Technoton DUT-E AF User manual

Contents

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 2

Contents

Revision history............................................................................................................. 5

Structure of external links .............................................................................................. 6

Terms and Definitions .................................................................................................... 7

Introduction.................................................................................................................. 9

1 General information and technical specifications ........................................................... 11

1.1 Purpose of use and application area ...................................................................... 11

1.2 Exterior view and delivery set............................................................................... 14

1.3 Design and operation principle.............................................................................. 15

1.4 Technical specifications........................................................................................ 17

1.4.1 Main specifications ........................................................................................ 17

1.4.2 Specifications of DUT-E AF output signal .......................................................... 18

1.4.3 Specifications of DUT-E A5/A10/F/I output signal .............................................. 19

1.4.4 Specifications of DUT-E 232/485 output signal.................................................. 20

1.4.5 Specifications of DUT-E CAN output signal........................................................ 21

1.4.6 DUT-E and Tracking devices compatibility ........................................................ 22

1.4.7 Overall dimensions ........................................................................................ 23

2 DUT-E installation ..................................................................................................... 24

2.1 Exterior inspection prior to starting works .............................................................. 24

2.2 Standard fuel sensor replacement ......................................................................... 25

2.3 Installation into a special hole............................................................................... 26

2.4 Probe cutting according to tank depth.................................................................... 29

2.5 Length extension ................................................................................................ 30

2.6 Mounting ........................................................................................................... 31

2.7 Electrical connection............................................................................................ 32

2.7.1 Electrical connection of DUT-E AF .................................................................... 34

2.7.2 Electrical connection of DUT-E A5/A10/F/I........................................................ 35

2.7.3 Electrical connection of DUT-E 232/485............................................................ 36

2.7.4 Electrical connection of DUT-E CAN.................................................................. 37

2.8 Monitoring of two and more tanks ......................................................................... 38

2.8.1 DUT-E 232 readings totalizing......................................................................... 38

2.8.2 DUT-E AF readings totalizing .......................................................................... 41

2.8.3 DUT-E CAN readings totalizing ........................................................................ 44

2.9 Sealing .............................................................................................................. 45

3 Configuration of sensor using service adapter............................................................... 46

3.1 SK DUT-E purpose of use ..................................................................................... 46

3.2 Hardware requirements ....................................................................................... 47

3.3 Service adapter components ................................................................................ 48

3.3.1 Exterior view and delivery set ......................................................................... 48

3.3.2 Universal service adapter ............................................................................... 49

3.3.3 USB A-B Cable .............................................................................................. 50

3.3.4 RS-485 service cable ..................................................................................... 51

Contents

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 3

3.3.5 RS-232 service cable ..................................................................................... 52

3.3.6 AF service cable ............................................................................................ 53

3.3.7 CAN service cable.......................................................................................... 54

3.4 Software installation............................................................................................ 55

3.4.1 USB driver installation ................................................................................... 55

3.4.2 Service DUT-E software installation ................................................................. 56

3.5 Service adapter connection .................................................................................. 57

3.5.1 Exterior inspection prior to connection ............................................................. 57

3.5.2 Operation restrictions .................................................................................... 58

3.5.3 Connecting DUT-E to PC................................................................................. 59

3.6 Operation test .................................................................................................... 62

3.7 Software launch.................................................................................................. 63

3.8 User interface and initial setup.............................................................................. 64

3.9 Operations with DUT-E profile............................................................................... 65

3.9.1 Load profile .................................................................................................. 65

3.9.2 Save profile .................................................................................................. 66

3.9.3 Print profile .................................................................................................. 67

3.10 Vertical menu description ................................................................................... 68

3.10.1 Passport..................................................................................................... 68

3.10.2 Authorization .............................................................................................. 69

3.10.3 Settings - Calibration ................................................................................... 71

3.10.4 Settings –Operation modes.......................................................................... 72

3.10.5 Settings –Thermal compensation.................................................................. 74

3.10.6 Settings –Output message........................................................................... 75

3.10.7 Settings –Calibration table........................................................................... 76

3.10.8 Settings - Interface ..................................................................................... 78

3.10.9 Settings –Analog output .............................................................................. 79

3.10.10 Diagnostics ............................................................................................... 81

3.11 Firmware update ............................................................................................... 83

3.12 Software shutdown and DUT-E disconnection........................................................ 85

4 Measurement accuracy check ..................................................................................... 86

4.1 Basic principles ................................................................................................... 86

4.2 Check tests procedure ......................................................................................... 87

5 Accessories .............................................................................................................. 88

5.1 MK DUT-E mounting kit ....................................................................................... 88

5.2 US-1 adapter unit ............................................................................................... 89

5.3 Screen filter ....................................................................................................... 90

5.4 Connection cables ............................................................................................... 91

5.5 Additional accessories.......................................................................................... 92

6 Diagnostics and troubleshooting ................................................................................. 93

6.1 DUT-E with analog output .................................................................................... 93

6.2 DUT-E with frequency output................................................................................ 94

6.3 DUT-E with digital output ..................................................................................... 95

Contents

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 4

7 Maintenance............................................................................................................. 96

7.1 General instructions ............................................................................................ 96

7.2 Demounting ....................................................................................................... 97

7.3 Examination ....................................................................................................... 98

7.4 Cleaning ............................................................................................................ 99

8 Packaging ...............................................................................................................100

9 Storage ..................................................................................................................101

10 Transportation .......................................................................................................102

11 Utilization/re-cycling...............................................................................................103

Contacts....................................................................................................................104

Annex A Template of check test report ..........................................................................105

Annex B Examples of DUT-E CAN connection.................................................................106

Annex C Messages of DUT-E CAN data transfer protocol ..................................................108

Annex D Example of DUT-E CAN connection via RS-232 interface,

to receive data on the total volume of fuel ........................................................112

Annex E DUT-E profile printed copy ..............................................................................113

Annex F DUT-E log file example....................................................................................114

Annex G Electromagnetic compatibility specifications of DUT-E.........................................115

Annex H Videography..................................................................................................116

Revision history

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 5

Revision history

Versio

n

Date

Editor

Description of changes

1.0

01.2007

Basic version.

7.0

04.2016

OD

•New design of measurement head of DUT-E.

•Changes in delivery set of DUT-E, MK DUT-E.

•Addition and updates to description of installation of DUT-E.

•Changes in description of Service software.

•New packaging of DUT-E.

•Methodology of thermal correction coefficient calculation

added.

•International certificates ISO 9001:2015 (DaKKs)

and Customs Union added.

8.0

01.2017

OD

•Instructions on S6 SK operation while configuring

DUT-E CAN added.

•Schemes of connection of DUT-E CAN to PC via S6 SK added

(including scheme of sensors for configuration within

S6 interface).

•Terminology updated.

•Operation instructions for software Service DUT-E updated.

•New accessories for DUT-E added.

8.1

02.2020

OD

1) Updated:

- currently valid certificates;

- composition of DUT-E and MK DUT-E delivery sets;

- diagrams of sensors connection to the PC with

S6 SK service adapter;

- minimum requirements for PC for work with

Service DUT-E software;

- examples of diagrams of DUT-E CAN connection

to the Telematics terminal;

- document terminology.

2) Information added on:

- sensors models codes;

- sensors electromagnetic compatibility;

- taking into account the dead zone while creating the tank

calibration table;

- additional sensors accessories.

3) The structure of the document external links is introduced.

Revision history

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 6

Structure of external links

S6 Website

Part S6 Data Base

JV Technoton Website

Part Technical support

Part Software/Firmware

YouTube Technoton

Page DUT-E

Page CANUp

DUT-E fuel level sensors. Operation manual

Document Center

ORF 4 Website

DUT-E/DUT-E 2Bio/DUT-E GSM.

Installation manual

CAN j1939/S6 Telematics interface.

Operation manual

Page DFM

Technoton Engineering Website

Terms and Definitions

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 7

Terms and Definitions

S6 is the Technology of combining smart sensors and other IoT devices within one

wire network for monitoring of complex stationary and mobile objects: vehicles,

locomotives, smart homes, technological equipment etc. The Technology is based

and expands SAE J1939 automotive standards.

Information on cabling system, service adapter and S6 software refer to CAN j1939/S6

Operation manual.

PGN (Parameter Group Number) —is a combined group of S6 parameters, which has common

name and number. Functional modules (FM) of the Unit can have input/output PGNs and setup

PGNs.

SPN (Suspect Parameter Number) —informational unit of S6. Each SPN has determined name,

number, extension, data type and numerical value. The following types of SPN exist:

Parameters, Counters, Events. SPN can have a qualifier which allows qualification of

parameter’s value (e.g. – Onboard power supply limit/Minimum).

ORF 4 —is the by JV Technoton developed for receiving and processing Onboard

reports via Internet, displaying Operational Data overlapped on area maps,

information storage in database and Analytical reports generation upon user’s

request.

Analytical report —report generated in ORF 4 on vehicle or group of vehicles operation for

chosen time period (usually a day, week or month). Can be composed of numbers, tables,

charts, mapped route of vehicle, diagrams.

Onboard equipment (OE) —Telematics system elements, directly installed in Vehicle.

Onboard reports (the Reports) —information about vehicle which is returned to a user of

Telematics system in accordance with inputted criteria. The Reports are generated by a

terminal unit both periodically (Periodic reports) and on Event occurrence (Event report).

GNSS (Global Navigation Satellite System) —System for area positioning of an object through

satellite signal processing. GNSS is composed of space, ground and user segments. Currently,

there are several GNSSs: GPS (USA), GLONASS (Russia), Galileo (EU), BeiDou (China).

Parameter —time-varying or space characteristic of the Vehicle (SPN value). For example,

speed, fuel volume in the tank, hourly fuel consumption, coordinates. Parameter is usually

displayed in the form of graph, or averaged data.

Server (AVL Server) —hardware-software complex of Telematics service ORF 4, used for

processing and storage of Operational data, formation and transmission of Analytical reports

through Internet by request of ORF 4 users.

Event —a relatively rare and sudden change in SPN. For example, the sharp increase of

volume in the tank is the Event «Fuelling». An Event may have one or more characteristics.

Thus, the Event «Fuelling» has the following characteristics: «volume of fuel at the beginning

of the fuelling», «volume of fuel at the end of the fuelling», «volume of the fuelling» and so

on. As soon as an Event is detected, the Terminal registers the time of the Event which is

subsequently specified in the Report of the Event. The Event is always linked to the time and

the location where it was detected.

Counter —cumulative numerical characteristic of Parameter. Counter is displayed by a single

number and over time its value is increasing. Examples of counters: fuel consumption, trip,

engine hours counter etc.

Terms and Definitions

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 8

Telematics system —complex solution for vehicle monitoring in real time and trip analysis.

The main monitored characteristics of the vehicle: Route, Fuel consumption, Working time,

technical integrity, Safety. In includes On-board report, Communication channels, Telematics

service ORF 4.

Telematics terminal (Tracking device, Telematics unit) is a unit of Telematics system used for

reading the signals of Vehicle standard and additional sensors, getting location data and

transmitting the data to the Server.

During the use of DUT-E GSM fuel level sensor within the Telematics system the Terminal is

not required.

Vehicle is an object controlled by the Vehicle Tracking System. This is generally a truck, a bus

or a tractor, sometimes a locomotive, a ship, a utility vehicle. From the point of view of Vehicle

Tracking System, static equipment such as diesel generators, heating boilers, burners, and so

on are considered vehicles.

Function module (FM) unit-embedded component of hardware and software combination,

executing a group of special functions. Uses input/output PGNs and settings PGNs.

Unit is an element of vehicle on-board equipment compatible with S6 bus, which uses

S6 Technology.

Introduction

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 9

Introduction

Recommendations and rules set out in this Operation Manual apply to DUT-E fuel level

sensors (further on —DUT-E), models codes: 116 (for DUT-E CAN),

111 (for DUT-E 232), 115 (for DUT-E 485), 124 (for DUT-E AF), 112 (for DUT-E A5),

113 (for DUT-E A10), 114 (for DUT-E F), 068 (for DUT-E I) and SK DUT-E service adapter

(further on —SK DUT-E) manufactured by JV Technoton, Minsk, Republic of Belarus.

The model code of DUT-E is identified by the first three digits of its serial number printed at its

measuring probe or on its packing label:

The manual contains information on design, operation principle, specifications and instructions

on installation, use and maintenance of DUT-E. The manual defines SK DUT-E connection and

usage guidelines as well as Service DUT-E software (version 3.26 and higher) installation and

use.

are additional sensors within Telematics systems. DUT-E sensors are used

for accurate level measurement in fuel tanks of vehicles and stationary units.

SK DUT-E serves for data exchange between the sensor and the personal computer.

DUT-E features:

DUT-E key features:

•compliance with Units, Database and cabling system S6 Technology*;

•adjustable temperature correction for automatic measurement correction based on

ambient temperature**;

•function of digital self-diagnostics for sensor quality control**;

•measuring probe length extension up to 6 m with additional sections**;

•measuring probe length reduction without min/max recalibration***;

•ergonomic bayonet mount allows to save installation time;

•bottom spring for better mounting rigidity;

•screen filter for secure protection from water and mud ****;

•full set of mounting accessories and connection cable included;

•built-in voltage stabilizer –output signal does not depend on vehicle power supply

voltage;

•reverse polarity and short circuit protection of any output to vehicle electrical

system and chassis;

•sealing possibility to avoid unauthorized intrusion and tampering;

•conformity with European and national automotive standards;

•high-quality technical support and documentation.

* DUT-E CAN.

** DUT-E AF/232/485/CAN.

*** DUT-E A5/A10/F/I.

**** Starting from 01.09.2017 the screen filter is purchased separately.

Introduction

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 10

See figure 1 for identification codes for DUT-E ordering.

* Per special order sensor can be manufactured with any custom measuring probe length up to

1400 mm. For orders less than 200 pieces in calendar quarter, 10 % extra fee is applied.

Figure 1 —DUT-E order identification codes

Examples of DUT-E ordering identification codes:

Fuel level sensor DUT-E A10 L=700 mm,

(output voltage from 2.5 to 9.0 V, nominal measuring probe length 700 mm)

.

Fuel level sensor DUT-E CAN L=1000 mm,

(CAN j1939/S6 interface, nominal measuring probe length 1000 mm)

.

For DUT-E AF/232/485/CAN configuration a service adapter (SK DUT-E or S6 SK) is used,

which is ordered additionally, and software Service DFM Marine you can download and/or

update your Service DUT-E software at https://www.jv-technoton.com/, in Software/Firmware

category.

ATTENTION: It is strongly recommended to follow strictly the instructions of the

present Manual when using, mounting or maintaining DUT-E.

The Manufacturer guarantees DUT-E compliance with the requirements of technical regulations

subject to the conditions of storage, transportation and operation set out in this Manual.

ATTENTION: Manufacturer reserves the right to modify DUT-E specifications that do

not lead to a deterioration of the consumer qualities without prior customer notice.

General information and technical specifications of DUT-E / Purpose of use and application area

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 11

1 General information and technical specifications

1.1 Purpose of use and application area

is designed to measure level of liquid fuel and other nonconductive liquids in

vehicle and stationary tanks (see figure 2).

Figure 2 —DUT-E purpose of use

Application area —DUT-E fuel level sensors are used in Vehicle Telematics systems as

additional fuel sensors or as a replacement of standard (factory built-in) fuel level sensors

(see figure 3).

Figure 3 —DUT-E application within Vehicle Telematics system

General information and technical specifications of DUT-E / Purpose of use and application area

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 12

DUT-E is installed into a fuel tank of a vehicle. The sensor measures fuel level in the tank and

generates an output signal to forward it to a Vehicle Tracking device.

Telematics terminal records and processes the sensor data for further transmission to the

telematics server. Server software processes and analyzes the received data to generate

Analytical reports for a selected period of time.

The availability of CAN j1939/S6 interface enables DUT-E CAN fuel level sensors to operate

together with DFM CAN fuel flow meters and other standard and additional equipment by

means of S6 Technology (see figure 4).

Figure 4 —Employment of DUT-E CAN sensors using S6 Technology

With the help of DUT-E CAN connected by means of S6 Technology, you can monitor in real

time:

•fuel tank level and volume;

•total volume of fuel in up to 8 tanks and a separate volume value for each of the tanks;

•fuel temperature;

•sensor specification data (passport);

•presence of water in fuel;

•sensor malfunctions.

Tracking device can receive data from up to 8 DUT-E CAN sensors and up to 8 DFM CAN fuel

flow meters via a single CAN interface port. This technical option is of particular importance for

complicated mobile or fixed objects.

General information and technical specifications of DUT-E / Purpose of use and application area

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 13

ORF-4 Telematics service allows convenient analysis of fuel volume inside tank of Vehicle

(see figure 5).

Figure 5 —Example of Analytical report generated in ORF 4 software,

based on the DUT-E data

DUT-E application as a part of vehicle Telematics system allows operator to:

•receive accurate information on the current amount of fuel in the tank;

•determine exact refueling amount;

•reveal fuel theft facts;

•monitor fuel consumption rate.

General information and technical specifications of DUT-E / Exterior view and delivery set

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 14

1.2 Exterior view and delivery set

1- DUT-E fuel level sensor –1 pc.;

2- Specification with factory settings sheet –1 pc.;

3- SC-CW-700-RS signal cable (7.5 m) –1 pc.*;

4- Mounting kit (1 pc.) including:

a) bottom stop –1 pc.;

b) plastic mounting plate –1 pc.;

c) rubber gasket –2 pcs.**;

d) sealing rubber ring –2 pcs.**;

e) bolt –5 pcs.;

f) threaded rivet –5 pcs.;

g) self-tapping screw –5 pcs.;

h) plastic seal –2 pcs.***;

i) sealing cord –2 pcs.;

j) fuse with holder (2 A) –2 pcs.;

k) hole placement template –1 pc.

Figure 6—DUT-E delivery set

*Ordered separately signal cable (7.0 m) for DUT-E CAN.

** 1 pc. is for initial DUT-E GSM mounting and 1 pc. as a spare part.

The delivery set may include just 1 gasket of 4 mm.

*** Exterior of seal can be different.

4 c

4 e

4 j

3

4 a

4 k

2

4 g

4 h

1

4 i

4 b

4 f

4 d

General information and technical specifications of DUT-E / Design and operation principle

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 15

1.3 Design and operation principle

DUT-E fuel level sensor (see figure 7) consists of a measuring probe (1), fuel level sensor

“head”with an electronic module located inside (2), interface cable (3) with connector for

electrical connection (4).

Figure 7 —DUT-E structure

DUT-E operation principle is based on condenser capacitance measurement, where measuring

probe pipes are used as capacitor plates. Electric capacitance changes depending on measuring

probe immersion depth in the fuel which is dielectric liquid. The sensor analyzes current value

of electric capacitance and then generates an appropriate output signal.

WARNING: Capacitive principle ensures highest accuracy of liquid measurement

when the liquid has constant dielectric permeability coefficient. Otherwise,

additional inaccuracy of measurement may appear.

DUT-E CAN

DUT-E A5

DUT-E A10

DUT-E F

DUT-E I

1

4

3

2

4

4

1

1

3

3

2

DUT-E AF

DUT-E 232

DUT-E 485

2

General information and technical specifications of DUT-E / Design and operation principle

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 16

Fuel level translation is carried out in accordance with calibration table. To create the table, it

is necessary to calibrate the fuel tank. This procedure is a sequence of fixed refueling portions

from empty to full tank. During calibration, the value of DUT-E output signal is established

depending on fuel amount in a particular tank (see DUT-E fuel level sensor installation video

for details).

DUT-E can be used in combination with recording and display units (including GPS/GLONASS

Vehicle Tracking devices), and their input signal specifications have to be compatible with

DUT-E output signal specification according to Clauses 1.4.2 —1.4.5.

When using DUT-E AF/A5/A10/F/I fuel level sensors, calculation of fuel amount is carried out in

a registration unit such as a GPS Tracking device or on the server using vehicle monitoring

system software.

DUT-E 232/485/CAN fuel level sensors can calculate current fuel amount independently in

accordance with calibration table recorded in the sensor internal memory with Service DUT-E

software.

General information and technical specifications of DUT-E / Technical specifications / Main specifications

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 17

1.4 Technical specifications

DUT-E is powered by on-board power supply of the Vehicle where it is installed.

DUT-E can be used in the conditions of temperate and cold climates.

For resistance to mechanical impact DUT-E is shake and shockproof.

1.4.1 Main specifications

Table 1 —DUT-E main specifications

Parameter, measuring unit

Value

Fuel level sensor operating principle

Capacitive

Relative measuring error (to the length of the

measuring part), %, not more than

±1.0

Power supply voltage range, V

10…50

Maximal current consumption at supply voltage

12/24 V, mA, not more than

50/25

150*/75*

Availability time after power-up, seconds,

not more than

10

Maximum trimming of the measuring probe

see 2.4

Maximum length increase, mm, not more than

see 2.5

Temperature range, °C

-40…+85

Ingress protection rating

IP55/57

Electromagnetic compatibility

see annex G

Weight, kg, not more than

0.6 (at L=1000 mm)

0.5 (at L=700 mm)

0.4 (at L=350 mm)

Overall dimensions, mm, not more than

see figure 8

*For DUT-E CAN.

General information and technical specifications of DUT-E / Technical specifications / Specifications of DUT-E AF output signal

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 18

1.4.2 Specifications of DUT-E AF output signal

DUT-E AF fuel level sensor has an analog and frequency output which can be configured via

K-Line (ISO 14230) interface.

Output signal value does not depend on supply voltage and is linear dependent on the fuel

level.

The capacity of analog-digital output signal converter is 12 bit.

DUT-E AF output signal ranges:

1) Voltage output —from 1.0 to 9.0 V. The lower limit of the range can be configured from

1.0 V to 8.0 V and the upper limit from 2.0 V to 9.0 V;

Note —variation of the output voltage of the sensor can be set in both direct and inverse

dependence.

2) Frequency output —from 500 to 1500 Hz. Frequency output signal has a meander shape

with 50 % duty ratio. High level voltage value equals to (10.0±1.0) V.

Low level voltage value is not more than 0.5 V.

Depending on settings DUT-E AF output signal value can stand for:

•fuel level in the tank (mm);

•fuel volume (l);

•total fuel volume (l) of up to eight tanks.

DUT-E AF output signal correspondent to fuel volume is generated according to calibration

Table of the fuel tank which is stored in the sensor’s memory.

Input resistance of the device DUT-E AF is connected to in frequency output mode should not

be less than 10 kOhm;

In voltage output mode output resistance value is not more than 5 kOhm for low level and not

more than 50 kOhm for high level.

General information and technical specifications of DUT-E / Technical specifications /

Specifications of DUT-E A5/A10/F/I output signal

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 19

1.4.3 Specifications of DUT-E A5/A10/F/I output signal

Output signal voltage values (for DUT-E A5 and DUT-E A10), frequency values (for DUT-E F)

and current values (for DUT-E I) are linear dependent on fuel level in the tank.

Output signal value does not depend on supply voltage value.

•Input resistance of the device DUT-E A5/A10 is connected to should not be less than

10 kOhm.

•Output stage of DUT-E F –open collector with load resistor of 10 kOhm.

•Input resistance of the device DUT-E I is connected to should not be more than

260 Ohm for 12 V power supply voltage and should not be more than 800 Ohm for 24 V

power supply voltage.

For DUT-E I correct performance the difference between minimum on-board power supply

voltage and load voltage for the full tank should not be less than 5 V.

Table 2 —DUT-E A5/A10/F/I output signal specifications

DUT-E

model

Fuel

tank

status

Voltage, V

Frequency

,

Hz

Current, mA

for

nominal

probe

length

for 30 %

cut probe

for

nominal

probe

length

for 30 %

cut probe

for

nominal

probe

length

for 30 %

cut probe

DUT-E A5

Empty

1.5

0.9

-

-

-

-

Full

4.5

3.7

-

-

-

-

DUT-E A10

Empty

2.5

1.0

-

-

-

-

Full

9.0

5.6

-

-

-

-

DUT-E F

Empty

-

-

500

262

-

-

Full

-

-

1500

941

-

-

DUT-E I

Empty

-

-

-

-

6.7

4.0

Full

-

-

-

-

20.0

16.4

General information and technical specifications of DUT-E / Technical specifications / Specifications of DUT-E 232/485 output signal

DUT-E fuel level sensors. Operation manual. Version 8.1

© Technoton, 2020 20

1.4.4 Specifications of DUT-E 232/485 output signal

Specifications of DUT-E 232 and DUT-E 485 output signal correspond to the specifications of

RS-232 and RS-485 interfaces.

Depending on settings output value of DUT-E 232 and DUT-E 485 can stand for:

•standard (normalized) units, from 0 to 1000 (0 –empty tank, 1000 –full tank);

•fuel level in the tank (mm);

•fuel volume (l);

•percentage of full tank capacity (%).

DUT-E sensor sends data on current temperature as well (value is measured with the

temperature sensor located on the PCB).

DUT-E 232 and DUT-E 485 data transfer is carried out according to DUT-E COM Protocol.

This manual suits for next models

7

Table of contents

Popular Adapter manuals by other brands

VOLTCRAFT

VOLTCRAFT CPUC-1000 operating instructions

StarTech.com

StarTech.com USB3S2SATA instruction manual

Mitsubishi Electric

Mitsubishi Electric BAC-HD150 instruction manual

D-Link

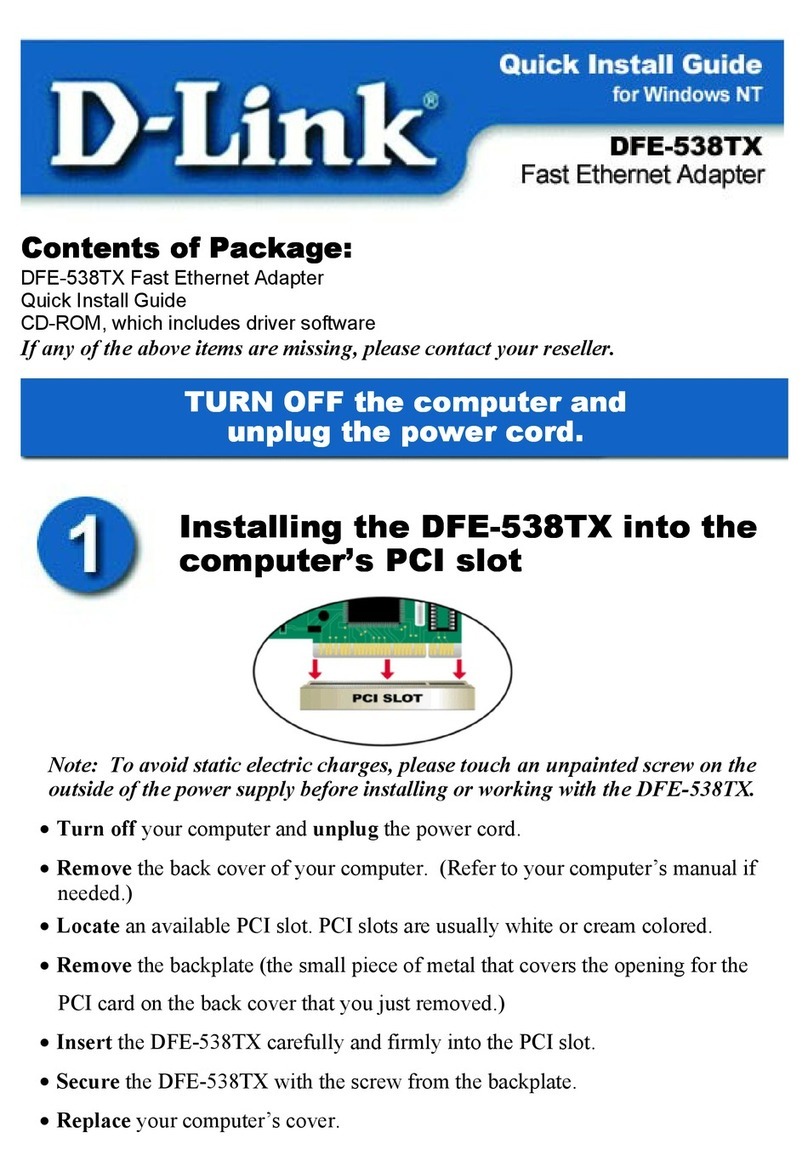

D-Link DFE-538TX Quick install guide

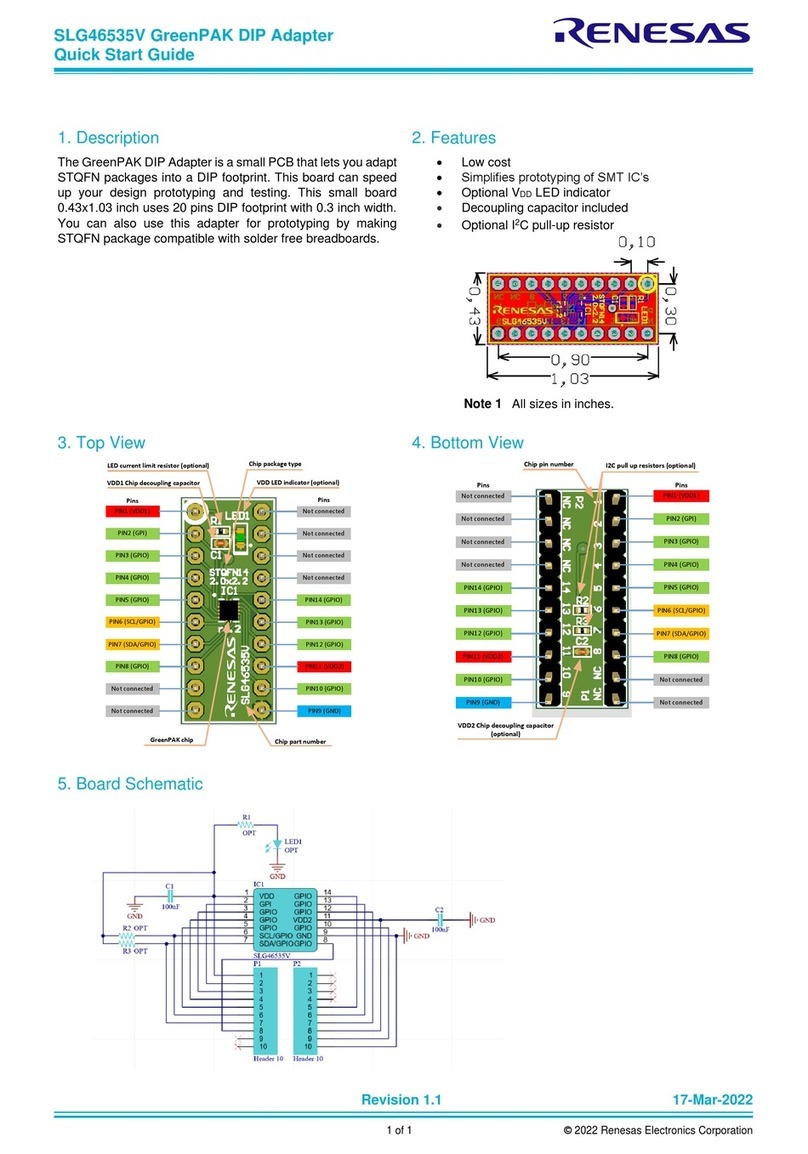

Renesas

Renesas GreenPAK SLG46535V quick start guide

3idee

3idee EX3203R Assembly instructions

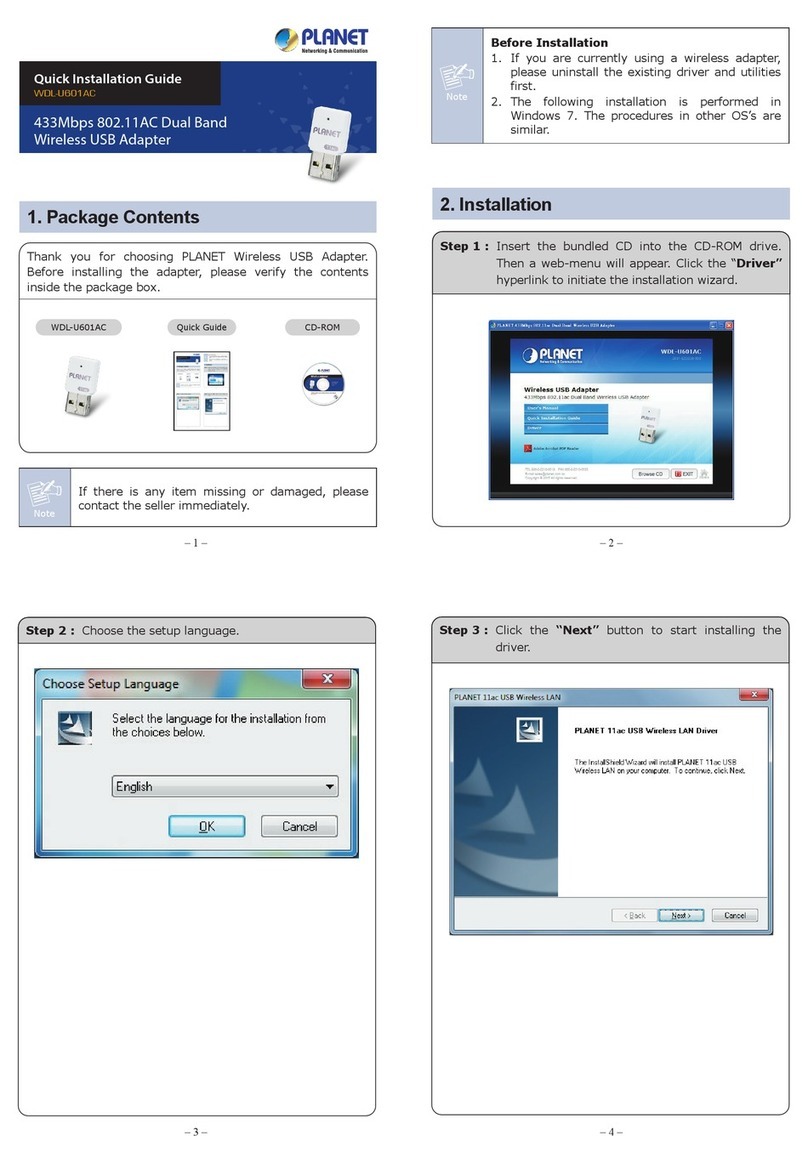

Planet Networking & Communication

Planet Networking & Communication WDL-U601AC Quick installation guide

Philips

Philips SWA4551W Specifications

Wize

Wize CA8XD instruction manual

Belkin

Belkin G+MIMO Specifications

Erskine Attachments

Erskine Attachments Mount Height Adapter Operator's manual

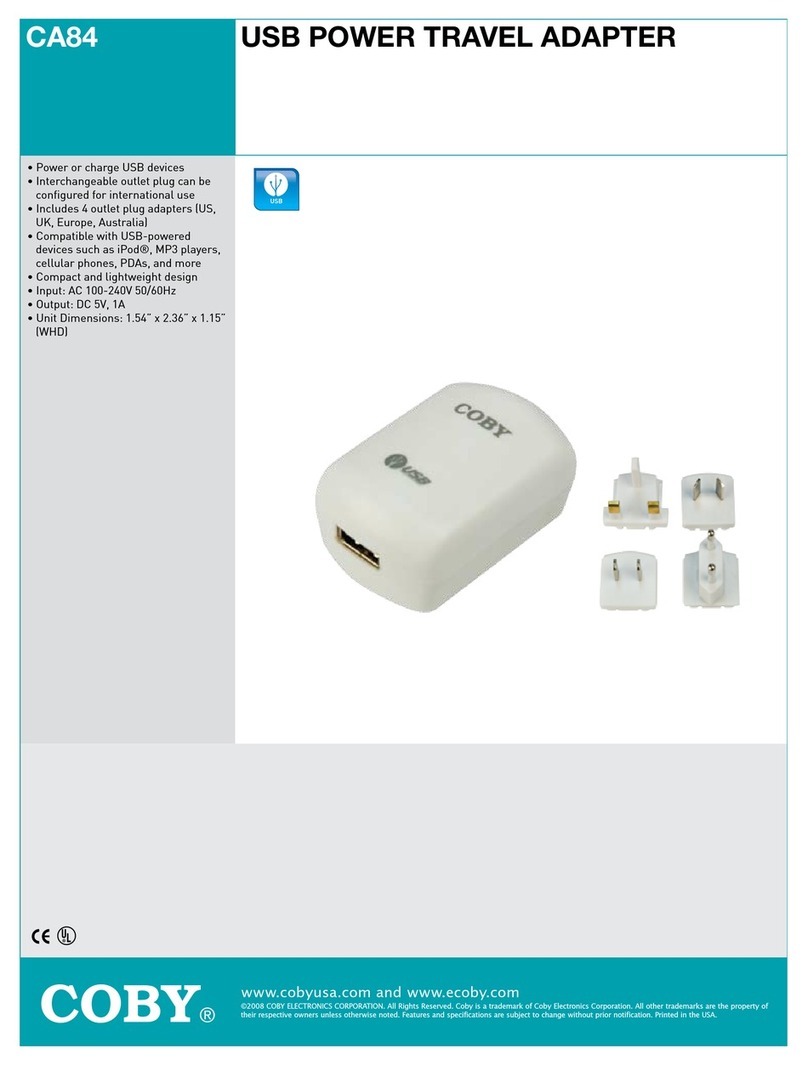

Coby

Coby CA84 Specifications