure 1.1. The controller

box may have to be moved or handled during

the unpacking of the machine. For shipping

purposes, the controller box may have been

moved forward.

I. Techno HD II Tabletop Quick Set up

1.2 - Have a licensed electrician connect power to the

controller. The machine requires 220V single phase 15amp

power in order to operate. Plug the power cable into the

rearofthemachineasshowningure1.2.The10ftpower

cable supplied must be hardwired to the power source.

Fig. 1.1 Fig. 1.2

Fig. 1.3

The cable provided will be one of two types: brown, blue, and green/

yellow wire or a cable with a black, white, and green wire. (Fig 1.3)

Power is connected as follows:

Green or Green/Yellow conductor is always ground .

The two other conductors will be the hot leads.

Connecting the Power

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 6

HD II Tabletop Manual

NK105G2

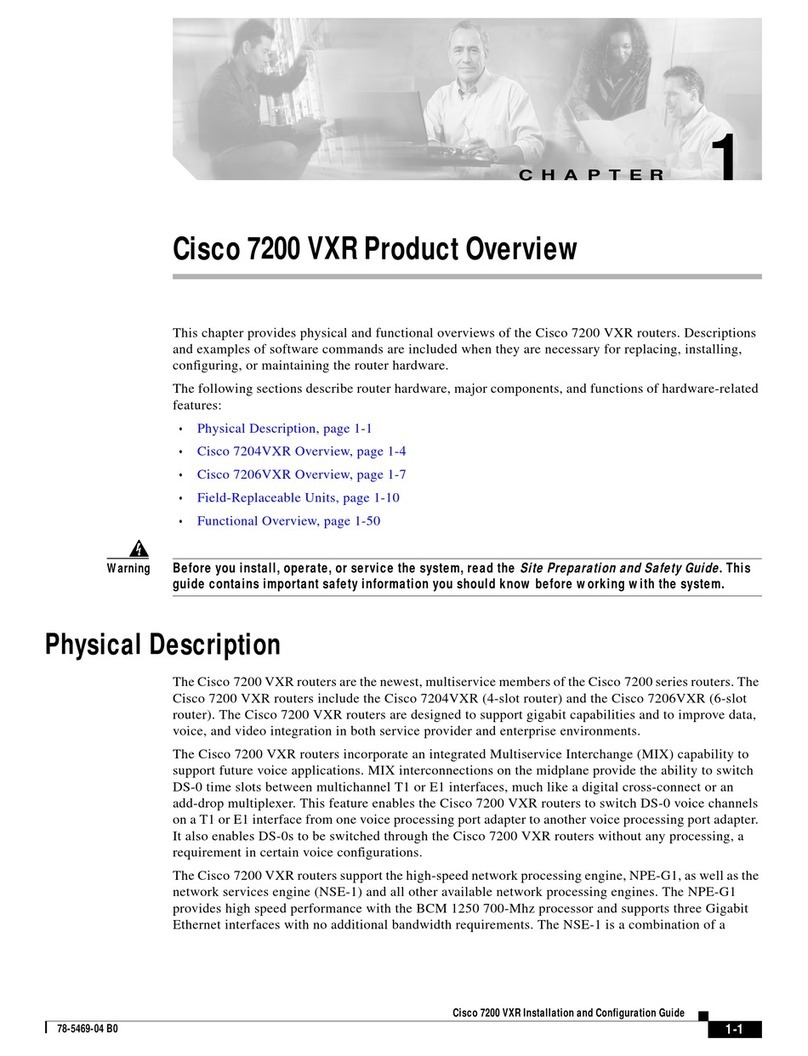

1.6 Enabling The Machine.

First make sure the Emergency Stop is not pressed by giving it a ¼ turn

clockwise. Then, activate the machine by pressing the green POWER but-

ton. Power is now applied to the machine. The green light will illuminate.

Emergency

Stop

Power

Enable

Power

Disable

Spindle VFD

Readout

USB

Port

IF EQUIPPED WITH SAFETY ENCLOSURE,

CHECK E-STOP ON THE FRONT OF THE

MACHINE NEAR THE DOOR!

Control Panel Functions

Latch

to open

controller

box

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 7

HD II Tabletop Manual

NK105G2

Whenthemachinerstpowerson,

the display on the controller will light

up and say “Starting System”. (Fig. 2.1a)

Once the system has booted it will ask

the user “Back to reference point?” Fig

2.2b

Fig. 2.1a Fig. 2.2b

Thisisalsoknownas‘homing’themachine.Itreferstotheprocessofthemachinendingitsmechanical

home position.

From this point, the user has two options;

Home the machine or cancel the homing process. We recommend that you home the machine every time

you start up.

Press “ESC” will skip the homing process.

WARNING:Therewillbenoreferencepositionandbreakpoints,osetsandallfunc-

tions that rely on a reference position will be invalid.

Once the machine has moved to its homing position on each axis, it will stop and enter an IDLE state and

will be ready to use.

Pressing“OK”willinitiatethehomingprocess.ThemachinewillrstmovetheZ-axis

to the top of travel and then the X and Y axis will move simultaneously until both are

at the home / reference position at the front left corner of the machine bed.

NOTE: The homing procedure can be aborted at anytime by pressing ESC.

ADVANCED HOMING:

If you hit “ESC” by accident, or would like to reindicate the axes, there are two ways to “Home” again.

1) Press Menu > 3. Operations > 1. Back REF Point > 1. All Home

2) Shortcut

+

II. HDII Tabletop Startup

Main Screens:

This picture shows that the machine has been homed

due to the X* Y* Z* symbols

This picture shows that the machine has not been

homed due to the X Y Z symbols (there are no *s next to

the symbols)

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 8

HD II Tabletop Manual

NK105G2

Single Keystroke Functions on the Handheld Pendant

Positive Feedrate

Override

(Input the number 7)

X- Movement

(Input the number 4)

Jog Speed Select

(Input the number 0)

Enter Manual Parameters

Screen

Change high/low speed

and XYZ step increment

Z+ Movement

(Input the number 9)

X+ Movement

(Input the number 6)

Z- Movement

(Input the number 3)

Menu Screen

(Input a decimal point)

Shift Key

Switch between

Jog and Step

modes

Down

Directional

Key

Set XY Zero Position

(Input a minus sign)

Stop

Cancel

Escape

Up Directional

Key

Pause

Start key

SpindleOn/O

(Input the number 5)

Negative Feedrate

Override

(Input the number 1)

Y+ Movement

(Input the number 8)

Y- Movement

(Input the number 2)

OK

Select

Yellow Keys are movement related

Blue Keys are speed and feed related

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 9

HD II Tabletop Manual

NK105G2

Increase feedrate override; input the number 7

Move Y axis in the positive direction (rear of table); input the number 8

Move Z axis in the positive direction (top of travel); input the number 9

Move X axis in the negative direction (left of table); input the number 4

Manuallyturnspindleon/o;inputthenumber5

Move X axis in the positive direction (right of table); input the number 4

Decrease feedrate override; input the number 1

Move Y axis in the negative direction (front of table); input the number 2

Move Z axis in negative direction (bottom of travel); input the number 3

Toggle between manual jog high/slow speeds; input the number 0

Set XY=0 point (XY origin); input a minus sign

Open the main menu; input a decimal point

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 10

HD II Tabletop Manual

NK105G2

Start machining

Pause machining; Up direction arrow when navigating menus

Stop machining; Cancel; Escape

Switch between jog and stepping modes; Auxilliary key

Down direction arrow when navigating menus

OK; Select; Open manual jog/step adjustment screen

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 11

HD II Tabletop Manual

NK105G2

Shift Commands / Combination Keystrokes

To use the shift commands, you must press and hold the shift key and then select a second key.

Increase spindle RPM

Switch between work (relative) and machine (absolute) cooridinates

When it reads X1 Y1 Z1, that is relative. When it reads X* Y* Z*, that

means absolute.

Go to XYZ home (mechanical origin)

Go to current work origin (relative origin)

Decrease spindle RPM

SetZOpositionusingtouch-opad

Resume from breakpoint MO command

Set ZO position manually

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 12

HD II Tabletop Manual

NK105G2

Select between high

and slow Jog speeds

3.1- Jogging the machine and changing from High/Low Jog Speed.

To Jog the machine, hold down one of the Yellow directional keys on the keypad

while in Jog mode. The keypad has X+,X-,Y+,Y-,Z+,Z- printed on the keys to indicate

direction.

The machine has two speeds, High and Slow.

When the machine starts it will be in the Slow speed.

To toggle between low and high speed press the Jog Speed Select Button. You can

only toggle speed when in Jog Mode.

The LCD will display High or Slow on the right of the screen.

Press ‘OK’ to change the default high and slow speeds, see section 3.3.

3.0- Switching Movement to Step or Jog.

There are two modes that allow the user to control the movement of the machine:

Jog and Step. To switch between these modes press the “Shift” button. The mode

will be displayed on the bottom left of the screen.

Jog- Also known as continuous mode. When a directional arrow is pressed, the

machine will move in that direction until the button is released.

Stepping- Also known as step mode. When a directional arrow is pressed, the

machine will move an exact amount, as dictated by the manual parameters page.

To move again, you must release the button and press it again.

NOTE: See section 3.3 to learn how to change jog speeds and step sizes.

3.2- Stepping the machine.

To move the machine in increments, press the shift key once so that the controller

indicates “stepping” . When in stepping mode, press down one of the Yellow

directional keys on the keypad The keypad has X+,X-,Y+,Y-,Z+,Z- printed on the keys

to indicate direction.

This will move the machine in predetermined increments for the axis selected.

By default, the X and Y axes will move in .005 inches and the Z axis will move in .001

inches.

III. Operating Tutorials

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 13

HD II Tabletop Manual

NK105G2

Decrease

Feedrate

Increase

Feedrate

3.3- Modifying the Jog Speed and Step Size.

The machine can be jogged at two speeds, slow and high. You can also change the increments in

which the machine will move in Step mode. These speeds are set in the Manual Parameters page.

To access the Manual Parameters page press OK from the Main Screen (Not menu)

Set the High and Slow speed to a suitable value.

Adjust the Step value as needed.

To Exit out of this screen and return to the main menu press ESC.

When inputting a decimal increment, you must enter the value as 0.### <Zero+decimal+(your increment)>

Low Speed

High Speed

Step Sizes

To move the cursor, use the Up and Down directional

arrows.

Enter a new value.

Press OK to accept that value.

3.4- Feedrate Override.

WhilerunningaG-Codele,theusercanmanuallyoverridethefeedrateorcuttingspeedofthe

program. The range of the override goes from 0% to 120% of the original feedrate.

Example: 50% of 100 IPM = 50 IPM

The user can override the feedrate using the following keys:

Adjust the step size carefully. If you set the step size to

an excessive value, the machine will move by that value

and could damage the machine.

WARNING:

DO NOT MAKE

0% OR

THE MACHINE

WILL NOT MOVE

The value being changed

will be highlighted as

shown

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 14

HD II Tabletop Manual

NK105G2

3.5- Adjusting the XYZ Zero position/WCS/User Origin.

XYZ zero position, Working Coordinate System (WCS), and

User Origin are all the same thing.

DierentCAMsystemsandusersjustnametheconcept

dierently.ForconvenienceXYZzeropositionwillbeusedin

the rest of this manual.

XYZ zero position is the location point on a drawing in a

CAD/CAM package where X,Y and Z all equal zero.

Generally, XY zero is on the bottom left corner and Z zero

isthetopofthepart.Ing3.5athelettersarelocatedaway

from the XY zero, all points representing positive integers.

In Fig 3.5b the object represents the material the letters will

be cut from. The machine should be jogged to the corner of

the material by using the directional arrows on the keypad.

Once the machine is in location press to set XY zero. The

coordinates on the controller will change to 0,0.XY zero is

now set.

Fig.3.5b

Fig. 3.5a

There are two methods for setting the Z-axis zero position:

1. Manual Method: Use the Z-axis directional arrows on the

keypad to move the router to the top of the material. Switch

to Step Mode to slowly move the machine into position.

When the router bit is in position press shift/aux and the Z=0

button as shown.

2.ToolCalibrationPad:Placethetouchopadontop

of the material and under the cutter. Press shift and 0

simultaneously. The spindle will slowly move down until it

touches the touchpad. The Z axis will now be set to the top

of the material.

The Z coordinate will now read ‘Z 0.000’, according to the

Relative Work Origin.

Zero Z-axis Manually

ActivateZ-Touchoprocedure.

+

+

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 15

HD II Tabletop Manual

NK105G2

3.6- Loading a G-code File.

Press the Menu button.

Select“2.USBles”toaccesstheashdrive.

OnlyaG-codelewithan“nc”extensionwithshow.

Scrollthroughtheleswith and

SelectlebypressingOK.

Thenloadthelebypressing1.

Note:

Files can be copied from this USB to the controller using the “2” button

Local disk space is limited!

Oncealeiscopiedlocally,itcanalsobeselectedfromthejogspeed/stepsizescreen

3.7- Running a G-code le.

OncetheXYZoriginhasbeensetaspersection3.5andthelehasbeenloadedaspersection3.6,the

userisreadytoruntheG-codele.

ToruntheG-codelesimplypressthestartbutton

Once the spindle has reached its programmed speed, the machine will move into position to start the

rstcut.

Thele can bepausedwhilerunningbypressing

the pause button.

Toresumethelepress. Toaborttheleatanytimepress.

NOTE: When the machine pauses, the spindle will stop and the Z axis will move to the Z

clearance/Safe height to allow inspection of the part.

Ifthemachineisjoggedothepartduringapause,itwillloseitspositionandwhentheleis

resumed it will start from the new position.

Loading G-Code le: Before pressing OK (notice that

there is no checkmark)

Loading G-Code le: Notice the check mark next to the

le I want to work with. e check mark appears aer

pressing OK. Finally, press 1 to load le, 2 to delete the

le, or 3 to copy it.

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 16

HD II Tabletop Manual

NK105G2

4.1- Alternating between Override and Programmed Feedrates.

IV. Advanced Tutorials.

ThecontrollercanrunG-codeleswithspeedsetbytheuseronthekeypad,overridespeed,orwith

speedsetintheCAMpackage/G-codele,programmedspeeds.

To determine what speed protocol will be used, do the following:

In the main screen, press menu to enter the menu screen .

Use the and key to scroll the cursor and highlight

Press OK to select.

Use the and key scroll the cursor and highlight

Press OK to select.

4. Oper Param

8. Ignore F code

9. Ignore S code

NOTE:

The F or S Option. F stands for Feed rates, and S stands for Spindle RPMs.

*Highly Recommended* “No”meansspeedintheG-codelewillbeobeyed.

“Yes” means speed will be overrode by the controller.

4.2 Setting the Override Speed for a G-code le.

From the main screen, press Menu

to access the Menu screen.

Use the up and down to move the cursor and highlight

Press OK to select this option and enter the Operations Parameters screen

Use the up and down keys to move between each option +

press enter to select the option.

Press OK to edit the data and use the number keys to enter data.

Press OK to save data and Cancel to exit out of the screen.

Keep pressing cancel until you return to the main screen.

G00 Speed is the rapid speed, or the speed the machine moves when the cutter is above the material.

GXX Speed is the speed the machine moves when the cutter is in the material.

This speed will vary with cutter size, material, cutter type, etc. Great care must be taken when setting

feedrates and spindle RPM, otherwise risk broken tools and loss of material.

4. Oper Param

1. G00 Speed

2. GXX Speed

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 17

HD II Tabletop Manual

NK105G2

7.5 How to Use all 6 Work Coordinates

This controller allows a user to have up to 6 work coordinates saved at a time. They are labeled as G54,

G55, G56, G57, G58, and G59. The controller should be automatically set for G54 (work coordinate system 1)

because next to X, Y and Z on the main screen should be a number 1. In order for the controller to use another

coordinate system like G55 (work coordinate system 2), there needs to be another number next to X, Y, and Z,

and in this case that would be number 2. In order to change between each coordinate system go to the Main

Menu, 3.Operations, and nally 6.Select WCS.

From the main screen, press Menu

to access the Menu screen.

Use the up and down to move the cursor and highlight

3. Operations

Use the up and down to move the cursor and highlight

6. Select WCS

Scroll through each of the WCS and press OK to

the work coordinate system that needs to be used.

Labeled here is the multiple work coordinate origins that can be saved for certain parts or

xtures. G54 represents Origin 1, G55 represents Origin 2, and G56 represents origin 3, etc

Origin 1

Origin 2

Origin 3

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 18

HD II Tabletop Manual

NK105G2

4.4 How to Use the Select Line Number Function

A le that is currently loaded to the machine may be ran using only certain line numbers of the G-Code if the

operator chooses to do so. If the operator accidentally presses STOP, they can use this function to run from

the last ran G-code line number (For ex: N100). This can be done by using the select line number function on

the controller.

First, turn the spindle on. Then, go to the Main Menu, then go to the 3.Operations, then go to 3.Select Line

No., and then type in the corresponding line numbers you would like to start and stop at.

From the main screen, press Menu

to access the Menu screen.

Use the up and down to move the cursor and highlight

3. Operations

Use the up and down to move the cursor and highlight

3. Select Line No.

Go to the Start Line and End Line and enter in where you would

like to start and end the le. The End Line will automatically be

set as the last line in the G-Code unless you decide to change it.

Scroll down to Execute Now and press OK for

the le to run from the Start Line to the End Line.

If we take a look at this G-code, we can see that we will be

starting from line 200 and ending the G-code le at line 463

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 19

HD II Tabletop Manual

NK105G2

Note: The 4th axis on the Techno HDII Tabletop machine is not a true 4th axis. You can only use this to do “wrap-

ping”toolpaths.Thismeansthattheleisdesignedasaregular,at,3-axisle,

which is scaled so that the width matches the circumference of round stock. Then, instead of

cuttingat,therotaryissubstitutedfortheX-axisandthecutfollowsthecircumferenceofthestock,asifitis

being “wrapped” around it.

To change from normal 3-axis operation to rotary operation, you must change some settings in the controller:

1. Press the menu button on the keypad. Go to and press OK to select “5. MFR Param”. The

password is 33587550.

2. Go to and press OK to select “3. Pulse Equiv”. Make note of the X-axis value, it should be

0.0031250.

3. Calculate the new pulse equivalent value based on the diameter of the cylindrical stock

being used through the following equation:

RotaryPulseEquivalent=(25.4*π*D)/80,000

Where D is the diameter of the rotary stock in inches.

4. Enter the calculated value for Rotary Pulse Equivalent in the location for X under Pulse

Equiv.Toinputadecimalnumber,pleasepress0(zero)rst,thenthebuttonforthe

decimal point and then the numbers.

5. Exit the menu and restart the machine. The new settings will now be applied.

6. Now jog to your starting point and set your X and Y origin. This position should be above the

rotarypart.Note:TheX-axiswillmostlikelymoveatadierentspeedthannormalandthe

coordinates will not look right.

7. Flip the switch in the front of the machine into Rotary mode.

8. Run your part

Torevertbacktonormal3-axisoperation,followthersttwostepsandthenputtheoriginal

value, 0.0031250, into the X-axis pulse equivalent variable, then reboot the machine to apply the

changes.

USING THE 4TH AXIS ON THE TECHNO HD II Tabletop TABLETOP MACHINES:

5. MFR Param

3. Pulse equiv

Notes On the G-code File

Ifapartrequiresmultipletools,itisbesttooutputadierentleforeachpart.

IftheG-codelereferencesatoolnumberhigherthanT10,thenthecontrollerwillgivean

erroratthestartofthele.M6T1toM6T10areallowed.

In general it is best to remove T commands by telling the CAM package that the machine is

not a tool changer machine, or insuring that the Tool number does not exceed 10.

G92istheAxispresettingcommand,whenthiscommandisencounteredintheG-codele

the XYZ zero position is set at the position the machine is in at that time.

IngeneralitisbesttoremovethisfromtheG-codele,orifitisintheG-codele,makesure

the machine is at the origin before you press start.

ThecontrollerwillrecogniseG54toG59osetcommands.

Call: 1-631-648-7481 or Visit:: www.technocnc.com/technical-support/ 20

HD II Tabletop Manual

NK105G2

Acceleration Set

Under the menu MFR Params, there is a sub menu called Velocity.

This menu controls the acceleration and cutting motion of the machine.

The Defaults for these parameters are:

Jerk 310

Single Axis Acc 25

Max Turn Acc 100

A low Max Turn Acc will result in arcs that move in a jerky motion or at a slow speed.

High/Low Speeds and Step Distances (from main screen, press ‘OK’)

MSpd: 240 / 100

Step XY: 0.005

Step Z: 0.005

File: (active file name) Note: These numbers can vary.

All following settings can be found by pressing the ‘Menu’ key and are worded/abbreviated as you

would see them on screen.

Note: All settings with ‘*’ on screen requires reboot to take effect.

1. LOCAL FILES

2. USB FILES

3. OPERATIONS

1. Back to REF Point

1. All Home

2. Z Home

3. X Home

4. Y Home

2. Rect Machining

1. Params Setting

Engr Depth

0.004

Each Depth

0.004

Tool Dia

0.118

Nose Gap

0.079

Height

3.937

Width

3.937

X Init

0

Y Init

0

Mode Horiz Mill

LOAD NOW

2. Load the Last

3. Select Line No

Total: 106

Start Line: -1

End Line: 106

EXECUTE NOW

4. Machining Info

Time: 0:0:0

X: 0.06 3.88

Y: 0.06 3.88

Z: -2.02 -1.82

5. Park MCS Site

1. Park Mode

Not Move

To Park Site

To WCS Origin

2. Park Site

Table of contents

Popular Network Router manuals by other brands

Cisco

Cisco 7200 VXR Series user manual

FiberHome

FiberHome AN5506-01-A user manual

Eicon Networks

Eicon Networks 1530 user guide

NETGEAR

NETGEAR XE102 - Wall-Plugged EN Bridge Specifications

Allied Telesis

Allied Telesis AR100 series user guide

Link electronics

Link electronics 860-XL165AV Specification sheet