TECNOVIS TEC-EW-CLASSIC Instruction Manual

Installing instructions TECNOVIS - TEC-EW-CLASSIC Seite 1 von 3

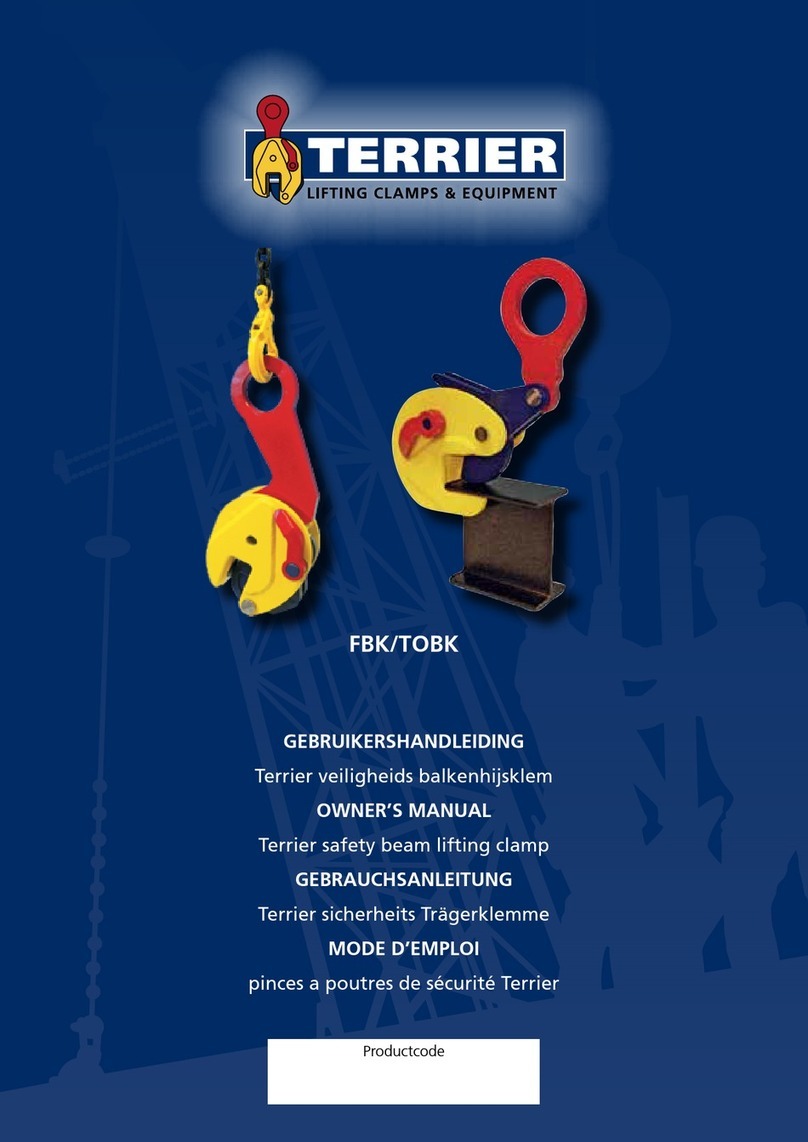

storm collar

length element

Kopfabdeckung

Montageschelle

Reinigungselement

inspection opening

length element

pipe tee 87°

cleaning door

neutralizer

Montageschelle

Reinigungswinkel 87°

Reinigungselement

Kondensatschale

condensate outlet

pipe bend 87° with

clean-out opening

assembly clamp

assembly clamp

chimney cowl cover

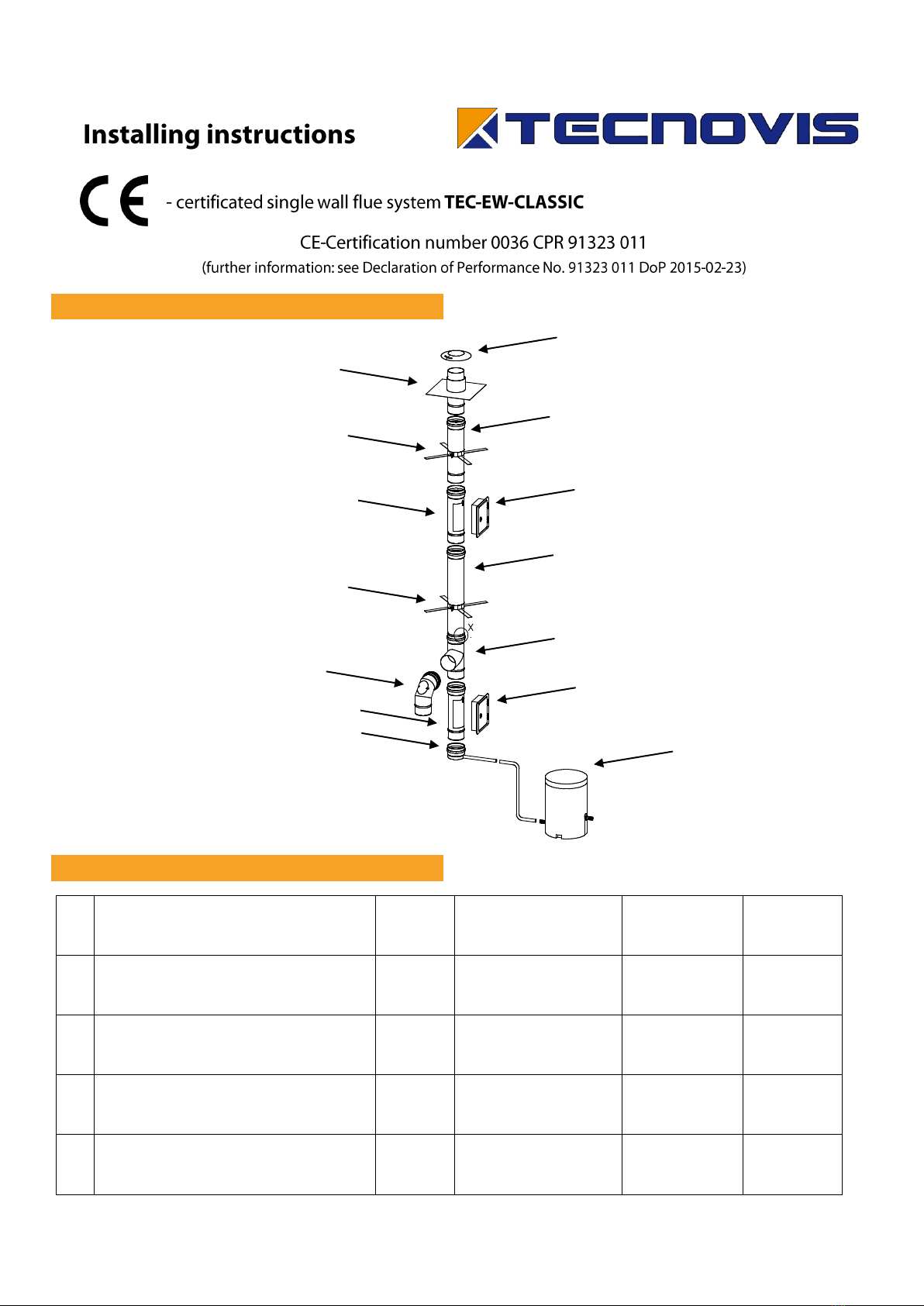

0.1

Used as system chimney (solid fuel)

Operation mode in negative pressure

up to 400°C

EN 1856-1

T400 –N1 –D –V2 –L50060

G50 (= 50 mm)

G75 (= 75 mm)

G100 (= 100 mm)

Ø 80 –300

Ø 350 –450

Ø 500 –600

0.2

Used as exhaust gas line (oil, gas)

Operation mode in negative pressure

up to 400°C

EN 1856-1

T400 –N1 –W –V2 –L50060

O50 (= 50 mm)

O75 (= 75 mm)

O100 (= 100 mm)

Ø 80 –300

Ø 350 –450

Ø 500 –600

0.3

Used as system chimney (solid fuel)

Operation mode in negative pressure

up to 600°C

EN 1856-1

T600 –N1 –D –V2 –L50060

G100 (= 100 mm)

G150 (= 150 mm)

G200 (= 200 mm)

Ø 80 –300

Ø 350 –450

Ø 500 –600

0.4

Used as exhaust gas line (oil, gas)

Operation mode in negative pressure

up to 600°C

EN 1856-1

T600 –N1 –W –V2 –L50060

O100 (= 100 mm)

O150 (= 150 mm)

O200 (= 200 mm)

Ø 80 –300

Ø 350 –450

Ø 500 –600

0.5

Used as system chimney (solid fuel)

with 25mm insulation, Operation mode in negative

pressure up to 600°C

EN 1856-1

T600 –N1 –D –V3 –L50060

G70 (= 70 mm)

G105 (= 105 mm)

G140 (= 140 mm)

Ø 80 –300

Ø 350 –450

Ø 500 –600

1) System construction variant

2) Minimum distance to combustible materials

inspection element

inspection element

Installing instructions TECNOVIS - TEC-EW-CLASSIC Page 2 of 3

The installing has to be performed professionally according to the installing instructions respectively according to the valid national regulations.

In Germany in particular DIN V 18160-1, as well as the applicable rules of regional building (LBauO), firing regulations (FeuVO), relevant DIN standards and all

other building- and safety regulations.

The required cross section has to be determined according to DIN EN 13384 and has to be rechecked by the executing specialist firm.

Before the installation the design of the system has to be clarified with the concerned district chimney sweeper.

The suitability and safe usability of the exhaust system is to be certified by a competent district chimney sweeper before

commissioning.

The exhaust gas line must be installed within into own longitudinally ventilated flue or channel. The fire safety requirements for the flues (LA30 to LA90) comply

with the construction legislation (firing ordinance) of the respective federal state. With the exception of the necessary cleaning and inspection openings, the

flue must not have any additional opening other than in the installation room of the CHP. (The inspection openings has to be certified by a competent district

chimney sweeper before commissioning.) Several exhaust gas lines can be installed in a flue if the national regulations and construction legislation allow this.

6) Cleaning opening

The position of the cleaning and inspection openings must (in Germany) comply with

DIN V 18160 Part 1 or other applicable regulations and should be discussed with the

competent authorised district chimney sweeper during the planning phase.

7) Installation of the chimney system

FITTING OF ELEMENTS:

•Insert and adjust the clean out element with condensate collector in the first opening

•Set the pipe tee connection 87° or 45° with mounted assembly clamp,

maybe you have to set between the clean-out element and the pipe tee connection levelling pieces.

•Attach a rope at the pipe with lower loop and put the pipes at the end capo f the chimney together.

•The pipes can now be let down. Assembly clamps are every three meters necessary to hold the space to the stonewalled ductwork. The last straight pipe

element has to be shortened that a linear expansion of approximately 3mm per rising is possible.

•If an intermediate clean-out opening should be installed in the attic, a intermediate support with expansion is necessary.

INSTALLATION FOR INTERMEDIATE CLEANING:

An inspection element is to be installed if inspection of the line and flue is necessary in the attic.

INCLINED CHIMNEYS:

In the case of inclined flues / chimneys, the inspection elements and the intermediate pieces (note linear expansion) must comply with state regulations.

Note: Corresponding measures to compensate for thermal linear expansion must be taken with high exhaust gas temperatures / extended distances prior to a slant.

INSTALLATION OF THE CHIMNEY COWL COVER:

The chimney cowl must be so designed that the exhaust air is guided via the extended inner pipe and the flue is ventilated between the inner pipe and inner wall of

the flue.

The cowl cover is plugged onto the chimney cowl. The cowl cover must be permanently protected from moisture penetration.

The weather protection fitting must be placed 30 mm/minimum ring gap width above the air discharge piece in order to ensure rear ventilation.

3) Mounting and regulations

4) Site requirements

5) Construction of pipes

All components have to be mounted in a way, that the nozzle is

above or rather in flow direction of the exhaust gas (see figure).

A:

B:

58

55

60

A:

B:

Smoke direction

Figure: length element

Installing instructions TECNOVIS - TEC-EW-CLASSIC Page 3 of 3

8) Connecting line

The connecting line must be laid at an incline of 3° to the CHP in order to optimally channel away any condensate which may form.

For long connecting lines, it is advisable to insulate them, in order to avoid cooling.

9) Concluding instructions

Place the endcap on the chimney top. It is advisable to have a sealant between the endcap and the chimney top. In the end attach the storm collar to the last

pipe so that the rainwater cannot penetrate, but the rear ventilation of the tubular column should be ensured. Finally, cover and clean all connection openings

and clean the condensate tray and the drain.

If moisture-resistant operation is required, the condensate tray must be provided with the siphon.

Before the assembly the execution of the chimney system has to be clarified with the concerned district chimney sweeper.

Technical changes and mistake reserved.

Lessingstraße 20 · 63110 Rodgau

Tel.: +49 (0) 37600 56398 0 · Fax: +49 (0) 37600 56398 2

mail@tecnovis.de · www.tecnovis.de

Popular Industrial Equipment manuals by other brands

FLENDER

FLENDER FLUDEX FGO Assembly and operating instructions

TLV

TLV UFO Series instruction manual

Qnubu

Qnubu KOMPACT 2.0 user manual

Daikin

Daikin EWWD 340 Installation, operation and maintenance manual

Innotech

Innotech INNOTECH BEF 401-10 Instructions for installation and use

CKD

CKD INDEXMAN PPLX Series instruction manual