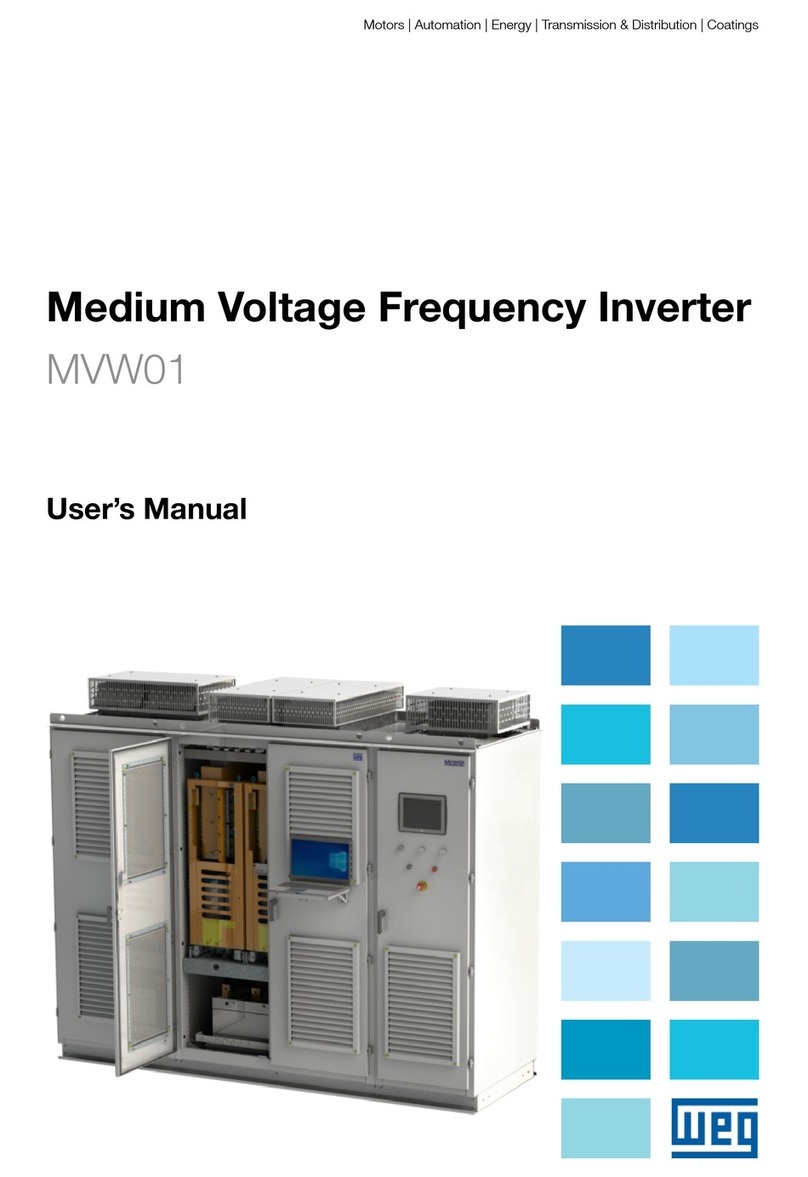

Summary

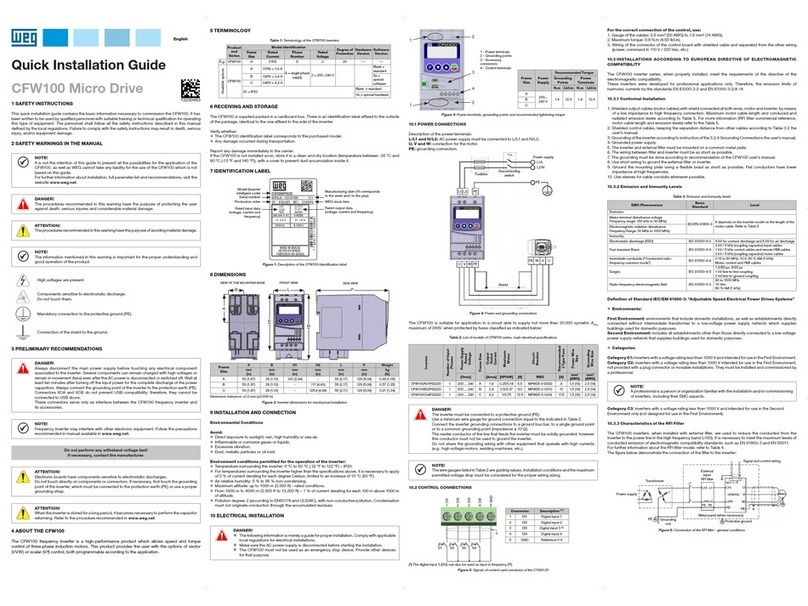

1 SAFETY INSTRUCTIONS .......................................................................... 5

1.1 SAFETY WARNINGS IN THE MANUAL .............................................................................................5

1.2 PRELIMINARY RECOMMENDATIONS ............................................................................................5

1.3 HANDLING...........................................................................................................................................6

1.3.1 Panel Handling...........................................................................................................................6

1.3.1.1 Representative Image of the AFW900 Packaged for Land Transport ....................6

1.3.1.2 Representative Image of the AFW900 Packaged for Land or Sea

Transport in a Closed Container.............................................................................................7

1.3.1.3 Representative Image of the AFW900 Handled by the Lifting Eyes .......................7

2 GENERAL INFORMATION......................................................................... 9

2.1 ABOUT THE MANUAL ........................................................................................................................9

2.2 TECHNICAL DATA ..............................................................................................................................9

2.3 FUSES................................................................................................................................................ 11

2.4 ACCESSORIES.................................................................................................................................. 11

2.4.1 Output Reactor (According to the Inverter Rated Current) ............................................... 11

2.4.2 Selector Switch for Operating Mode (Local / Remote)...................................................... 11

2.4.3 CANopen/DNet Communication...........................................................................................12

2.4.4 Relay Output Module..............................................................................................................13

2.4.5 Analog Input and Output Module..........................................................................................14

2.4.6 Temperature Sensor Module.................................................................................................15

2.4.7 Digital Input and Output Module...........................................................................................16

2.4.8 Encoder Module...................................................................................................................... 17

2.4.9 7 Slots Module.........................................................................................................................18

2.5 POWER AND CONTROL UNITS ......................................................................................................18

2.6 LABEL................................................................................................................................................19

3 TYPICAL SCHEMES ................................................................................ 20

4 INSTALLING .............................................................................................23

4.1 MOUNTING THE PANELS ON THE FLOOR....................................................................................23

4.2 MOUNTING THE PANELS ON THE WALL......................................................................................24

4.3 MECHANICAL DETAILS...................................................................................................................25

4.4 ELECTRICAL CONNECTION ...........................................................................................................28

4.4.1 Dimension, Weight and Dissipated Power Table.................................................................29

4.4.2 Power Cable Minimum Gauge Table ....................................................................................30

4.4.3 Connecting the Power Supply...............................................................................................31

4.4.4 Connecting the Output Cables..............................................................................................31

5 PRODUCT OPERATION ......................................................................... 32

6 MAINTENANCE INSTRUCTIONS ........................................................... 33

6.1 PREVENTIVE MAINTENANCE .........................................................................................................33

6.2 CORRECTIVE MAINTENANCES .....................................................................................................33

7 ONE-LINE DIAGRAM............................................................................... 34