6

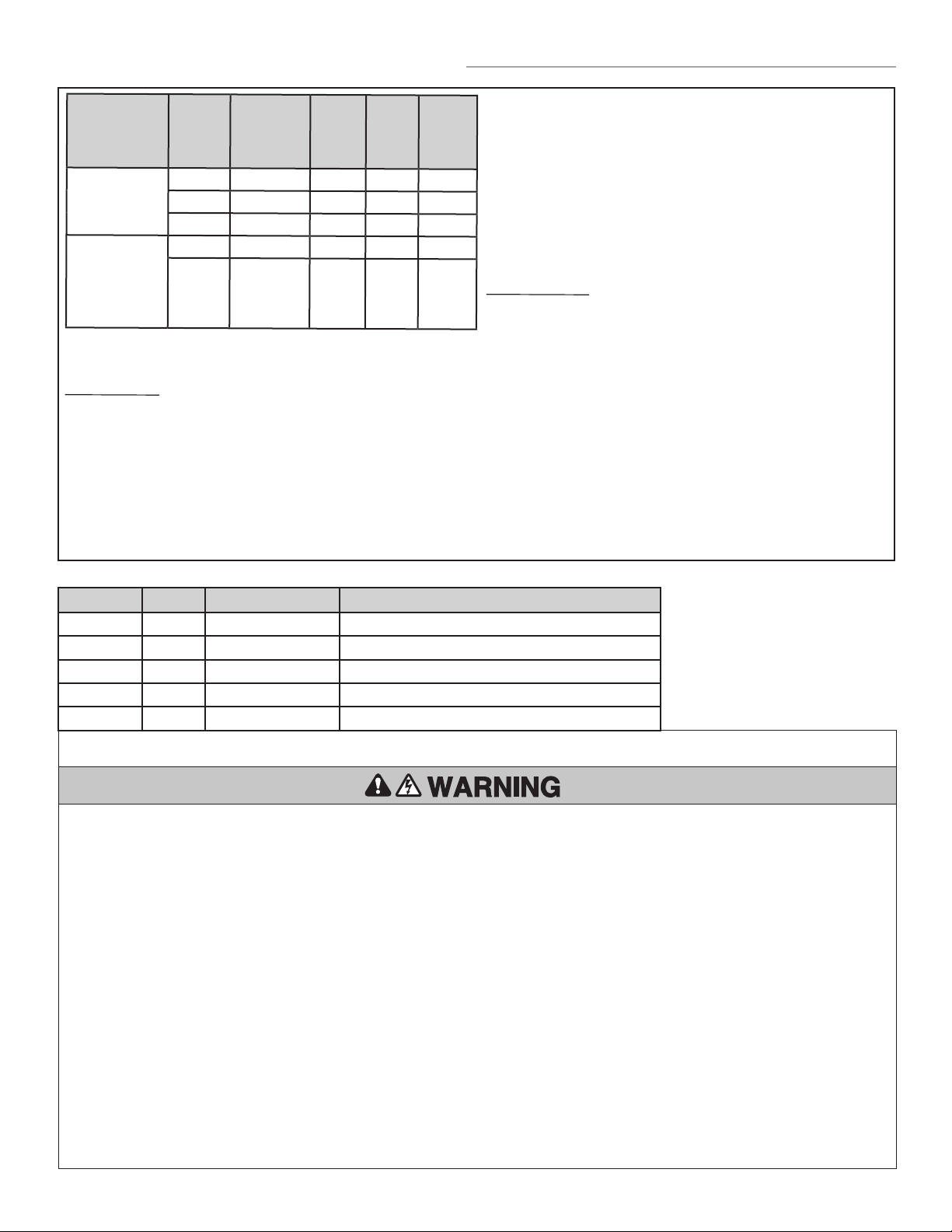

MODEL HP VOLTAGE PHASE AMPS POWER

(FT

LBS/

SEC)

HPH1

1.25 HP 120V 116A 348

1.25 HP 240V 1 9A 348

1.25 HP 230V 39A 348

HPH1 W/

STEP DOWN

TRANS-

FORMER

1.25 HP 460V 34A 348

1.25 HP 575V 34A 348

TYPE: Limited Duty: up to 100 cycles per hour

up to 600 cycles per day

ELECTRICAL

DOOR IN MOTION RELAY: 5A @ 42Vdc

AUXILIARY OUTPUT VOLTAGE: 24Vdc ; 500mA

CONTROL STATION: VFD Controller with Integrated Open/Close/

Stop Controls, LCD Display, floor level

wiring, and floor level commissioning

through intuitive user menu.

OPERATING MODES: B2, C2, D1, E2. See page 23 for more

information regarding operating modes.

BRAKE: Solenoid powered-off brake standard on all

units.

MANUAL HOIST: Manual hoist with integral manual operation

protection circuit.

CABLE TENSION MONITOR: Detects ANY slack that may

occur in the cables and responds

accordingly.

MECHANICAL

DRIVE REDUCTION:

1.25HP Operator: 20:1 High-Efficiency 2-Stage

Gearbox.

DOOR SPEED: Automatically set based on door type.

LIMIT ADJUST: Electronic limits, Floor level adjustability up

to 20ft.

TEMPERATURE RATINGS: -20°C (14°F) to +40°C (104°F)

ENVIRONMENT: For indoor use only.

MAX. DOOR WEIGHT: 92–1025 lbs

DOOR DIMENSIONS (W X H): 8'x7' – 16'x14'

OPERATOR SPECIFICATIONS

VOLTAGE SELECTION

MODEL HP VOLTAGE PHASE

HPH1 1.25 120V 1 Phase

HPH1 1.25 240V 1 Phase

HPH1 1.25 230V 3 Phase

HPH1 1.25 460V 3 Phase (via separate stepdown transformer)

HPH1 1.25 575V 3 Phase (via separate stepdown transformer)

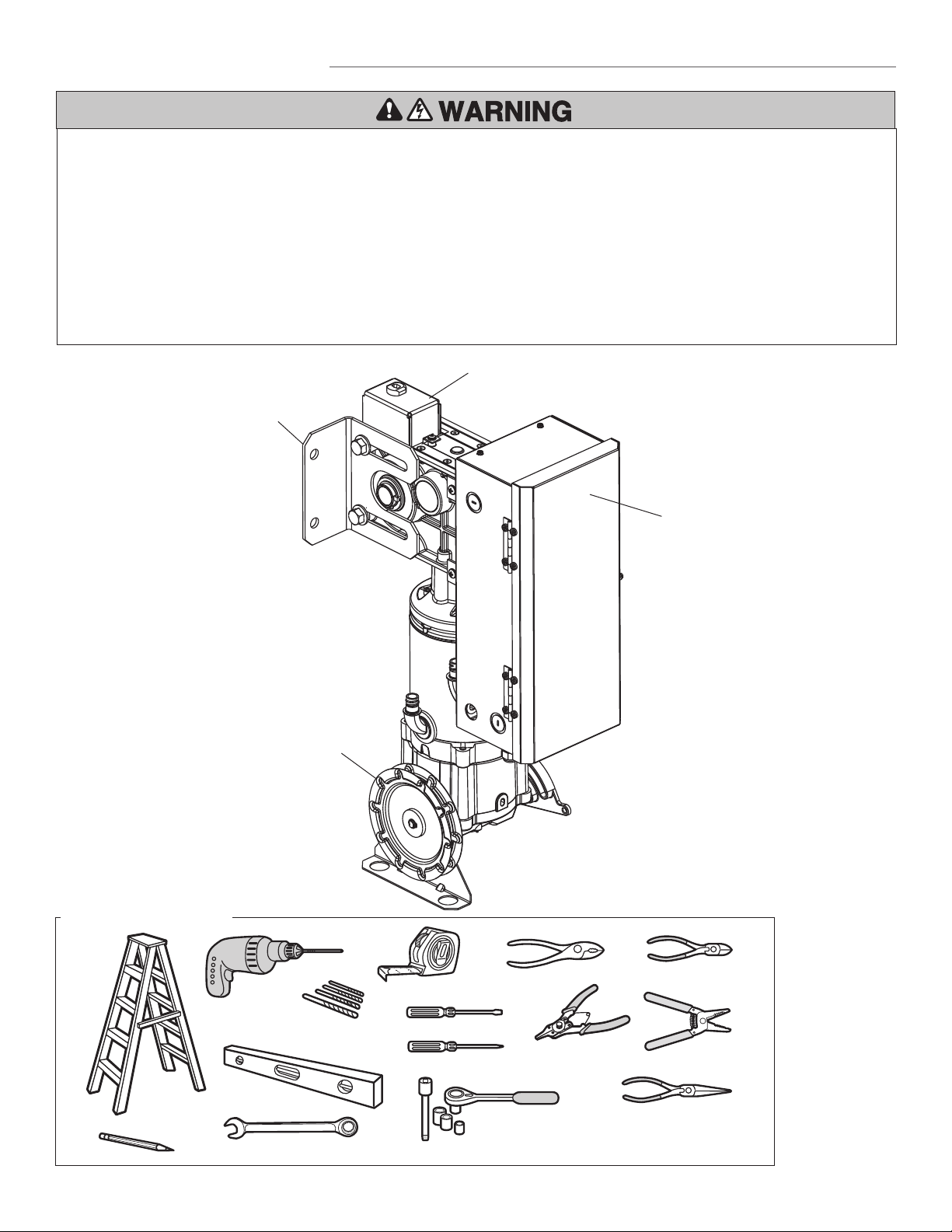

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

IMPORTANT SAFETY INSTRUCTIONS

1. READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS.

2. ALWAYS keep remote controls out of reach of children.

NEVER permit children to operate or play with door control

push buttons or remote controls.

3. ONLY activate a door when it can be seen clearly, it is

properly adjusted and no obstructions exist in the path the

door will travel.

4. Personnel should keep away from a door in motion and

ALWAYS keep a door in sight until completely closed. NO

ONE SHOULD CROSS THE PATH OF A MOVING DOOR.

5. NO ONE SHOULD GO UNDER A STOPPED OR PARTIALLY

OPENED DOOR.

6. If possible, use the manual release handle to disengage a

door ONLY when a door is CLOSED. Weak or broken springs

or an unbalanced door could result in an open door falling

rapidly and/or unexpectedly causing SEVERE INJURY or

DEATH.

7. NEVER use manual release handle unless the doorway is

clear of persons and obstructions.

8. After ANY adjustments are made, the entrapment protection

device(s) MUST be tested. Failure to adjust the operator

properly may cause SEVERE INJURY and DEATH.

9. Entrapment protection device(s) MUST be tested every

month. Failure to adjust the operator properly may cause

SEVERE INJURY and DEATH.

10. ALWAYS KEEP DOOR PROPERLY BALANCED. An

improperly balanced door may NOT reverse when required

and could result in SEVERE INJURY or DEATH. See the door

manufacturer’s owners manual.

11. ALL repairs to cables, spring assemblies and other

hardware, ALL of which are under EXTREME tension, MUST

be made by an Authorized Service Technician.

12. ALWAYS disconnect electric power to the door operator

BEFORE making ANY repairs or removing covers.

13. SAVE THESE INSTRUCTIONS.