Tecnotion UC Series Instruction Manual

TECNOTION B.V.

PO BOX 23

7600 AA ALMELO

THE NETHERLANDS

Document nr. 4022.363.4197.1

Version 2.1

Issue Date: February 2005

Installing

Tecnotion Ironless Linear

Motors

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 1CONTENTS

Contents

Co Contents

Installing Tecnotion Ironless Linear Motors

Contents...................................................................................................................................................1

Introduction ..............................................................................................................................................2

1. Before you start ...............................................................................................................................3

1.1. Important notice....................................................................................................................3

1.2. Safety warnings ....................................................................................................................4

1.3. EC declaration ......................................................................................................................5

2. Components ....................................................................................................................................6

2.1. Basic components................................................................................................................7

2.2. Additional Features ..............................................................................................................8

2.2.1. Bolts and dowel pins........................................................................................................9

2.2.2. Controller and measurement unit ...................................................................................9

2.2.3. Tools...............................................................................................................................10

3. Installation ......................................................................................................................................11

3.1. Installation order .................................................................................................................12

3.2. Requirements for the mounting surfaces..........................................................................13

3.3. Magnet track mounting instructions...................................................................................15

3.4. Coil unit mounting instructions...........................................................................................17

3.5. Electrical Connections........................................................................................................18

3.5.1. General remarks............................................................................................................18

3.5.2. Power lines.....................................................................................................................20

3.5.3. Protective earth..............................................................................................................20

3.5.4. Temperature Sensor .....................................................................................................21

3.5.5. PTC specification...........................................................................................................21

3.5.6. KTY specification ...........................................................................................................22

3.5.7. Polarization test .............................................................................................................23

4. Operation .......................................................................................................................................24

4.1. General ...............................................................................................................................24

4.2. Configuring..........................................................................................................................25

4.3. Testing ................................................................................................................................26

4.3.1. End switches..................................................................................................................26

4.4. Starting up...........................................................................................................................27

4.5. Optimization of control settings..........................................................................................27

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 2INTRODUCTION

Intro

IIntroduction

Generally a linear motor system is a part of a specific machine.

Tecnotion’s linear motors can be combined with numerous application

devices. This installation manual is intended for those technicians who

construct a machine that includes a linear motor system

When installing a linear motor system one should be familiar with some

important safety remarks. In the first chapter these remarks are made.

Please, read them carefully.

Besides mounting the coil unit and the magnet plates, the installation

includes the electrical wiring and the connections between the motor

and the servo-controller.

Before starting up, some required settings will be discussed. Finally

your linear motor can take off for it’s first ride.

For further information and support, please contact:

TECNOTION B.V. Telephone: +31(0)546 536 300

PO Box 23 Fax: +31(0)546 536 310

7600 AA Almelo sales@tecnotion.com

The Netherlands www.tecnotion.com

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 3BEFORE YOU START

Chapter

Ch 1. Before you start

Please read the following instructions very carefully. They are important

for a safe and warranted installation and operation of the Linear Motor.

1.1. Important notice

Before installing and using the Linear Motor, read this

instruction manual carefully. The manufacturer declines all

responsibility in case of accident or damage due to

negligence or lack of observance of the instructions

described in this manual. The manufacturer also declines all

responsibility in case of accident or damage in conditions

that differ from those indicated in the manual; Tecnotion also

declines all responsibility for damage caused by improper

use of the Linear Motor.

Handle the components of the Linear Motor with care,

packed as well as unpacked. Especially the magnet yokes

are sensitive to mechanical shocks. Never drop a magnet

yoke or release it in an uncontrolled way.

Do not expose the magnets to temperatures higher than

70° C. The magnets may be demagnetized at higher

temperatures.

Unpack the Linear Motor and check its integrity. If there is

any irregularity, contact the dealer or manufacturer,

signalling the nature of the defects.

Make a note of the serial number. This facilitates the

correspondence with the supplier.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 4BEFORE YOU START

1.2. Safety warnings

The Linear Motor is used as a part of a machine. The user

has to take care that the machine as a whole fulfils all CE

requirements.

The magnet yokes contain a strong magnetic field. Lose iron

objects that are brought within 5cm of the yokes, can be

drawn into the yokes and cause damage.

The magnet yokes do attract each other while mounting.

Take care that the closing plates of one yoke do not damage

the magnets of the neighbour magnet yoke while mounting.

If at any time and in any situation there is any doubt about

the safety of the Linear Motor, do not use it and contact your

supplier.

The Linear Motor is powered by a servo amplifier. In case of

a power disruption or fatal error this may automatically result

in a free run out of the motor. Make mechanical precautions

to prevent damage on the motor or your machine in the case

of such an event.

Before installing the motor, make sure that the supply mains

are grounded and operate in conformity with the regulations

in force.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 5BEFORE YOU START

Make sure that there is an effective protective earth. Make

sure that there is no voltage at the line wire terminals before

connecting.

An earth connection does not work on non-conducting

mounting surfaces like granite. In these cases the protective

earth must be established by an earthing wire

Before carrying out checks or doing any maintenance, clear

the system by disconnecting the voltage. Be sure that there

is no possibility of accidental connections.

1.3. EC declaration

Tecnotion B.V. declares that the all linear motors produced by

Tecnotion are manufactured in accordance with the applicable

European directives and in conformity with the following standards:

Standard # Date of issue Name of Standard

EN 60034 05-1998 Rotating electrical machines

EN 60204 (-1) 02-1995 Safety of machinery

EN 50081-2 08-1993 Emission requirements for products in an

industrial environment

EN 50082-2 03-1995 Immunity requirements for products in an

industrial environment

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 6COMPONENTS

Chapter

Ch 2. Components

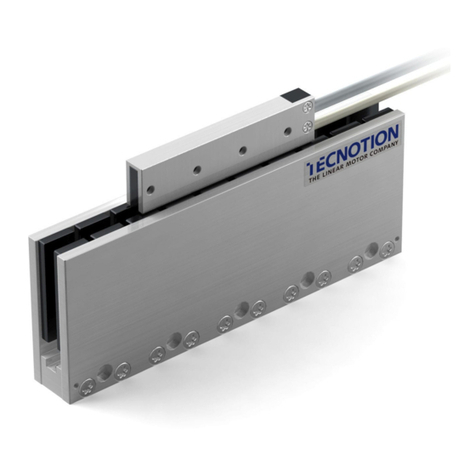

Figure 1: A complete ironless linear motor system

An ironless linear motor of Tecnotion is not a system on itself. It

contains several components, such as a coil unit and magnet yokes.

The components should be build within a total machine concept or a

working unit. The size and the shape of the mounting frame, the design

of the slide, the type bearings or the kind of dampers depend of the

required application. For instance the mounting frame and the slide

should be designed in such a way that a correct air gap between coil

unit and magnet yokes will be obtained.

Tecnotion provides standard and special components which are

suitable for numerous linear motor applications. These components

can easily be applied in your system.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 7COMPONENTS

2.1. Basic components

The basic Linear Motor components supplied by Tecnotion are:

•The coil unit (the N and S version differing in voltage and current

requirements)

Figure 2: Coil unit

•The magnet yoke (in different lengths, varying in outer dimensions

and mounting)

Figure 3: Magnet yoke

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 8COMPONENTS

Before starting the installation, check the presence of the

right number and type of the delivered components. In case

of doubt, please contact Tecnotion immediately.

2.2. Additional Features

For a proper installation of your linear motor system you also need

•fixing components, like bolts and pins;

•additional devices, like a servo controller and a linear encoder;

•the right tools.

These features are no part of Tecnotion’s standard delivery. If desired

Tecnotion can supply all additional components as well as some types

of devices.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 9COMPONENTS

2.2.1. Bolts and dowel pins

Figure 4: Dowel pins

The following bolts and dowel pins are required for positioning and

fixing the coil unit to the slide as well as connecting the magnet yokes

to the mounting frame:

Features UC UM UL UX

Bolts for coil unit (steel) M3,

DIN912

M3x16,

DIN912

M4x20,

DIN912

M5x20,

DIN912

Bolts for magnet yoke

(steel)

M4x20,

DIN7984

M4x25,

DIN912

M5x35,

DIN912

M6x40,

DIN912

Dowel pins for magnet

yoke (optional)

3h8,

DIN7

2.2.2. Controller and measurement unit

Required is:

•An appropriate servo controller/amplifier

•A ruler and a linear encoder or an analogue Hall module

•Power supply, cabling and connectors

For more information please contact Tecnotion.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 10 COMPONENTS

2.2.3. Tools

Necessary for the installation is:

•Allen Key set

Occasionally useful are:

•Heat sink compound (optional)

•Wipes to clean mounting surfaces

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 11 INSTALLATION

Chapter

Ch 3. Installation

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 12 INSTALLATION

3.1. Installation order

Figure 5: Ironless linear motor system

Yoke

Magnet

Coil unit

Slid e

Mounting surface

for magnet track

Figure 6: Coil unit, slide, magnet yoke and mounting surface, schematically

The installation order of this instruction manual must be

followed. A different order may cause damage to your

machine.

Before installing the Linear Motor components, the installation of the

mounting frame should be completed. The slide should be provided

with bearings, dampers, linear probe and required cabling in such a

way that a smooth, save and well positioned transport of the slide over

the stroke is established. The ruler should be properly positioned and

fixed to the frame. The operation of bearings and dampers should be

tested as well as the guidance of the moving cables.

The correct installation order is for electrical safety reasons:

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 13 INSTALLATION

1. Mount the magnet yokes to the mounting surface of the machine.

2. Mount the coil unit to the involved machine parts

3. Connect the wiring to the coil unit.

From a magnetical point of view the installation order of the mechanics

is not critical, because no attraction is present between the coil unit and

magnet yokes.

The de-installation order is:

1. Disconnect the wiring from the coil unit.

2. Dismount the coil unit from the machine parts.

3. Dismount the magnet yokes from the machine’s mounting surface

Before mounting the Linear Motor, special attention must be paid tot

the mounting surface of the motor.

3.2. Requirements for the mounting surfaces

A

0.1

0.05 A(p a p e rp la ne o nly)

Figure 7: Flatness and parallelism of mounting surfaces, schematically

The mounting surfaces of both magnet yokes and coil units have to be

flat to prevent them from being submitted to bending forces.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 14 INSTALLATION

Specifications:

•Surface for coil unit having a flatness better then 0.1mm.

•Surface for the track of magnet yokes having a flatness better than

0.1mm.

The track of the magnet yokes – from now on to be called the magnet

track – and the coil unit have to be aligned with respect to each other.

Note that this has to be accomplished by the machine’s construction.

To guarantee a non-contact running, the mounting surfaces of coil unit

and the magnet track must be parallel:

•Parallelism of both surfaces better then 0.05mm in the plane

perpendicular to the travelling direction.

To prevent disturbance forces, the axial direction of both components

should be parallel. This has to be accomplished by supporting axial

references for both the coil unit and the magnet yokes.

•axial references for both coil unit and magnet track with parallelism

better than 0.2mm.

A1

MR

CR

A2

Figure 8: Air gaps and axial references, schematically

Axial reference for the magnet track (MR, see figure above) can be

obtained by the use of

•dowel pins in the middle yoke of a short track,

•dowel pins along the complete side of a long track,

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 15 INSTALLATION

•milled reference along complete side of a long track (inner radius <

0.2mm), or

•alignment by hand during mounting.

Axial reference for the coil unit (CR) is obtained by

•two dowel pins beside the first and last bolt of the coil unit,

•milled reference along complete side (inner radius < 0.2mm), or

•alignment by hand during mounting.

Note that only when the right references and dimensions are applied

the right dimensioned air gaps (A1 and A2) will be obtained. The

dimensions of the coil units and magnet yokes can be found on the

internet site of Tecnotion: www.tecnotion.com.

3.3. Magnet track mounting instructions

Especially the magnet yokes must be handled with care.

They are sensitive to mechanical shocks. Never drop a

magnet yoke or release it in an uncontrolled way!

Be sure that the mounting surfaces are free of

contamination. Particles > 0.1mm can cause inaccurate

placement and consequently damage to your Linear Motor.

It is recommended to start the mounting of the magnet track with the

middle – and preferably the longest – magnet yoke. This middle yoke

can be aligned using the 3mm dowel pins or a milled reference.

Fix the magnet yoke on the mounting surface with bolts using the

prescripted tightening torque.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 16 INSTALLATION

The following yokes can be mounted with mechanical contact using the

mutual attraction force of the magnet yokes.

Take care: apply the principle of controlled rotational

mounting. Uncontrolled approach may cause damage to the

magnets (see Figure 9).

Because a straight forward directing and placing of the yokes implies

the risk of striking due to magnetical forces (as well as the risk of

damaged magnets), the principle of rotational mounting is

recommended here.

Yoke 1

Y

oke3

Y

oke 2

Figure 9: Principle of controlled rotational mounting of the magnet yokes

The next magnet yokes should not be aligned on dowel pins. Using a

track of pins has namely two disadvantages:

1. In that situation rotational mounting is difficult.

2. Mounting can be impossible because of tolerances. The yokes are

designed for a contact mounting without guaranteed gap between

them.

Using a milled axial reference is advised for placement of the next

tracks (longer than 200mm).

Placement of just one yoke on each side of the middle yoke can be

done by simply aligning the yokes with respect to each other.

There is no danger of mounting the magnet yokes with an incorrect

orientation, they are “Murphy-safe”. A 180° rotated yoke does not have

any effect on the motor function.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 17 INSTALLATION

3.4. Coil unit mounting instructions

Be sure that the mounting surfaces are free of

contamination. Particles > 0.1mm can cause inaccurate

placement and consequently damage to your Linear Motor.

The mounting of the coil unit on appropriate and clean mounting

surfaces is very straightforward because no attraction forces are

present between coil unit and magnet yokes.

The coil unit can be placed into the machine by hand carefully, pushed

to the axial reference and fixed with bolts. Tightening torque of the bolts

as prescipted.

For applications which are susceptible to vibrations, the

bolts have to be secured against loosening by means of

rings or (Loctite) thread lock.

In case of high continous forces, apply a heatsink compound

to obtain optimal thermal contact between the coil unit and

the mounting surface.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 18 INSTALLATION

3.5. Electrical Connections

Before starting any activity on the wiring, make sure that the

mains are disconnected. Work carefully according the

instructions belonging to the applied servo controller. Be

sure your machine meets the requirements of the EN 60204

standard.

3.5.1. General remarks

The linear motor’s electrical wiring is externally configured with two 1.0

meter cables: a power cable and a temperature cable. If desired you

can shorten these cables and provide them with appropriate

connectors.

Note that the UM, UL and UX cables are not meant for use

within cable chains. For that purpose user defined cables

should be used which meet the specifications concerning

bending radius, length, replacebility, etcetera. Take care of

connecting the motor’s standard cables properly to the user

defined cables.

Only the UC power cable is suited for use within a cable chain.

Both power cable and temperature cable (except UC) are shielded with

a plaited metal cable sheath for electromagnetic immunity.

Besides this manual you should follow carefully the installation

instructions of your servo amplifier supplier. Make sure that the linear

motor system as a whole meets all the applicable electrical directives.

TECNOTION INSTALLING IRONLESS LINEAR MOTORS

DOCUMENT NR 4022.363.4197.1 19 INSTALLATION

For wiring scheme see figure below.

L1

L1

L2

L2

L3

L3

gr/ye

white

brown

ye

green

PE

Line a r

motor

Slid e

PTC

KTY

Se r v o

amplifier

Figure 10: Wiring scheme UM, UL and UX series ironless

L1

L1

L2

L2

L3

L3

gr/ye

PE

Linear

motor

Slid e

Se r v o

am plifier

Figure 11: Wiring scheme UC series ironless

This manual suits for next models

3

Table of contents

Other Tecnotion Engine manuals

Popular Engine manuals by other brands

Hyundai Seasall

Hyundai Seasall U125S Installation & operation manual

Packard

Packard 320725-753 installation instructions

Motolux

Motolux 802311012 Programming instructions

Kubota

Kubota V3600-E3 Operator's manual

PTM Engines

PTM Engines 120F owner's manual

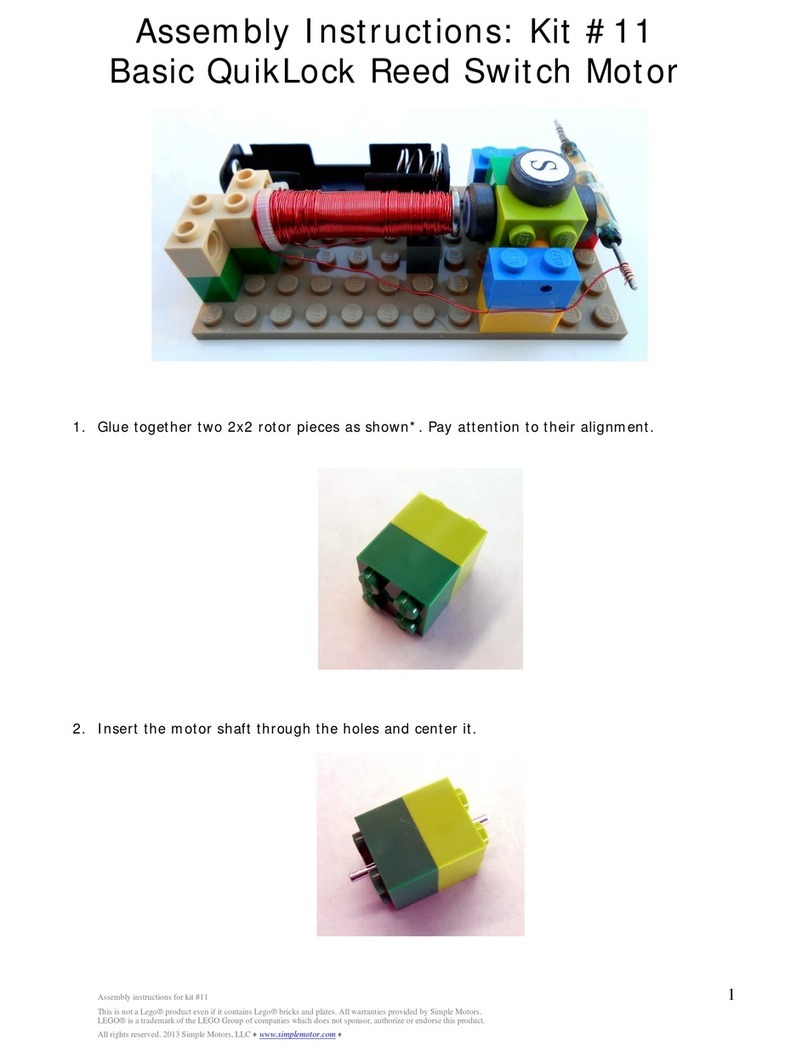

Simple Motors

Simple Motors Kit 11 Assembly instructions