Tectrix Climbmax 150 User manual

•

•

C/imbMax

MADE

IN

U.S.A.

Everyone

Should

Be

This

Well

Built

THIS

MANUAL,

(INCLUDING

PART

NUMBERS),

APPLIES

TO

THE

'INSTITUTIONAL

STYLE'

CUMBMAX,

SERIAL

NUMBER

166190

AND

Up,

MANUFACTURED

JULY

1993

OR

LATER.

FOR

OPERATION

AND

PART

NUMBER

INFORMATION

FOR

CUMBMAXMODEL

150

(SERIAL

NUMBERS

PRIOR

TO

166190)

REFER

TO

THE

CUMBMAX

MODEL

150

OWNERS

MANUAL

(part

number

03001)

.

Page

1

Table

of

Contents

1.

Assembly

Instructions

4

2.

Setup

Mode

7

3.

Test

Mode

10

MAINTENANCE

4.

Cleaning

11

5.

Drive

Cable

/

Clevis

Bearing

&

Bolt

Replacement

11

6.

Pedal/Cable

Clevis

Lubrication

11

7.

Clutch

Bearing,

Chain,

Crank

Arm

&

Parallel

Shafts

Lubrication

12

8.

Friction

Belt

Replacement

/

Switch

Ends

13

9.

Pedal

Bearing

Inspection

13

TROUBLESHOOTING

GUIDE

10.

'Can't

Slow

Down'

or

'Control

Lost

14

11.

'No

Slack"

17

12.

'No

Brake'

17

13.

'Memory

Lost'

18

14.

A

Numeral

Appears

In

The

Interval

Display

18

15.

Some

LED's

(lights)

Are

Out

On

The

Display

And

There

Is

No

Beep

When

The

Power

Switch

Is

Turned

On

19

16.

All

LED's

(lights)

Are

Out

On

The

Display

And

There

Is

No

Beep

When

The

Power

Switch

Is

Turned

On

19

17.

Reset

Problem

20

18.

A

Key

On

The

Display

Console

Doesn't

Work

21

19.

Pedal

Squeak

21

20.

A

Pedal

Doesn't

Return

To

The

Top

or

A

Pedal

Won't

Go

Down

21

21.

No

Speed

Control

And

No

Error

Message

Is

Displayed

22

22.

Speed

Control

is

Jerky

or

Varies

Speed

22

23.

The

ClimbMax

Won't

Accelerate

To

Top

Speed

23

24.

Cannot

Select

Group

Race

24

PART

REPLACEMENT

25.

Cover

26

26.

Motor

Assembly

27

27.

Slack

Switch

Adjustment

28

28.

Friction

Belt

Replacement

28

29.

Power

Board

Assembly

28

30.

Display

Console

29

31.

Display

Cable

30

32.

RPM

Assembly

:.:

31

33.

Switch

Plate

Assembly

31

34.

Spring

/

Drive

Cable

Replacement

32

35.

Flywheel

Assembly

33

36.

Crank

/

Pedal

Removal

From

Frame

34

37.

Crank

Arm

Assembly

34

38.

Parallel

Arm

Assembly

35

39.

Pedal

Assembly

36

40.

Transmission

Assembly

37

Page

2

•

41.

FIGURES

40

Description

Paqe#

1

Attaching

the

Hand

Rail

Upright

40

2

Attaching

the

Hand

Rails

41

3

Connecting

the

Display

Cable

42

4

Power/Communications

Connectors

43

5

Brake

and

Motor

Assembly

44

6

Parallel

Arm

Assembly

45

7

Spring

Cable

Routing

46

8

Flywheel

Assembly

47

9

Crank

Arm

Assembly

48

10

Pedal

Assembly

49

11

Transmission

Assembly

50

12

Display

Overlay

51

13

Display

Board

Component

Layout

52

14

Display

Board

Schematic

(page

1

of

2)

53

15

Display

Board

Schematic

(page

2

of

2)

54

•

16

Power

Board

Assembly

55

17

Power

Board

Schematic

56

•

Page

3

1.

ASSEMBLY

INSTRUCTIONS

The

ClimbMax

is

quite

easy

to

assemble

and

should

take

around

30

minutes

to

complete.

It

will

require

the

following

common

tools:

1/4"

Allen

Wrench,

3/16"

Allen

Wrench,

Medium

Phillips

Screwdriver

(#2)

7/16"

socket

and

ratchet

1/2"

socket

and

ratchet

Unpacking

your

new

ClimbMaJC

Remove

the

Chassis

base

from

the

pallet

by

removing

the

clamps

and

screws

(use

the

7/16"

socket

and

ratchet).

Remove

all

the

parts

from

the

box

and

check

that

they

are

all

present.

CAUTION:

Do

not

at

any

time

lean

the

display

console

upright

tube

up

on

its

end.

The

display

ribbon

cable

could

be

damaged.

Parts

List

#

Part

Name

Part

#

atv

1

Main

Chassis

Base

(WHT,

BLK,

GRAY)

Color

1

2

Hand

Rail

Upright

1

3

Hand

Rails

(WHT,

BLt<,

GRAY)

Color

2

Ship

Kit

(Contains

the

Following)

1

4

Right

Hand

Rail

Clamp

53003

1

5

Left

Hand

Rail

Clamp

53006

1

6

5/16"-18

X

2"

Socket

Screws

41011

2

7

5/16"

Flat

Washers

53017

2

8

5/16"

Lock

Washer

53018

2

9

1/4"-20

X

1/14"

Socket

Screws

41012

4

10

1/4"

Flat

Washer

53019

4

11

#10-24

x

1/2"

Self-Tapping

Screw

41006

6

12

Hand

Rail

End

Caps

40006

2

13

Telephone

Cable

61033

1

14

Termination

Plug

61026

1

15

Power

Cord

14007

1

16

Owners

Manual

13010

1

17

Reading

Rack

61029

1

18

Maintenance

Manual

03012

1

19

Friction

Belt

with

Button

Hole

61077

1

Page

4•

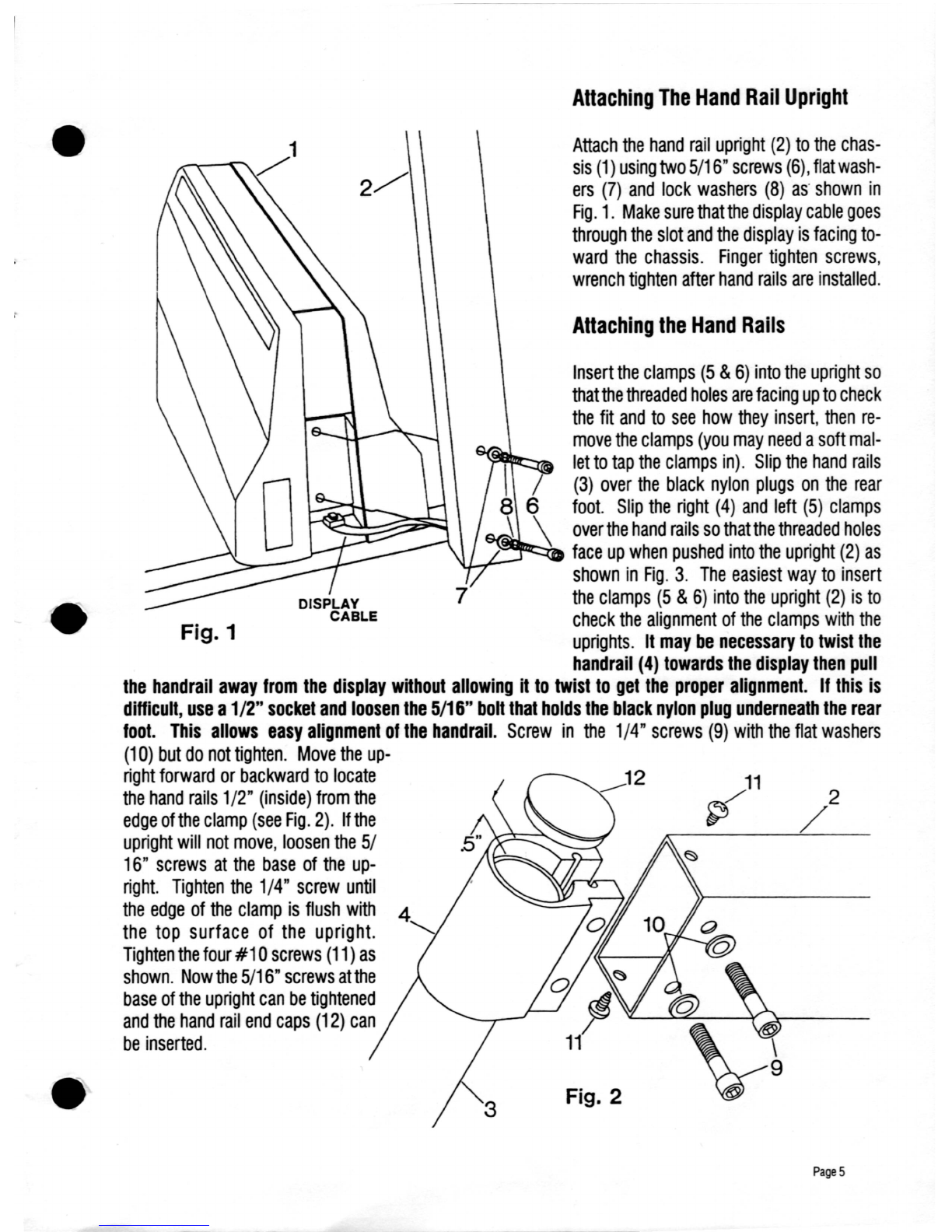

Attaching

The

Hand

Rail

Upright

2

/

11

~

Attaching

the

Hand

Rails

Attach

the

hand

rail

upright

(2)

to

the

chas-

sis

(1)

using

two

5/16"

screws

(6),

flat

wash-

ers

(7)

and

lock

washers

(8)

as'

shown

in

Fig.

1.

Make

sure

that

the

display

cable

goes

through

the

slot

and

the

display

is

facing

to-

ward

the

chassis.

Finger

tighten

screws,

wrench

tighten

after

hand

rails

are

installed.

Fig. 2

Fig. 1

Insert

the

clamps

(5

&

6)

into

the

upright

so

that

the

threaded

holes

are

facing

up

to

check

the

fit

and

to

see

how

they

insert,

then

re-

move

the

clamps

(you

may

need

a

soft

mal-

let

to

tap

the

clamps

in).

Slip

the

hand

rails

(3)

over

the

black

nylon

plugs

on

the

rear

foot.

Slip

the

right

(4)

and

left

(5)

clamps

over

the

hand

rails

so

that

the

threaded

holes

-~~~

face

up

when

pushed

into

the

upright

(2)

as

..

~-

shown

in

Fig.

3.

The

easiest

way

to

insert

the

clamps

(5

&

6)

into

the

upright

(2)

is

to

check

the

alignment

of

the

clamps

with

the

uprights.

It

may

be

necessary

to

twist

the

handrail

(4)

towards

the

display

then

pull

the

handrail

away

from

the

display

without

allowing

it

to

twist

to

get

the

proper

alignment.

If

this

is

difficult,

use

a1/2"

socket

and

loosen

the

5/16"

boh

that

holds

the

black

nylon

plug

underneath

the

rear

foot.

This

allows

easy

alignment

of

the

handrail.

Screw

in

the

1/4"

screws

(9)

with

the

flat

washers

(10)

but

do

not

tighten.

Move

the

up-

right

forward

or

backward

to

locate

the

hand

rails

1/2"

(inside)

from

the

edge

ofthe

clamp

(see

Fig.

2).

If

the

upright

will

not

move,

loosen

the

5/

16"

screws

at

the

base

of

the

up-

right.

Tighten

the

1/4"

screw

until

the

edge

of

the

clamp

is

flush

with

the

top

surface

of

the

upright.

Tighten

the

four

#1

0

screws

(11)

as

shown.

Now

the

5/16"

screws

atthe

base

of

the

upright

can

be

tightened

and

the

hand

rail

end

caps

(12)

can

be

inserted.

•

•

•

Page

5

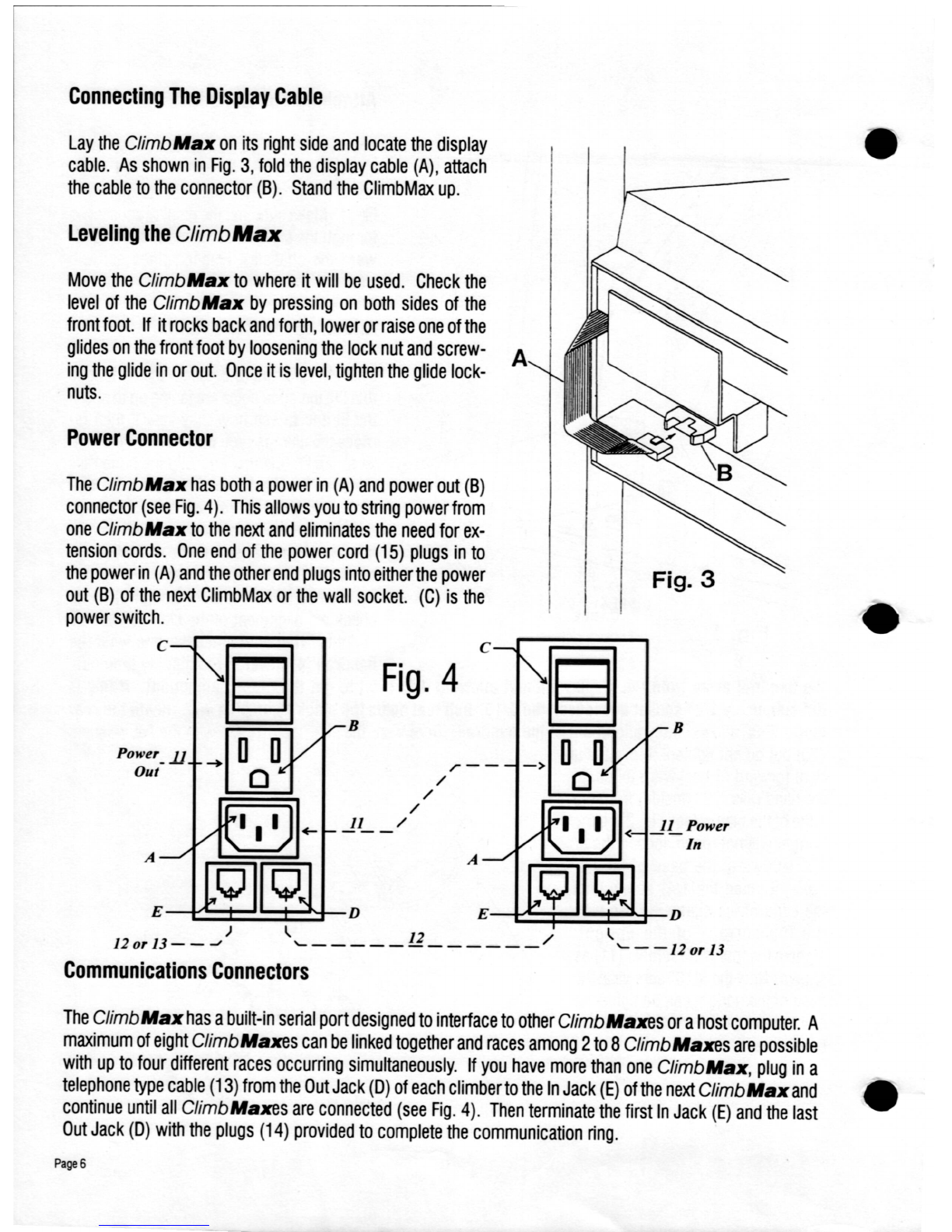

Connecting

The

Display

Cable

B

Fig. 3

<

~LPower

In

c

A

r--

/

/

/

/

Fig.

4

11

B

Power_lJ

Out

A

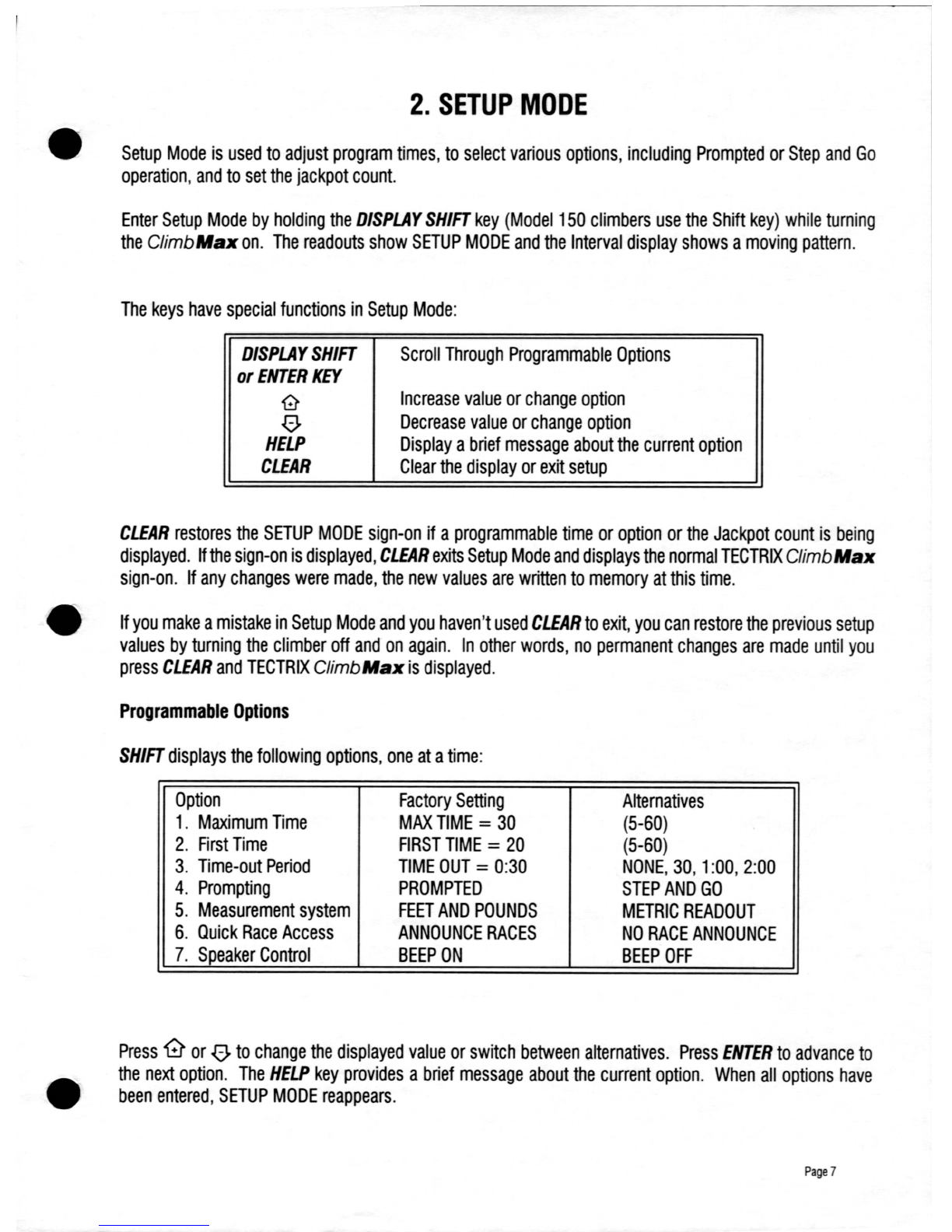

The

Climb

Max

has

both

a

power

in

(A)

and

power

out

(B)

connector

(see

Fig.

4).

This

allows

you

to

string

power

from

one

Climb

Max

to

the

next

and

eliminates

the

need

for

ex-

tension

cords.

One

end

of

the

power

cord

(15)

plugs

in

to

the

power

in

(A)

and

the

other

end

plugs

into

either

the

power

out

(B)

of

the

next

ClimbMax

or

the

wall

socket.

(C)

is

the

power

switch.

c

Move

the

ClimbMax

to

where

it

will

be

used.

Check

the

level

of

the

Climb

Max

by

pressing

on

both

sides

of

the

front

foot.

If

it

rocks

back

and

forth,

lower

or

raise

one

of

the

glides

on

the

front

foot

by

loosening

the

lock

nut

and

screw-

A

ing

the

glide

in

or

out.

Once

it

is

level,

tighten

the

glide

lock-

nuts.

Power

Connector

Leveling

the

ClimbMaJC

Lay

the

Climb

Max

on

its

right

side

and

locate

the

display

cable.

As

shown

in

Fig.

3,

fold

the

display

cable

(A),

attach

the

cable

to

the

connector

(B).

Stand

the

ClimbMax

up.

)

120r

13-

_-oJ

E

---1~:::t:::~:::t:::~-D

E---1~=i=~:±::t--D

~

12

/

~

'-------------

'---120r13

Communications

Connectors

The

Climb

Max

has

a

built-in

serial

port

designed

to

interface

to

other

ClimbMaxes

or

a

host

computer.

A

maximum

of

eight

ClimbMaxes

can

be

linked

together

and

races

among

2

to

8ClimbMaxes

are

possible

with

up

to

four

different

races

occurring

simultaneously.

If

you

have

more

than

one

ClimbMax,

plug

in

a

telephone

type

cable

(13)

from

the

Out

Jack

(D)

of

each

climber

to

the

In

Jack

(E)

of

the

next

Climb

Max

and

continue

until

all

ClimbMaxes

are

connected

(see

Fig.

4).

Then

terminate

the

first

In

Jack

(E)

and

the

last

Out

Jack

(D)

with

the

plugs

(14)

provided

to

complete

the

communication

ring.

Page

6

•

2.

SETUP

MODE

Setup

Mode

is

used

to

adjust

program

times,

to

select

various

options,

including

Prompted

or

Step

and

Go

operation,

and

to set

the

jackpot

count.

Enter

Setup

Mode

by

holding

the

DISPLAY

SHIFT

key

(Model

150

climbers

use

the

Shift

key)

while

turning

the

ClimbMaJC

on.

The

readouts

show

SETUP

MODE

and

the

Interval

display

shows

a

moving

pattern.

The

keys

have

special

functions

in

Setup

Mode:

DISPLAY

SHIFT

or

ENTER

KEY

G

o

HELP

CLEAR

Scroll

Through

Programmable

Options

Increase

value

or

change

option

Decrease

value

or

change

option

Display

a

brief

message

about

the

current

option

Clear

the

display

or

exit

setup

CLEAR

restores

the

SETUP

MODE

sign-on

if

a

programmable

time

or

option

or

the

Jackpot

count

is

being

displayed.

If

the

sign-on

is

displayed,

CLEAR

exits

Setup

Mode

and

displays

the

normal

TECTRIX

ClimbMaJC

sign-on.

If

any

changes

were

made,

the

new

values

are

written

to

memory

at

this

time.

•

If

you

make

a

mistake

in

Setup

Mode

and

you

haven't

used

CLEAR

to

exit,

you

can

restore

the

previous

setup

values

by

turning

the

climber

off

and

on

again.

In

other

words,

no

permanent

changes

are

made

until

you

press

CLEAR

and

TECTRIX

ClimbMaJC

is

displayed.

Programmable

Options

SHIFT

displays

the

following

options,

one

at

a

time:

Option

Factory

Setting

Alternatives

1.

Maximum

Time

MAX

TIME

=

30

(5-60)

2.

First

Time

FIRST

TIME

=

20

(5-60)

3.

Time-out

Period

TIME

OUT

=

0:30

NONE,

30,

1

:00,

2:00

4.

Prompting

PROMPTED

STEP

AND

GO

5.

Measurement

system

FEET

AND

POUNDS

METRIC

READOUT

6.

Quick

Race

Access

ANNOUNCE

RACES

NO

RACE

ANNOUNCE

7.

Speaker

Control

BEEP

ON

BEEP

OFF

•

Press

'0

or

0.

to

change

the

displayed

value

or

switch

between

alternatives.

Press

ENTER

to

advance

to

the

next

option.

The

HELP

key

provides

a

brief

message

about

the

current

option.

When

all

options

have

been

entered,

SETUP

MODE

reappears.

Page

7

PROGRAMMABLE

TIMES

1.

MAXTIME

The

length

of

the

longest

workout

can

be

adjusted

in

5-minute

increments

from

5

to

60.

2.

FIRST

TIME

The

number

of

minutes

first

offered

after

weight

has

been

entered

also

ranges

from

5

to

60.

It

can't

be

longer

than

the

maximum

time.

3.

TIME

OUT

The

length

of

time

that

the

climber

retains

its

settings

before

resetting

and

displaying

the

sign-on

message

if

the

user

quits

stepping.

The

period

can

be

set

to

thirty

seconds,

one

minute,

two

minutes,

or

NONE,

which

keeps

it

from

timing

out.

OPTIONS

4.

PROMPTING

Prompted

Prompting

begins

when

you

press

a

key

or

when

you

start

climbing.

5.

MEASUREMENT

SYSTEM

Feet

and

Pounds

Distance

is

displayed

in

feet

and

weight

is

entered

in

pounds.

6.

QUICK

RACE

ACCESS

Announce

Races

Idle

climbers

display

a

message

during

a

race

countdown,

and

anyone

can

join

by

just

pressing

ENTER.

7.

SPEAKER

CONTROL

Beep

On

The

speaker

operates.

Page

8

Step

and

Go

If

you

start

climbing

without

press-

ing

a

key,

the

climber

starts

in

Manual.

If

you

press

a

key

first,

prompting

begins.

Pressing

ENTER

in

Manual

always

begins

the

prompt-

in

sequence.

Metric

Readouts

Distance

is

displayed

in

meters

and

weight

is

entered

in

kilograms

No

Race

Announce

No

special

handling

for

races.

Beep

Off

Turns

the

speaker

off

completely.

•

•

•

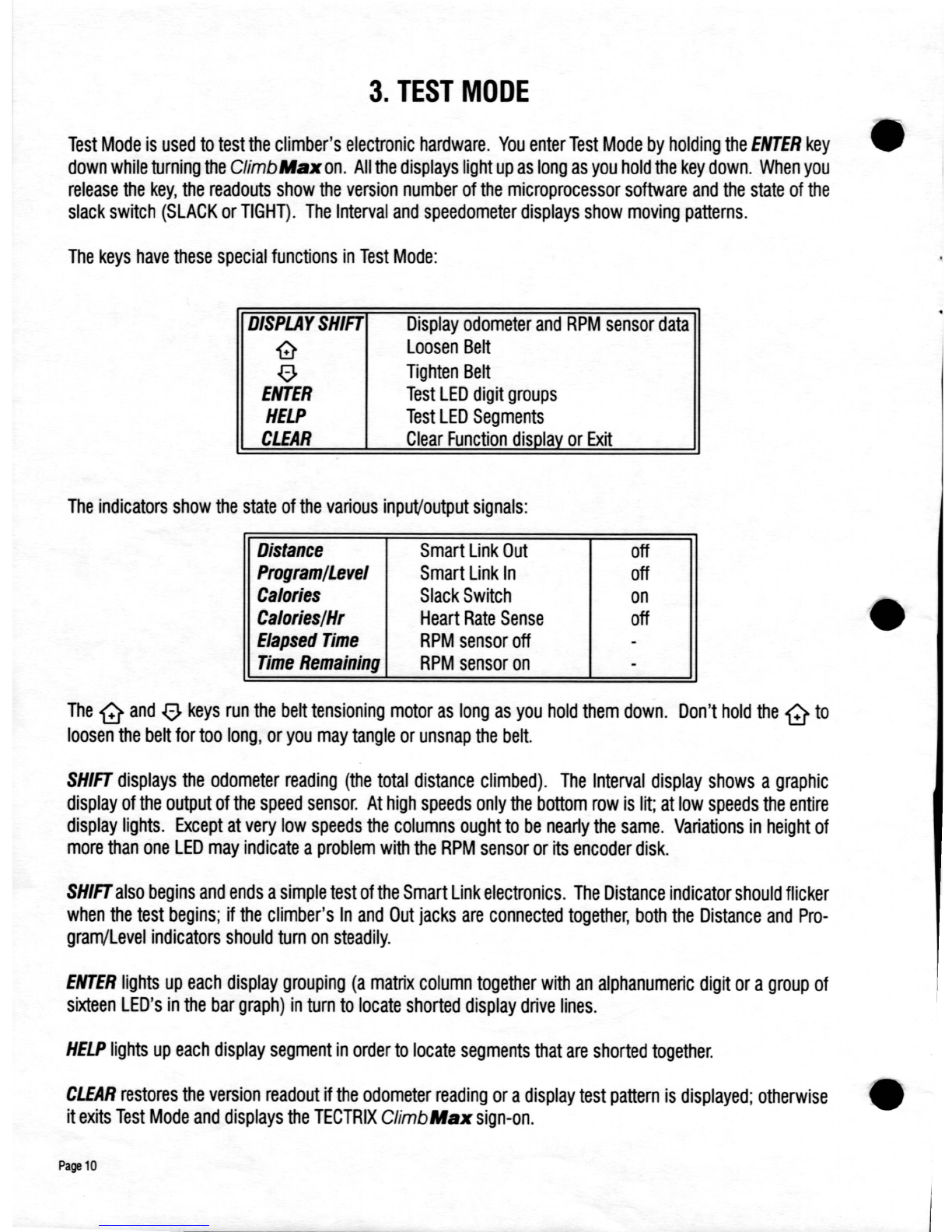

3.

TEST

MODE

Test

Mode

is

used

to

test

the

climber's

electronic

hardware.

You

enter

Test

Mode

by

holding

the

ENTER

key

down

while

turning

the

ClimbMaJlon.

All

the

displays

light

up

as

long

as

you

hold

the

key

down.

When

you

release

the

key,

the

readouts

show

the

version

number

of

the

microprocessor

software

and

the

state

of

the

slack

switch

(SLACK

or

TIGHT).

The

Interval

and

speedometer

displays

show

moving

patterns.

The

keys

have

these

special

functions

in

Test

Mode:

DISPLAY

SHIFT

'0

00

ENTER

HELP

CLEAR

Display

odometer

and

RPM

sensor

data

Loosen

Belt

Tighten

Belt

Test

LED

digit

groups

Test

LED

Segments

Clear

Function

disolav

or

Exit

The

indicators

show

the

state

of

the

various

inpuVoutput

signals:

Distance

Smart

Link

Out

off

Program/Level

Smart

Link

In

off

Calories

Slack

Switch

on

Calories/Hr

Heart

Rate

Sense

off

Elapsed

Time

RPM

sensor

off

-

Time

Remaining

RPM

sensor

on

-

The

G

and

00

keys

run

the

belt

tensioning

motor

as

long

as

you

hold

them

down.

Don't

hold

the

G

to

loosen

the

belt

for

too

long,

or

you

may

tangle

or

unsnap

the

belt.

SHIFT

displays

the

odometer

reading

(the

total

distance

climbed).

The

Interval

display

shows

a

graphic

display

of

the

output

of

the

speed

sensor.

At

high

speeds

only

the

bottom

row

is

lit;

at

low

speeds

the

entire

display

lights.

Except

at

very

low

speeds

the

columns

ought

to

be

nearly

the

same.

Variations

in

height

of

more

than

one

LED

may

indicate

a

problem

with

the

RPM

sensor

or

its

encoder

disk.

SHIFT

also

begins

and

ends

a

simple

test

of

the

Smart

Link

electronics.

The

Distance

indicator

should

flicker

when

the

test

begins;

if

the

climber's

In

and

Out

jacks

are

connected

together,

both

the

Distance

and

Pro-

gram/Level

indicators

should

turn

on

steadily.

ENTER

lights

up

each

display

grouping

(a

matrix

column

together

with

an

alphanumeric

digit

or

a

group

of

sixteen

LED's

in

the

bar

graph)

in

turn

to

locate

shorted

display

drive

lines.

HELP

lights

up

each

display

segment

in

order

to

locate

segments

that

are

shorted

together.

CLEAR

restores

the

version

readout

if

the

odometer

reading

or

a

display

test

pattern

is

displayed;

otherwise

it

exits

Test

Mode

and

displays

the

TECTRIX

ClimbMaJl

sign-on.

Page

10

MAINTENANCE

•

This

section

covers

maintenance

that

should

be

regularly

performed

to

minimize

wear

and

to

keep

the

Climb

Max

in

top

operating

order.

The

following

recommendations

are

for

heavy

institutional

use

(8

or

more

hours

daily,

20

thousand

feet

climbed)

and

can

be

scaled

down

accordingly.

Required

Maintenance

4.

5.

6.

7.

8.

Maintenance

Procedure

Cleaning

Drive

Cable

/

Clevis

Replacement

Pedal/Cable

Clevis

Lubrication

Clutch

Bearing

Lube,

Chain,

Crank

Arm

&

Parallel

Shaft

Lube

Friction

Belt

Replacement

/

Switch

Ends

Period

Daily

8-10

Months

Weekly

Yearly

3-6

Months

3

Months

Feet

Climbed

5

Million

7

Million

3

Million

2

Million

•

•

4.

Cleaning

Keeping

the

Climb

Max

clean

helps

to

prevent

rust

and

dirt

from

getting

into

the

moving

parts.

The

Climb

Max

should

be

wiped

down

at

least

once

a

day

and

club

members

should

be

encouraged

to

wipe

off

the

climber

after

they

use

it.

Most

household

cleaners

are

fine

to

use

on

the

ClimbMaxexceptforthose

that

have

abrasives.

Solvents

should

not

be

used

on

any

plastic

parts.

A

stiff

scrub

brush

works

well

for

cleaning

dirt

off

the

pedals.

Scratches

or

chips

in

the

paint

should

be

touched

up

to

prevent

rust.

5.

Drive

Cable

/

Clevis

Bearing

&

Bolt

Replacement

Drive

Cable

-

Fig.

9,

Part

#12

and

Fig.

7,

Part

#

2.

Clevis

Bearing

&

Bolt

-

Fig.

9,

Part

# 4

.

The

drive

cables

and

clevis

bearing

&

bolt

should

be

replaced

every

8

to

10

months

or

5

million

feet

climbed.

The

cables

wear

internally,

darkening

with

use.

A

black

cable

is

a

worn

cable

and

will

even-

tually

break

(see

section

34

for

replacement).

The

clevis

bearing

&

bolt

should

be

inspected

when

replacing

a

drive

cable.

A

corroded

bolt

will

quickly

wear

through

the

bearing.

This

will

result

in

damage

to

the

crank

arm

leading

to

an

expensive

repair

(see

section

37

for

replacement).

6.

Pedal/Cable

Clevis

Lubrication

Pedal

Parallel

Arm

Bearing

(see

Fig.

10,

Part

#4)

Cable

Clevis

Bearing

(see

Fig.

9,

Part

#4)

A

few

drops

of

light

machine

oil

(example:

'TRI-FLO'

or

3-in-1

oil)

each

week

will

improve

wear

life.

Make

sure

to

wipe

off

excess

oil

as

it

will

attract

dirt.

Inspect

the

clevis

action.

The

clevis

must

swivel

freely.

Page

11

7,

Clutch

Bearing,

Chain,

Crank

Arm

&

Parallel

Shafts

Lubrication

7,1

Clutch

Bearing

Lubrication

Remove

the

cover.

See

Fig,

11,

item

#7,

Apply

a

few

drops

of

90

weight

gear

oil

only,

in

the

hole,

CRANK

ARIi

ASSEIiBLY

Fi,ure 9

CIANI

All

ASSY.

::~~~

:=:1

,

--

-,.

I

CRAll:

MIl

-

LfFI

5«]1. 1

2

CRAll:

MIl

-

R(()lT

5«]15 1

]1',I-I..,..a112"

_De;

44021

4

•

],111".15132",112"

_De;

_ 2

(I/(}Wf

10

ALIQI

WIDI

IIITOI

I.

ORllIE

CAIl.E,

mil

U1IU1IC'

COIPO/fIltTS

,

--

-,

5

IlETADe;

RIll; -

;zs..,

4l106

6l'a1-],III"

uve

lPR. WASIQ 401l'

7

PMIT

lIW'T

51111l

8

l'a1I2"

•.

IO

lKl.

WASIQ

40031

9.48"

•.

lIr

lI'Il.lJj WASIQ

4n!9

10

],III"xlW

Q..EY(S

lIJIEl

5~16

II

5116'-18

NI'lII:

lIlT

Q]]]

12

DRive

CAIl.E

51015

13

CRAll:

...

I.IF8!

5Oal2

7.2

Chain

Lubrication

Remove

the

cover

(see

section

25),

Use

a

throwaway

rag

to

wipe

the

sludge

from

the

chain,

Apply

a

roller

chain

lubricant

(example:

CRC

brand

part

number

03050)

evenly

and

wipe

the

chain

to

remove

the

excess,

14

15

17

PEDAL

ASSEMBLY

-

61063

1

NIl.,.

Nlrl

I

PBlAl.

-

1IAOt.

,

AICIlIZED

52011

231. I

718

I

SIB

IlEAl!II(j

~

3

112

I

1!lI32

I

112

IlEAl!II(j

...cI2S

•

ltll

I

15132

I

112

IlEAl!II(j

"'4026

5

PEOAl

llJf'EI!

SllXl3

Page

12

<

......

.......

PEDAL

ASSEMBLY

Fiture

10

OTHER

UFERENCE

COIPONENTS

1

NIl.,.

Nlrl

6ltll-16

lEX

FUICiE

lIlT

.2043 I

731. I

1-5116

I.lBl

WASIO

OJ31 2

831.

WAVE

SI'l!II(j

WASIO

~

I

931. E;/11(j

.3201

I

10

SIB-18.Jo\1l

lIlT

.20~

I

II

SIB

SEIlI!A

TEll

un

WASIO

Ol2ll

1

12

RIGHT

CJ!N«

Al!Il

-

IIAOtIIEll

54015

I

13

ltll-18 I1-118 lIl.T .1043 I

I.

ltll

QJMD

SI'l!II(j

wASIEl!

~

I

IS

ltll

DIll

TE

IIIDlZE

wASIEl!

44027

I

16

PBlAl.

SHoIFT

5I

048

I

J7

PAI!ALla.

Al!Il

52021

I

•

•

•

PARALLEL

ARM

ASSEMBLY

Fi:ure 6

5

PARALLEL

ARI

ASSY.

-

61032

I

NIr

lUll

1111

I

trf.

I

PARAlLEl

ARM

5202\

2

2

314.

\51\6 •

314

lEAl/II(;

4400!1

2

OTHER

REFERENCE

CO.PONEIiTS

I,.,-

NIl

I

3

314.

1111

NYLl)l

W~

0)25

4

4

314

WAVE

WAS!£R

4lXXJ5

\

5PARAllR

ARM

SHAFT

5\172

\

6

314

E-I1II(;

43201

2

7.3

Crank

Arm

(see

Fig.

9)

&

Parallel

(see

Fig.

6)

Shafts

Lubrication

Apply

a

few

drops

of

light

machine

oil

(example:

'TRI-FLO'

or

3-in-1

oil)

on

the

pedal

bearing

surfaces.

Wipe

off

any

excess

so

that

it

does

not

attract

dirt.

At

the

base

of

each

crank

arm

is

a

lubrication

point.

Apply

three

squirts

of

a

polymer

grease

(example:

Clenesco

Polylube')

to

each

crank

arm

lubrication

point.

Apply

one

small

squirt

between

the

two

parallel

arms.

8.

Friction

Belt

Replacement

/

Switch

Ends

The

friction

belt

should

be

replaced

when

the

speed

control

degrades

(see

sections

21

&

22).

In

many

cases

the

belt

can

be

reversed

to

extend

its

life

because

the

major

wear

is

at

the

end

that

attaches

to

the

motor

pulley.

Inspect

the

flywheel

surface

and

remove

any

flywheel

deposits

with

Scotch

Brite

or

sandpa-

per.

9.

Pedal

Bearing

Inspection

Pedal/Parallel

Arm

Bearing

-

Fig.

10,

Part

#4

The

3/8"

bearings

should

be

checked

annually

or

after

7

million

feet

and

replaced

if

needed

(see

section

39).

Page

13

TROUBLESHOOTING

GUIDE

This

guide

will

help

to

locate

a

problem

in

the

ClimbAfax.

Troubleshooting

is

much

easier

with

spare

parts.

We

highly

recommend

the

purchase

of

a

Dealer

Service

Kit

as

this

guide

refers

to

spare

parts

in

some

sections.

DISPLAY

ERRORS

10.

CAN'T

SLOW

DOWN

or

CONTROL

LOST

11.

NO

SLACK

12.

NO

BRAKE

13.

MEMORY

LOST

14.

A

Numeral

Appears

in

the

Interval

Display

OTHER

PROBLEMS

15.

Some

LED's

(lights)

Are

Out

On

The

Display

And

There

Is

No

Beep

When

The

Power

Is

Turned

On

16.

All

LED's

(lights)

Are

Out

On

The

Display

And

There

Is

No

Beep

When

The

Power

Is

Turned

On

17.

Reset

Problem

18.

A

Key

On

The

Display

Console

Doesn't

Work

19.

Pedal

Squeak

20.

A

Pedal

Doesn't

Return

To

The

Top

or

A

Pedal

Won't

Go

Down

21.

Speed

Control

Is

Jerky

Or

Varies

Speed

22.

No

Speed

Control

And

No

Error

Message

Is

Displayed

23.

The

ClimbAfax

Won't

Accelerate

To

Top

Speed

24.

Cannot

Select

Group

Race

DISPLAY

ERRORS

The

first

thing

to

do

if

you

get

a

Display

Error

is

to

press

CLEAR.

Sometimes

the

errors

'CAN'T

SLOW

DOWN'

or

'CONTROL

LOST'

may

be

displayed

in

conjunction

with

other

errors

such

as

'NO

BRAKE'

or

'

NO

SLACK.'

If

this

is

the

case,

follow

the

'CAN'T

SLOW

DOWN'

or

'CONTROL

LOST'

error.

The

following

is

a

list

of

things

to

check

which

can

cause

'CAN'T

SLOW

DOWN'

or

'CONTROL

LOST':

10.

'CAN'T

SLOW

DOWN'

or

'CONTROL

LOST'

10.1

Friction

Belt

Disconnect

the

power

cord

from

the

Climb

Max

and

remove

the

cover

(see

section

25).

See

if

the

friction

belt

has

worn

through

or

is

disconnected.

If

this

has

happened

see

section

28,

Friction

Belt

Replacement.

Page

14

10.2

Electrical

Cables

•

If

the

belt

is

ok,

look

for

any

loose

connections

or

wires

around

the

power

board

or

motor

assemblies.

10.3

Test

Motor

Put

the

climber

in

the

Test

Mode

(see

section

3)

and

run

the

motor

in

both

directions

by

using

the

arrow

keys.

If

the

motor

is

not

running

refer

to

section

10.5.

10.4

Motor

Runs

If

the

motor

runs,

check

that

the

motor

shaft

is

not

spinning

inside

the

pulley

on

which

the

belt wraps

and

that

the

motor

does

not

have

a

stripped

gearbox.

If

the

motor

shaft

is

spinning

inside

the

pulley,

remove

the

motor

assembly

(see

section

26)

and

tighten

the

set

screws

(see

Fig.

5).

Make

sure

that

one

of

the

set

screws

is

on

the

flat

portion

of

the

shaft.

To

verify

that

the

motor

does

not

have

a

stripped

gearbox,

look

at

the

armature

shaft

on

the

outside

of

the

motor.

If

the

armature

shaft

on

the

outside

of

the

motor

spins

but

the

output

shaft

and

belt

pulley

do

not,

the

gearbox

is

stripped.

Replace

the

motor

assembly.

10.5

Motor

Doesn't

Run

•

•

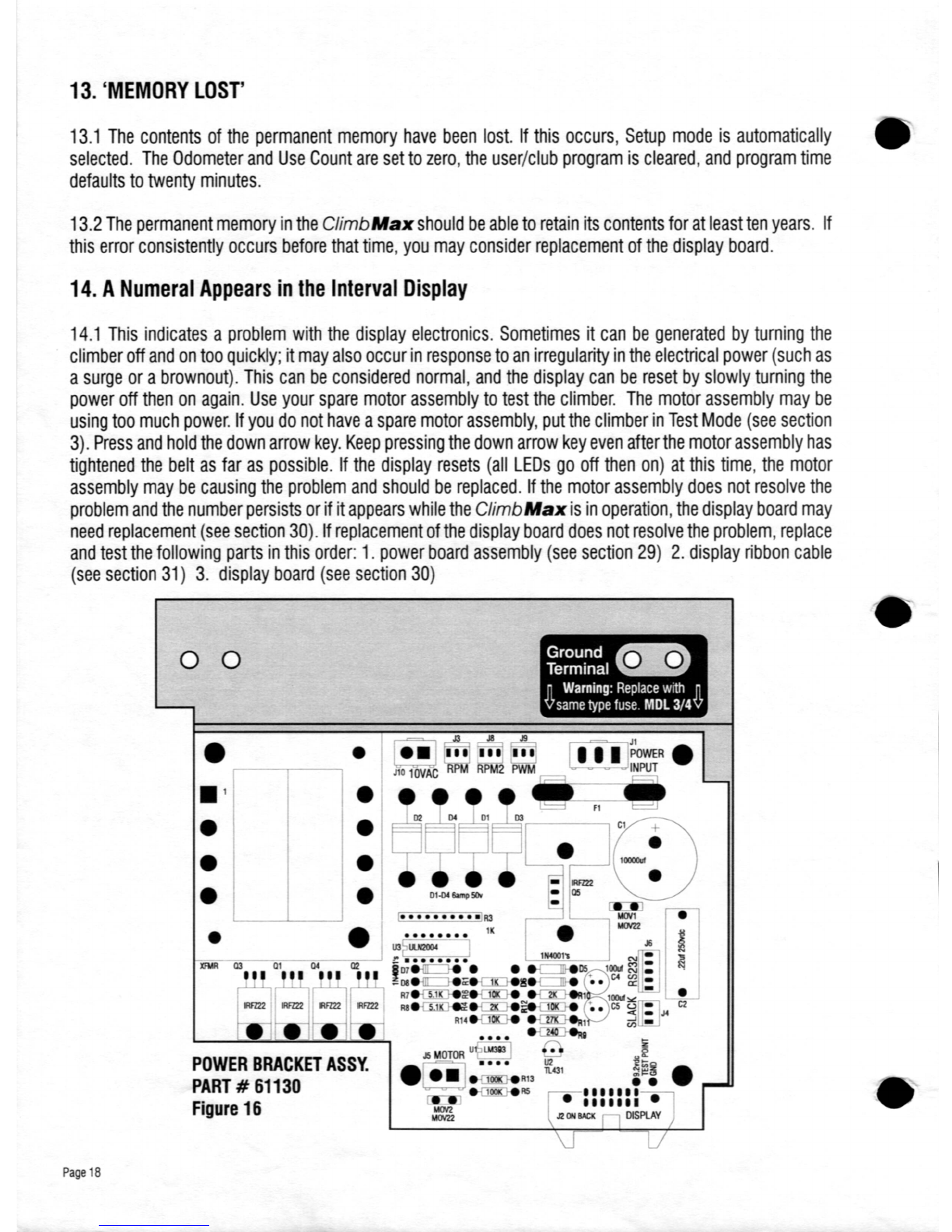

Unplug

the

motor

cable

from

the

power

board

assembly

(see

Fig.

16).

Plug

in

the

spare

motor

assembly

and

see

if it

will

run

in

both

directions.

If

the

spare

motor

assembly

runs,

replace

the

original

motor

assembly.

If

you

do

not

have

a

spare

motor

assembly,

use

an

analog

(not

digital)

meter

(observe

polarity!)

to

verify

voltage

at

connector

J5

on

the

power

board.

(see

Fig.

16).

Place

the

climber

in

the

Test

Mode

(see

section

3)

.

Measure

the

voltage

across

the

two

pins

of

J5

while

an

assistant

presses

the

up

&

down

arrow

keys

on

the

console.

J5

voltage

with

no

load

should

read

approximately

13

to

14

volts

DC.

If

you

do

read

the

expected

voltage,

replace

the

motor

assy.

If

the

voltage

is

incorrect

replace

each

of

these

parts

in

the

following

order:

1.

power

board

assembly

(see

section

29),

2.

display

ribbon

cable

(see

section

31),

3.

display

board

(see

section

30)

.

Page

15

'NO

SLACK'

&

'NO

BRAKE'

ERRORS

'NO

SLACK'

&

'NO

BRAKE'

refers

to

the

slack

switch

located

on

the

motor

assembly

(see

Fig.

5).

The

purpose

of

the

slack

switch

is

to

tell

the

microprocessor

(located

on

the

display

board)

whether

the

belt

is

loose

or

tight

on

the

flywheel.

When

the

Climb

Max

is

turned

on

or

after

someone

stops

climbing

the

microprocessor

uses

the

slack

switch

to

initialize

the

belt

position.

The

following

is

the

initialization

process:

MOTOR

ASSEMBLY

-

61015

,,mlUl

,m,

I

GEAR

I()TlR

:JiOO5

2

I()T!R

II1ACKET

51021

3

SLACl:

SVJT(H

1ml

4

SLACl:

SVJT(H

AIlJJST

SlOT

-

5

I()TlR

LEADS

V/TlJ!llIO

14042

6

IB.T

Pll.LEY

(5116'

tnE)

46012

7IB.T

Pll.LEY

SCREV

STlfl

41lDi

8IB.T

OCHlR

511155

9IB.T

OCHlR

SCREV

STlfl

41lDi

'OTOR

ASSY.

-

FRONT

VI"

OTHER

REFERENCE

CO.PONENTS

,

NIr..

,lit

1

10

H1I(TJ~

IELl

610n

II

FL

YVtEEl

61005

12

DIS(

51018

13

IIPM

SENSlJ/

ASSY.

61

()4.4

14

SENSD1

INIllJT

AIlJJST

15

SENSD1

FI1lJH

18ACl:

AO.1JST

-

14

16

SlACl:

SVJT(H

ARM

1m7

17

SlACl:

SVJT(H

CAELE

61021

BRAKE

fil'"

5

The

microprocessor

checks

the

status

of

the

slack

switch.

If

the

belt

is

pressed

upon

the

slack

switch

arm,

the

motor

will

loosen

the

belt.

If

after

1.5

seconds

the

slack

switch

is

not

deactivated

the

display

will

show

a

'NO

SLACK'

error.

If

the

belt

is

not

pressed

upon

the

slack

switch

arm,

the

microprocessor

then

commands

the

motor

to

run

slowly

in

the

belt

tightening

direction

until

the

belt

presses

the

slack

switch

arm.

If

after

12

seconds

the

slack

switch

is

not

activated

the

display

will

show

a

'NO

BRAKE'

error.

Once

the

microprocessor

gets

the

signal

from

the

slack

switch

that

the

belt

has

pressed

it

(the

belt

is

tight),

the

microprocessor

runs

the

motor

fast

in

the

belt

loosening

direction

until

the

belt

is

off

the

slack

switch

(this

is

the

loose

point).

If

after

1.5

seconds

the

slack

switch

is

not

deactivated

the

display

will

show

a

'NO

SLACK'

error.

No

error

will

occur

if

you

start

climbing

prior

to

initialization

being

completed.

Page

16

11.

'NO

SLACK"

11.1

Test

Motor

•

Remove

the

cover

(see

section

25).

Put

the

climber

in

the

Test

Mode

(see

section

3)

and

run

the

motor

in

both

directions

by

using

the

arrow

keys.

If

the

motor

is

not

running

refer

to

section

10.5.

11.2

Test

Slack

Switch

Place

the

Climb

Max

in

Test

Mode

(see

section

3).

Watch

the

'CALORIES'

LED

on

the

display

board

while

pressing

the

slack

switch

on

the

motor

assembly.

The

'CALORIES'

LED

should

be

ON

when

the

slack

switch

is

NOT

pressed,

and

the

'CALORIES'

LED

should

go

OFF

when

the

slack

switch

is

pressed.

Pre-serial

number

166190

ClimbMaxes

(Model

150)

require

an

assistant

to

observe

the

'CALORIES'

LED

while

you

press

the

slack

switch.

Current

models

emit

an

audible

tone

in

response

to

the

slack

switch.

(A

status

indicator

also

displays

'SLACK'

or

'TIGHT'

on

the

readouts).

If

the

climber

passes

the

slack

switch

test,

but

displays

a

'NO

SLACK'

error,

the

slack

switch

may

be

out

of

adjustment.

Refer

to

section

27

for

slack

switch

adjustment

procedure.

11.3

Bad

Slack

Switch

If

the

'CALORIES'

LED

(or

audible

tone)

does

not

respond

to

the

slack

switch

as

described

above,

turn

the

climber

off.

Disconnect

the

slack

switch

cable

from

the

power

board

assembly

(see

Fig.

16).

Plug

the

slack

switch

cable

of

the

spare

motor

assembly

into

the

power

board

without

mounting

the

spare

motor

assembly

and

repeat

the

test.

If

the

climber

now

passes

the

slack

switch

test,

replace

the

slack

switch

and

slack

switch

cable.

Otherwise,

plug

the

original

slack

switch

back

in

and

replace

the

following

parts

in

this

order:

1.

display

ribbon

cable

(see

section

31)

2.

power

board

assembly

(see

section

29),

3.

display

board

(see

section

30).

•

12.

'NO

BRAKE'

12.1

Belt

Remove

the

cover

(see

section

25).

See

if

the

friction

belt

has

worn

through

or

is

disconnected.

If

this

has

happened

see

section

28,

Friction

Belt

Replacement.

12.2

Test

Motor

Put

the

climber

in

the

Test

Mode

(see

section

3)

and

run

the

motor

in

both

directions

by

using

the

arrow

keys.

If

the

motor

is

not

running

refer

to

section

10.5.

12.3

Test

Slack

Switch

Test

the

slack

switch

as

described

in

section

11.2.

If

the

climber

passes

the

slack

switch

test,

but

displays

a

'NO

BRAKE'

error,

the

slack

switch

may

be

out

of

adjustment.

Refer

to

section

27

for

slack

switch

adjustment

procedure.

12.4

Slack

Belt

Test

•

If

the

motor

is

running

and

the

slack

switch

is

adjusted

properly

(see

section

11.2)

turn

the

Climb

Max

off

and

on.

Start

climbing

to

100

fVmin

and

stop.

Watch

the

belt

as

the

flywheel

slows.

If

the

motor

assembly

unwinds

an

exces-

sive

amount

of

belt,

check

for

friction

belt

wear

and

belt

residue

on

the

flywheel

surface.

If

there

is

considerable

wear

and

residue,

replace

or

flip

the

belt

end

for

end

and

use

Scotch

Brite

or

sandpaper

to

remove

the

residue.

If

the

motor

passes

the

motor

test

(see

section

10.4

and

12.2)

and

all

prior

tests

have

been

completed

but

the

motor

still

gives

a

poor

response

in

operation,

replace

the

motor

assembly.

Page

17

,-----------------

- -

--------

13.

'MEMORY

LOST'

13.1

The

contents

of

the

permanent

memory

have

been

lost.

If

this

occurs,

Setup

mode

is

automatically

selected.

The

Odometer

and

Use

Count

are

set to

zero,

the

user/club

program

is

cleared,

and

program

time

defaults

to

twenty

minutes.

13.2

The

permanent

memory

in

the

Climb

Max

should

be

able

to

retain

its

contents

for

at

least

ten

years.

If

this

error

consistently

occurs

before

that

time,

you

may

consider

replacement

of

the

display

board.

14.

A

Numeral

Appears

in

the

Interval

Display

14.1

This

indicates

a

problem

with

the

display

electronics.

Sometimes

it

can

be

generated

by

turning

the

climber

off

and

on

too

quickly;

it

may

also

occur

in

response

to

an

irregularity

in

the

electrical

power

(such

as

a

surge

or

a

brownout).

This

can

be

considered

normal,

and

the

display

can

be

reset

by

slowly

turning

the

power

off

then

on

again.

Use

your

spare

motor

assembly

to

test

the

climber.

The

motor

assembly

may

be

using

too

much

power.

If

you

do

not

have

a

spare

motor

assembly,

put

the

climber

in

Test

Mode

(see

section

3).

Press

and

hold

the

down

arrow

key.

Keep

pressing

the

down

arrow

key

even

after

the

motor

assembly

has

tightened

the

belt

as

far

as

possible.

If

the

display

resets

(all

LEOs

go

off

then

on)

at

this

time,

the

motor

assembly

may

be

causing

the

problem

and

should

be

replaced.

If

the

motor

assembly

does

not

resolve

the

problem

and

the

number

persists

or

if it

appears

while

the

Climb

Max

is

in

operation,

the

display

board

may

need

replacement

(see

section

30).

If

replacement

of

the

display

board

does

not

resolve

the

problem,

replace

and

test

the

following

parts

in

this

order:

1.

power

board

assembly

(see

section

29)

2.

display

ribbon

cable

(see

section

31)

3.

display

board

(see

section

30)

POWER

BRACKET

ASSY.

PART

#

61130

Figure

16

Page

18

o0

•

•

•

•

•

• I

Le:-J

II'

.:.,

~

,-----,

J1

0

10VAC

RPM

RPM2

PWM

J5

MOTOR

u

Uotl83

.Le:-J.····

R13

e-ru!~R5

•

•

•

•

1_

OTHER

PROBLEMS

15.

Some

LED's

(lights)

Are

Out

On

The

Display

And

There

Is

A

Beep

When

The

Power

Is

Turned

On

Power

up

in

the

Test

Mode

(see

section

3)

to

check

for

LED's

out.

Replace

the

display

board

(see

section

30)

if

there

are

some

LED's

out.

16.

All

LED's

(lights)

Are

Out

On

The

Display

And

There

Is

No

Beep

When

The

Power

Is

Turned

On

16.1

Blown

Fuse

Remove

the

cover

(see

section

25)

and

check

the

fuse

(11

OVAC

-

MOL

3/4A

250V,

or

220V

-

MOL

1/2A

250V)

located

on

the

power

board

(see

Fig.

16).

Check

the

fuse

for

zero

ohms

(good)

using

a

volt

ohm

meter

(a

visual

check

is

not

reliable).

Usually

a

fuse

doesn't

blow

for

no

reason

so

it

may

blow

again

(because

it

is

a

slow

blow

fuse

it

may

take

up

to

a

minute

to

blow).

If

it

does,

replace

the

fuse

and

unplug

all

of

the

connectors

except

J1

(see

Fig.

16).

If

it

blows

again,

replace

the

power

board

assembly.

If

it

doesn't

blow,

plug

each

connector

back

in

one

at

a

time

to

find

the

part

that

is

causing

the

fuse

to

blow.

Replace

that

part.

16.2

Power

Switch

Test

Check

that

all

wires

are

intact

on

the

switch

plate

and

power

board.

Using

the

volt

ohm

meter,

check

that

the

power

switch

is

supplying

110

volts

AC

to

the

power

board.

Place

the

meter

probes

on

the

black

and

white

wires

on

top

of

the

power

switch

(switch

on

and

power

cord

plugged

in).

CAUTION:

Care

is

required

when

reading

high

voltage.

Do

not

touch

the

two

leads

of

the

volt

ohm

meter

together

during

the

test

as

this

can

create

a

short.

If

no

AC

voltage

is

present

at

the

power

switch

try

a

different

power

cord.

Make

sure

that

110

VAC

is

present

at

the

wall

outlet.

If

there

is

still

no

power,

replace

the

switch

plate

assembly

(see

section

33).

16.3

Power

Board

Test

(see

Fig.

16

&

17)

Check

that

there

is

9.2

+/-.2

volts

DC

at

the

test

points

(labeled

'9.2

VDC'

and

'GND')

located

in

the

right

bottom

corner

of

the

board

(older

versions

of

the

power

board

do

not

have

the

test

points,

voltage

may

be

tested

at

pin

14

on

the

display

connector

(J2)

using

pin

1

(or

the

square

pad)

as

the

ground

reference).

Ifthe

voltage

reading

is

less

than

9

volts,

unplug

the

display

ribbon

cable

at

the

power

board

(J2)

and

read

the

voltage

again.

If

it

is

still

less

than

9

volts,

replace

the

power

board

assembly.

If

the

voltage

is

correct,

replace

and

test

each

of

these

parts

in

the

following

order:

1.

display

ribbon

cable

(see

section

31),

2.

display

board

(see

section

30).

Page

19

17.

Reset

Problem

If

the

display

doesn't

light

when

you

first

switch

power

on,

try

switching

power

off

and

on

slowly

several

times.

The

microprocessor

(located

on

the

display

board)

may

have

had

a

bad

reset

and

hung

up.

A

bad

motor

assembly

may

cause

apparent

display

symptoms.

Examples

include:

1

Intermittent

reset

2.

Oscillating

reset

3.

Temporarily

display

LED's

(lights)

go

out

Such

motors

may

pass

the

motor

power

test

and

provide

acceptable

speed

regulation.

Use

your

spare

motor

assembly

to

test

the

climber.

If

you

do

not

have

a

spare

motor

assembly,

put

the

climber

in

Test

Mode

(see

section

3).

Press

and

hold

the

down

arrow

key.

Keep

pressing

the

down

arrow

key

even

after

the

motor

assembly

has

tightened

the

belt

as

far

as

possible.

If

the

display

resets

(all

LEOs

go

off

and

the

sign-on

prompt

is

displayed)

at

this

time,

the

motor

assembly

may

be

causing

the

problem

and

should

be

replaced.

Even

though

the

motor

assembly

passes

this

test,

it

could

be

the

source

of

the

problem

and

should

be

replaced.

If

the

motor

assembly

does

not

resolve

the

problem

replace

and

test

the

following

parts

in

this

order:

1.

power

board

assembly

(see

section

29)

2.

display

ribbon

cable

(see

section

31)

3.

display

board

(see

section

30)

Irvine,

CaIIfomIa

(BOO)

767-8082

Made

In

U.S.A.

CAUTIO.:

Stop

climbing

If

you

don't

feel

well!

•

Adjust

TIME

&

Enter

•

Select

PROGRAM

&

Enter

•

Adjust

LEVEL

&

Enter

."

..

J

...

,.

,

••

,

,.

Page

20

Table of contents

Other Tectrix Fitness Equipment manuals