TECO-Westinghouse F510 Series User manual

OUT of the Box Startup – Overview

This document is intended as a quick start guide to get familiarity with keypad

navigation, changing parameters, and setting the F510 drive up for external

start/stop and external potentiometer signal. Please note this document is not

a substitute for the F510 User Manual and it is important that you reference the

F510 user manual before proceeding.

1Check Nameplate and Connect Input / Output Wiring -

Check the inverter nameplate to insure that the informationagrees with your order.Also insure that the power available is rated

appropriately forthe drive being used.

Secure the Inverter in

a suitable location

DANGER

Do not apply power until all

connections are correct

and secure, and all

protective covers are in

place.

!

Removeprotectivecovers to access

the power terminal blocks. (Refer to

the F510 User Manual for detailed

instructions.)

MOTOR

T1 T2 T3

INPUT POWER

L1 L2 L3

AppropriateInput

Power

3Ø Induction Motor

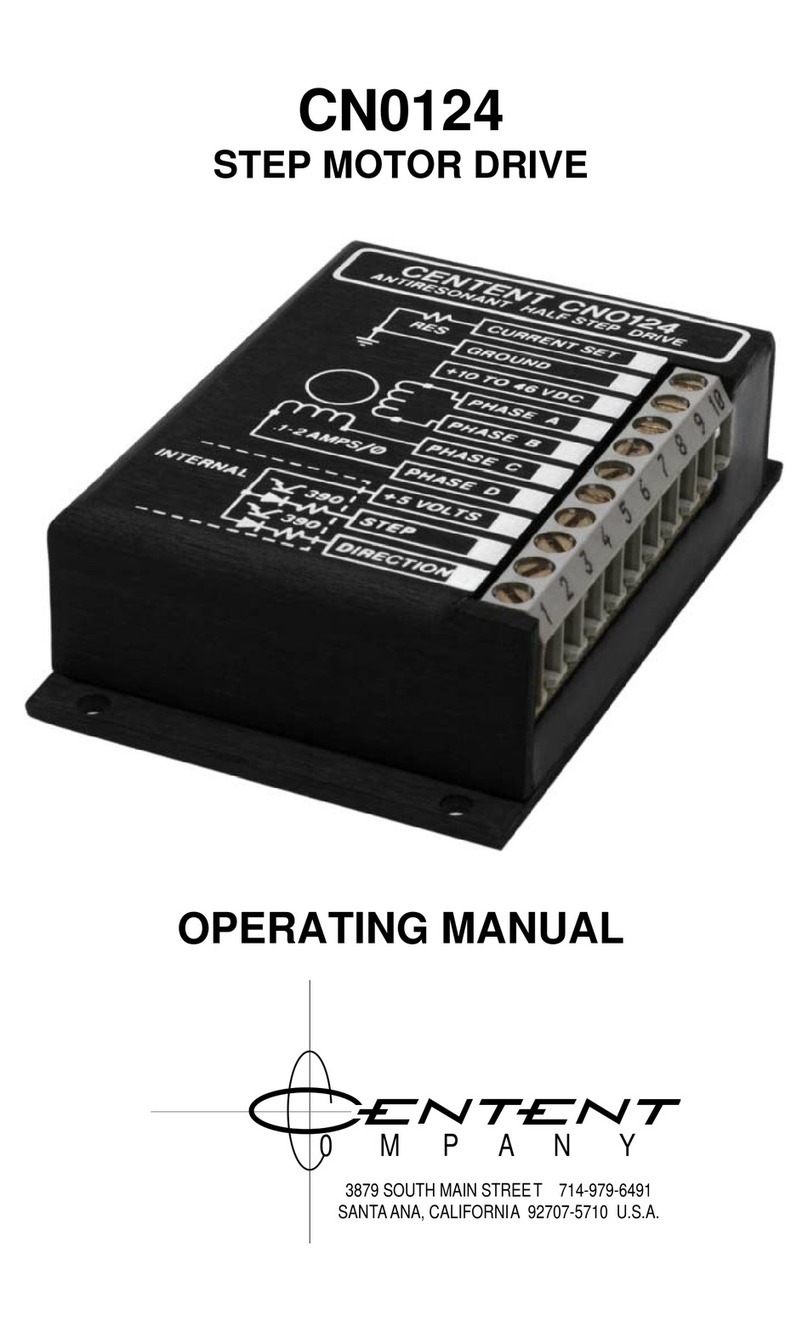

2Power-up the Inverter, check the Digital Operator

In this step, after the initial power-up you will become familiar with the indications and functions of the Digital Operator.

STEP

STEP

To reverse direction

of motor rotation

swap any two leads

KEYS (8) Description

RUN: RUN Inverter inLocal Mode

STOP: STOP Inverter

LOC/REM: Switches between Local and Remoteoperation

DSP/FUN: Switches between available displays

</RESET: Left Shift: Used to change parameters orvalues, RESET

alarms and faults

ENTER: Used to display the preset value of parameters and to save

changes

Parameters navigation Up, Increase parameters orreference value

Parameters navigation Down, Decreaseparameters or reference value

F510 Control Settings (Factory Default)

RUN/STOP Control: Keypad (RUN / STOP key)

SPEED Control: Keypad (Default 5.00 Hz)

See step 5. to change to RUN/STOP to external switch/contact.

See step 6. to change to external potentiometer control.

Press RUN to start the drive or STOP to stop the drive.

Changing Speed Reference

Press ENTER button and use

to change reference.

Press </RESET button to shift cursor to

the left

Press ENTER button to save

3Ø Input

LCD Display

Run Status

Indicator 8 button

Membrane Keypad

Stop Status Indicator

Fault Status

Indicator

Forward

Direction

Status Indicator

ReverseDirection

Status Indicator

External Reference

Indicator

External Sequence

Indicator

Fref Ref

12-16=005.00Hz

Monitor

12-17=000.00Hz

12-18=0000.0A

Fref Ref

12-16=005.00Hz

Monitor

12-17=000.00Hz

12-18=0000.0A

Note: For 1Ø Input use terminals L1- L3 NOTE:Properly check the

GROUNDCONNECTION

Ground

DANGER

!

Check Motor Rotation

3

STEP

This test is to be performed solely from the inverter keypad. Apply power to

the inverter after all the electrical connections have been made and protective

covers have been re-attached. At this point, DO NOT RUN THE MOTOR, the

keypad should display as shown below in Fig. 1a and the speed reference

5.00 Hz should be blinking.

Solid

Next press the RUN key. The motor should now be operating at low speed

running in forward (clockwise) direction. The keypad should display as shown

above in Fig. 1b and the speed reference 5.00 Hz should be solid. Next press

STOP key to stop the motor.

Fig. 1a Fig. 1b

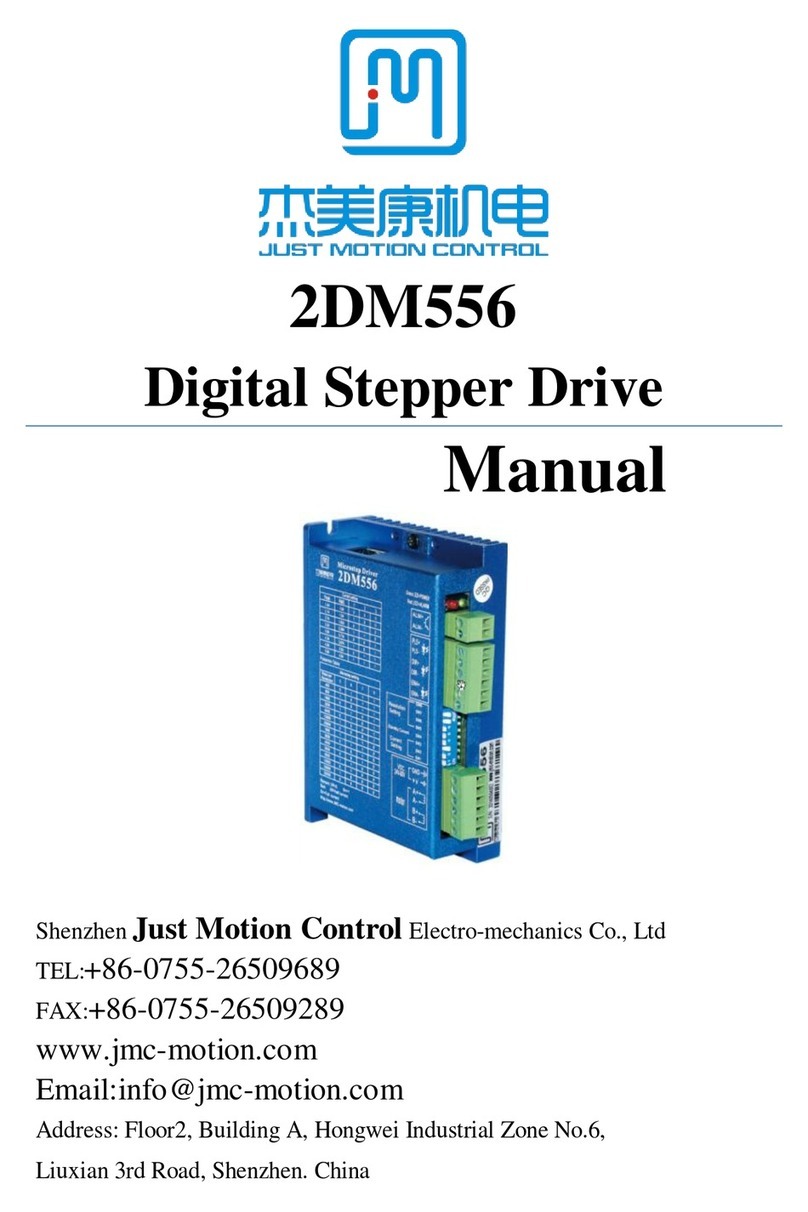

How to Change Parameters

4

STEP

Important: Motor rotation and direction only applies to standard AC

motors with a base frequency of 60Hz. For 50Hz or other frequency AC

motors please set V/F pattern in group 01 before running the motor.

If the motor rotation is incorrect, power down the inverter. After the power

has been turned OFF, wait at least ten minutes until the charge indicator

extinguishes completely before touching any wiring, circuit boards or

components.

Using Safety precaution, and referring to step 1 exchange any two of the three

output leads to the motor (T1, T2 and T3). After the wiring change, repeat this

step and recheck motor direction.

POWER ON

DS P

FUN

RE AD

ENTE R

RE AD

ENTE R

RE AD

ENTE R

RE AD

ENTE R

Monitor Freq Ref

12-17=000.00Hz

12-18=0000.0A

12-16=005.00Hz

Control Method

Edit 00-00

0V/F

(0~4)

<0>

Motor Direction

0Forward

(0~1)

<0>

Run Source

0 Digital Op

(0~4)

<1>

DS P

FUN

Edit 00-01

Edit 00-02

DS P

FUN

DS P

FUN

DS P

FUN

Group

01 V/F Pattern

02 Motor Parameter

00 Basic Func.

PARA 00

-00 Control Method

-01 Motor Direction

-02 RunSource

PARA 00

-00 Control Method

-01 Motor Direction

-02 RunSource

PARA 00

-00Control Method

-01 Motor Direction

-02 RunSource

Parameter

Group

Selection

Mode

Parameter

Group

Mode

Parameter

Edit Mode

DS P

FUN

Press ▼or ▲

key to edit

parameter value,

and press

READ/ENTER

key to save the

change.

Stop

Light

Solid

Run light flashing until

desired frequency set in

12-16 is reached after

which light turns solid.

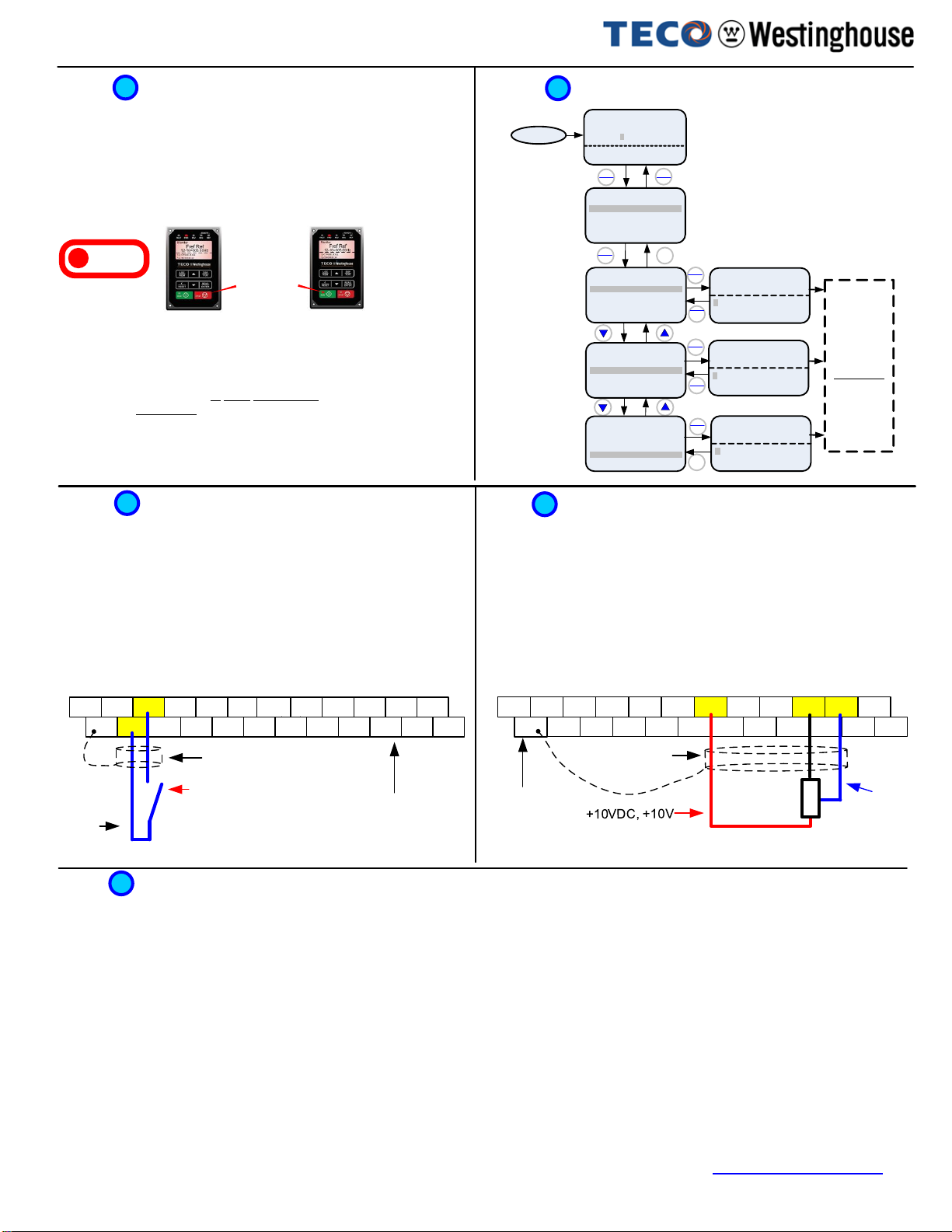

Afterpower-up set parameter 00-05=1 (Speed Reference from Control Terminals).

Using an external potentiometer for speed control

6

STEP

Default Setting: The F510 by default uses the keypadfor frequency reference,

followinstructionsbelow to use a remote reference (external potentiometer).

Instructions to change to remote reference:

- Powerdown thedrive,wait10 min.

- Remove theprotective covers (See F510 UserManual) and make the

connections as shown below in Fig. 2b.

- Verifythat all connections are secure, replace covers and power-up the drive.

Do not apply power until all connections are correct and secure, and all

protective covers are in place.

After power-up set parameters 00-02=1 (Run Source from Control Terminals).

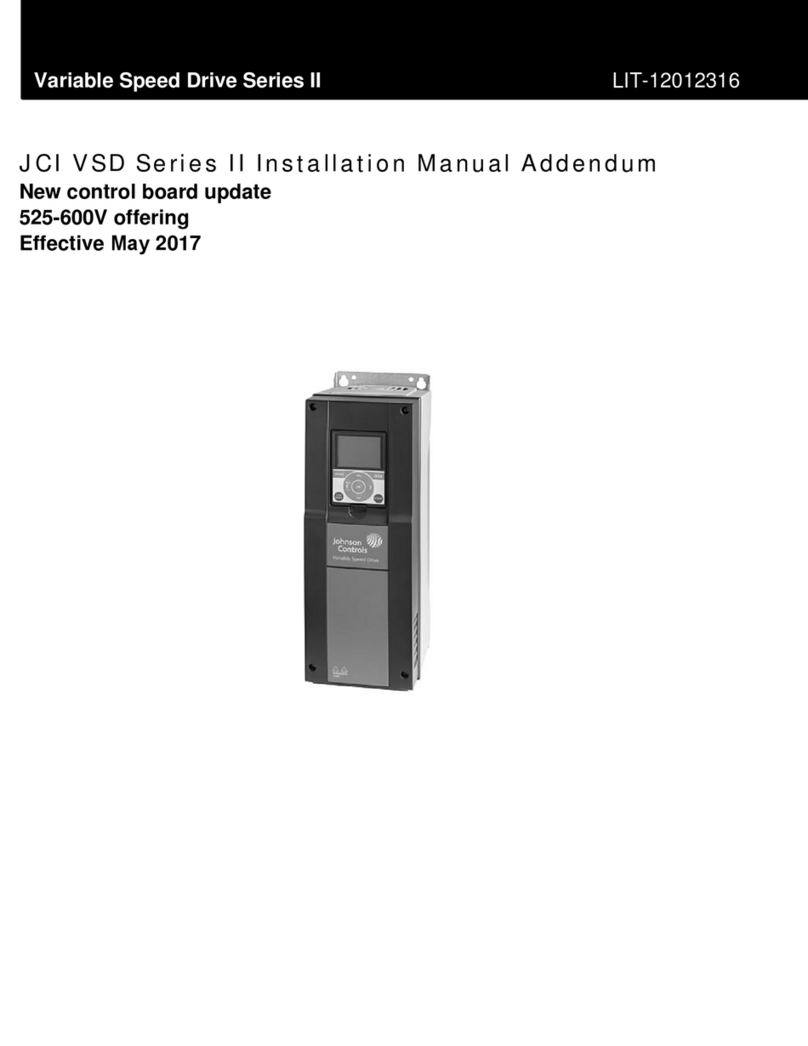

Default Setting: The F510 by default uses the keypadto run andstop, follow

instructions below to change toa remotestart/stop (maintained contact/switch).

Instructions to change toremote run/stop:

- Powerdown thedrive,wait10 min.

- Remove theprotective covers (See F510 UserManual) and make the

connections as shown below in Fig. 2a.

- Verifythat all connections are secure, replace covers and power-up the drive.

Using Remote Run/Stop (Maintained Contact/Switch)

Do not apply power until all connections are correct and secure, and all

protective covers are in place.

5

STEP

Potentiometer

1 ~ 5K Ohm (½ W) Fig. 2b

Common

/24VG

Fig. 2a

Terminal representation for 230V: 1 ~ 3 HP, 460V: 1 ~ 3HP

(See section 3.3 ofthe instruction manual for other sizes) Terminal representation for 230V: 1~ 3 HP, 460V: 1 ~ 3 HP

(See section 3.3 ofthe instruction manualfor other sizes)

Start / Stop Switch

(Maintained)

Forward Command/FWD Control

Terminals / User

Terminals

Connect shield to

control ground terminal

S(+) S(-) S1 S3 S5 24V +10V MT GND GND AI1 AI2

E 24VG S2 S4 S6 SF1 SG SF2 PO PI AO1 AO2

Connect shield to

control ground

terminal

Common/0V, GND

Analog

Input AI1

S(+) S(-) S1 S3 S5 24V +10V MT GND GND AI1 AI2

E24VG S2 S4 S6 SF1 SG SF2 PO PI AO1 AO2

Control Terminals /

UserTerminals

Motor Nameplate Data (Parameter 02-01)

The motor rated current is set at the factory based on the inverter model. Enter the motor rated current from the motor nameplate if it does not match the value

shown in parameter 02-01.

Setting range: Varies by model.

Frequently Used Parameters

7

STEP

Acceleration and Deceleration Time (Parameter 00-14, 00-15)

Acceleration and Deceleration times directly control the system dynamic response. In general, the longer the acceleration and deceleration time, the slower the

system response, and the shorter time, the faster the response. An excessive amount of time can result in sluggish system performance while too short of a time

may result in system instability.

Using Keypad for Speed Reference (Parameter 00-05)

To use the keypad set parameter 00-05 to 0.

The default values suggested normally result in good system performance for the majority of general purpose applications. If the values need to be adjusted,

caution should be exercised, and the changes should be in small increments to avoid system instability.

00-14 Acceleration time 1

00-15 Deceleration time 1

These parameters set the acceleration and deceleration times of the output frequency from 0 to maximum frequency and from maximum frequency to 0.

Factory Reset (Parameter 13-08)

To reset all parameters back to factory default set parameter 13-08 to 9.

F510 Startup Guide V1.6 –01/23/20

For the complete F510 parameter listing and descriptions, refer to the F510 Instruction manual on our website www.tecowestinghouse.com

Other manuals for F510 Series

2

Other TECO-Westinghouse DC Drive manuals

Popular DC Drive manuals by other brands

Graham

Graham 1703 Series Installation, operation and maintenance manual

Electro-Voice

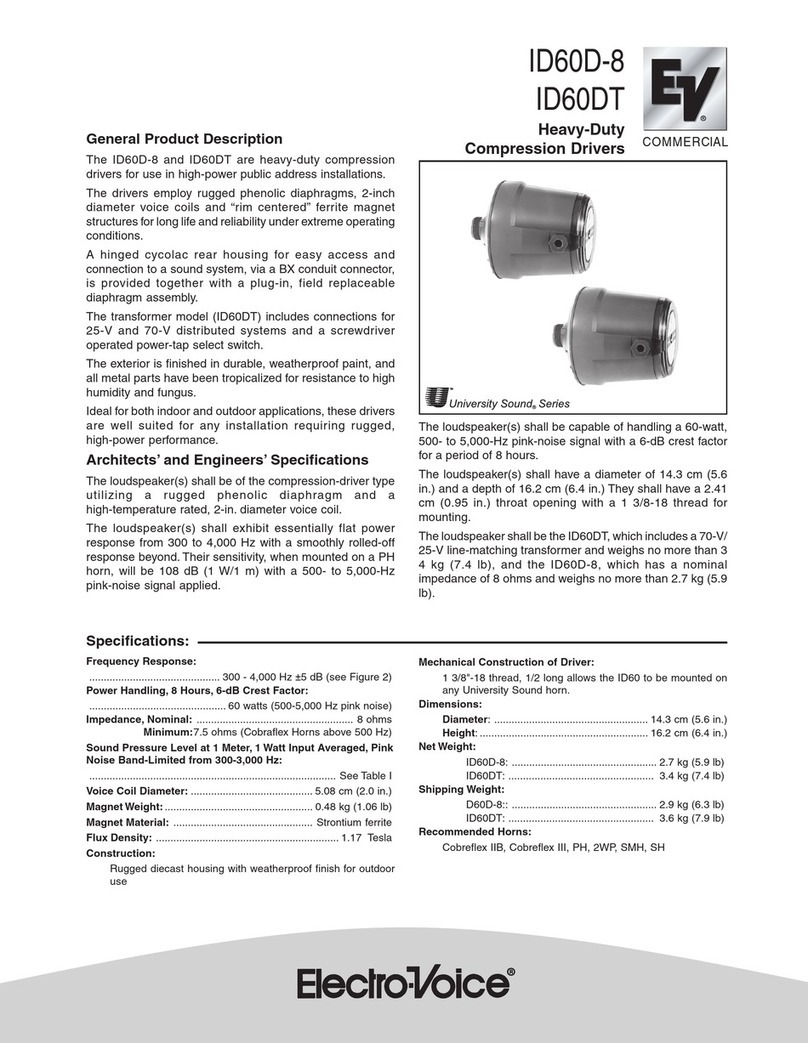

Electro-Voice ID60D-8 Specifications

Parker

Parker Compax3H C3H1xxV4 Series installation manual

eldoLED

eldoLED LINEARdrive 720D quick start guide

Nidec

Nidec Unidrive M100 Installation sheet

ITOH DENKI

ITOH DENKI POWER MOLLER HBM-604BN manual