Tecnotion TM3 Series User manual

Iron Core linear motor manual

2

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

[ INTRODUCTION ]

A linear motor system is a part of a specific machine. Tecnotion’s Iron core linear motors are components that can be combined

with numerous application devices. This manual is intended for technicians who want to construct a machine that includes a

linear motor system.

It gives insight in the basic components of aTecnotion iron core linear motor and additional components to complete the whole

motion system. The manual further informs about important design and installation aspects of the linear motors. The settings

required before starting up are discussed.

In the appendix the important dimensions for designing the construction that will hold the linear motor can be found. Finally,

the glossary offers insight into the definition of all specifications of a Tecnotion linear motor.

When installing a linear motor system one should be familiar with some important safety remarks. In the first chapter these

remarks are made. Please, read them carefully.

3

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

TABLE OF CONTENTS

TOC

TABLE OF CONTENTS

1. [ BEFORE YOU START ] 5

1.1 Important notice 5

1.2 Safety warnings 5

1.3 Certication 7

1.3.1 CE certication

1.3.2 UL / CSA certication

1.3.3 Restriction of Hazardous Substances (RoHS)

2. [ MOTOR COMPONENTS ] 8

2.1 Components 8

2.1.1 Coil unit

2.1.2 Magnet plates

2.1.3 Magnetic eld protection plates

2.1.4 Bolts and dowelpins

2.2 Additional features 10

2.2.1 Analog Hall module

2.2.2 Digital Hall module

2.2.3 Additional motion system components

3. [ MOTOR CONFIGURATION ] 11

3.1 Conguration options 11

3.1.1 Magnet track length

3.1.2 Air gap

3.1.3 Coupling of motors

3.2 Mechanical interface 14

3.2.1 Flatness

3.2.2 Mounting height

3.2.3 Coil positioning over the magnet track

3.2.4 Bolts for coil unit

3.2.5 Dowelpins for coil unit

3.2.6 Magnettrack

3.2.7 Bolts for magnet plates

3.2.8 Dowelpins for magnet plates

3.2.9 Water cooling connections

3.3 Watercooling 18

3.4 Electrical interface 19

3.5 Temperature sensors 21

3.6 Accessories 23

3.6.1 Analog Hall module

3.6.2 Digital Hall module

3.7 Storage 26

4. [ INSTALLATION ] 27

4.1 Installation material 27

4.2 Cleaning 27

4.3 Installation order 28

4.3.1 Mounting the Coil Unit

4.3.2 Mounting the magnet plates

4.4 Electrical connections 33

4.4.1 General remarks

4.4.2 Powerlines

4.4.3 Protective earth

4.4.4 Polarization test

4.4.5 Temperature sensor cable wiring

4.5 De-installation order 34

5. [ ADDITIONAL INSTALLATIONS ] 35

5.1 Stainless steel magnet track cover 35

5.2 Covering the magnet plate 35

5.3 Installing water cooling connections 36

5.3.1 Additional installation material

5.3.2 Fitting water-cooling connections

5.4 Installing the analog hall module 38

5.4.1 Additional installation material

5.4.2 Mounting the analog hall module

5.5 Installing the digital hall module 39

5.5.1 Additional installation material

5.5.2 Mounting the digital hall module

4

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

6. [ OPERATION ] 40

6.1 Pre-commissioning 40

6.2 Conguring 40

6.3 Testing 41

6.4 Starting up 41

APPENDIX A 43

Dimensions - TM Coil 43

Dimensions - TM Magnet plates 44

Dimensions - TL Coil 45

Dimensions - TL Magnet plates 46

Dimensions - TB Coil 47

Dimensions - TB Magnet plates 48

Dimensions - TBW Coil 49

Dimensions - TBW Magnet plates 50

APPENDIX B 51

Motor cable conguration 51

APPENDIX C 52

Temperature sensor location 52

APPENDIX D 53

Package weight 53

APPENDIX E 54

EC - ROHS Declaration 54

CSA Certication 55

APPENDIX F 56

Coupling - TM Series 56

Coupling - TL Series 57

APPENDIX F 58

Coupling - TB Series 58

Coupling - TBW Series 59

APPENDIX G 60

F / v Graphs 60

GLOSSARY 66

5

Tecnotion | www.tecnotion.com | [email protected]

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

1. [ BEFORE YOU START ]

BEFORE YOU START

CH 1

Please read the following instructions very carefully.

They are important for a safe and warranted installation and operation of

the Linear Motor

1.1 Important notice

Before installing and using the Linear Motor, read this instruction

manual carefully. The manufacturer declines all responsibility

in case of accident or damage due to negligence or lack of

observance of the instructions described in this manual. The

manufacturer also declines all responsibility in case of accident

or damage in conditions that differ from those indicated

in the manual; Tecnotion also declines all responsibility

for damage caused by improper use of the Linear Motor.

Handle the components of the Linear Motor with care, packed

as well as unpacked. Especially the magnet plates are sensitive

to mechanical shocks. Never drop a magnet plate or release it in

an uncontrolled way.

Do not expose the magnets to temperatures higher than 70° C.

The magnets may be demagnetized at higher temperatures.

Unpack the Linear Motor and check its integrity. If there is any

irregularity, contact the dealer or manufacturer, signalling the

nature of the defects.

Make a note of the serial number. This facilitates the

correspondence with the supplier.

1.2 Safety warnings

The Linear Motor is used as a part of a machine. The user has to

take care that the machine as a whole fulfils all CE require-

ments.

The magnet plates show large attraction forces on all soft

magnetic objects such as iron.These forces cannot be controlled

by hand. They may cause serious jamming danger. Do not

bring any soft magnetic objects (iron) nearer than 25cm of the

magnetic side of the magnet plate.

Be sure that the magnetic plates are fixed into your machine

before removing the magnetic field protection plates. Put the

magnetic field protection plates on the magnetic plates again

before dismounting them.

Magnetic sensitive objects like banking cards, pacemakers or

other magnetic information carriers may be damaged if they are

brought within 1m of the magnet plates.

Safety and information symbols:

The lightbulb describes a‘Tip’.

The exclamation mark is a, non safety related, important notice

that the user should be aware of.

The warning signs inform about safety information that the user

should respect.

6

Tecnotion | www.tecnotion.com | [email protected]

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

BEFORE YOU START

CH 1

The magnet plate and coil unit can be damaged when cleaned

with a non-prescribed cleaning agent.

Use only Isopropanol as a cleaning agent.

UV Blacklight can cause irreversible damage to the eyes

and other tissue when exposed. When using a UV Blacklight

installation wear appropriate protective clothing and glasses.

The magnet plates attract each other while mounting. This may

cause serious jamming danger. Take care that a magnetplate

does not damage the adjecent magnet plate while mounting.

If at any time and in any situation there is any doubt about

the safety of the Linear Motor, do not use it and contact your

supplier.

The Linear Motor is powered by a servo amplifier. In case of a

power disruption or fatal error this may automatically result in

a free run out of the motor. Make mechanical precautions to

prevent damage on the motor or your machine in the case of

such an event.

Before installing the motor, make sure that the supply mains

are grounded and operate in conformity with the regulations in

force.

Make sure that there is an effective protective earth. Make sure

that there is no voltage at the wire terminals before connecting.

An earth connection does not work on non-conducting

mounting surfaces like granite. In these cases the protective

earth must be established by an earthing wire.

Before carrying out checks or doing any maintenance, clear the

system by disconnecting the voltage. Be sure that there is no

possibility of accidental connections.

7

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

BEFORE YOU START

CH 1

Series CE UL / CSA RoHS

TM3 Yes Yes Yes

TM6 Yes Yes Yes

TM12 Yes Yes Yes

TM18 Yes Yes Yes

TL6 Yes Yes Yes

TL9 Yes Yes Yes

TL12 Yes Yes Yes

TL15 Yes Yes Yes

TL18 Yes Yes Yes

TL24 Yes Yes Yes

TB12 Yes Yes Yes

TB15 Yes Yes Yes

TB30 Yes Yes Yes

TBW18 Yes Yes Yes

TBW30 Yes Yes Yes

TBW45 Yes Yes Yes

1.3 Certication

All information about certifications can be found in this chapter. The de-

claration of comformity or compliance can be found in APPENDIX E.

1.3.1 CE certication

Tecnotion B.V. declares that all linear motors mentioned in this Installa-

tion manual are manufactured in accordance with European directive

2006/95/EC and in conformity with the following standards, see table 1.1.

Standard Name of standard

EN 60034-1: 2010 Rotating Electrical Machines,

Part 1: Rating and performance

EN 60204-1: 2010 Safety of machinery - Electrical equipment of machines, Part 1:

General requirements

Table 1.1: Applicable standards

1.3.2 UL / CSA certication

All Tecnotion B.V. Ironcore motors have UL / CSA certification. Please

contact your local Tecnotion representative for more information.

1.3.3 Restriction of Hazardous Substances (RoHS)

Tecnotion B.V. declares to be compliant with the RoHS-guideline. Therefore

Tecnotion ensures that all products are free from lead, cadmium, mercury,

hexavalent chromium, polybrominated biphenyls or polybrominated

diphenyl ethers.

Table 1.2: Overview of applicable standards per motortype

8

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR COMPONENTS

CH 2

2. [ MOTOR COMPONENTS ]

2.1 Components

Winding TM TL TB TBW

3 6 12 18 6 9 12 15 18 24 12 15 30 18 30 45

Nx x x x x x x x x x x x x

Sx x x x x x x x x x x x x x x x

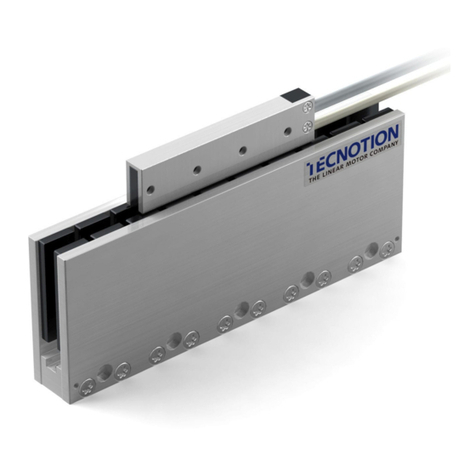

A Tecnotion iron core linear motor consists out of a coil unit and one or

more magnet plates. Together with a slide, mounting frame, rails and be-

aring system, dampers, encoder, controller and amplifier the linear motor

forms a complete machine concept.

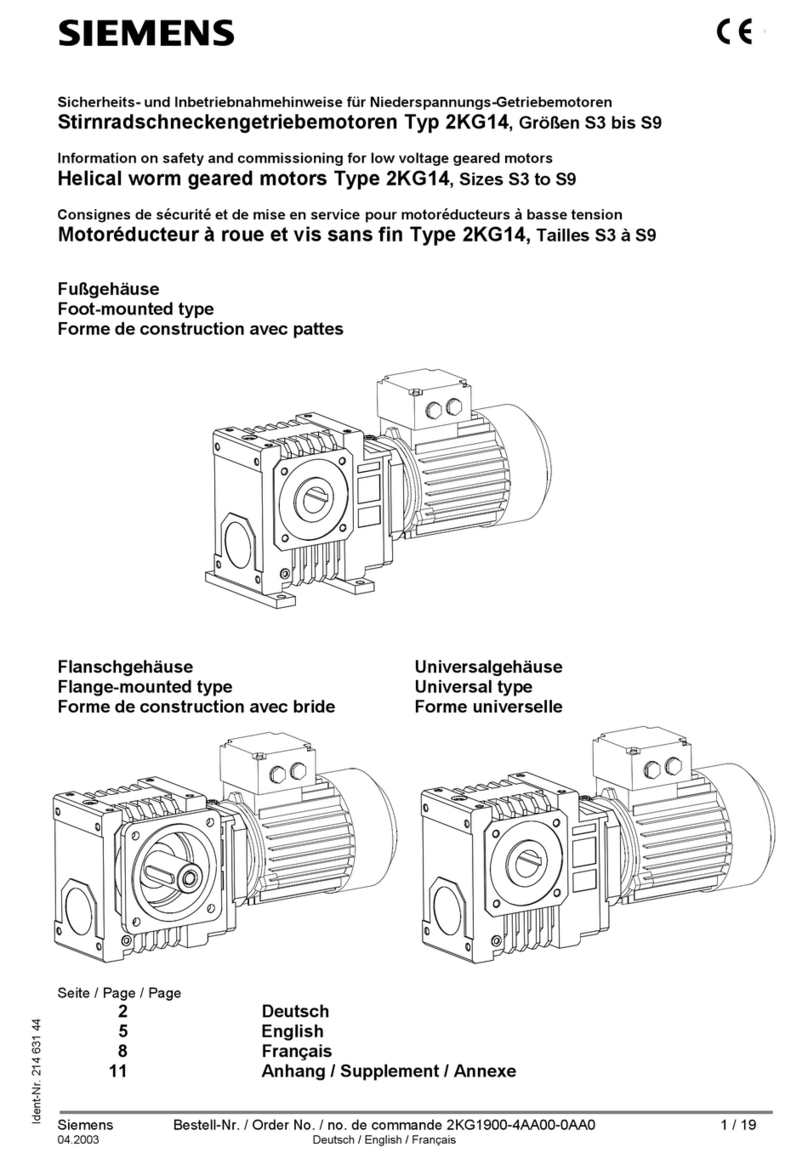

Picture 2.1: A complete axis system with Tecnotion coil unit and magnet plates installed

2.1.1 Coil unit

Tecnotion offers most of the coilunits as an N- and S-winding version. What

type is required depends on the voltage, current and speed requirements

of the application.

The N-winding type is optimized for current, enabling the use of a smaller

less costly amplifier. S-winding is optimized for higher speeds or lower

voltages. It can however require a larger amplifier.

Table2.3: available N- and S-winding type coilunits

Tecnotion only supplies coils and magnet plates and offers a few additional

components like Hall modules and stainless steel cover plates. All other

components need to be sourced from other suppliers. Please review this

chapter carefully to determine what is necessary to design a complete

system.

Picture2.2: A TL6 coil unit

Power cable

Temperature

sensor cable

Coil unit

Bearing

Damper

Ruler

Slide

Cable chain

Magnet plate

Rail

Encoder

9

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR COMPONENTS

CH 2

All iron core linear motors have various magnet plate lengths. This enables

efficient design of the magnet track length. For more information on

magnet track design please review chapter 3.1.1 Magnet track length on

page 11

To prevent serious jamming danger only handle the magnet

plates covered with the magnetic field protection plates.

2.1.2 Magnet plates

Picture 2.4: A TL192mm magnet plate

2.1.3 Magnetic eld protection plates

Magnet plates produce very high attraction forces. These forces are

unpredictable and cannot be controlled by hand.

Tecnotion iron core magnet plates are always delivered with protective

plates. These plates function as a shield for the magnetic forces. With the

protective plates the magnet plates can be handled safely.

Also use the protective plates during assembly and disassembly. Please

review chapter 4.3.2 Mounting the magnet plates on page 30 how to

do this.

Picture 2.5: A magnet plate with a protection plate.

10

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR COMPONENTS

CH 2

Picture 2.6: The analog hall module

Picture 2.7: The digital hall module

Applying too long bolts for the coil unit may inconspicuously

cause damage and dangerous situations. Please, check

(1) bolt length before mounting

(2) bolt height after mounting

2.1.4 Bolts and dowelpins

The bolts and dowelpins for mounting the coil and magnet plates are

not provided by Tecnotion. The bolt length depends on the mechanical

dimensions of the mounting slide.

Please review chapter 4.3.1 Mounting the Coil Unit on page 29 and

4.3.2 Mounting the magnet plates on page 30 to see what bolts and

dowelpins are required.

2.2 Additional features

The components mentioned in this paragraph can also be delivered by

Tecnotion. The digital hall module for commutation and the analog hall

module for positioning can be used as cost effective alternatives to a

separate encoder system when positioning requirements are not extreme.

The maximal repeatable accuracy is ~30 µm and absolute accuracy is

~ 100 µm, depending on the interpolation. Finally Tecnotion can also

deliver a stainless steel cover plate for the magnet track.

2.2.1 Analog Hall module

This analog hall module can function as a incremental encoder. It uses the

magnettrack as the linear scale. Please review chapter 5.4 Installing the

analog hall module on page 38 for more information.

2.2.2 Digital Hall module

The digital hall module can be used when a controller does not offer the

possibility to commutate within the servo drive. It uses the magnettrack as

the linear scale. Please review chapter 5.5 Installing the digital hall module

on page 39 for more information.

11

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR COMPONENTS

CH 3

2.2.3 Additional motion system components

A complete motion system would require at a minimum the following

components that are not supplied by Tecnotion.

■Power supply

■Cables and connectors

■Amplifier and servo controller system

■Bearing system

■Ruler and encoder system if Tecnotion’s analog or digital hall module

is not used

■Bolts and dowelpins

3. [ MOTOR CONFIGURATION ]

3.1 Conguration options

Individual iron core coils can be coupled.This can be done on two separate

magnet tracks for gantry type applications or on a single magnet track to

yield more force.

This last option is especially interesting for cost reduction in long stroke

applications.

By coupling two coils a smaller series coil and magnet track can be used.

This will reduce the magnet track cost.

3.1.1 Magnet track length

This paragraph describes how to determine the required amount of mag-

net plates for an application. There are two ways to determine the required

amount.

The easiest way to determine the required number of magnet plates is to

add up the necessary stroke for the application and the length of the coil

unit. Please review the example for further information. This will provide

the minimum magnet track length that needs to be constructed with the

available magnet plate sizes. Please refer to APPENDIX A for an overview of

the available length per series.

12

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

It can be cost effective to determine the required magnet track length by

means of the effective area instead of the coil unit length. This is especially

interesting when an extra magnet plate is required to attain the minimum

hub length when, according to the coil length, it falls short by approxima-

tely 25mm. This method will save the need for one magnet plate.

The effective area of a coil unit is the area where the actual windings are

situated in the coil, see picture 3.1. In this area the force is created that

propels a linear motor. The remaining space accommodates for example

the wiring, the PCB or filler material. This non effective area of the coil can

overrun the end of the magnet track without any loss of force.

ABC

Picture 3.1: Location of effective area

Example

Magnet length calculation with coil

unit length

Hr = Required stroke 440mm

Lc = TL6 Coil unit length 146mm

Mpl = Magnet plate length 288mm

Required number of magnet plates

=(Hr+Lc)/Mpl>two288mmmagnetplates

Magnet length calculation by means

of effective area

Hr = Required stroke 440mm

Leff = Lc – (a + b) = TL6 Coil unit effective

area 114mm

Mpl = Magnet plate length 288mm

Required number of magnet plates

=(Hr+Leff)/Mpl<two288mm magnetplates

Table 3.2 states the location where the effective area of a coil starts and

ends.

TM

Parameter Unit Dimension 3 6 12 18

Cableside mm A19 23 23 26,7

End mm B 8 6 2 3,7

Effective area mm C66 114 216 305,6

TL

Parameter Unit Dimension 6 9 12 15 18 24

Cableside mm A26 25 26 26,2 26,7 26

End mm B 6 5 2 6,2 3,7 2

Effective area mm C114 164 216 257,6 305,6 440

TB TBW

Parameter Unit Dimension 12 15 30 18 30 45

Cableside mm A26 26,2 26,2 34,7 39,2 39,2

End mm B 2 6,2 6,2 3,7 11,2 11,2

Effective area mm C216 257,6 529,6 305,6 529,6 801,6

Table 3.2: Dimensions of the effective area per motor type

3.1.2 Air gap

The air gap between the magnet plates and the coil unit can be increased

to overcome tolerance issues in clearance or deviations in parallelism or

flatness. Especially for large axis configurations this can be helpful.

Decreasing the air gap is not recommended because of the tight toleran-

ces this creates for the mechanics in the design and the increase in costs

this creates.

CH 3

13

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

Mounting height (nominal)

TM,TL series 40mm ±0.1mm

TB series 45mm ±0.1mm

TBW series 47mm ±0.1mm

Table 3.3: Mounting height of T-Series

Tecnotion doesn’t specify the nominal air gap because of the casted finish

of the coil unit and the magnet plate. This finish makes it difficult to get

an accurate reading of the air gap with the use of a feeler gage. To get an

accurate measurement Tecnotion advices to derive the air gap from the

total mounting height .

The reduction in force which the increase of the air gap creates is a non-li-

near function which is showed in graph 3.3.

0%

20%

40%

60%

80%

100%

0 2 4 6 8

Percentage of nominal Fc (%)

Airgap (mm)

Fc

Fa

Graph 3.3 Continuous force and attraction force airgap dependency.

3.1.3 Coupling of motors

Different type of motors within one series can be coupled as long as they

have the same motor constant (N and S can not be coupled). The forces of

both coils can be added up.

Motors must always be connected to the drive in parallel. Series coupling

isn’t possible because of voltage limitations of the cables. Refer to appen-

dix F for details about phase connections.

Parallel coupled: If cables of both motors face the same direction then

the motors can simply be placed at the same position on each individual

magnet plate parallel to each other.

In line coupling: Different orientations are possible.

.

.

.

.

.

.

Cables facing each other

Cables facing left or right

Cables facing outwards

14

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

Applying too long bolts for the coil unit may inconspicuously

cause damage and dangerous situations. Please, check

(1) bolt length before mounting

(2) bolt height after mounting

Use only the specified type of flat head fasteners with the correct

length. The coil and magnet plate can be damaged by non flat

head bolts.

Make sure the dowelpins do not extend further than the

specified height. The magnet plate can be damaged by too long

dowelpins.

The use of other water cooling connnections may cause higher

pressure drops than indicated due to smaller throughput.

3.2 Mechanical interface

When using a Tecnotion linear motor please take notice of the ad-

vice, tips and warnings in this chapter. It will make sure that your li-

near motor will perform as best as possible. Special attention should

be given to the orientation of the coil over the magnet track. All

dimensions for the ironcore series products can be found in APPENDIX A.

3.2.1 Flatness

With the prescribed flatness, see picture 3.4, the specified mounting height

can be used. If a lower flatness ratio is to be used the mounting height

needs to be increased. Please refer to 3.2.2 Mounting height on page 15

for further information.

Details about minimum mounting distances between both coils can be

found in appendix F. For other coupling possibilities please contact your

local Tecnotion representative.

Use only one of the temperature sensors

Make sure that the cables of both motors have exactly the same length

Please remember to respect the coil positioning over the magnet track as

described in 3.2.3

Picture 3.4: Flatness and parallelism requirements for coil and magnet plate

r

0,1

i

0,1 A

r

0,1

Mounting Frame

Magnet Plate

Coil Unit

Slide

H

u

0,1mm

A

15

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

Picture 3.5: Non symmetrical positioning of the coil unit over the magnet track

Applying too long bolts for the coil unit may inconspicuously

cause damage and dangerous situations. Please, check

(1) bolt length before mounting

(2) bolt height after mounting

All mounting holes must be used. The bolt length depends on the

mechanical dimensions of the mounting slide, see table 3.6.

3.2.2 Mounting height

By using the specified mounting height between the bottom of the magnet

plate and the top of the coil unit the correct air gap will be attained.The air

gap between the coil and magnet plate does not need to be verified. Refer

to APPENDIX A for the dimensions.

The mounting height can be increased. This will cause the rated

specifications of the linear motor to deteriorate exponentially.

For more information on air gap influences refer to 3.1.3 Coupling of motors

on page 13.

3.2.3 Coil positioning over the magnet track

Do not construct the coils symmetrically over the magnet track. The

windings are not positioned in the middle of the coil.This would deteriorate

the available force. Please construct according to the specified dimension

in drawing 0 in APPENDIX A in this manual.

The dowel pin holes of the coil unit will exactly line up over the length axis

of the magnet plate when properly constructed, see picture 3.5.

Dowel pin

Magnetplate magnec

and mechanical cen-

terline

3.2.4 Bolts for coil unit

Bolts for coil unit TM TL TB and TBW

Bolts (steel) M4

DIN912

M5

DIN912

M5

DIN912

Depth bolt in thread hole Min: 4 mm

Max: 5 mm

Min 4 mm

Max: 5 mm

Min: 4.5 mm

Max: 6 mm

Tightening torque 2.0 – 3.0 Nm 3.0 – 5.0 Nm

Dowelpins (stainless) 5h8 M3

Table 3.6: Bolts for coil unit

16

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

Positioning holes

Mounting holes

Positioning holes

for Dowelpins

Mounting holes with

inner M5 thread

MOTOR CONFIGURATION

CH 3

Dowelpins for coil unit TM TL TB/TBW

Dowelpins (Stainless) 5h8 M3

Table 3.7: Dowelpins for coil unit

3.2.5 Dowelpins for coil unit

Use only the specified type of flat head fasteners with the correct

length. The coil and magnet plate can be damaged by non flat

head bolts.

Make sure the dowelpins do not extend further than the

specified height. The magnet plate can be damaged by too long

dowelpins.

3.2.6 Magnettrack

For short magnet track length magnet plates can be butted directly

together. For magnet track length over 2000mm or when using the analog

hall module it is advised to use positioning holes with dowelpins.

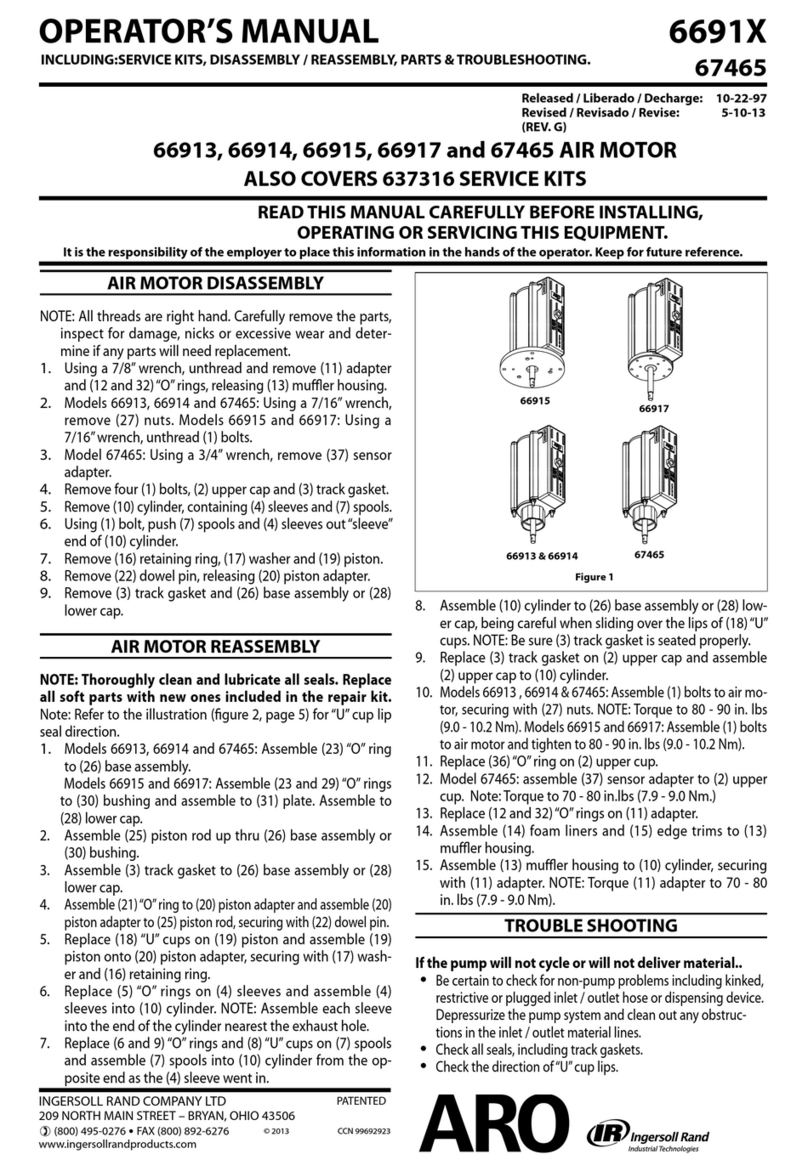

Picture 3.8: Location of the mounting holes, dowel pin and reference marker

The magnet plates have a magnetic north and south pole. They need to be

correctly positioned adjacent to each other. This can be verified in several

ways:

■The dowel pin holes should be on the same side

■The reference marker between the mounting holes on one side of the

magnet plate should all be on the same side

■Adjacent magnet plates should attract and not repel each other

Bolts for magnet plates TM TL TB/TBW

Bolts (steel) M5x10, DIN7984 M5x10, DIN7984 M5x16, DIN912

Depth bolt in thread hole Min: 6.5mm

Tightening torque 2.0 –3.5Nm

Reference marker

Table 3.9: Flathead bolts for magnet plates

3.2.7 Bolts for magnet plates

Dowelpins for magnet plates TM TL TB/TBW

Dowelpins (stainless) 5h8 M3

Table 3.10: Dowelpins for magnet plates

3.2.8 Dowelpins for magnet plates

3.2.9 Water cooling connections

The TL and TBW series come equipped with integrated water cooling

channels. These can be used when water cooling is required to attain a

higher continuous force.

Dowel pin holes

17

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

The use of other connnections may cause higher pressure drops

than indicated due to smaller throughput.

Picture 3.13: TBW water cooling channels form a closed loop within the coil unit. The entrance and

exit holes of the cooling channels are located on the same side of the coil unit.

For the TL series the nipples will extend above the top mounting surface

of the coil, see picture 3.12. The slide needs to accommodate room for this.

Hose

Nipple Coil unit - TL

Slide

Beware of extending

nippels

Picture 3.12: TL nipples extend above mounting surface

TBW water cooling

The watercooling channels for the TBW series form a closed loop within the

coil unit, see picture 3.13. The entrance and exit are located on one side of

the coil unit. Please refer to Table 3.14: recommendations for TL and TBW

water cooling connections. on page 18 for the nipples dimensions.

Picture 3.11: TL water cooling channels run completely through the coil. The cooling circuit needs

to be closed externally by means of a tube.

TL water cooling

The TL series coils come equipped with two channels that run completely

throughthecoilunit,seepicture 3.13.Thecircuitneedstobeclosed externally

by means of a tube. Please refer to Table 3.14: recommendations for TL and

TBW water cooling connections. on page 18 for the nipple dimensions.

18

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

3.3 Watercooling

Tecnotion TL and TBW series iron core motors come equipped with wa-

ter cooling capabilities. The continuous force water cooled specifications

for the TL and TBW series are based on pure water cooling. This chapter

explains how to design your water cooling system with water and other

common coolants.

Further information regarding the location and dimension of the

water cooling connections can be found in chapter 3.2.9 Water cooling

connections on page 16.

Connection of hoses

When fitting the hoses, the connections have to be free of greases and oil.

The two cooling channels of the TL-motor can be connected in series. Both

cooling channels can also be used in parallel configuration. This connecti-

on reduces the pressure drop, but only if cavitation is less ø6mm-ø8mm,

when using Y-joints.

TL-series TBW-series

Hose diameter ø4mm (inner diameter) Ø8mm (outer diameter)

Minimum flow diameter fitting ø2.5mm Ø5mm

Hose examples: Festo PU-4*

Rauclair PVC E 4x1*

flexible

Festo PUN-H-8x1,25*

*Other hoses can also be applied, but the outer diameter should Ø8mm to fit properly on a 1/8”

push and pull fitting.

Table 3.15: Recommended watercooling connections

TL6 TL12 TL15 TL18 TL24 TBW18 TBW30 TBW45

Minimum

Flow (l/min)*

0.7 1.4 1.8 2.2 2.9 3.1 5.2 7.8

Pressure drop

(bar)*

1 2 2 2 3 1 1.5 2.5

*Values are based on pure water coolant and depend on used connections and hose-system.

Table 3.16: Presure drop value per coil type

Nipples TL-series TBW-series

Thread holes 4 times M5 (on both

sides of coilunit)

2 times 1/8”NPT (both on

one side)

Recommended Nipple/Fitting M5 nipple Push-Pull Fitting, -Festo

QS-1/8-8*

Sealings M5 plastic sealings and

Loctite 638/648 glue

Teflon tape

Tightening torque 0,2 - 0,3 Nm 4.0 Nm

* Other 1/8” Push and Pull Fitting can also be applied. The use of smaller hose diameter and /or

nipple diameter can reduce the flow.

Table 3.14: recommendations for TL and TBW water cooling connections.

19

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

3.4 Electrical interface

Be sure your machine as a whole meets the requirements of all

applicable electrical standards, such as the EN 60204 standard.

Cables

Tecnotion linear motor’s electrical wiring is externally configured with two

cables:

■a power cable

■a temperature sensor cable.

Both power cable and temperature sensor cable are shielded with a brai-

ded metal cable shield.

Details about the motor cable configuration can be found in appendix B

on page 52.

The TM series comes equipped with a 3m long power- and temperature

sensor cable suited for use in a power chain. All other motors have a 1m

long non flexible cable.

Cable Type

Series

Length Remark TM TL TB TBW

Power 1m X X X

3m Flex X

Temperature 1m X X X

3m Flex X

For wiring scheme of both cables please see the figure 3.18. If desired you

can shorten these cables and provide them with appropriate connectors.

Servo

amplifier

L1

L3 L2

PTC

KTY

L1

L2

L3

PE

green/

yellow

white

brown

yellow

green

Linear motor

Slide

Power cable

Temperature

sensor cable

Figure 3.18: Wiring scheme for iron core

Not all cables are meant for use within cable chains. Therefore user defin-

ed cables should be used that meet the specifications concerning bending

radius, length, replacebility, velocity, acceleration, etc. The coil’s standard

cables must be connected properly to the user defined cables.

Table 3.17: Cable length per series

20

Iron Core linear motor manual - ver. 1.02. Document nr 4022.363.4190.2

©2015 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

MOTOR CONFIGURATION

CH 3

Power cable

The power cable can be confectioned by the user to fit the servo drive. All

motors require an extra flexible cable between the coil and the servo drive

except for the TM –series.

Powercable Color code TM/TL/TB/TBW Connection to servo controller

3-phases L1 black‘1’ 3-phases

L2 black‘2’

L3 black‘3’

Protective Earth green/yellow Protective Earth

Shield Metal shield Protective Earth

Table 3.19: Power cables wire identification

Protective earth

Internally the motor’s protective earth wire is galvanically connected to the

motor housing. This wire must be connected to the protective earth con-

nector of the servo amplifier.

Provide the motor system with protective earth lines to the amplifier that

are as short as possible.

Provide the magnet track with an effective protective earth connection.

Temperature sensor cable

The coil unit is equipped with two temperature sensors, one PTC-1k-type

for protection and one of the KTY83-122 type for temperature measure-

ment.

Please refer to chapter 3.5 Temperature sensors on page 21 for more

information regarding the sensors. The temperature cable consists of four

wires. For wire color and function, see table 3.19. Refer to Table 3.17: Cable

length per series on page 19 for the length of the temperature sensor

cable.

All motors require an extra flexible temperature sensor cable between the

coil and the servo drive except for the TM-series.

Sensor cable (color) Connection to servo controller

PTC (white) PTC

PTC (brown) PTC

KTY83-122 (green ) KTY83-122

KTY83-122 (yellow) KTY83-122

Shield Protective Earth

Table 3.20: Sensor cable wire identification

This manual suits for next models

15

Table of contents

Other Tecnotion Engine manuals

Popular Engine manuals by other brands

MPI

MPI Himax HC2816 Series manual

Assun

Assun AM-CL1935MAE Series product manual

Robin America

Robin America EH12-2, EH17-2, EH25-2 parts manual

Weston UK

Weston UK WEST EUROTECH 52 V2 instructions

Nice

Nice Era Fit S Instructions and warnings for installation and use

Ingersoll-Rand

Ingersoll-Rand AF0860 Series Operator's manual