TeeJet Legacy 6000 User manual

Legacy 6000

98-05053 R2

i

TABLE OF CONTENTS

CHAPTER 1 - INTRODUCTION ..................................................................................1

SYSTEM FEATURES...................................................................................................1

CAN BUS - VERSATILITY AND VALUE.......................................................................2

System Components............................................................................................3

Dual Control Module.....................................................................................3

Swath XL Lightbar ........................................................................................3

Switch Function Module ...............................................................................4

CAN Switchbox ............................................................................................4

Input Status Module .....................................................................................5

FieldPilot Module..........................................................................................5

SWATH MANAGER 5 (SM5) ........................................................................................6

LEGACY 6000 CONFIGURATIONS.............................................................................6

CHAPTER 2 - SYSTEM OVERVIEW.........................................................................11

INITIAL POWERUP....................................................................................................12

PAGE LAYOUT AND NAVIGATION............................................................................15

SYSTEM SETUP........................................................................................................17

Console Setup ...................................................................................................18

Lightbar Setup....................................................................................................19

GPS RECEIVER SETUP............................................................................................20

Implement Setup................................................................................................21

CHANNEL SETUP......................................................................................................24

Channel Favorite................................................................................................25

Application Type.................................................................................................26

Application Type Settings ........................................................................... 27

Drive Type..........................................................................................................28

Drive Type Settings ....................................................................................28

Units...................................................................................................................31

Primary Sensor ..................................................................................................32

Primary Sensor Settings.............................................................................33

SECONDARY SENSOR.............................................................................................34

Monitor Selection ...............................................................................................36

Monitor Settings .........................................................................................37

Channel Setup Completion ................................................................................38

Saving Channel Setup................................................................................39

FIELDPILOT SETUP ..................................................................................................40

FieldPilot Calibration ..........................................................................................41

Adjust Oil Flow ...........................................................................................42

Drive Straight A-B Line...............................................................................43

Adjust Valve Gain in FieldPilot Setup (If Required) ....................................44

Adjust Aggressiveness in FieldPilot Setup (If Required) ............................44

Adjust Lookahead in FieldPilot Setup (If Required)....................................45

Adjust Sensitivity in FieldPilot Setup (If Required) .....................................45

Table of Contentsii

CHAPTER 3 - PRODUCT APPLICATION SETUP ....................................................47

STARTING JOBS .......................................................................................................48

New Job Creation ..............................................................................................48

Existing Job Selection........................................................................................49

Job Creation Based on Existing Jobs ................................................................49

Manually Naming Jobs.......................................................................................49

Automatic Job Naming.......................................................................................50

No PCMCIA Card...............................................................................................50

ARM LAUNCHER.......................................................................................................51

No PCMCIA Card...............................................................................................51

Calibrations ........................................................................................................51

Calibration Procedure ........................................................................................52

PRIME INJECTION SYSTEM ....................................................................................53

Reverse Prime Injection System........................................................................56

JOB REPORT SETUP................................................................................................57

No PCMCIA Card...............................................................................................57

Job Report Wizard .............................................................................................57

ARM SETUP...............................................................................................................59

No PCMCIA Card...............................................................................................59

ARM Setup Wizard ............................................................................................59

Entering File Names ..........................................................................................61

Swath Manager Automatic Boom Section Control .............................................61

Swath Manager Lookahead ...............................................................................61

Swath Manager 0%, 50%, and 100% Settings ..................................................62

Swath Manager Boom 50% and 100% Settings ................................................63

CAN Switchbox ..................................................................................................63

Input Status Module (ISM) .................................................................................64

Swath Manager 5...............................................................................................65

PRODUCT SETUP.....................................................................................................66

Product Name Selection ....................................................................................67

Favorites.....................................................................................................68

New Products.............................................................................................68

Variable Rate Application ...................................................................................68

Prescription Map Selection.........................................................................68

Variable Rates for Multiple Products ..........................................................69

ARM Color (Skip if not using Variable Rate) ......................................................70

Tilt Sensor Functions .........................................................................................71

Tilt Compensation Module Installation ...............................................................72

Antenna Height...........................................................................................73

Tilt Sensor Calibration ................................................................................74

CHAPTER 4 - OPERATION.......................................................................................77

PRODUCT APPLICATION .........................................................................................77

Rates Pages ......................................................................................................77

GPS/BOUNDARY PAGE............................................................................................78

Rate Adjustment.................................................................................................79

Test Speed .........................................................................................................80

Reset Initial Quantity .........................................................................................80

FieldPilot Adjustments........................................................................................81

The Map Page ...................................................................................................82

Legacy 6000

98-05053 R2

iii

Solid and Boom Patterns ...................................................................................85

SYSTEM, WARNING, AND ERROR MESSAGES.....................................................85

System Messages..............................................................................................86

Warning Messages ............................................................................................86

Error Messages..................................................................................................87

VEHICLE GUIDANCE ................................................................................................87

Changing Guidance Patterns.............................................................................88

Straight-Line A-B Guidance ...............................................................................88

Mark A ........................................................................................................88

Mark B........................................................................................................89

Curved A-B Guidance ........................................................................................90

Mark A ........................................................................................................90

Mark B........................................................................................................90

Headland Guidance ...........................................................................................91

Mark A ........................................................................................................92

Mark B........................................................................................................92

Switching from Headland to Straight-Line A-B Guidance ..................................92

Ignore Headland Guidance ................................................................................93

Circle Pivot Guidance ........................................................................................95

Mark A ........................................................................................................95

Mark B........................................................................................................96

Circle Pivot Guidance Navigation...............................................................96

FIELDPILOT...............................................................................................................98

LIGHTBAR .................................................................................................................99

Curved Guidance ...............................................................................................99

Applied Area Detection ....................................................................................100

Previously Applied Area Detection ...................................................................100

Neighboring Swath Detection ..........................................................................101

MAPPING FIELD BOUNDARIES.............................................................................101

Close/Pause Boundary Map Process ..............................................................102

MAPPING POINTS AND HAZARDS........................................................................102

Points Mapping ................................................................................................103

Hazard Mapping...............................................................................................103

Object Name Files ...........................................................................................104

EXITING OPERATION .............................................................................................104

SHAPE FILES ..........................................................................................................105

FIELDWARE MAP MANAGER.................................................................................106

LIGHTBAR INDEX....................................................................................................106

CHAPTER 5 - SYSTEM TOOLS..............................................................................109

DEVICE MANAGER.................................................................................................109

Console............................................................................................................ 110

Backup Files............................................................................................. 110

Restoring System Files ............................................................................ 111

Importing Files.......................................................................................... 111

Speedometer ................................................................................................... 112

Swath Manager LED Brightness...................................................................... 113

Channels.......................................................................................................... 114

Channel Setup.......................................................................................... 114

Table of Contentsiv

GPS Receiver .................................................................................................. 116

LightBar............................................................................................................ 116

Channels 1,2,3................................................................................................. 117

CARD MANAGER .................................................................................................... 118

CHAPTER 6 - MAPPER...........................................................................................121

DATA SETUP............................................................................................................121

New Job Creation ............................................................................................122

Existing Job Selection......................................................................................122

Naming Jobs Automatically..............................................................................122

MAPPER SETUP AND MARKERS ..........................................................................123

Mapper Setup ..................................................................................................123

Markers ............................................................................................................124

Entering Marker Names ...........................................................................125

Object Name Creation .....................................................................................125

Object Names Folders .....................................................................................126

MAPPER APPLICATION ..........................................................................................127

Map Page.........................................................................................................127

Information Page..............................................................................................129

MAPPER TOOLS .....................................................................................................130

MAPPER OPTIONS .................................................................................................131

EXITING OPERATION .............................................................................................132

CHAPTER 7 - EXT...................................................................................................133

GUIDANCE ONLY MODE ........................................................................................133

LOG DATA MODE ....................................................................................................133

RATE CONTROL MODE ..........................................................................................134

RUNNING IMPLEMENT SETUP WITH A RATE CONTROLLER.............................135

Entering Implement Width................................................................................135

Entering Offset Direction Y...............................................................................136

Entering Offset Distance Y...............................................................................137

Implement Setup Completion...........................................................................138

CONTROLLER SETUP............................................................................................138

PRODUCT SETUP OPERATION .............................................................................140

Product Setup Wizard ......................................................................................141

Select Prescription Map Layer .........................................................................141

RATES PAGE ...........................................................................................................142

EXITING OPERATIONS...........................................................................................143

APPENDIX A - CHANNEL FAVORITE SETTINGS .................................................145

APPENDIX B - CREATING CALIBRATION TABLE................................................149

Creating a Calibration Table on a PC...............................................................149

Loading Calibration Table in Legacy 6000 ...............................................150

Using the Calibration Table ......................................................................150

Creating a Calibration Table Using the Legacy 6000 ...............................151

APPENDIX C - NH3 APPLICATION ........................................................................153

NH3 Application Cal# .......................................................................................153

Density for NH3 and Actual N .........................................................................153

Legacy 6000

98-05053 R2

1

CHAPTER 1 - INTRODUCTION

The Legacy 6000 system allows the control of multiple products plus GPS map-

ping, guidance, assisted steering, automated Boom Section Control, and data col-

lection in a single console using CAN bus technology. Replacing multiple consoles

in the cab with one robust system, TeeJet Technologies’ Legacy 6000 sets a new

standard for control systems of the future.

The Legacy 6000 runs Fieldware software in a Windows CE environment, an ex-

tremely dependable and stable operating system. Operation is intuitive with on-

screen menu choices and prompts. An on-board Help Menu is built in.

SYSTEM FEATURES

System features include:

Six product control•

Five guidance modes (Ignore Headland, Curved [Headland], Straight-Line•

[Parallel], Curved A-B, and Center Pivot)

Single console in the cab with a single cable connection to the console•

SimpliedoperationofproductcontrolandGPSrecordkeeping•

Auto boom section shutoff using Switch Function Module (SFM) or Swath•

Manager 5

FieldPilot module for assisted steering on straight, circle pivot, and curved•

paths

Works with TeeJet Technologies’ Swath XL Lightbar•

Comes fully loaded with “Fieldware for the Legacy 6000” software•

Precise control of liquid, injection, and dry products on common delivery•

systems

Flow or pressure-based liquid control with multiple sensor inputs for each•

product

Handles up to 20 individual boom sections and 4 swaths•

Up to 5 application rates per product can be preset and accessed on the•

go

Supports granular application control using 2 rate sensors per product•

Compatible with most sensors, valves, and D.C. driven motors•

Operates bidirectional or PWM valves•

Operator selectable gain settings for control valves•

Chapter 1 - Introduction2

Adding additional product control is easy•

Single high speed CAN bus cable entering the cab•

Mapper utility for mapping points, lines, and polygons using just the Leg-•

acy console

Version 3.11 or later capable of working with Gen I and Gen II CAN mod-•

ules

External (EXT) option to operate as external computer to already installed•

controllers

Multiple Product Variable Rate capable•

CAN BUS - VERSATILITY AND VALUE

The Legacy 6000 utilizes CAN Bus technology, an industry standard that TeeJet

Technologies uses to execute precise product control in an environment more ro-

bust than any of its predecessors. Controller Area Network (CAN) is a system

comprised of independent, intelligent modules connected by a single high-speed

cable known as a bus, over which all the data in the system travels. CAN was origi-

nally developed for the automotive industry to provide a cost-effective means for a

large number of electronic functions or systems to be interconnected without large,

expensive, and troublesome wiring harnesses.

Within a CAN system each module contains its own microprocessor. All modules

share a standard protocol or communication sequence that conforms to the ISO

11898 standard. Since modules have built-in computing power, a CAN system is

extremelyexibleandeasilyexpandstomeetacustomer’sneeds.

Individualmoduleshavespecicanduniquefunctionstoexecute,aswellasthe

responsibility to constantly report the functions and current status. Data on the

CAN is available many times a second, allowing the operation of a quick and re-

sponsive control system.

The Legacy 6000 uses 4 types of modules, each having a unique function de-

scribed in the following text. The console located inside the cab is one of the

modules and serves as the user interface. The remaining modules are positioned

aroundthechassisclosetotheareatheyinuence.Forinstance,theDualControl

Module (DCM) connects to the actuator and sensor and controls the actual release

of the product. Upgrading from two-product to four-product application (or more) is

simply a matter of adding additional DCM’s to the system.

Legacy 6000

98-05053 R2

3

System Components

Dual Control Module

The Dual Control Module (DCM) performs the control function for the CAN Bus

and connects the actuator and up to 6 sensors to the system. Control outputs can

be bidirectional or Pulse Width Modulated (PWM). One DCM is required for every

two products to be controlled.

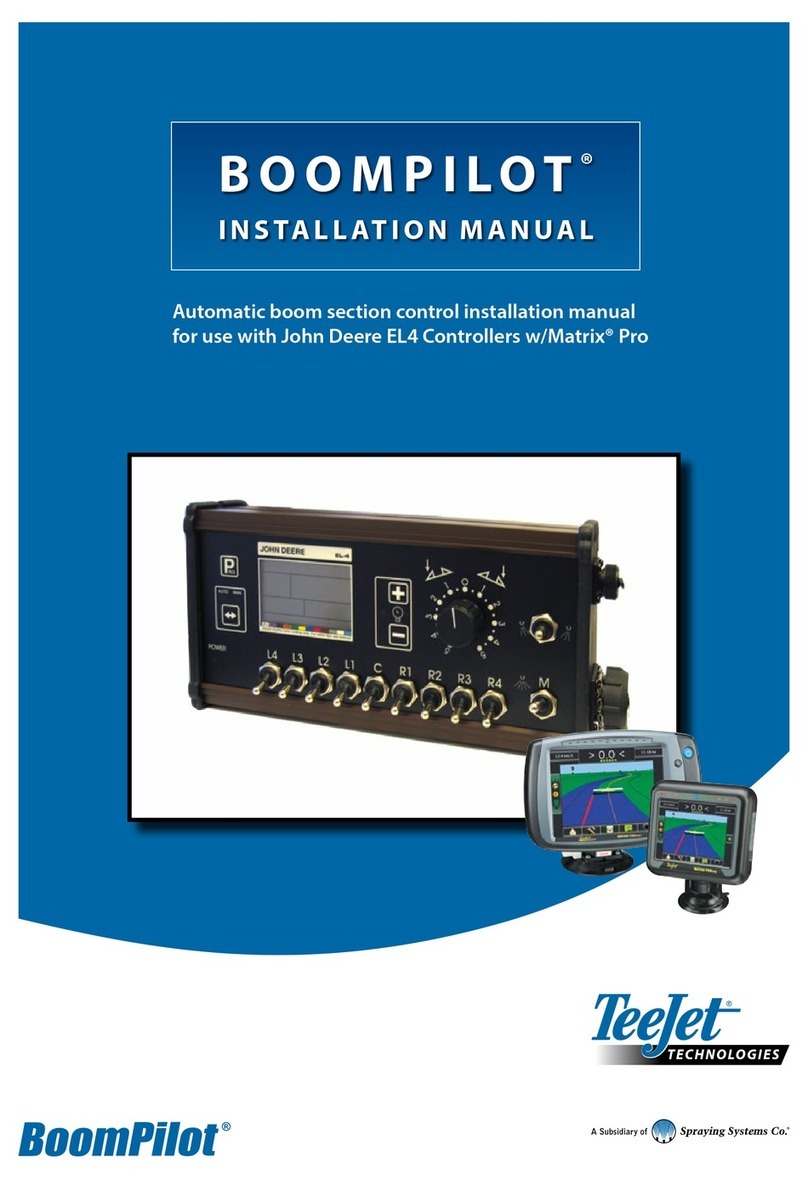

Figure 1-1: Dual Control Module (DCM)

Swath XL Lightbar

The Swath XL Lightbar is required for applications using guidance (recommended

for non-guidance uses). For non-guidance (data logging), the lightbar provides

area and rate feedback.

Figure 1-2: Swath XL Lightbar

Chapter 1 - Introduction4

Switch Function Module

The Switch Function Module (SFM) enables manual and automated boom section

control (expandable to 20).

Figure 1-3: Switch Function Module (SFM)

CAN Switchbox

The CAN Switchbox is used when existing switches are not present in the vehicle

and is nearly always used in conjunction with a Switch Function Module (SFM).

Each switchbox controls up to 10 sections (expandable to 20).

Figure 1-4: CAN Switchbox

Legacy 6000

98-05053 R2

5

Input Status Module

The Input Status Module (ISM) senses the status of existing switches on the vehi-

cle and transforms the voltage switch state into messages on the CAN Bus. Boom

valves are connected directly to these same switches, or are alternately driven by

a Switch Function Module on the CAN bus.

Figure 1-5: Input Status Module (ISM)

FieldPilot Module

The FieldPilot Module performs assisted steering on straight and contour paths.

Figure 1-6: FieldPilot Module

Chapter 1 - Introduction6

SWATH MANAGER 5 (SM5)

SwathManager5isusedformanual andautomatedboomcontrolof uptove

boom sections.

Figure 1-7: Swath Manager 5 (SM5)

NOTE: Most systems will incorporate a Swath Manager 5 or an Input Status Mod-

ule or a CAN Boom Switchbox (typically one per system).

LEGACY 6000 CONFIGURATIONS

ThefollowingdiagramsarereectiveoftypicalLegacy6000congurations.Dueto

thevarietyofpossiblecongurations,theseshouldbeusedforreferencepurposes

only.

Figure 1-8: Single Channel Liquid Flow Meter Conguration

45-053 4 0

45-08 10 6

CA N

ISM C o ntro l

Cab le

45-07 6 02

D/C xx: xx

Legacy 6000

98-05053 R2

7

Figure 1-9: Single Channel Liquid Flow Meter Conguration w/ Swath Manager 5

Figure 1-10: Single Channel Liquid With AutoBoom Shutoff (SFM) and Switchbox

45-053 4 0

45-08 10 6

CA N

45-05340

45-08106

CAN

1

3

4

5

2

Connect to

Battery

+12v Only

+12v O nly

Chapter 1 - Introduction8

Figure 1-11: Single Channel Granular Spreader

Figure 1-12: Dual Channel Granular Spreader

45-053 4 0

45-08 10 6

CA N

ISM C o ntro l

Cab le

45-07 6 02

D/C xx:x x

45-053 4 0

45-08 10 6

CA N

ISM C o ntro l

Cab le

45-07 6 02

D/C xx:x x

Legacy 6000

98-05053 R2

9

Figure 1-13: Carrier Plus Three Pump Injection System

45-053 40

45-081 0 6 45-081 0 6

CAN CAN

Chapter 1 - Introduction10

Legacy 6000

98-05053 R2

11

CHAPTER 2 - SYSTEM OVERVIEW

It is assumed that the Legacy 6000 hardware has been properly installed and

clean, reliable power has been supplied.

Figure 2-1: Legacy 6000 Console

NOTE: When powering the Legacy console ON or OFF, press the Power ON/

OFF button for 1-2 seconds, then release the button and wait approxi-

mately 10 seconds for the console to respond.

Function

buttons:

F1

F2

F3

F4

F5

Power On/Off

Escape key

Arrow keys

Function

buttons:

F6

F7

F8

F9

F10

Brightness/Contrast

Enter button

Chapter 2 - System Overview12

Figure 2-2: (OPTIONAL) USB Keyboard Screen Navigation / Selection Buttons

INITIAL POWERUP

NOTE: Version 3.14 Legacy software is capable of working with both Gen I/CAN

modules (PCM/PSM/SSM) and Gen II CAN modules (DCM). This User

Guide is written primarily for Gen II CAN modules, although much of it

still applies if used with Gen I modules. Refer to an earlier User Guide for

System Tools information and other data specic to Gen I.

If system operation is desired with Gen I CAN modules, or in EXT mode

with an external rate controller, refer to Console Setup (page 18 in this

User Guide) and select the appropriate application before proceeding.

The following steps should be performed upon initial power up of the system.

1. Press the orange Power button (located on the bottom left side of the

console). Launcher, the rst page of the Legacy 6000 system, will be

displayed.

2. A message indicating a CAN Bus change has occurred will be dis-

played. Press the Enter button to review the status of the module.

The ten Function buttons located on the left

and right sides of the console are used to select

the icons located next to them. This selection

process takes the place of using the Arrow keys

and Enter button.

The Escape

button works the

same as the ESC

key on the com-

puter keyboard.

When pressed,

the screen will

back up one

screen at a time

until the main

Launcher screen

is reached. Note:

changes are not

saved when ESC

is used before

saving changes. The Enter button launches the

function of the icon highlighted.

The Arrow keys allow the operator to move

the highlighted cursor across the screen to

the desired icon.

Power button

Enter button

Legacy 6000

98-05053 R2

13

Figure 2-3: Initial Installation - Change Notication

Each DCM is capable of running two products (channels). Each channel must be

turned on (YES) and an ID assigned if the channel is used.

3. Highlight the desired channel in the center of the screen by using the Ar-

row keys and press the Enter button.

4. Turn the channel on (YES) if in use. Set a unique ID number for each

channel (channel one is typically set to ID 1).

Figure 2-4: Channel Assignment

The system will guide the operator through a series of commands to establish

thebasechannelandcongurecontroloftheotherexistingchannels.Oneofthe

channels must be established as the base channel to handle speed input.

Arrow keys

Enter button

Chapter 2 - System Overview14

Figure 2-5: Establishing Base Channel

Upon initial power up, it is recommended to reset the settings to factory default.

The system will prompt the operator to perform this operation for each channel by

pressing the Forward Arrow softkey.

Reset is an option for each channel. For new installations, choose YES. Reset

willoccuroncethelastchannel is congured and theForward Arrow softkey is

executed to exit Channel Setup.

Figure 2-6: Reset CAN Bus to Factory Default

Once the CAN Bus is congured, the Launcher page will be displayed. The

Launcher page is the main page of the Fieldware software. All software applica-

tions are accessed from this main page: System Setup, System Tools, Application

Rate Manager (ARM), and Mapper.

Forward Arrow

softkey (F6)

Legacy 6000

98-05053 R2

15

Figure 2-7: Launcher Page

PAGE LAYOUT AND NAVIGATION

There are three types of page layouts used throughout the Fieldware software:

Launcher pages, Menu pages, and Parameter Setup pages.

Launcher pages provide access to multiple setup applications as illustrated in Fig-

ure 2-8.

Figure 2-8: Examples of Launcher Pages

Menu pages contain setup parameters associated with a particular theme (e.g.,

GPS Receiver Setup). Typically a setup wizard guides the operator through the

setupprocessforeachspecictopic.Sub-groupbuttonsdisplayonlythoseparam-

etersassociatedwiththespecictopicbeingcongured.

Navigation through Menu Setup pages is accomplished by using the Arrow keys

to scroll to the appropriate parameter and the Enter button to view the parameter

options.

System Tools

softkey

System Setup

softkey ARM Bullseye

softkey

Mapper softkey

Highlighted Application

Help Window

Software Version, Page

Name and Number

Arrow keys

Enter button

Table of contents

Other TeeJet Control Unit manuals