23

INTRODUCTION

This manual includes the technical description, operation, installation and assembly instructions,

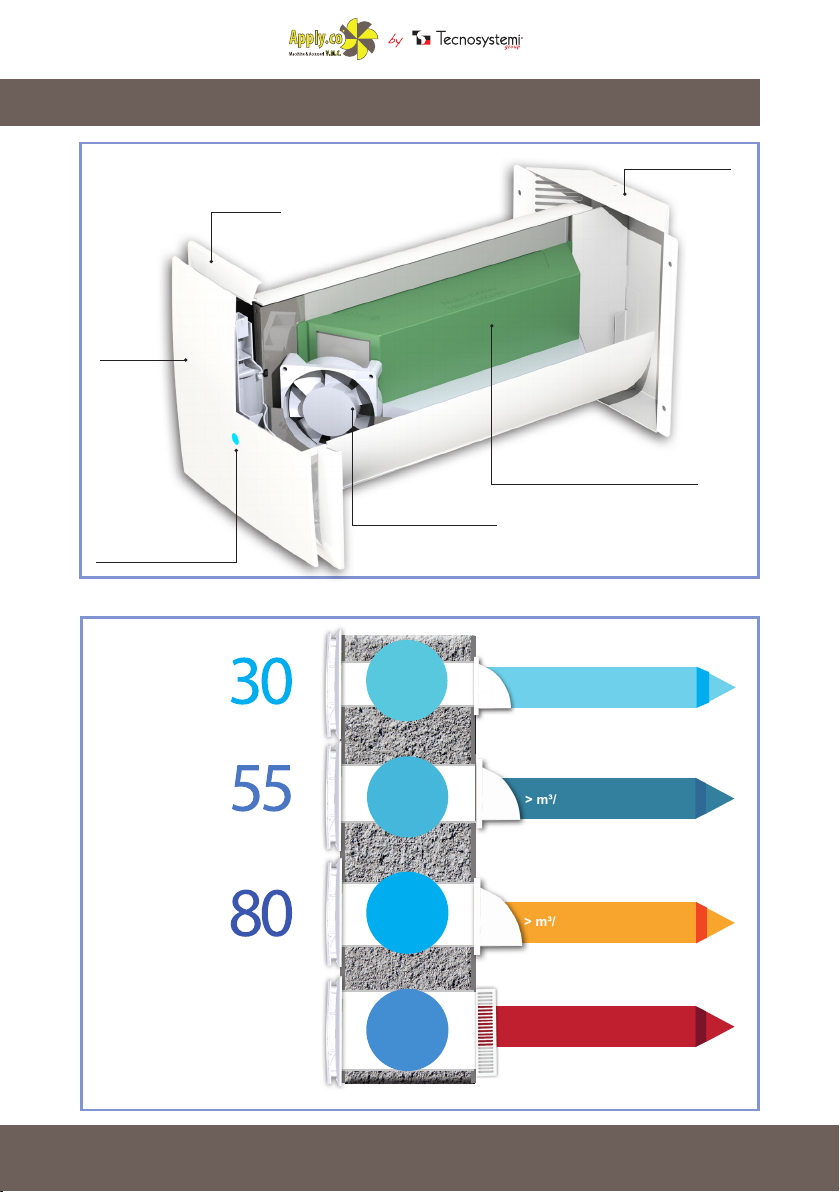

technical data for the intake extractor unit with energy regeneration “PICO HP2”, “PICO RECO

100”, hereinafter referred to as recovery unit.

The recovery unit was designed to ensure the air exchange in apartments, holiday farms, hotels,

bars and, in general, domestic and public places.

The recovery unit is tted with a ceramic exchanger which allows the air recirculation thanks to the

energy regeneration with the heat from the intake air.

The recovery unit was designed to be installed in premises on walls with a thickness between 310 mm

and 500 mm (optional tube L=1,500 mm), for the “Pico Reco 100”, the minimum thickness is 370 mm.

The recovery unit was tested for continuous operation connected always to be mains supply.

The transported air must not contain ammable or explosive mixtures, chemical substance

vapours, large dust particles, soot and oil particles, dangerous substances, brous

materials, pathogenic agents or other harmful substances.

The recovery unit was designed for application within premises with a room temperature varying

from -20°C to +50°C and relative humidity of up to 80%.

THE RECOVERY UNIT WAS NOT DESIGNED FOR USE BY CHILDREN, PERSONS

WITH PHYSICAL OR MENTAL DISABILITIES, PERSONS WITH SENSORY

DISABILITIES, OR PERSONS WITHOUT ADEQUATE QUALIFICATIONS.

THE INSTALLATION AND CONNECTION OPERATIONS CAN BE PERFORMED

ONLY BY QUALIFIED PERSONNEL AFTER FOLLOWING THE ADEQUATE

SAFETY TRAINING.

UNATTENDED CHILDREN SHOULD NOT BE ALLOWED ACCESS TO THE SITES

WHERE THE FAN IS INSTALLED.

MAIN TECHNICAL PARAMETERS

Read the user manual carefully before use and installation of heat reversible recovery unit with

individual chamber with energy regeneration.

The installation and the operation of the recovery unit must be carried out in compliance with the

user manual, as well as with applicable legislations, local and national laws and technical and

electrical regulations. The warnings, contained in the user manual, should be heeded, as they

contain vital information for personal safety.

Failure to follow the safety rules can result in damage to the recovery unit. Read this manual

carefully and keep it for as long as the recovery unit is used.

Legend of symbols used in the manual:

SAFETY REQUIREMENTS

USE OF THE RECOVERY UNIT

WARNING

PROHIBITION