3

TROUBLESHOOTING:

1 – Possible problems during installation

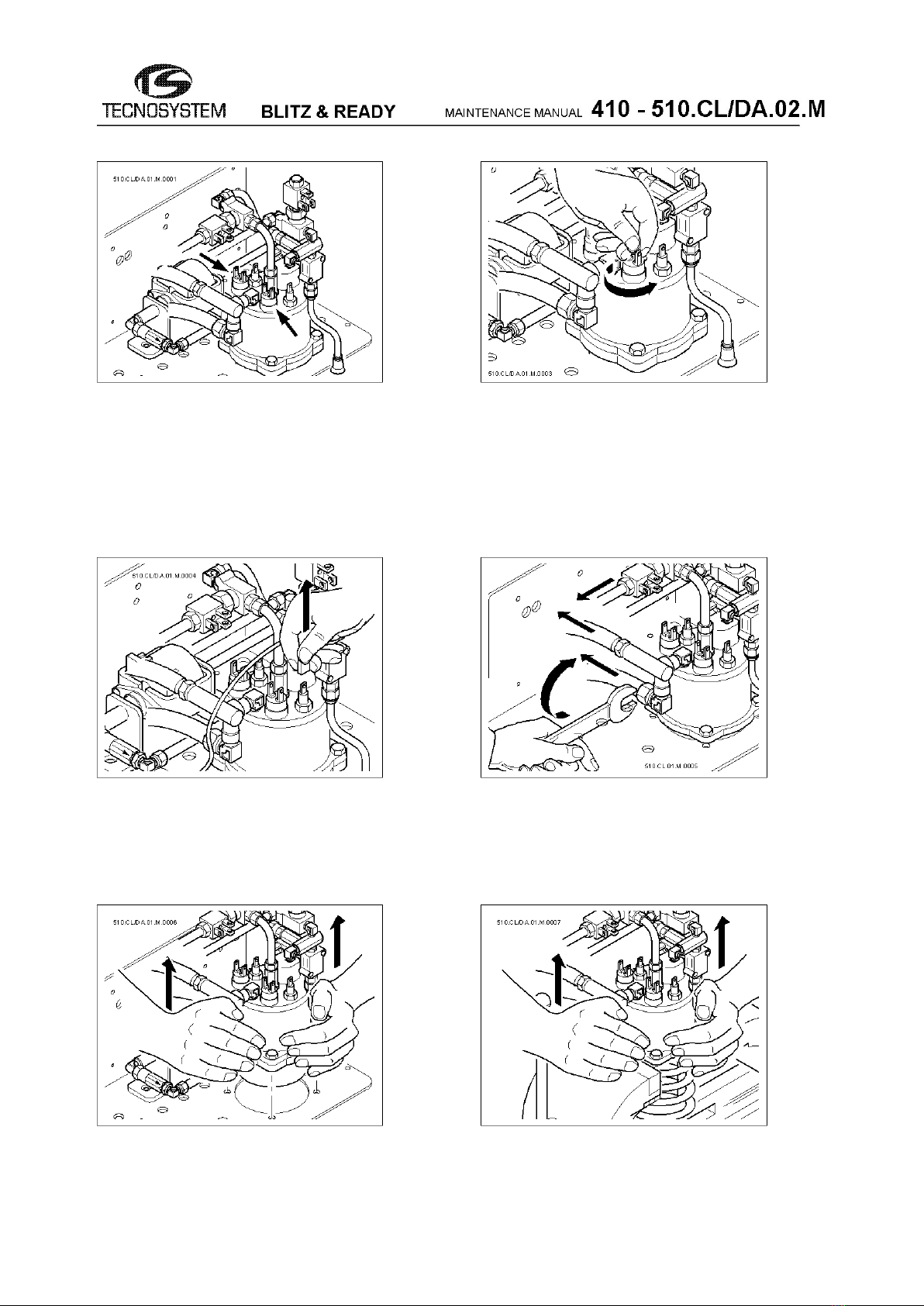

1.1 – Pump loading manual phase relation.

2 – Possible problems due to failure to provide maintenance

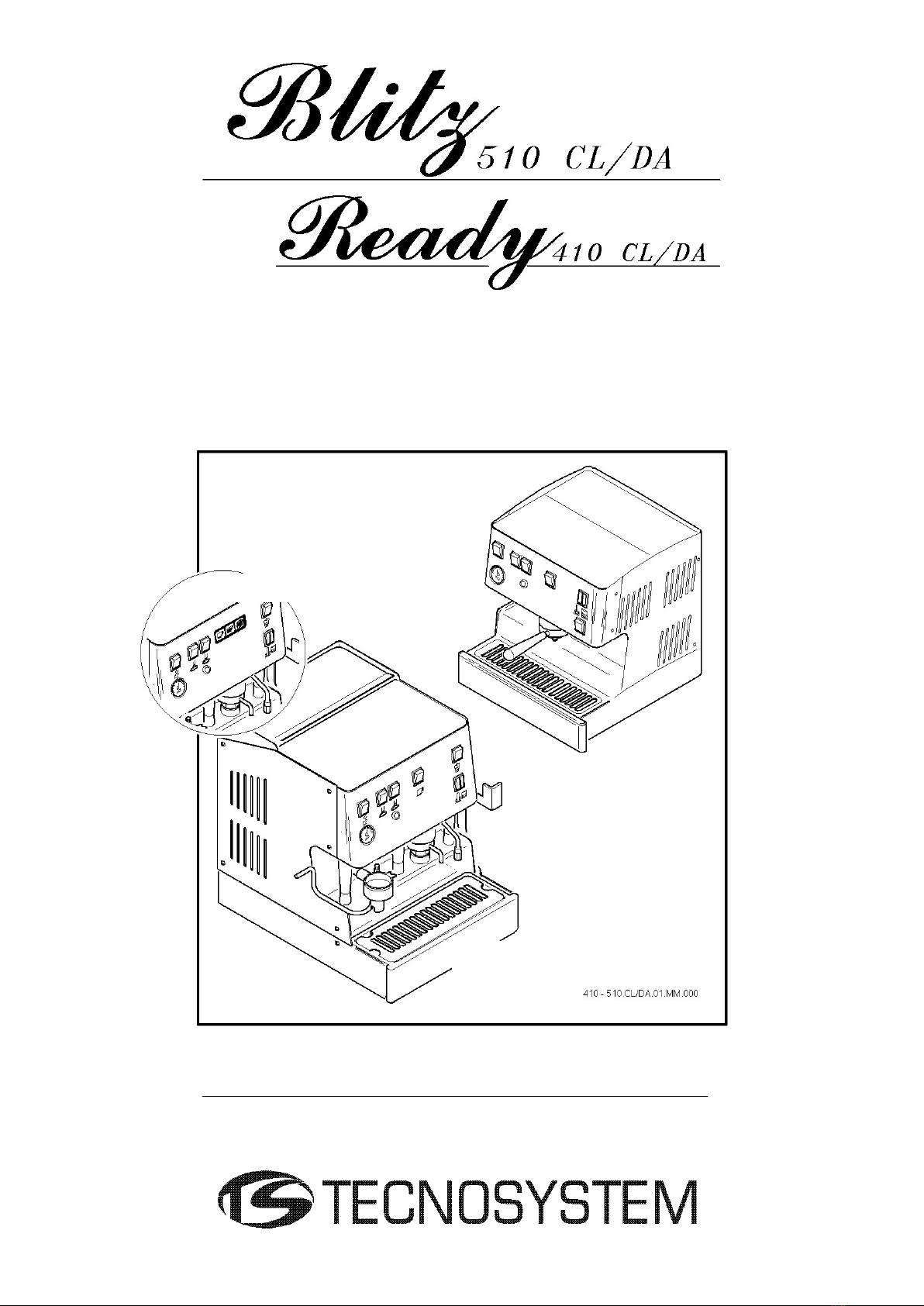

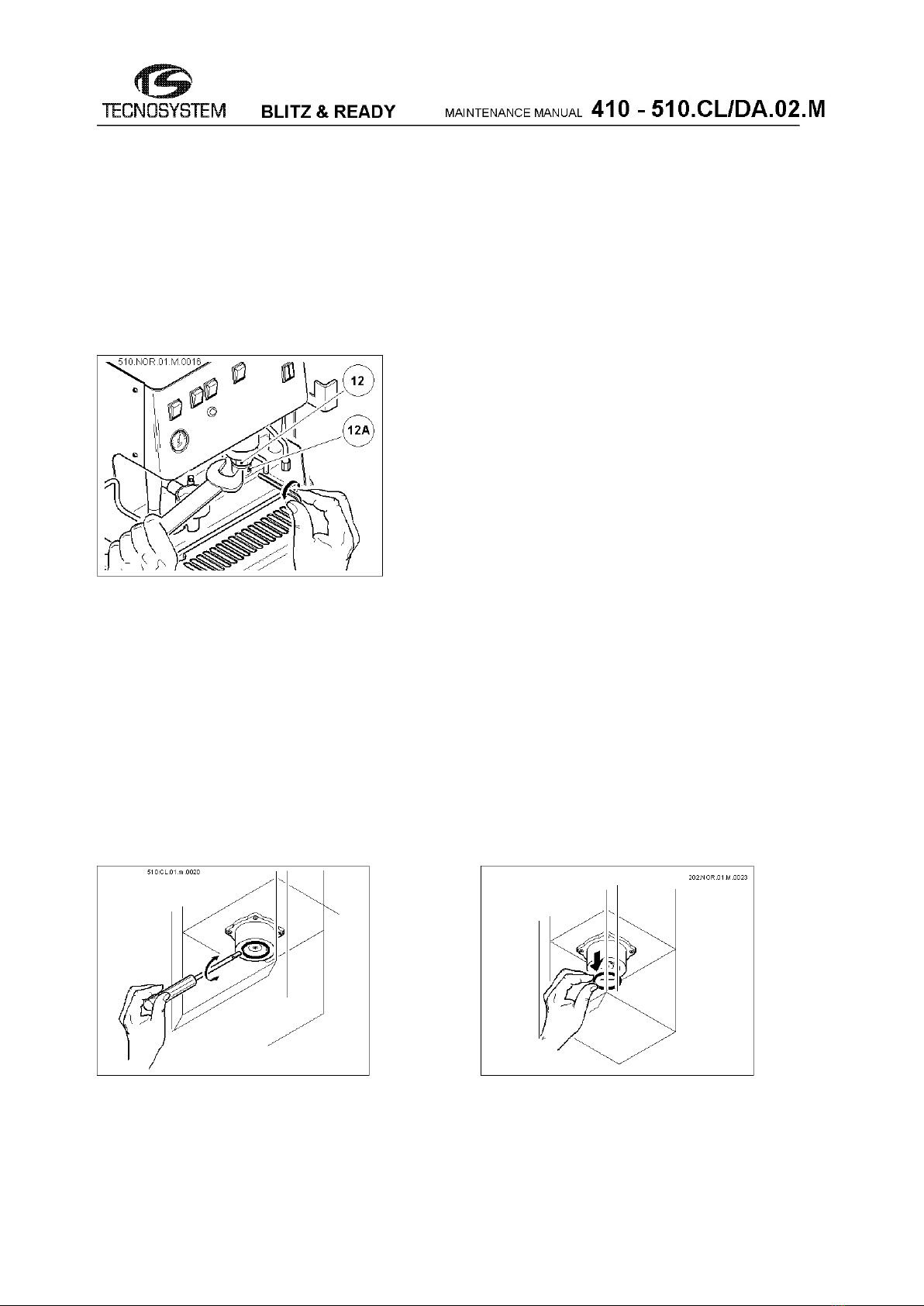

2.1 - Pod holder setting (Only for model 510)

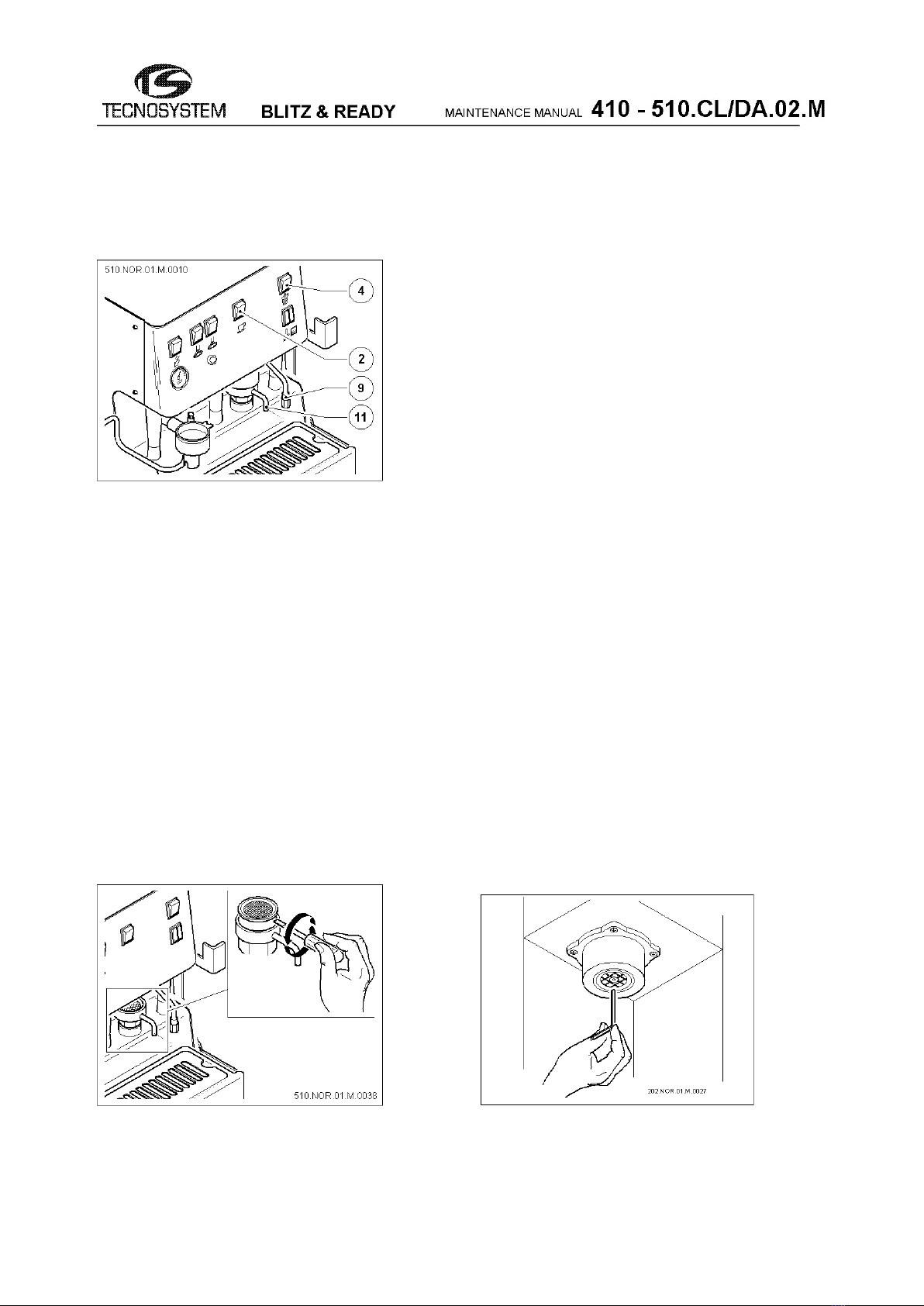

2.2 – Filter cleaning (Only for model 510)

2.3 – Maintenance of the cappuccino maker

3 – Possible problems due to electro-mechanical faults

3.1 - The machine does not turn on.

3.2 - The machine turns on but does not heat.

3.3 - When you press the coffee switch, the pump goes on in a very noisy

way, but no coffee comes out of the pipe.

3.4 - When you press the coffee switch, the pump goes on but no coffee

comes out of its spout and water comes out of the hot water pipe.

3.5 - When you press the water delivery button, the pump goes on, but the

water exits through the by-pass instead of coming out from the relevant pipe,

and goes into the tank (short pipe).

3.6 - When you press the coffee delivery button, the pump goes on but does

not let any coffee out from the relevant pipe.

3.7 - During the steam boiler water level renewal phase, the pump goes on

working for a maximum time of 2 minutes, leading to safety stopping of the

machine.

3.8 - Continuous dripping from the coffee spout when the machine is on,

even when it is not working.

3.9 – When you press the water or coffee switch, the pump is not turned

on.

3.9A - The machine makes the automatic differential switch intervene in

order to protect the power line it is connected to.

3.10 - Steam boiler pressure fault.

3.11 - The steam boiler does not heat.

3.12 - Fault with steam output during working phase.

3.13 - Faulty water output from the safety valve of the boiler during

coffee delivery phase.

3.14 – If steam delivery is requested, the pressure switch shows zero

pressure and the steam delivery stops immediately.

4 - Problems, diagnostics and instructions about the station, the

keyboard and the dosing of the DA model.

4.1 - When turning the machine on, the leds on the keyboard stay off, without

performing the turning on/off sequence.

4.2A - When selecting a coffee (high or low coffee level), a quantity of coffee

different from the preset one is obtained.