Tecnotion UC3 Series User manual

Ironless linear motor manual

2

Ironless linear motor manual - ver. 1.03

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

[ INTRODUCTION ]

A linear motor system is a part of a specific machine. Tecnotion’s Ironless linear motors are components that can be combined

with numerous application devices. This manual is intended for technicians who want to construct a machine that includes a

linear motor system.

It gives insight in the basic components of a Tecnotion ironless linear motor and additional components to complete the whole

motion system. The manual further informs about important design and installation aspects of the linear motors. The settings

required before starting up are discussed.

In the appendix the important dimensions for designing the construction that will hold the linear motor can be found. Finally,

the glossary gives insight in the definition of all specifications of a Tecnotion linear motor.

When installing a linear motor system one should be familiar with some important safety remarks. In the first chapter these

remarks are made. Please, read them carefully.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

3

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

TABLE OF CONTENTS

TOC

TABLE OF CONTENTS

1. [ BEFORE YOU START ] 4

1.2 Safety warnings 4

1.3 Certication 6

1.3.1 CE certication

1.3.2 UL / CSA certication

1.3.3 Restriction of Hazardous Substance (RoHS)

2. [ MOTOR COMPONENTS ] 7

2.1 Basic components 7

2.2 Additional features 8

2.2.1 Bolts and dowel pins

2.2.2 Controller and measurement unit

2.2.3 Tools

3. [ INSTALLATION ] 9

3.1 Cleaning 9

3.2 Cleanroom cleaning 9

3.2.1 Tools

3.2.2 Cleaning instructions

3.3 Installation 11

3.4 Requirements for the mounting surface 12

3.5 Magnet yoke mounting 13

3.6 Coil unit mounting instructions 14

3.7 Electrical connections 14

3.7.1 General remarks

3.7.2 Power lines

3.7.3 Protective earth

3.7.4 Temperature Sensor

3.7.5 Temperature protection

3.7.6 PTC specication

3.7.7 Maximum operating temperature

3.7.8 NTC Characteristic

3.7.9 Polarization test

3.8 Transportation 19

3.9 Storage 19

4. [ OPERATION ] 20

4.1 Pre-commissioning 20

4.2 Conguring 20

4.3 Testing 21

4.3.1 End switches

4.4 Starting up 21

[ APPENDIX ]

APPENDIX A Dimensions - UC 22

APPENDIX B Motor cable conguration 28

APPENDIX C Digital Hall Modules 30

APPENDIX D Vacuum Installation 35

APPENDIX E Declarations 37

APPENDIX F F / v Graphs 38

GLOSSARY 43

4

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

BEFORE YOU START

CH 1

1. [ BEFORE YOU START ]

Please read the following instructions very carefully.

They are important for a safe and warranted installation and operation of

the Linear Motor.

1.1. Important notice

Before installing and using the Linear Motor, read this instruction

manual carefully. The manufacturer declines all responsibility

in case of accident or damage due to negligence or lack of

observance of the instructions described in this manual. The

manufacturer also declines all responsibility in case of accident

or damage in conditions that differ from those indicated in the

manual; Tecnotion also declines all responsibility for damage

caused by improper use of the Linear Motor.

Handle the components of the Linear Motor with care, packed

as well as unpacked. Especially the magnet yokes are sensitive

to mechanical shocks. Never drop a magnet yoke or release it in

an uncontrolled way.

Do not expose the magnets to temperatures higher than 70° C.

The magnets may be demagnetized at higher temperatures.

Unpack the Linear Motor and check its integrity. If there is any

irregularity. If there is any irregularity contact the dealer or

manufacturer, signalling the nature of the defects.

Make a note of the serial number. This facilitates the

correspondence with the supplier.

Safety and information symbols:

The lightbulb describes a‘Tip’.

The exclamation mark is a, non safety related, important notice

that the user should be aware of.

The warning signs inform about safety information that the user

should respect.

1.2 Safety warnings

The Linear Motor is used as a part of a machine. The machine

manufacturer or representative has to take care that the

machine as a whole fulfils all CE requirements.

The magnet yokes show large attraction forces on all soft

magnetic objects such as iron.These forces cannot be controlled

by hand. They may cause serious jamming danger. Do not

bring any soft magnetic objects (iron) nearer than 25cm of the

magnetic side of the magnet yoke.

Magnetic sensitive objects like banking cards, pacemakers or

other magnetic information carriers may be damaged if they are

brought within 1m of the magnet yokes.

5

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

BEFORE YOU START

CH 1

The magnet yoke and coil unit can be damaged when cleaned

with a non-prescribed cleaning agent.

Use only isopropanol as a cleaning agent.

UV Blacklight can cause irreversible damage to the eyes

and other tissue when exposed. When using a UV Blacklight

installation wear appropriate protective clothing and glasses.

The magnet yokes do attract each other while mounting. Take

care that the closing plates of one yoke do not damage the

magnets of the neighbour magnet yoke while mounting.

If at any time and in any situation there is any doubt about

the safety of the Linear Motor, do not use it and contact your

supplier.

The Linear Motor is powered by a servo amplifier. In case of a

power disruption or fatal error this may automatically result in

a free run out of the motor. Make mechanical precautions to

prevent damage on the motor or your machine in the case of

such an event.

Before installing the motor, make sure that the supply mains

are grounded and operate in conformity with the regulations in

force.

Make sure that there is an effective protective earth.

Make sure that there is no voltage at the wire terminals before

connecting.

An earth connection does not work on non-conducting

mounting surfaces like granite. In these cases the protective

earth must be established by an earthing wire

Before carrying out checks or doing any maintenance, clear the

system by disconnecting the voltage. Be sure that there is no

possibility of accidental connections.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

6

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

BEFORE YOU START

CH 1

Series CE UL / CSA RoHS

UC3 Yes No Yes

UC6 Yes No Yes

UF3 Yes No Yes

UF6 Yes No Yes

UM3 Yes No Yes

UM6 Yes No Yes

UM9 Yes No Yes

UM12 Yes No Yes

UMV12 Yes No Yes

UL3 Yes No Yes

UL6 Yes No Yes

UL9 Yes No Yes

ULV9 Yes No Yes

UL12 Yes No Yes

UL15 Yes No Yes

UXA3 Yes No Yes

UXA6 Yes No Yes

UXA9 Yes No Yes

UXA12 Yes No Yes

UXA18 Yes No Yes

UXX3 Yes No Yes

UXX6 Yes No Yes

UXX9 Yes No Yes

UXX12 Yes No Yes

UXX18 Yes No Yes

Table 1.2: Overview of applicable standards per motortype

1.3 Certication

All information about certifications can be found in this chapter. The

declaration of comformity can be found in APPENDIX E.

1.3.1 CE certication

Tecnotion B.V. declares that the UM, UL, UX,UXA and UXX linear motors

mentioned in this Installation manual are manufactured in accordance

with European directive 2006/95/EC and in conformity with the following

standards, see table 1.1.

Tecnotion B.V. declares that the UC and UF linear motors mentioned in

this Installation manual are destined to be incorporated in other machines

or to be combined with other machines, and is not (entirely) in complian-

ce with the Machine Directive (98/37/EC). The UC and UF linear motors are

in conformity with the following standards, see table 1.1.

1.3.2 UL / CSA certication

Tecnotion B.V. Ironless motors currently do not have UL / CSA certification.

Please contact your local Tecnotion representative for more information.

Standard Name of standard

EN 60034-1: 2010 Rotating Electrical Machines,

Part 1: Rating and performance

EN 60204-1: 2010 Safety of machinery - Electrical equipment of machines, Part 1:

General requirements

Table 1.1: Applicable standards

1.3.3 Restriction of Hazardous Substance (RoHS)

Tecnotion B.V. declares to be compliant with the RoHS-guideline. Therefore

Tecnotion ensures that all products are free from lead, cadmium, mercury,

hexavalent chromium, polybrominated biphenyls or probrominated

diphenyl ethers.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

7

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

MOTOR COMPONENTS

CH 2

2. [ MOTOR COMPONENTS ]

An ironless linear motor of Tecnotion is not a system on itself. It contains

several components, such as a coil unit and magnet yokes. The compo-

nents should be build within a total machine concept or a working unit.

The size and the shape of the mounting frame, the design of the slide, the

type bearings or the kind of dampers depend of the required application.

For instance the mounting frame and the slide should be designed in such

a way that a correct air gap between coil unit and magnet yokes will be

obtained.

Tecnotion provides standard and special components which are suitable

for numerous linear motor applications. These components can easily be

applied in your system.

2.1 Basic components

The basic Linear Motor components supplied by Tecnotion are:

■The coil unit (the N and S version differing in voltage and current re-

quirements)

■The magnet yoke (in different lengths, varying in outer dimensions)

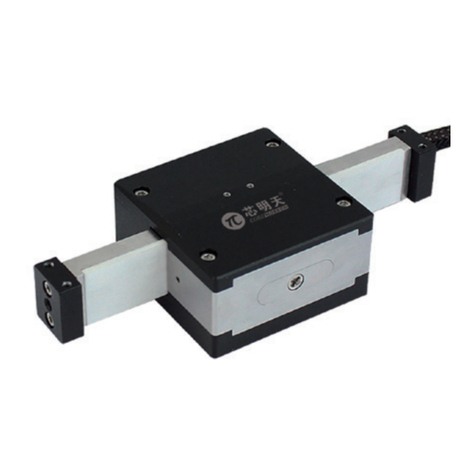

Picture 2.1: A complete ironless linear motor system

Picture 2.2: A coil unit and magnet yoke

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

8

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

MOTOR COMPONENTS

CH 2

2.2 Additional features

For a proper installation of your linear motor system you also need:

■fixing components, like bolts and dowel pins;

■additional devices, like a servo controller and a linear encoder;

■the right tools.

These features are no part of Tecnotion’s standard delivery.

2.2.1 Bolts and dowel pins

The following bolts and dowel pins are required for positioning and fixing

the coil unit to the slide as well as connecting the magnet yokes to the

mounting frame:

Features UM UL UXA UXX

Bolts for coil unit (steel) M3x16,

DIN912

M4x20,

DIN912

M5x20,

DIN912

M5x20,

DIN912

Tightening torque 1.0 - 2.0 Nm 2.0 - 3.0 Nm 3.0 - 5.0 Nm 3.0 - 5.0 Nm

Bolts for magnet yoke

(steel)

M4x25,

DIN912

M5x35,

DIN912

M6x40,

DIN912

M6x50,

DIN912

Dowel pins for magnet

yoke (optional) 3h8, DIN7

Table 2.4: Bolts for coil unit and yoke UC and UF series

Features UC UF

Bolts for coil unit (steel) M3, DIN912, Class 12.9 M3, DIN912, Class 12.9

Tightening torque 1.0 - 2.0 Nm 1.0 - 2.0 Nm

Dept bolt in threat hole Top: through coil unit

Side: 1.5 - 2.8mm

Top: through coil unit

Side: 1.5 - 2.8mm

Bolts for magnet yoke (steel) M4x20, DIN912 M4x25, DIN912

Dowel pins for magnet yoke

(optional) 3h8, DIN7

Table 2.3: Bolts for coil unit and yoke UM,UL,UXA and UXX series

2.2.2 Controller and measurement unit

Required is:

■An appropriate servo controller/amplifier

■A ruler and a linear encoder or an Hall module

■Power supply, cabling and connectors

For more information please contact Tecnotion.

2.2.3 Tools

Necessary for the installation is:

■Allen Key set

Occasionally useful are:

■Heat sink compound (optional)

■Isopropanolwipes to clean mounting surfaces

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

9

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

3. [ INSTALLATION ]

3.1 Cleaning

The magnet yokes show large attraction forces on all soft

magnetic objects such as iron. These forces cannot be controlled

by hand. They may cause serious jamming danger.

Do not bring any soft magnetic objects (iron) nearer than 1m of

the magnetic side of the magnet yoke.

Magnetic sensitive objects like banking cards, pacemakers or

other magnetic information carriers may be damaged if they are

brought within 25cm of the magnet yokes.

The magnet yoke and coil unit can be damaged when cleaned

with a non-prescribed cleaning agent.

Use only Isopropanol as a cleaning agent.

For general, non-cleanroom applications, the magnet yokes and coil units

do not need to be cleaned intensively.

For cleaning purposes Tecnotions prescribes Isopropanol as cleaning agent

for the magnet yoke and coil.

3.2 Cleanroom cleaning

For cleanroom applications Tecnotion products need to be cleaned additi-

onally to remove dust particles.

3.2.1 Tools

■Isopropanol cleaning wipes

■Filtered pressed air installation

■Blacklight installation

■UV Glasses

■Cleanroom compatible vacuum cleaner

■Cotton swap

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

10

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

3.2.2 Cleaning instructions

Only the cleaning of the yokes is described. The same method can be used

to clean the coils and the cables.

Initial cleaning

1. Clean the workstation with Isopropanol cleaning wipes (IPA).

Make sure the workstation is clean.

2. Blow filtered pressed air in to the gap between each pair of

magnets.

3. Blow filtered pressed air in to the side of the yoke. Repeat for

the other side.

7. Clean the yoke with a cleanroom compatible vacuum cleaner.

8. Repeat the process for the other side of the yoke.

9. Clean all sides of the magnet yoke with IPA cleaning wipes.

Only move the IPA cleaning wipe in one direction, do not move back and

forward. This will enhance the cleaning action.

10. Clean the inside of the magnet yoke with an IPA cleaning wipe

and a cotton swab.

Verication of cleaning

11. Inspect the magnet yoke with the blacklight installation for

remaining dust particles.

Especially check the areas between the magnets and the gab between the

magnets and the bottom of the yoke.

12. Ifdustparticlesarevisible:RemovethemwithanIPAcleaning wipe

andcottonswabuntilthesurface is cleaned toanacceptablelevel.

UV Blacklight can cause irreversible damage to the eyes and other

tissue when exposed. When using a UV Blacklight installation

wear appropriate protective clothing and glasses.

Verication of surface pollution

4. Inspect the yoke with the blacklight installation for dust particles.

Intensive cleaning

5. Clean the workstation with IPA cleaning wipes.

6. Place the magnet yoke on the cleaned workstation.

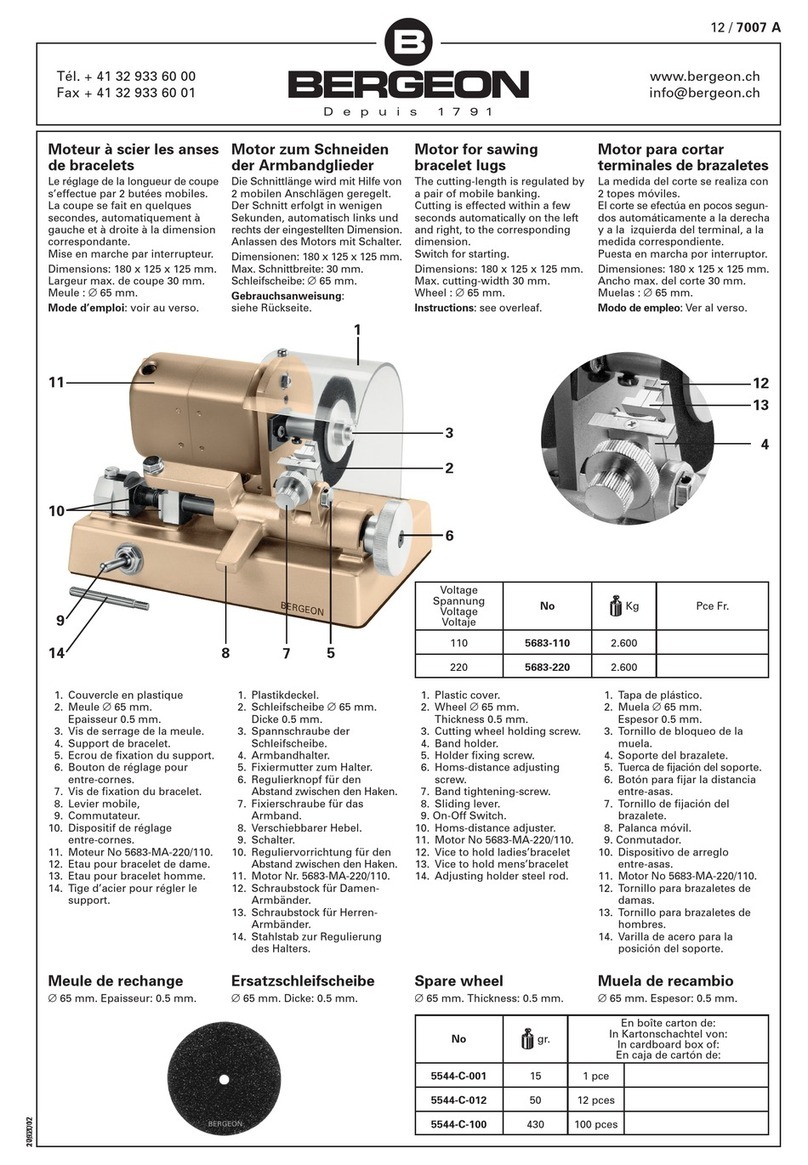

step 1/5 step 2 step 3 step 4/11 step 7/8 step 9

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

11

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

Picture 3.1: A ironless linear motor system

Picture 3.2: Coil unit, slide, magnet yoke and mounting surface

3.3 Installation

Vacuum installation

For installation of vacuum motors special instructions are required, these

instructions can be found in the vacuum appendix.

Before installing the Linear Motor components, the installation of the

mounting frame should be completed. The slide should be provided with

bearings, dampers, linear probe and required cabling in such a way that

a smooth, save and well positioned transport of the slide over the stroke

is established. The ruler should be properly positioned and fixed to the

frame. The operation of bearings and dampers should be tested as well as

the guidance of the moving cables.

The correct installation order is for electrical safety reasons:

1. Mount the magnet yokes to the mounting surface of the machine.

2. Mount the coil unit to the involved machine parts

3. Connect the wiring to the coil unit.

From a magnetic point of view the installation order of the mechanics is

not critical, because no attraction is present between the coil unit and

magnet yokes.

The de-installation order is:

1. Disconnect the wiring from the coil unit.

2. Dismount the coil unit from the machine parts.

3. Dismountthemagnetyokesfrom the machine’smounting surface

Before mounting the Linear Motor, special attention must be paid tot the

mounting surface of the motor.

Before starting the installation, check the presence of the right

number and type of the delivered components. In case of doubt,

please contact Tecnotion immediately.

Magnet

H

Yoke

Coil unit

Mounting surface for magnet track

Slide

Bearing

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

12

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

3.4 Requirements for the mounting surface

Picture 3.3: Flatness and parallelism of mounting surfaces

The mounting surfaces of both magnet yokes and coil units have to be flat

to prevent them from being submitted to bending forces (see picture 3.3

and table 3.5).

Type Coil unit flatness Parallelism H Seperation of mounting faces

R (mm) S (mm) (mm) V (mm)

UC 0.02 0.02 51 0.375 +/- 0.05

UF 0.05 0.02 53 0.625 +/- 0.05

UM 0.05 0.05 68 5.5 +/- 0.1

UMX 0.05 0.05 68 6.5 +/- 0.1

UL 0.1 0.05 105 8.2 +/- 0.1

ULX 0.1 0.05 105 12.0 +/- 0.1

UXA 0.1 0.05 124.8 11.5 +/- 0.1

UXX 0.1 0.05 124.8 16.5 +/- 0.1

Table 3.5: Installation tolerances U-series

The track of the magnet yokes – from now on to be called the magnet track

– and the coil unit have to be aligned with respect to each other. Note that

this has to be accomplished by the machine’s construction.

Picture 3.6: Air gaps and axial references, schematically

Axial reference for the magnet track (MR, see picture 3.6) can be obtained

by the use of:

■Dowel pins in the middle yoke of a short track

■Dowel pins along the complete side of a long track

■Milled reference along complete side of a long track (inner radius <

0.2mm), or

■Alignment by hand during mounting

Axial reference for the coil unit (CR, see picture 3.6) is obtained by:

■Two dowel pins beside the first and last bolt of the coil unit

■Milled reference along complete side (inner radius < 0.2mm), or

■Alignment by hand during mounting

V

// | S

// | S

R

Only use the aluminium side of the UC and UF series

housing as mounting surface (see picture 3.4). The

epoxy/power cable side is not suited for alignment.

Picture 3.4: UC-UF coil

A1

A2

MR

CR

H

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

13

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

Note that only when the right references and dimensions as listed in table

3.5 are applied the right dimensioned air gaps (A1 and A2, see picture 3.6)

will be obtained.The dimensions of the coil units and magnet yokes can be

found in APPENDIX A.

3.5 Magnet yoke mounting

Especially the magnet yokes must be handled with care. They are

sensitive to mechanical shocks. Never drop a magnet yoke or

release it in an uncontrolled way!

Be sure that the mounting surfaces are free of contamination.

Particles > 0.1mm can cause inaccurate placement and

consequently damage to your Linear Motor.

The magnet yokes contain a strong magnetic field. Lose iron

objects that are brought within 5cm of the yokes, can be drawn

into the yokes and cause damage.

Magnetic sensitive objects like banking cards or other magnetic

information carriers may be damaged if they are brought within

1m of the magnet yokes.

The magnet yokes do attract each other while mounting. Take

care that the closing plates of one yoke do not damage the

magnets of the neighbour magnet yoke while mounting.

It is recommended to start the mounting of the magnet track with the

middle – and preferably the longest – magnet yoke. This middle yoke can

be aligned using the 3mm dowel pins or a milled reference.

Fix the magnet yoke on the mounting surface with bolts using the

prescripted tightening torque.

The following yokes can be mounted with mechanical contact using the

mutual attraction force of the magnet yokes.

Take care: apply the principle of controlled rotational mounting.

A straight forward directing and placing of the yokes implies the

risk of striking due to magnetic forces. Uncontrolled approach

may cause damage to the magnets (see picture 3.7)

Picture 3.7: Principle of controlled rotational mounting of the magnet yokes

The next magnet yokes should not be aligned on dowel pins. Using a track

of pins has two disadvantages:

1. In that situation rotational mounting is difficult.

2. Mounting can be impossible because of tolerances. The yokes are

designed for a contact mounting without guaranteed gap

between them.

Using a milled axial reference is advised for placement of the next tracks.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

14

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

Placement of just one yoke on each side of the middle yoke can be done by

simply aligning the yokes with respect to each other.

There is no danger of mounting the magnet yokes with an incorrect orien-

tation, the standard yokes are“Murphy-safe”. A 180° rotated yoke does not

have any effect on the motor function.

3.6 Coil unit mounting instructions

Be sure that the mounting surfaces are free of contamination.

Particles > 0.1mm can cause inaccurate placement and

consequently damage to your Linear Motor.

The mounting of the coil unit on appropriate and clean mounting surfaces is

very straightforward because no attraction forces are present between coil

unit and magnet yokes. Please review chapter 3.1 Cleaning on page 9.

The coil unit can be placed into the machine by hand carefully, pushed to

the axial reference and fixed with bolts. Tightening torque of the bolts as

prescribed in chapter 2.1 Basic components on page 7.

For applications which are susceptible to vibrations, the bolts

have to be secured against loosening by means of rings or

(Loctite) thread lock.

In case of high continous forces, apply a heatsink compound to

obtain optimal thermal contact between the coil unit and the

mounting surface.

3.7 Electrical connections

Before starting any activity on the wiring, make sure that the

mainsaredisconnected.Workcarefullyaccordingtheinstructions

belonging to the applied servo controller. Be sure your machine

as a whole meets the requirements of all applicable electrical

standards, such as the EN 60204 standard.

3.7.1 General remarks

The linear motor’s electrical wiring is externally configured with two 1.0

meter cables: a power cable and a temperature cable. If desired you can

shorten these cables and provide them with appropriate connectors.

The UXA/UXX3S is delivered with a FLEX cable of 3m. Suitable for cable chains.

Both power cable and temperature cable are shielded with a braided

metal cable shield for electromagnetic immunity. The shield is galvanically

connected inside the coil unit housing.

Besides this manual you should follow carefully the installation instructions

of your servo amplifier supplier. Make sure that the linear motor system as a

whole meets all the applicable electrical directives.

For wiring scheme of the UM, UL,UXA and UXX series see figure 3.8.

The wiring scheme of the UF type is shown in figure 3.9.

The wiring scheme of the UC type is shown in figure 3.10.

The UC coil is supplied with a five wire cable. The green and the yellow wire

do not have a function.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

15

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

Servo

amplifier

L1

L3 L2

PTC

NTC

L1

L2

L3

PE

green

Shielded cable

white

brown

yellow

green

Linear motor

Slide

Servo

amplifier

L1

L3 L2

NTC

L1

L2

L3

yellow

green

Linear motor

Slide

Shielded cable

Picture 3.8: Wiring scheme UM, UL, UXA and UXX series ironless

Picture 3.9: Wiring scheme UF series ironless

Servo

amplifier

L1

L3 L2

L1

L2

L3

yellow

green

Linear motor

Slide

Shielded cable

Picture 3.10: Wiring scheme UC series ironless, green and yellow wires are unused

3.7.2 Power lines

The three phases of the motor’s power cable have to be connected to

the servo amplifier in such a way that the positive three phase direction

of the motor conforms the positive direction of the linear encoder. This

polarization has to be tested, it cannot be seen at first sight.

Testing the polarization is very important, because a wrong

polarization will result in an uncontrolled run out of the slide.

The power cable can be confectioned by the user to fit on the servo drive.

The power cables are not suited for use in cable chains.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

16

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

Powercable Color code Connection to servo controller

3-phases L1 black 3-phases

L2 red

L3 white

Protective Earth green/yellow Protective Earth

Shield (Protective) Earth

Table 3.11: Powercables wire identification

3.7.3 Protective earth

Be sure that the earth shield of the cable is well connected – also through

the connecting devices – to the PE connector or the housing of the ampli-

fier. Most linear motors are driven on the principle of pulse width modula-

tion. This involves large electrical impulses and causes a significant risk of

electromagnetical interference.

Internally the motor’s PE wire (green/yellow) is galvanic connected to the

motor housing. This wire must be connected to the PE connector of the

servo amplifier. Provide the motor system with PE lines to the amplifier that

are as short as possible.

3.7.4 Temperature Sensor

The coil unit of the UM,UL,UXA and UXX Linear Motors come equipped

with two temperature sensors, one PTC-1k-type and one NTC-sensor. The

UF series has only a NTC-sensor. The UC series has no temperature sensors.

For more details about both sensor see the next three paragraphs.

The temperature cable consists of four wires. For wire color and function,

see table 3.12.

Sensor cable (color) Connection to servo controller

PTC (white) PTC

PTC (brown) PTC

NTC (green ) NTC

NTC (yellow) NTC

Shield Protective Earth

Table 3.12: Sensor cable wire identification

3.7.5 Temperature protection

The temperature sensors are normally used for overheating protection of

the coil unit. The NTC-sensor can be used for monitoring temperature, the

PTC can be used as cut off sensor when the maximal temperature is ex-

ceeded. For specifications and characteristics see the next two paragraphs.

In cases where long peak currents are demanded, the thermal response

time of the coil unit is too long to ensure a proper overheating protection

by the sensors.The temperature sensors can ensure a proper protection up

to an Irms of 25% of the peak current of the motor. This corresponds to a

temperature increase of 4,5°C/s.

These long peak current conditions can occur for example during an acci-

dental run or by taking a new axis in control.

In this case I²t protection is essential to prevent the coil unit from overhe-

ating. In almost all controllers an I²t-protention can be set in the software.

For more information contact Tecnotion’s Application support team.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

17

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

3.7.6 PTC specification

The PTC-1k type is a sensor which has a very sudden resistance rise near the

critical temperature of the coils. It is almost a digital indicator: temperature

below vs. over critical temperature.Therefore it is very useful for signalizing

over temperature without requiring sensitive electronics. Disadvantage is

that it is not possible to obtain a temperate signal.

At room temperature the PTC has an electrical resistance <100 .When the

temperature raises to the critical temperature the resistance will increase

rather uniformly up to 1000 . Above this temperature the resistance in-

creases exponentially. Now, 1000 is the switching resistance. The ampli-

fier should immediately stop the power supply when this resistance is ex-

ceeded. In this way overheating and motor damage can be prevented. No

need to say that the PTC cable must be connected properly to the amplifier.

Temperature Resistance

Up to 20°C below critical temperature < 250

Up to 5°C below critical temperature < 550

Nominal switching resistance 1000

Above critical temperature > 1330

Table 3.13: Resistance range of the PTC-1K sensor

3.7.7 Maximum operating temperature

Series Maximum operating temperature

UC 80C

UF, UM, UL, UXA, UXX 110C

T (°C)

R (Ω)

10 30 50 70 90 110 130 150 180

101

102

103

104

105

106

107

Graph 3.14: Temperature dependence of the PTC-1k sensor. The sensor follows the 110°C

characteristic

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

18

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

3.7.8 NTC Characteristic

The Coil has a NTC temperature sensor for monitoring the temperature.

Graph 3.15: Temperature dependency of the NTC

0050 100 150

Rntc

°C

Ω

T

R

10000

2000020000

30000

Sensor specification of NTC-sensor

Tolerance RR / RR5%

Max power 60mW

Table 3.16: Scheme for obtaining a linear voltage signal from the NTC-sensor

T (ºC) 010 20 30 40 50 60

RNTC () 32650 19900 12490 8057 5327 3603 2488

T (ºC) 70 80 90 100 110 120 130

RNTC () 1752 1258 918 680 511 389 301

3.7.9 Polarization test

Before testing, make sure that the electrical and mechanical

protection of the linear motor system is well configured!

Make sure that there is an effective protective earth. Make sure

that there is no voltage at the wire terminals before connecting.

There is one regular way of testing the polarization. Some servo amplifiers

can operate in an in moment service mode. By means of regulating an ex-

ternal resolver manually, it can be determined whether the motor’s direc-

tion of running conforms the resolver’s sense of rotation. If so, the motor

is well connected. If not, two phases of the power cable – phase 1 and 3

– must be changed.

Internally all ironless linear motors are equally wired and connected, so one

test satisfies to find out the polarization of a motor ruler combination. If

more axes are constructed in exactly the same way the polarization will be

equal.

For more information, please contact Tecnotion.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

19

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

INSTALLATION

CH 3

3.8 Transportation

For transport, additional transport packacking is neccesary.

3.9 Storage

The Storage area for linear motor components needs to be clearly

delimited with a warning sign: “Caution! Powerful magnets”

To ensure the product quality Tecnotion advises the folowing storage

conditions:

Only store motors and magnetyokes in their original packaging.

Stacking height 4 cartons

Storage temperature -25°C to +55°C and a maximum rate of change of 20oC/hour

Storage humidity 5 to 95%, relative humidity with no condensation

Storage duration No limitation.

©2016 Tecnotion BV - All rights reserved - The contents of this document are subject to change without prior notice.

20

Tecnotion | www.tecnotion.com | [email protected]

Ironless linear motor manual - ver. 1.03

OPERATION

CH 4

4. [ OPERATION ]

4.1 Pre-commissioning

When you are convinced that your application’s linear motor system is

assembled in a proper way, both mechanically and electrically, you can

proceed to the next step. You can put your motor system into operation.

But before powering the system, please do have a final check:

1. Does the slide have a free run over the whole

magnet track, without touching small mechanical

parts like bolts or contamination?

2. Are the mechanical end stops, end switches and

the dampers well dimensioned and properly

configured?

3. Does your system have an emergency stop?

4. When used, is the temperature cable properly

connected?

5. Does the motor ruler combination have the right

polarization?

6. Has the power cable been connected properly?

7. Does the physical earth has been connected properly?

4.2 Conguring

After the amplifier is powered up some input and output signals need to

be examined.

1. Check the end switches by pushing the slide manually to the

switch position. Simultaneously check whether the signal is

detected by the amplifier.

2. Check the presence of the PTC signal.

3. The following motor items should be configured as parameter

settings of the servo amplifier:

■Maximum continuous current.

■Maximum peak current.

■Amount of coils.

■Maximum speed.

■Presence/absence of an electromechanical motor brake.

■Magnet interval (North-South distance) and/or pole pitch

(North-North distance).

■Switching resistance of PTC.

4. The following settings for the ruler system should be configured

as parameters of the servo amplifier:

■Type of interface of the ruler system.

■Resolution or period of the linear encoder.

5. These are the I/O parameters to be configured:

■Settings of the available digital inputs and outputs. For instance,

■pay attention to the type of end switches.

■Settings of the available analog inputs and outputs.

6. Finally the controlling parameters must be configured.

■Current control settings. These settings depend on both motor

and amplifier.

■Speed control settings.

■Position control settings.

This manual suits for next models

24

Table of contents

Other Tecnotion Engine manuals