Tecsis EZE30 Owner's manual

Operating manual/Programmer`s manualOperating manual/Programmer`s manual

EZE30

Digital load cell ampilfier with analogue output

and setpoints

||

Pressure |||

Temperature Switch ServiceForce

BE 948 a

CONTENTS

Page 2

Wiring Diagram and Key Functions Page 3

Quick Setup and Calibration using Weights Page 4

1. Enable Zero Button / Calibrate Zero point Page 8

2. Setup and calibrate the Span Function / Display Input Signal in mV/V Page 10

3. Setup the Display (Over/Under Range Limits, steps size & decimal point, Logic I/O Status) Page 12

4. Filter Setting and No Motion Page 14

5. Analogue Output (4-20mA) Settings Page 16

6. Logic Inputs 1,2&3 Page 17

7. Logic Outputs 1,2&3 Page 19

8. Data Communication Settings Page 20

Error Codes / Return to Factory Settings Page 21

Communication Protocol Page 22

Examples

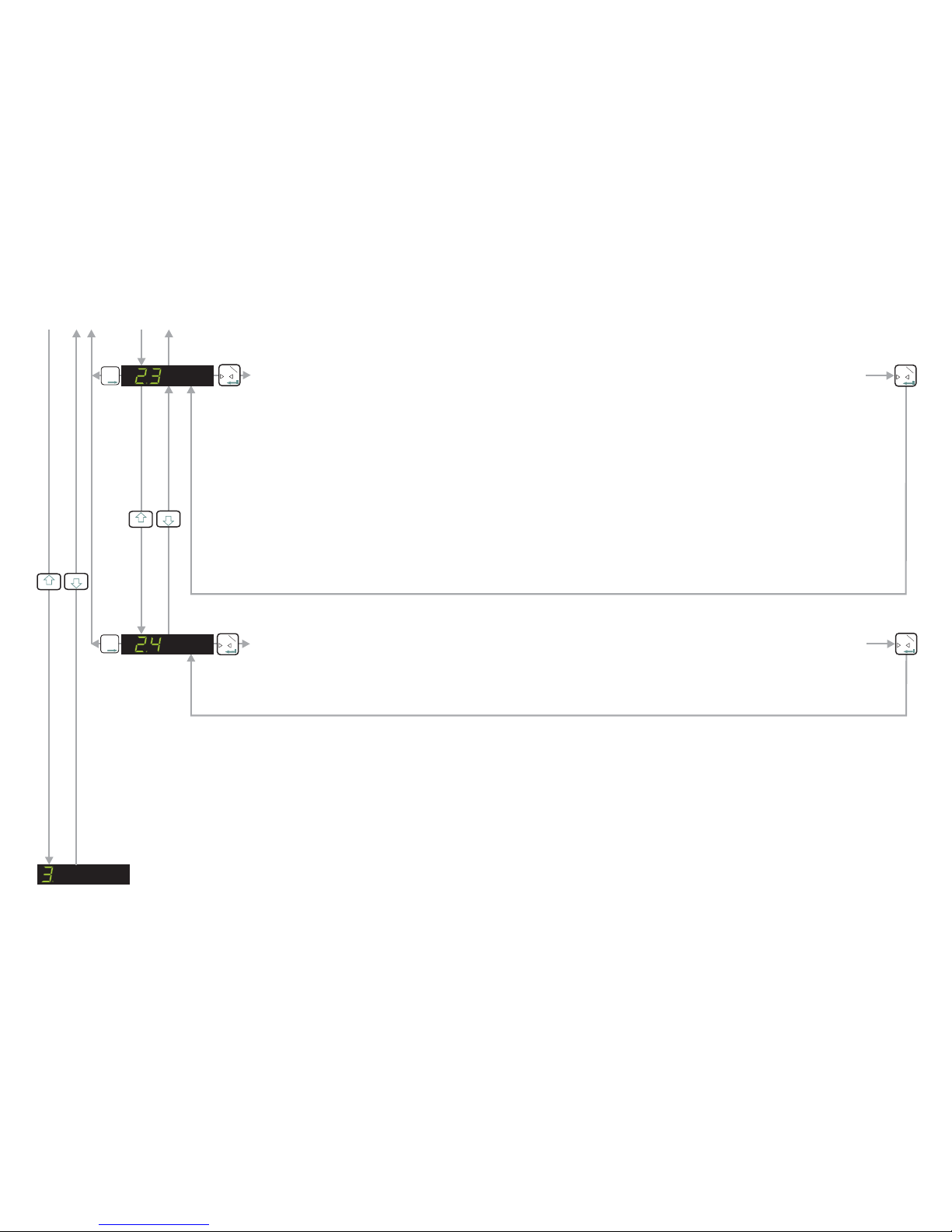

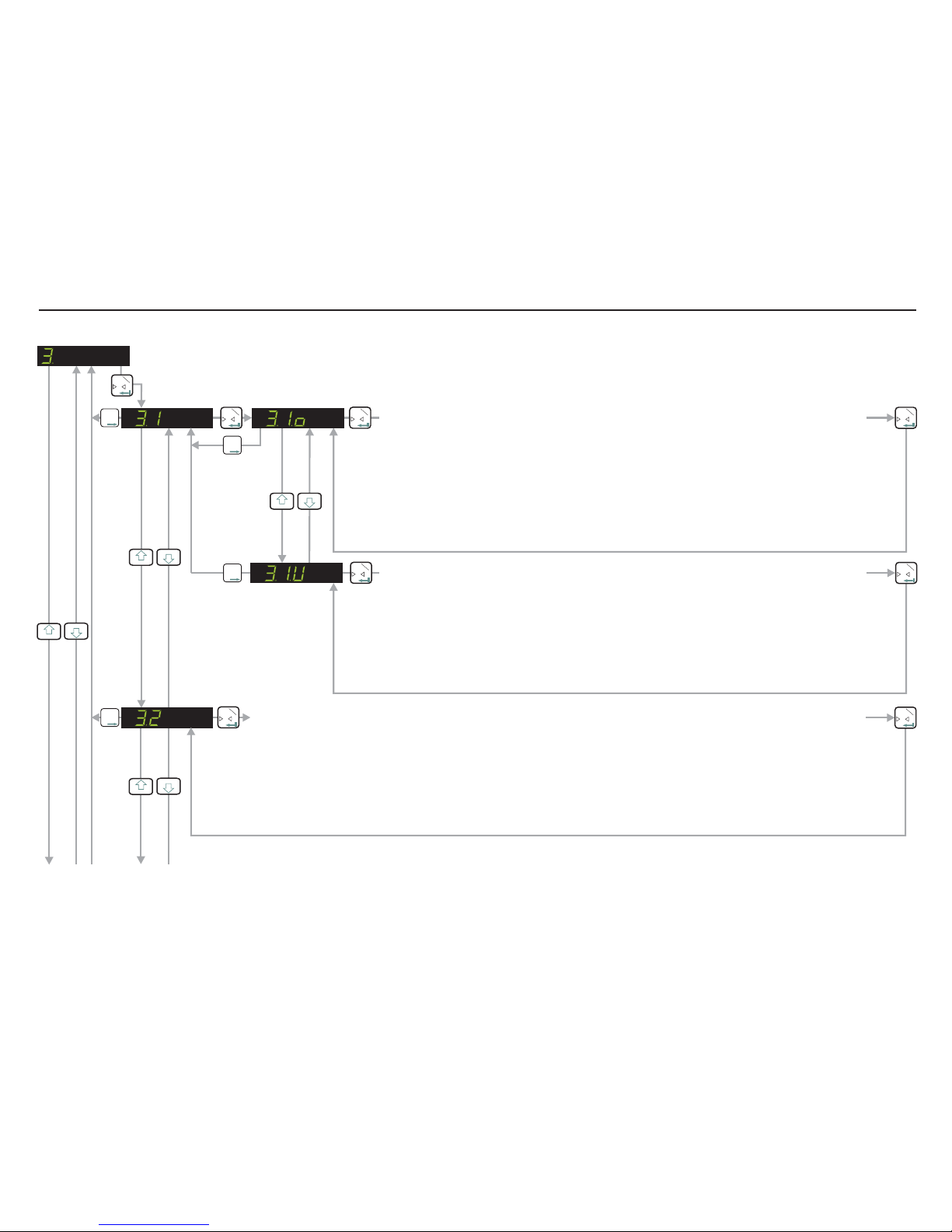

Calibration Procedure using weights Page 23

Calibration Procedure from known load cell mV/V sensitivities - Multiple active load cells Page 24

Single active load cell plus pivot Page 25

Programmers manual Annex A

Quick Setup and Calibration using the load cell mV/V Sensitivities Page 6

Filter Setting Tables & Update Rates (Number of Readings Averaged) Page 15

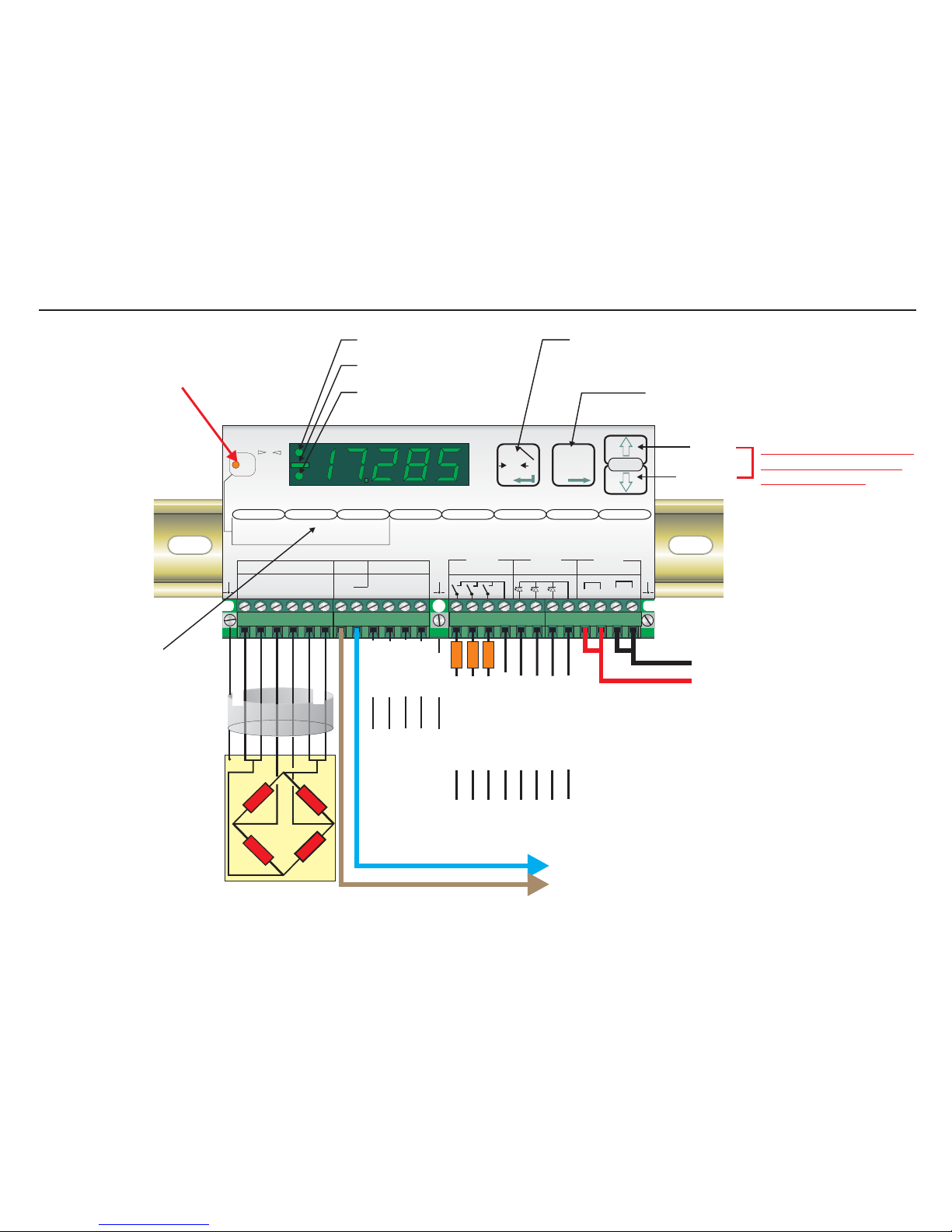

- SIGNAL

SHIELD

- EXCITATION

- SENSE

+ EXCITATION

+ SENSE

+SIGNAL

Load cell connections*

11-25

VDC

4-20mA

Output

Ground

RS422/485

Comms.

Recessed Enable Switch

(Enables changes to be made to important parameters.

Must be pressed AFTER entering ‘Set up’ mode but

before attempting to change parameters 1.1 to 1.3,

2.1 to 2.3 and 3.1 to 3.3)

Centre of Zero LED (±0.5d)

Minus Sign (>4 Digits ONLY)

Unit in Net Mode LED

Up Key

Down Key

Press either Key for more

than 3 seconds to enter

the ‘Set up’ Mode

Zero Key - Sets new zero (if enabled). Reverts to calibrated zero

if the button is held down for more than 3 seconds.

Switches unit back to ‘Gross’ mode if a tare has been set.

Acts as the ‘Enter’ key in the ‘Set-up’ Mode.

Tare Key - Puts unit into ‘Net’ mode. When inside

‘Set-up’ Menu this key moves the menu

back one step. Also moves ‘Digit Selected’

to the right when inside sub menus.

‘Set-up’ menu structure

0

Net

Digital Amplifier + Setpoint EZE30

+++ ++

--- 0

0

Exc Sen Inp Inp Sen Exc

Load cell 5Vdc < 80mA Isolated

Logic Outputs

Isolated

Logic Inputs

Isolated

Power 11 -25Vdc

++

--

Rx Rx Tx Tx

RS422/485

Gnd

0-20mA

Io

CL out

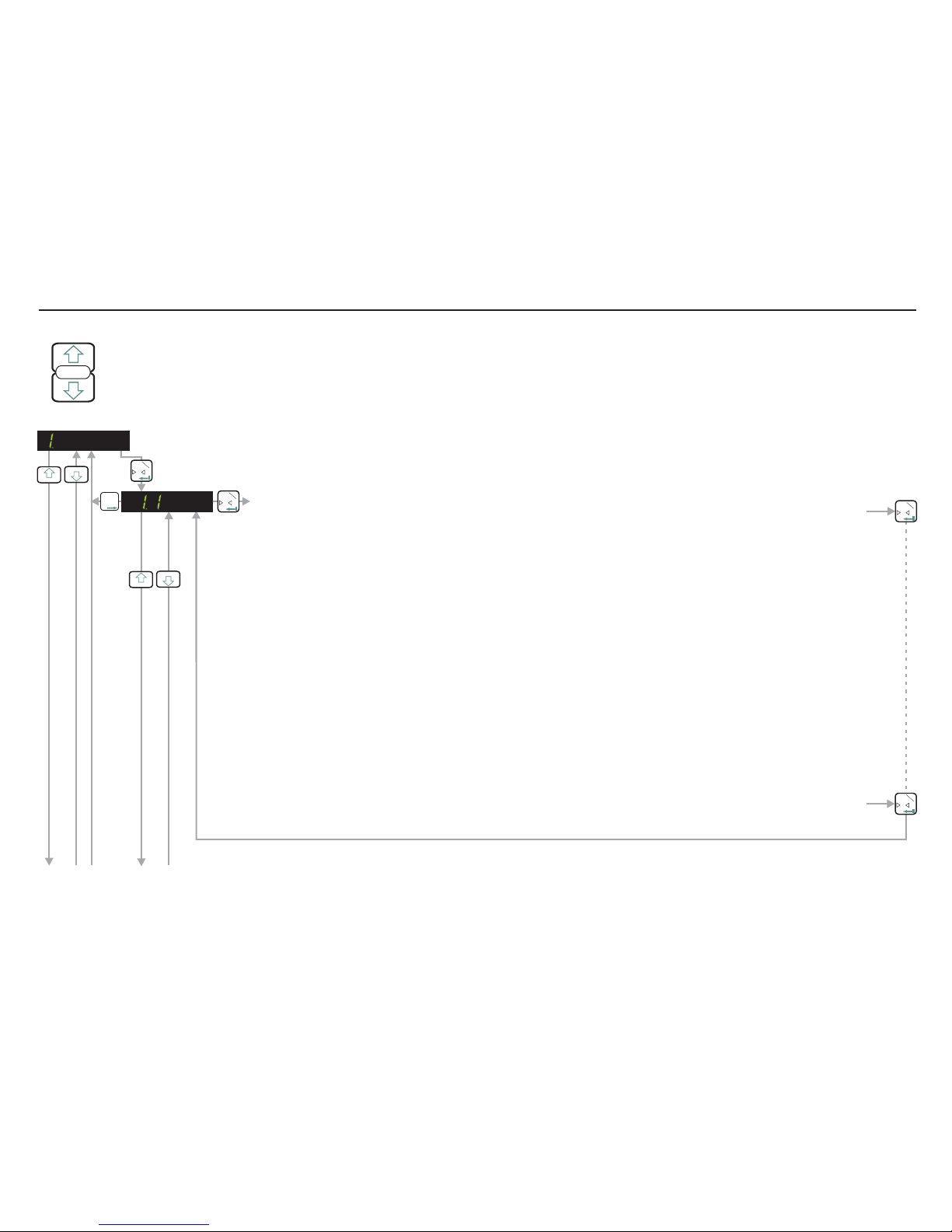

SET UP

1.Zero

1.0/allow>0<

2.Calibrate

3.Set mV/V

2.Span

1.Set cal ´n´

2.Calibrate

3.Set mV/V

4.Disp.mV/V

3.Display

1.o/u limits ´n´

2.

3.

4.Logic stats

Step*´n´

Dec.point

4.Filter

1.f Hz

2.Algorithm

3.Update rate

4.Motion´n´

cut

5.CLout

1.4mA=´n´

2.20mA=´n´

3.Base

4.Test I mA

6.Input 1/2/3

1.Assign Key

2.

3.

4.Test

7.Outp. 1/2/3

1.SPoint´n´

2.Hyst. ±´n´

3.Base

4.Test

8.Datacom.

1.Baud rate

2.422/485

3.Address

4.Auto trnsm.

T

T

T

0

T

12

3

4

1 2 3 com 1 2 3 com

depress

to

change

Logic input

Logic output

123

123

Logic Input 1 (+)

Logic Input 2 (+)

Logic Input 3 (+)

Logic Inputs (0V)

Logic Inputs

Receive +

Logic Outputs (0V)

Transmit +

Transmit -

Receive -

Logic Output 1 (+)

LOAD

Logic Output 2 (+)

LOAD

Logic Output 3 (+)

LOAD

*Please note that if you have a 4

wire cable from your junction box

or load cell to the EZE30, you

MUST put in additional links

between the Exc+ and Sen+

terminals and between the Exc-

and Sen- terminals. Otherwise the

display will show Err 5 (faulty load

cell connection)

Page 3

QUICK SET UP AND CALIBRATION USING WEIGHTS

Press the UP or DOWN key for more than 3 seconds to enter the Set-up Menu

Enter the

Setup menu SET UP

3

4Please note that if you wish to change any values in these sections, you have to first

press the recessed enable switch (top left corner of unit)

0T

1

Set the Display

Upper Limit SET THE DISPLAY OVER RANGE LIMIT. (MAXIMUM VALUE +99,999)

Use this menu point to define the display maximum value. If the displayed weight

exceeds this maximum, the display will then show over range (dashes at the top of

the display). This can be useful to indicate when a weight value is outside a normal

range. Use the UP/DOWN & MOVE RIGHT keys to set the maximum display value

and store by pressing the enter key. Factory default value 10,000. Please note that

the zero button is limited to ±2% of the display maximum value. See section 1.1

Zero Button Enable for more details

0T

1

Set the Display

Lower Limit SET THE DISPLAY UNDER RANGE LIMIT. (MINIMUM VALUE -99,999).

Use this menu point to define the display minimum value. If the displayed

weight drops below this minimum, the display will then show under range

(dashes at the bottom of the display) This can be useful to indicate when a

weight value is outside a normal range. Use the UP/DOWN & MOVE RIGHT

keys to set the minimum display value and store by pressing the enter key.

Factory default value -9,999.

0T

1

Set the Display

Step Size SELECT THE DISPLAY STEP SIZE. (1, 2, 5, 10, 20, 50, 100, 200 or 500)

Use this menu point to select the display step size. The minimum display step

size is 1 [Factory default] up to a maximum step size of 500. If for example you

select a display step size of 50, the display will show 000, 050, 100, 150 etc as

the weight value increases. Using higher step sizes will give a more stable

weight display but with a lower resolution. Use the UP or DOWN key to select

the required display step size. Press the enter key to store.

QUICK SET UP AND CALIBRATION USING WEIGHTS (Continues on the next page)

(Also see calibration examples on page 22)

Page 4

QUICK SET UP AND CALIBRATION USING WEIGHTS (Continued)

SELECT THE DECIMAL POINT POSITION ON THE DISPLAY (0, 0.0, 0.00,

0.000 or 0.0000)

Use the UP or DOWN key to set the required decimal point position on the

display. The factory default is no decimal place [0]. The maximum number of

places after the decimal point is four [0.0000]. Please note that this parameter

should be set before the span calibration value [menu 2.1] is entered. Setting

or moving the decimal point position after calibration will not alter the

display resolution

0T

1

Set the Decimal

Point position

0T

1

Calibrate the

Zero point CALIBRATE OR ADJUST THE ZERO POINT (CONVENTIONAL WEIGHING

SYSTEM)

Use this menu point to store a new calibration zero. The display will show the

actual input signal in mV/V. Ensure that the weighing system is at zero or has

no load on it. Pressing the Enter key will store the new zero.

0T

1

Define the Span

Calibration weight

DEFINE THE SPAN CALIBRATION WEIGHT

This menu point defines the span calibration value. If you intend to calibrate the

span conventionally using weights, you need to enter the value of the span test

weight you intend to apply here. Use the UP/DOWN & MOVE RIGHT keys to

enter the span test weight. For example if you intend to calibrate with 3000 kg

of weight (stepping in 1 kg steps with no decimal places) then enter 3000 here.

0T

1

Calibrate the Span CALIBRATE THE SPAN (CONVENTIONAL WEIGHING SYSTEM)

Use this menu point to calibrate the span using weights. Apply the span test

weight [the test weight value is defined in menu 2.1] to the weighing system.

The display will show the actual signal from the weighing system .

Press the Enter key to store the new span value.

in mV/V

Page 5

QUICK SET UP AND CALIBRATION USING THE LOAD CELL mV/V SENSITIVITY

QUICK SET UP AND CALIBRATION USING LOAD CELL mV/V (Continues on the next page)

Press the UP or DOWN key for more than 3 seconds to enter the Set-up Menu

Enter the

Setup menu SET UP

3

4Please note that if you wish to change any values in these sections, you have to first

press the recessed enable switch (top left corner of unit)

0T

1

Set the Display

Upper Limit SET THE DISPLAY OVER RANGE LIMIT. (MAXIMUM VALUE +99,999)

Use this menu point to define the display maximum value. If the displayed weight

exceeds this maximum, the display will then show over range (dashes at the top of

the display). This can be useful to indicate when a weight value is outside a normal

range. Use the UP/DOWN & MOVE RIGHT keys to set the maximum display value

and store by pressing the enter key. Factory default value 10,000. Please note that

the zero button is limited to ±2% of the display maximum value. See section 1.1

Zero Button Enable for more details

0T

1

Set the Display

Lower Limit SET THE DISPLAY UNDER RANGE LIMIT. (MINIMUM VALUE -99,999).

Use this menu point to define the display minimum value. If the displayed

weight drops below this minimum, the display will then show under range

(dashes at the bottom of the display) This can be useful to indicate when a

weight value is outside a normal range. Use the UP/DOWN & MOVE RIGHT

keys to set the minimum display value and store by pressing the enter key.

Factory default value -9,999.

0T

1

Set the Display

Step Size SELECT THE DISPLAY STEP SIZE. (1, 2, 5, 10, 20, 50, 100, 200 or 500)

Use this menu point to select the display step size. The minimum display step

size is 1 [Factory default] up to a maximum step size of 500. If for example you

select a display step size of 50, the display will show 000, 050, 100, 150 etc as

the weight value increases. Using higher step sizes will give a more stable

weight display but with a lower resolution. Use the UP or DOWN key to select

the required display step size. Press the enter key to store.

(Also see calibration examples on page 23)

Page 6

QUICK SET UP AND CALIBRATION USING LOAD CELL mV/V (Continued)

SELECT THE DECIMAL POINT POSITION ON THE DISPLAY (0, 0.0, 0.00,

0.000 or 0.0000)

Use the UP or DOWN key to set the required decimal point position on the

display. The factory default is no decimal place [0]. The maximum number of

places after the decimal point is four [0.0000]. Please note that this parameter

should be set before the span calibration value [menu 2.1] is entered. Setting

or moving the decimal point position after calibration will not alter the

display resolution

0T

1

Set the Decimal

Point position

0T

1

Calibrate the

Zero point CALIBRATE OR ADJUST THE ZERO POINT.(CONVENTIONAL WEIGHING

SYSTEM)

Use this menu point to store a new calibration zero. The display will show the

actual input signal in mV/V. Ensure that the weighing system is at zero or has

no load on it. Pressing the Enter key will store the new zero.

0T

1

Enter the weighing

system capacity

DEFINE THE SPAN CALIBRATION VALUE.

This menu point defines the span calibration value. If you intend to calibrate the

span using the mV/V readings from the load cell certificates, you should enter

the total load cell capacity here. So for example if you have a weighing system

consisting of 3 off 2000 kg load cells you should enter 6000 (3 x 2000) here.

Use the UP/DOWN & MOVE RIGHT keys to enter the total load cell capacity.

0T

1

Enter the weighing

system mV/V value CALIBRATE THE SPAN FROM THE LOAD CELL mV/V READING

If you are calibrating the weighing system without weights, use this menu point

to enter the mV/V value for the weighing system. The weighing system mV/V

value can be derived from the load cell test data. Normally a test data

certificate is provided with each load cell stating amongst other things, the

Output at Rated Load (ORL) in mV/V. In single load cell applications the

weighing system mV/V value will be the load cell ORL value. In applications

using more than one load cell, the weighing system mV/V value will be the

average of the individual load cells ORLs. Normally load cells used in multi-cell

applications have matched or rationalized ORLs typically 2 or 3 mV/V for

example. So if you have 4 load cells in your system, each 1000 kg capacity

with ORLs of 2 mV/V then the weighing system capacity will be 4000 kg at 2

mV/V. Use the UP/DOWN & MOVE RIGHT keys to enter the weighing system

ORL reading in mV/V. The reading should be in the format x.xxxx e.g 2.0000 if

the ORL is 2 mV/V exactly. The corresponding weighing system capacity should

be entered in menu point 2.1

Page 7

ENTERING THE SETUP MENU

Press the UP or DOWN key for more than 3 seconds to enter the Set-up Menu

SET UP

ENABLE ZERO BUTTON / SET ZERO TRACK RANGE / CALIBRATE ZERO POINT

ENABLE ZERO BUTTON / CALIBRATE ZERO POINT (Continues on next page)

0T

1

0T

1

T

T

T

2

3

3

3

4

4

4

ZERO BUTTON ENABLE (± 20% of DISPLAY MAX) / ZERO TRACK RANGE (± 255 d).

Use this menu point to enable or disable the zero button and to set the zero track range. If this parameter is set to

0 then the zero button and the zero tracking will be disabled. If this parameter is set between 1 and 255, the zero

button will be enabled and the zero track range will be equal to the number set. Use the UP/DOWN & MOVE

RIGHT keys to set the zero track range and store by pressing the enter key. Factory default value 00001.

In the normal weighing mode, the zero button will set a new zero providing that the displayed weight value is less

than ± 20% of the maximum display value (see Menu 3.1 o). So if for instance, the maximum display value is set

to 10,000 [Factory Default] the maximum display value that can be set to zero using this button is ± 20% of 10,000

i.e. ± 2000 display counts. If you try to set a new zero which is greater than ± 20% of the display maximum you will

see the error message ‘Err 2’ on the display. To overcome this problem you can either re-calibrate the zero using

Menu 1.2 or 1.3 or you can increase the display maximum (Menu 3.1.o) to allow higher offsets to be corrected.

If this parameter is set between 1 and 255 (not 0) then the zero tracking will also be enabled. The value set will be

equivalent to the zero track range (plus and minus around zero). The zero tracking will work on the no load or zero

value of the weighing system to bring it back to exactly 0. If for instance the no load value or zero of the weighing

system comes back to 5d when unloaded (due to product build up in the weigh hopper for instance), the zero

tracking will automatically reduce this zero offset back to zero providing that the zero is stable (no motion) and is

inside the zero track range. The no load output will be reduced at a fixed rate of 0.4 d/second until the value

reaches 0. The value of d is equal to the display step size.

0T

1

If you wish to change any values in these sections, you have to first press the recessed enable switch (top left corner of unit)

0T

1

Page 8

SET UPAND CALIBRATE SPAN FUNCTION / DISPLAY INPUT SIGNAL IN mV/V - See Next Page

ENABLE EX MODE (WIDER TOLERANCE BAND ON SENSE INPUT)

Use this menu point to enable (E - on) a wider tolerance on the sense input. This will

allow the EZE30 to be used with electrical safety barriers (hazardous area

applications) which reduce the sense voltage. If the sense voltage is too low ‘Err 5’

(load cell fault) will be displayed. There are 2 possible settings E - off (factory default)

standard sense input tolerance or E - on wider sense input tolerance enabled.

0T

1

0T

1

ENABLE ZERO BUTTON / CALIBRATE ZERO POINT (Continued)

CALIBRATE THE ZERO POINT FROM THE LOAD CELL mV/V READING

Use this menu point to enter a mV/V value at which you want the weighing system to read zero. Use the

UP/DOWN & MOVE RIGHT keys to set the mV/V reading. Pressing the Enter key will store this value. The

weighing system will now read zero at this mV/V reading.

0T

1

T

T

T

2

0T

1

3

4

3

4

3

4

3

4

CALIBRATE OR ADJUST THE ZERO POINT.(CONVENTIONAL WEIGHING SYSTEM)

Use this menu point to store a new calibration zero. The display will show the actual input signal in mV/V

from the load cells. Ensure that the weighing system is at zero or has no load on it. Pressing the Enter key

will store the new zero.

0T

1

T

T

T

2

0T

1

0T

1

T

T

T

2ENABLE STORING OF TARE VALUE (NON-VOLATILE)

Use this menu point to enable (t - on) the storing of the tare value in memory. This

will prevent the loss of the tare value in the event of a power failure. There are 2

possible settings t - off (factory default) tare storing not enabled or t - on tare storing

enabled.

0T

1

0T

1

T

T

T

2

T

T

T

2

Page 9

SET UPAND CALIBRATE SPAN / DISPLAY INPUT SIGNAL IN mV/V

0T

1

3

4

0T

1

T

T

T

2

3

4

0T

1DEFINE THE SPAN CALIBRATION VALUE.

This menu point defines the span calibration value. If you intend to calibrate the span conventionally using

weights, you need to enter the value of the span test weight you intend to apply here. Use the UP/DOWN &

MOVE RIGHT keys to enter the span test weight. For example if you intend to calibrate with 3000 kg of

weight (stepping in 1 kg steps with no decimal places) then enter 3000 here. If however, you intend to

calibrate with 3000 kg and you want to step in 0.1 kg steps you must enter 30000 here. The decimal point

can be added later in menu 3.3.

If you intend to calibrate the span using the mV/V readings from the load cell certificates, you should enter

the total load cell capacity here. Use the UP/DOWN & MOVE RIGHT keys to enter the total load cell

capacity. For example if you have a weighing system consisting of 3 off 2000 kg load cells and you want to

display in 1 kg steps with no decimal places, you should enter 6000 (3 x 2000) here. If however you want to

display 6000 kg in 0.1 kg steps you should enter 60000 here. The decimal point can be added later in menu

3.3.

T

T

T

2CALIBRATE THE SPAN. (CONVENTIONAL WEIGHING SYSTEM)

Use this menu point to calibrate the span using weights. Apply the span test weight [the test weight value is

defined in menu 2.1] to the weighing system. The display will show the actual signal from the weighing

system . Press the Enter key to store the new span value.in mV/V

0T

1

0T

1

3

4

If you wish to change any values in these sections, you have to first press the recessed enable switch (top left corner of unit)

SET UPAND CALIBRATE SPAN /DISPLAY INPUT SIGNAL IN mV/V (Continues on next page)

Page 10

DISPLAY THE INPUT SIGNAL IN mV/V

Use this function to view the raw signal coming from the load cells into the EZE30. The display shows the

load cell signal directly in mV/V. This can be useful when either commissioning or fault finding.

0T

1

T

T

T

2

0T

1

CALIBRATE THE SPAN FROM THE LOAD CELL mV/V READING

If you are calibrating the weighing system without weights, use this menu point to enter the mV/V value for

the weighing system. The weighing system mV/V value can be derived from the load cell test data. Normally

a test data certificate is provided with each load cell stating amongst other things, the Output at Rated Load

(ORL) in mV/V. In single load cell applications the weighing system mV/V value will be the load cell ORL

value. In applications using more than one load cell, the weighing system mV/V value will be the average of

the individual load cells ORLs. Normally load cells used in multi-cell applications have matched or

rationalized ORLs typically 2 or 3 mV/V for example. So if you have 4 load cells in your system, each 1000

kg capacity with ORLs of 2 mV/V then the weighing system capacity will be 4000 kg at 2 mV/V.

Use the UP/DOWN & MOVE RIGHT keys to enter the weighing system ORL reading in mV/V. The reading

should be in the format x.xxxx e.g 2.0000 if the ORL is 2 mV/V exactly. The corresponding weighing system

capacity should be entered in menu point 2.1

0T

1

T

T

T

2

0T

1

3

4

SET UP THE DISPLAY - See Next Page

SET UPAND CALIBRATE SPAN /DISPLAY INPUT SIGNAL IN mV/V (Continued)

3

4

Page11

SET UP THE DISPLAY (Continues on next page)

0T

1

T

T

T

2

0T

1

0T

1

T

T

T

2

0T

1

SET THE DISPLAY OVER RANGE LIMIT. (MAXIMUM VALUE +99,999)

Use this menu point to define the display maximum value. If the displayed weight

exceeds this maximum, the display will then show over range (dashes at the top of the

display). This can be useful to indicate when a weight value is outside a normal range.

Use the UP/DOWN & MOVE RIGHT keys to set the maximum display value and store by

pressing the enter key. Factory default value 10,000. Please note that the zero button is

limited to ±2% of the display maximum value. See section 1.1 Zero Button Enable for

more details

0T

1

T

T

T

2SET THE DISPLAY UNDER RANGE LIMIT. (MINIMUM VALUE -99,999).

Use this menu point to define the display minimum value. If the displayed weight

drops below this minimum, the display will then show under range (dashes at the

bottom of the display) This can be useful to indicate when a weight value is outside a

normal range.

Use the UP/DOWN & MOVE RIGHT keys to set the minimum display value and store by

pressing the enter key. Factory default value -9,999.

0T

1

3

4

3

4

3

4

T

T

T

2

0T

1SELECT THE DISPLAY STEP SIZE. (1, 2, 5, 10, 20, 50, 100, 200 or 500)

Use this menu point to select the display step size. The minimum display step size is 1 [Factory default] up

to a maximum step size of 500. If for example you select a display step size of 50, the display will show 000,

050, 100, 150 etc as the weight value increases. Using higher step sizes will give a more stable weight

display but with a lower resolution.

Use the UP or DOWN key to select the required display step size. Press the enter key to store.

0T

1

3

4

SET UP THE DISPLAY (OVER/UNDER RANGE LIMITS, STEP SIZE & DECIMAL POINT, LOGIC I/O STATUS)

If you wish to change any values in these sections, you have to first press the recessed enable switch (top left corner of unit)

Page 12

T

T

T

2

FILTER SETTINGS & NO MOTION - See Next Page

LOGIC INPUTS & OUTPUT STATUS (SHOW CONTINUOUSLY)

When this parameter is selected the status of the inputs and outputs are continuously

displayed on the main weight display. No weight values are displayed in this mode. This

can be useful when commissioning the system as you can see the exact status of the

inputs and outputs continuously.

0T

1

LOGIC INPUTS & OUTPUTS STATUS (NO INDICATION)

When this parameter is selected there will be no indications on the main display of the

status of the logic inputs and outputs. The weight value is shown continuously

irrespective of the logic inputs and outputs status [Factory Default]

0T

1

0T

1

3

4

LOGIC INPUTS & OUTPUT STATUS (ONLY SHOW WHEN I/O STATE CHANGES)

When this parameter is selected, there will be a momentary indication on the main

display of the logic input/output status ONLY when the status changes. The weight value

display is temporarily disabled whilst the logic input/output status is shown momentarily.

The display then reverts back to displaying the weight value. This can be useful when

commissioning the system as you can see the exact status of the inputs and outputs as

and when they change.

0T

1

3

4

SET UP THE DISPLAY (Continued)

3

4

T

T

T

2

0T

1

0T

1

SELECT THE DECIMAL POINT POSITION ON THE DISPLAY (0, 0.0, 0.00, 0.000 or 0.0000)

Use the UP or DOWN key to set the required decimal point position on the display. The factory default is no

decimal place [0]. The maximum number of places after the decimal point is four [0.0000]. Please note that

this parameter should be set before the span calibration value [menu 2.1] is entered. Setting or moving the

decimal point position after calibration will not alter the display resolution

3

4

Page 13

ANALOGUE OUTPUT SETTINGS - See Page 16

FILTER SETTINGS & NO MOTION

0T

1

SELECT THE TYPE OF LOW PASS FILTER REQUIRED. (TYPE Fir [Mode 1] or IIr [Mode 0])

Use the UP/DOWN keys to select the type of filter used. Type IIR should be used where heavy damping is

required. Type FIR should be used where high speed is required. Default setting IIR. See Filter Level (FL)

versus Cut off Frequency tables on the next page.

0T

1

T

T

T

2

0T

1

0T

1

T

T

T

2SET THE STABILISATION TIME. (RANGE 0 - 65535)

Use the UP/DOWN & MOVE RIGHT keys to set the time in milliseconds within which

the weight value displayed has to remain within the no motion range, for the weigh to

be considered ‘stable’. Default value 1000

0T

1

3

4

0T

1

0T

1

T

T

T

2SELECT THE LOW PASS FILTER CUT OFF FREQUENCY. (RANGE 0 - 8)

Use the UP/DOWN keys to select the cut off frequency required. A setting of 0 will disable the filter in both FIR &

IIR modes. A setting of 1 provides the least filtering and a setting of 8 provides the most. Default setting 4. See

Filter Level (FL) versus Cut off Frequency tables on the next page.

3

4

3

4

SELECT THE NUMBER OF FILTERED READINGS AVERAGED (RANGE 0 - 7)

Use the UP or DOWN key to select the number of readings from the IIR or FIR filter that will be averaged.

Default setting 0 (off). See Update Rates versus Number of Samples table on the next page.

0T

1

T

T

T

2

0T

1

3

4

T

T

T

2

0T

1

0T

1

T

T

T

2

SET THE NO MOTION RANGE. (RANGE 0 - 65535)

Use the UP/DOWN & MOVE RIGHT keys to set the no motion range. Fluctuations in

weight values inside this range will be considered as ‘stable’. Default value 1

0T

1

3

4

Page 14

FILTER SETTINGS TABLES & UPDATE RATES (NUMBER OF READINGS AVERAGED)

Filter Setting

1

2

3

4

5

6

7

8

3dB Cut-off

Frequency in Hz

18

8

4

3

2

1

0.5

0.25

Settling time to

0.1% in ms.

55

122

242

322

482

963

1923

3847

Damping in dB

At 300Hz

57

78

96

104

114

132

149

164

Update Rate in

Samples/sec.

600

600

600

600

600

600

600

600

MENU 4.1-4.2 FILTER TYPE IIR (MODE 0) SECOND ORDER GAUSSIAN LOW

Filter Setting

1

2

3

4

5

6

7

8

3dB Cut-off

Frequency in Hz

19.7

9.8

6.5

4.9

3.9

3.2

2.8

2.5

Settling time to

0.1% in ms.

47

93

140

187

233

280

327

373

20dB Damping

@ frequency Hz

48

24

16

12

10

8

7

6

40dB Damping

@ frequency Hz

64

32

21

16

13

11

9

8

Damping in dB

in Stopband

>90

>90

>90

>90

>90

>90

>90

>90

Stopband in Hz

>80

>40

>26

>20

>16

>13

>11

>10

Update Rate in

Samples/sec.

600

300

200

150

120

100

85.7

75

MENU 4.1- 4.2 FILTER TYPE FIR (MODE 1) COMBINATION LOW PASS

Update Rates

No. of Samples

0

1

2

4

3

8

4

16

6

64

7

128

5

32

1

2

MENU 4.3 UPDATE RATE - DEFINES HOW MANY MEASUREMENTS ARE USED TO CALCULATE AN AVERAGE

This section refers to Menu points 4.1 - 4.3.

Setting the filter level to 0 will disable the filters

in either modes (0 or 1). The Gaussian filter type

IIR (mode 0) filter level 4 is the factory default.

This provides a slower response with a high

level of damping. The FIR filter type provides

better response where high speed is required.

Both types of filter can be enhanced further by

using the UR parameter Menu 4.3 to average

between 1 (UR=0) and 128 (UR=7)

measurements.

Page 15

LOGIC INPUTS - See Next Page

ANALOGUE OUTPUT (4-20 mA) SETTINGS

0T

1

3

4

0T

1

0T

1

T

T

T

2SET THE WEIGHT VALUE AT WHICH 4 mA IS SENT

Use the UP/DOWN & MOVE RIGHT keys to set the weight value at which 4 mAis sent. This typically will be set to

zero, so that when the display reads zero weight, 4 mA will be sent down the analogue output. If you want the

analogue output to run between 0 mA and 20 mA, you will need to calculate what the 4 mA value will be and store

it here. To do this take the difference between the weight value at 20 mAand the weight value at 0 mAand divide it

by the 20 and multiply by 4. For example if the analogue output is 0 - 20 mA for 0 - 1000 kg then the 4 mAvalue will

be 1000/20*4 = 200.

3

4

0T

1

T

T

T

2TEST MODE FOR THE CURRENT OUTPUT (Range 0mA - 21mA)

Use the UP or DOWN & MOVE RIGHT key to set a current value in mA, which will be sent down the

analogue output, independent of the load applied to the weighting system. If values below 0mA are selected

the DAS will send its minimum value (0mA) until a value within its normal range is selected. Similarly if

values above 21mA are selected then the DAS will send its maximum value (21mA) until a value within its

normal range is selected.

0T

1

SET THE WEIGHT VALUE AT WHICH 20 mA IS SENT.

Use the UP/DOWN & MOVE RIGHT keys to set the weight value at which 20 mA is sent. Typically this will

be set to the weight value at which you want 20 mA to be sent down the analogue output.

0T

1

T

T

T

2

0T

1

3

4

SET THE ANALOGUE OUTPUT BASE (groS, nEt [Default], PEA, AUEr, HoLd, PP, UALL, dISP, oFF)

groS

nEt PEA

AUEr HOLd

oFF

Use the UP or DOWN key to set which parameter the analogue output will follow : - the analogue

output follows the Gross value: - the analogue output follows the Net value : - the analogue output

follows the Peak value: - the analogue output follows the Average value:

-

the analogue output is switched off.

- the analogue output

follows the Hold value: - the analogue output follows the Peak to Peak value: - the analogue

output follows the Valley value: - the analogue output follows the value shown on the display:

PP UALL

dISP

0T

1

T

T

T

2

0T

1

3

4

Page 16

LOGIC INPUTS

0T

1

T

T

T

2

3

4

3

4

0T

1

0T

1SET THE FUNCTION OF LOGIC INPUT 1. (RANGE 00 - 14)

Use the UP/DOWN keys to set the function of logic input 1.

.00 - No function. .01 - Remote Zero. .02 - Remote Tare. .03 - Up Arrow Key. .04 - Down

Arrow Key. .05 - Trigger the average function. .06 - Display average value. .07 - Display

peak value. .08 - Clear peak, valley and hold values. .09 - Display hold value. .10 - Display

peak to peak value. .11 - Display valley value. .12 - Lock keyboard. .13 - Trigger hold

function. .14 - Set tare and reset/clear the peak/valley/hold values. Please ensure that

this logic input is NOT high when setting or changing the function of this logic input.

0T

1

T

T

T

2

3

4

T

T

T

2NOT IN USE

T

T

T

2

NOT IN USE

T

T

T

2

READ THE STATUS OF LOGIC INPUT 1. (In1 0 or In1 1)

Read the status of Logic Input 1. If the input is high the display reads In1 1. If the input is

low the display reads In1 0. In order for the status of this logic input to be read correctly,

you must set the function (as defined in section 6.1.1) to 0 [No function]

T

T

T

2

3

4

3

4

0T

1

LOGIC INPUTS (Continues on next page)

0T

1

0T

1

0T

1

3

4

T

T

T

2

3

4

SET THE FUNCTION OF LOGIC INPUT 2. (RANGE 00 - 14)

Use the UP/DOWN keys to set the function of logic input 2.

.00 - No function. .01 - Remote Zero. .02 - Remote Tare. .03 - Up Arrow Key. .04 - Down

Arrow Key. .05 - Trigger the average function. .06 - Display average value. .07 - Display

peak value. .08 - Clear peak, valley and hold values. .09 - Display hold value. .10 - Display

peak to peak value. .11 - Display valley value. .12 - Lock keyboard. .13 - Trigger hold

function. .14 - Set tare and reset/clear the peak/valley/hold values. Please ensure that

this logic input is NOT high when setting or changing the function of this logic input.

Page 17

LOGIC OUTPUTS - See Next Page

LOGIC INPUTS (Continued)

READ THE STATUS OF LOGIC INPUT 2. (In2 0 or In2 1)

Read the status of Logic Input 2. If the input is high the display reads In2 1. If the input is

low the display reads In2 0. In order for the status of this logic input to be read correctly,

you must set the function (as defined in section 6.2.1) to 0 [No function]

T

T

T

2T

T

T

2

0T

1

NOT IN USE

T

T

T

2

0T

1

0T

1

0T

1

T

T

T

2

3

4

T

T

T

2NOT IN USE

T

T

T

2

NOT IN USE

T

T

T

2

READ THE STATUS OF LOGIC INPUT 3. (In3 0 or In3 1)

Read the status of Logic Input 3. If the input is high the display reads In3 1. If the input is

low the display reads In3 0. In order for the status of this logic input to be read correctly,

you must set the function (as defined in section 6.3.1) to 0 [No function]

T

T

T

2

0T

1

T

T

T

2

T

T

T

2

NOT IN USE

3

4

3

4

3

4

3

4

SET THE FUNCTION OF LOGIC INPUT 3. (RANGE 00 - 14)

Use the UP/DOWN keys to set the function of logic input 3.

.00 - No function. .01 - Remote Zero. .02 - Remote Tare. .03 - Up Arrow Key. .04 - Down

Arrow Key. .05 - Trigger the average function. .06 - Display average value. .07 - Display

peak value. .08 - Clear peak, valley and hold values. .09 - Display hold value. .10 - Display

peak to peak value. .11 - Display valley value. .12 - Lock keyboard. .13 - Trigger hold

function. .14 - Set tare and reset/clear the peak/valley/hold values. Please ensure that

this logic input is NOT high when setting or changing the function of this logic input.

Page 18

DATACOMS - See Next Page

LOGIC OUTPUTS

0T

1

0T

1

T

T

T

2

0T

1

0T

1

0T

1

SET WEIGHT VALUE AT WHICH LOGIC OUTPUT 1 SWITCHES

Use the UP/DOWN and MOVE RIGHT keys to set the weight value

(SETPOINT) at which logic output1 changes state (switches on/off)

SET WHETHER LOGIC OUTPUT 1 SWITCHES ON OR OFF

Use the UP/DOWN keys to set whether logic output 1 switches on or

off at the set point.

0T

1

0T

1

T

T

T

2

T

T

T

2

T

T

T

2SET THE HYSTERESIS VALUE ON THE SETPOINT FOR LOGIC OUTPUT 1

Use the UP/DOWN and MOVE RIGHT keys to set the hysteresis value on logic output 1

setpoint.

0T

1

0T

1

T

T

T

2

0T

1

0T

1

SET LOGIC OUTPUT 1 BASE (groS, nEt, PEA, AUEr, HOLd, PP, UALL, Error, oFF)

groS nEt

PEA

Use the UP or DOWN key to define the parameter, based on which Logic Output 1 will

operate : - operates when the Gross value reaches or exceeds the setpoint : -

operates when the net value reaches or exceeds the setpoint. - operates when the

peak value reaches or exceeds the setpoint. - operates when the average value

reaches or exceeds the setpoint. - operates when the Hold value reaches or

exceeds the setpoint. - operates when the peak to peak value reaches or exceeds

the setpoint. - operates when the Valley value reaches or exceeds the setpoint.

- operates when Err 4 or Err 5 occurs. - Logic Output 1 is disabled.

AUEr

HOLd

PP

UALL

Error oFF

0T

1

T

T

T

2

0

T

1

TEST MODE FOR LOGIC OUTPUT 1 (0 - Off, 1 - ON)

Use the UP or DOWN key to switch on (1) or off (0) Logic Output 1.

3

4

3

4

3

4

3

4

3

4

AS PER SECTIONS 7.1 BUT FOR LOGIC OUTPUT 2

T

T

T

2

AS PER SECTIONS 7.1 BUT FOR LOGIC OUTPUT 3

T

T

T

2

3

4

3

4

Page 19

Table of contents

Other Tecsis Amplifier manuals