Meteo Control Power Control User manual

Operating manual

meteocontrol Power Control

Version 03082012

2/78 meteocontrol Power Control 03082012 - en

Spicherer Str. 48

D-86157 Augsburg

Tel.: +49 (0) 821 / 3 46 66-0

Web: www.meteocontrol.de

Technical support:

Tel.: +49 (0) 821 / 3 46 66-88

Fax: +49 (0) 821 / 3 46 66-11

© 2012 meteocontrol GmbH

All rights reserved.

All information in these operating instructions has been compiled and

checked with the greatest care and diligence. However, the possibility of

errors cannot be entirely excluded. meteocontrol GmbH therefore cannot

accept any liability for errors or any circumstances resulting from errors.

Subject to technical alterations.

meteocontrol Power Control 03082012 - en 3/78

Contents

Operating manual............................................................................................................1

meteocontrol Power Control............................................................................................1

1.

Use....................................................................................................................6

1.1

Introduction.......................................................................................................6

1.2

About this operating manual .............................................................................6

1.3

Disclaimer.........................................................................................................6

2.

Safety................................................................................................................8

2.1

Meaning of the notices......................................................................................8

2.1.1

Further notices.........................................................................................8

2.2

Product safety...................................................................................................9

2.2.1

Safety instructions for operation..............................................................9

2.2.2

Transportation and storage ...................................................................10

3.

Technical requirements...................................................................................11

3.1

EEG (German Renewable Energy Law) .........................................................11

3.2

meteocontrol Power Control requirements......................................................11

4.

Functionality....................................................................................................12

4.1

meteocontrol Power Control Industrial............................................................12

4.2

Functional display Power Control with WEB`log PRO and PCU.....................13

4.3

Functional display Power Control with WEB`log PRO.....................................14

4.4

Functions ........................................................................................................15

4.4.1

Power control.........................................................................................15

4.4.2

Master functions....................................................................................15

4.4.3

Power requirements change message..................................................15

4.4.4

Deactivation of the alert.........................................................................15

4.4.5

Calculation of the residual energy balance............................................16

4.4.6

Reporting function .................................................................................16

5.

Power Control status WEB`log display............................................................17

5.1

Menu entries in the device display..................................................................17

6.

Power Control config WEB`log browser..........................................................18

6.1

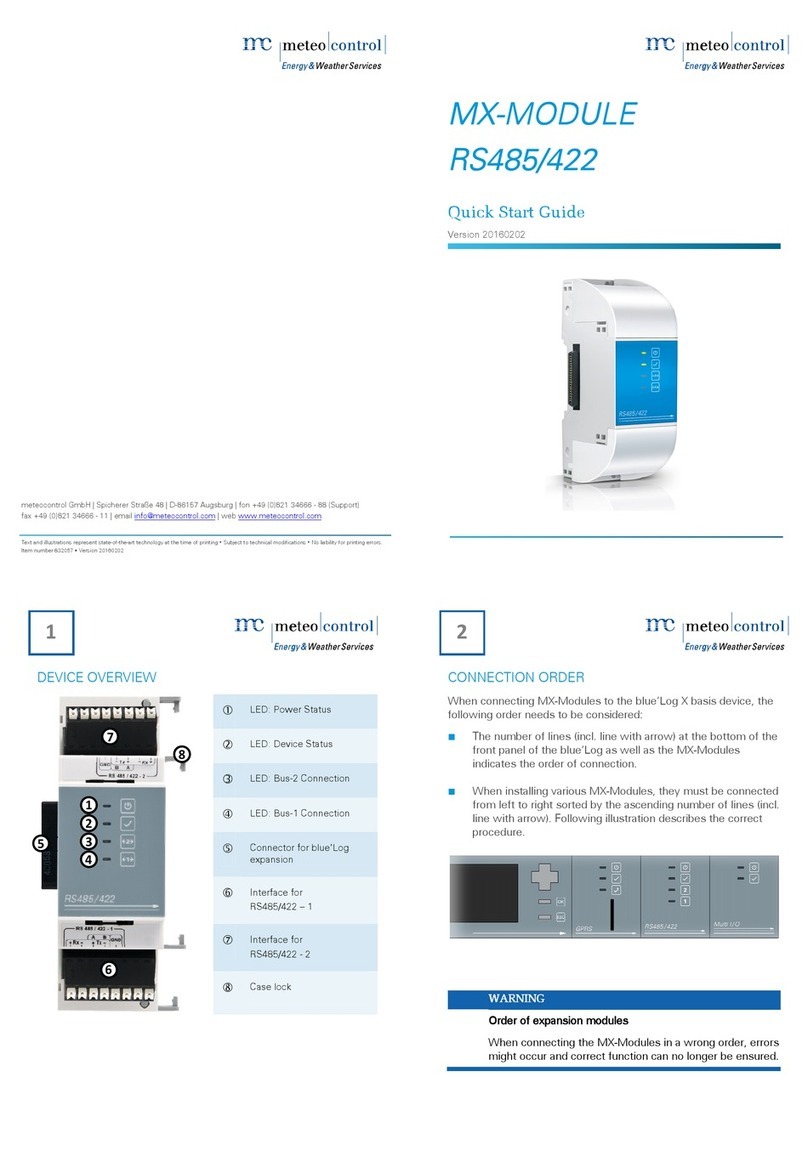

Selection of Modbus device profiles................................................................18

6.2

Assignment of Modbus device profiles............................................................20

6.3

Details on the PCU interface configuration.....................................................21

6.3.1

PCU IP configuration.............................................................................21

6.3.2

PCU serial configuration........................................................................21

4/78 meteocontrol Power Control 03082012 - en

6.3.3

Assignment of the PCU in WEB`log......................................................21

6.4

Details on the PCU device configuration ........................................................22

6.5

Power Control online values...........................................................................26

6.6

Power requirements configuration..................................................................27

7.

Active and reactive power procedures............................................................32

7.1

Active power procedures................................................................................34

7.1.1

P(DI)......................................................................................................34

7.1.2

P(AI)......................................................................................................36

7.1.3

P(DI) internal.........................................................................................37

7.2

Reactive power procedures............................................................................39

7.2.1

cos φ(DI)...............................................................................................39

7.2.2

cos φ(AI) ...............................................................................................41

7.2.3

Control procedure cos φFix..................................................................44

7.2.4

Q(DI) .....................................................................................................45

7.2.5

Power procedures P(DI) and Q(DI) combined.......................................47

7.2.6

Q(AI) .....................................................................................................49

7.2.7

Q fix.......................................................................................................52

7.2.8

Q(U) ......................................................................................................52

7.2.9

cos φ(P) ................................................................................................53

7.2.10

cos φ(U)................................................................................................55

7.3

Details fallback operation................................................................................56

8.

System control circuit......................................................................................57

9.

Application cases............................................................................................59

9.1

Querying Power Control status.......................................................................59

9.2

Power Control power procedures ...................................................................59

9.2.1

Electric installation PCU to WEB`log.....................................................59

9.2.2

Installation PCU to WEB`log .................................................................59

9.2.3

Configuring PCU...................................................................................59

9.2.4

Configuring Power Control....................................................................60

9.3

Power Control system control circuit GCP control..........................................60

9.4

Enabling Power Control..................................................................................60

9.5

Performing test run (optional).........................................................................60

9.6

Power Control slave WEB`log ........................................................................61

10.

The WEB`log..................................................................................................62

10.1

Connection options....................................................................................62

meteocontrol Power Control 03082012 - en 5/78

10.1.1

Ripple control receiver with WEB`log, digital inputs...............................62

10.1.2

WEB`log Pro master - slave ..................................................................63

11.

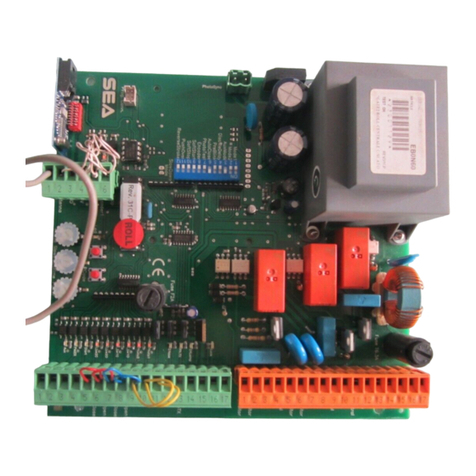

The Power Control Unit (PCU)........................................................................64

11.1

PCU Connections.......................................................................................64

11.1.1

Description of the elements...................................................................65

11.2

PCU operating elements............................................................................68

11.2.1

Write protect slide switch.......................................................................68

11.2.2

Modbus address coding switch..............................................................68

11.2.3

Modbus bus termination switch .............................................................68

11.3

Installation..................................................................................................68

11.3.1

Safety instructions for installation..........................................................68

11.3.2

Mounting................................................................................................70

11.3.3

Connection options................................................................................72

12.

The plant control circuit/GCP control...............................................................76

13.

Power procedures overview............................................................................76

14.

GlossaryTOA ..................................................................................................77

15.

List of figures...................................................................................................77

6/78 meteocontrol Power Control 03082012 - en

1. Use

1.1 Introduction

This operating manual describes the meteocontrol Power Control function in

connection with the WEB`log data logger, the power control unit (PCU) and

further components for power control.

The full operating manual can be downloaded in electronic form from

meteocontrol’s website.

The meteocontrol Power Control is broken down into three areas:

Homeline, Industrial and Special Solutions

The focus of this documentation is meteocontrol Power Control Industrial for

industrial solutions

Information on Homeline or Special Solutions can be obtained via the

meteocontrol website or the respective sales contacts.

1.2 About this operating manual

This operating manual is intended for plant planners and installers and forms

the basis for a safe operation of meteocontrol Power Control. The personnel

responsible for installation, operation and maintenance must have read and

understood this operating manual

The operating manual must be accessible at all times.

The term WEB`log Pro is used in representation of the WEB`log Pro and

WEB`log Pro Unlimited device types in this manual.

meteocontrol GmbH accepts no liability for personal injury, damage to

property, or malfunctions and their consequences, insofar as these result

from non-observance of this operating manual.

1.3 Disclaimer

meteocontrol rejects any liability for damage arising from the non-observance

of the operating manual.

This applies, in particular, for damage from:

•Unintended use

•Faulty operation

•Wrongly chosen materials and tools

•Faulty or non-executed maintenance and repairs

meteocontrol Power Control 03082012 - en 7/78

With Power Control, meteocontrol shall not be liable for events or

occurrences that are outside its area of influence, such as for the correctness

of the control commands of an energy supplier, non-carrying out of

forwarded control commands, hardware and/or software failures with the

system operator, switching events at the end customer. Any liability for

damage caused by such events and occurrences, such as lost profits, grid

instability, damage to parts of the customer's system, for instance of an

inverter, shall remain expressly excluded.

8/78 meteocontrol Power Control 03082012 - en

2. Safety

2.1 Meaning of the notices

Safety notices are classified by a signal word and corresponding colour. The

different safety notices stated below are explained as follows:

Warning

Type

Consequences

–Indicates a possibly dangerous situation. Death

in the event of electric shock or severe injury with irreversible damage

may be the result.

Notice

Type

Consequences

–Indicates a possibly damaging situation. Material damage to the

system and its immediate environment may be the result.

2.1.1 Further notices

A general notice is a piece of information for better understanding and may

include the following:

•Background information

•Special circumstance

•Further or additional information

meteocontrol Power Control 03082012 - en 9/78

Information about this topic:

Operating manual Refers to another manual

WEB`log WEB`log PRO operating manual

Web portal Documentation Web portal

Inverter Documents on the inverter

2.2 Product safety

Power Control is a system for controlling and steering different operating

parameters of PV systems (such as reactive and active power).

The connections of the data loggers and modules used here may be loaded

with the permissible signals and signal strengths only.

Installation is only permitted indoors. For installation outdoors or in a dusty

environment, the device must be installed in a standardised protective

enclosure.

2.2.1 Safety instructions for operation

The following must be observed when the data logger is in operation:

•Do not remove the memory card (compact flash) or SIM card.

•Do not open the device.

•Do not make any modifications to the device.

•Immediately take damaged devices out of operation and have them

checked by a qualified electrician.

•Observe local provisions when using the device.

•The safety of the device and the operator cannot be guaranteed if the

device is operated in contravention of the described safety instructions

10/78 meteocontrol Power Control 03082012 - en

2.2.2 Transportation and storage

Inspect the device for transport damage on delivery. Notify the transport

company in the event of visible damage.

A damaged device must not be put into operation!

Transport the device in original packaging only. Protect the device from dust

and moisture.

Further information about this topic:

Operating manual end customer Technical data

meteocontrol Power Control 03082012 - en 11/78

3. Technical requirements

3.1 EEG (German Renewable Energy Law)

The necessity of active participation of operators of PV systems in the grid

safety management increases with the rising share in the overall power

production. This requires an option to reduce the feed-in power and

participation in the compensation of the reactive power in the grid.

As such, the plant operators must fulfil the following requirements:

•They must be able to reduce the feed-in capacities of plants by remote

control or disconnect plants from the grid entirely.

•They must be able to reduce the reactive power in the grid by reactive

power compensation.

3.2 meteocontrol Power Control requirements

It is recommended to clarify the following requirements of the energy

supplier, inverter manufacturer and plant operator for the Power Control

already in the phase of plant planning:

•Power procedures according to which the requirements of the energy

supplier are implemented in control values for the inverters.

•Power procedures that are supported by WEB`log PRO for the inverter

types used (inverter drivers).

•Characteristic requirements for the power procedure made by the system

operator:

Note: If difficulties regarding the requirement areas arise or

necessary configuration options are not available, consult

your sales contact at meteocontrol.

12/78 meteocontrol Power Control 03082012 - en

4. Functionality

4.1 meteocontrol Power Control Industrial

Basic function:

•The requirements for power reduction and control are received from the

energy supplier via a selected interface (digital, analogue, IEC 60870-5-

101) by PCU or WEB`log PRO inputs.

•The control values are determined from the requirements in accordance

with configurable rules. The rules can be defined in accordance with the

requirements. Feedback to the operator is derived optionally.

•The control values are set on the inverter within a response time required

by the energy supplier.

•The energy supplier receives a message about the control value set on

the inverters.

meteocontrol Power Control 03082012 - en 13/78

4.2 Functional display Power Control with WEB`log PRO and

PCU

safer Sun

P/Q

P/Q

123

12

10

11

6

5

4

7

8

9

9

8

13

9

Fig. 1: Functionality PCU<>Power Control

(1) Energy supplier (8) WEB`log PRO as slave

(2) Public grid (9) Inverter

(3) Ripple control receiver (10) Internet

(4) Central computer (11) Web portal

(5) Power control unit (PCU) (12) Power requirements report

(6) WEB`log PRO as master (13) Alert, residual energy balance report

(7) Ethernet switch

14/78 meteocontrol Power Control 03082012 - en

4.3 Functional display Power Control with WEB`log PRO

safer Sun

P

P

123

10

11

65

4

7

98

7

6

7

Fig. 2: Functionality Power Control

(1) Energy supplier (7) Inverter

(2) Public grid (8) Internet

(3) Ripple control receiver (9) Web portal

(4) WEB`log master (10) Power requirements report

(5) Ethernet switch (11) Alert, residual energy balance

(6) WEB`log slave Report

meteocontrol Power Control 03082012 - en 15/78

4.4 Functions

4.4.1 Power control

P

P/Q

Active power procedure (P procedure)

With the internal inputs of the WEB`log PRO only the active

power procedure can be carried out via digital requirements,

Active and reactive power procedures (P/Q/cos φprocedures)

With the PCU different active and reactive power procedures

can be selected and configured.

4.4.2 Master functions

In larger plants with several WEB`log PRO devices, a WEB`log

PRO assumes the master function.

The master receives the requirement values from the energy

supplier. The information is forwarded to all WEB`log PRO

devices (slaves) or the configured IP addresses via Ethernet

using a broadcast.

4.4.3 Power requirements change message

When changing the power requirements, the WEB`log PRO

informs one or more recipients via the reporting route

configured.

The message contains information on the time of changing and

the required power level.

4.4.4 Deactivation of the alert

(portal function, in preparation)

In the event of an enforced reduction, certain alerts are

deactivated for the duration of the reduction (e.g. comparison

energy to irradiance).

The SaferSun internet portal identifies the required reduction

and deactivates the alerts for this period.

16/78 meteocontrol Power Control 03082012 - en

4.4.5 Calculation of the residual energy balance

(portal function, in preparation)

Provides an overview of the energy not fed in.

The residual energy balance is calculated from the energy

quantity of the daily simulation and the energy actually fed in

on this day and saved and displayed in the internet portal.

4.4.6 Reporting function

(portal function, in preparation)

Reports can be created, which provide detailed information in

the event of a reduction.

meteocontrol Power Control 03082012 - en 17/78

5. Power Control status WEB`log display

The status of the Power Control can be queried and modified via the device

display. The configuration is possible via the browser only.

Fig. 3: Power Control settings

Note: The PC settings are available via the installer login only.

Default 0010

5.1 Menu entries in the device display

PC status

•Active: Power Control is active

•Inactive: Power Control is inactive

18/78 meteocontrol Power Control 03082012 - en

6. Power Control config WEB`log

browser

Administrator rights are required to configure the meteocontrol Power Control

in WEB`log.

Login procedure for configuration websites

1. Select the "Profi page" in the start centre.

2. Select the "General" menu item.

3. Select "Login".

4. Enter the administrator password and click "Login"

(default: ist02)

The WEB`log page for device configuration is displayed in the web

browser,

6.1 Selection of Modbus device profiles

Both the power control unit (PCU) and the power quality analyser (PQA) are

connected to the WEB`log via the Modbus protocol.

To this end, the required device types from the list of available devices must

be selected and saved.

Under the "Admin Measurement" menu item, "General configuration" item,

the required Modbus settings and Modbus device types are selected.

Fig. 4: Selection of the Modbus settings and Modbus device types

meteocontrol Power Control 03082012 - en 19/78

General information

Input field Meaning

Modbus driver version Current driver software version

Serial interface settings

Input field Meaning

Modbus Modbus protocol used, ASCII or RTU,

standard: RTU

Baud rate Baud rate of the serial interface

Standard: 9600 Baud

Data bits \ Parity \ Stop bits Definition of the serial protocol

Standard: 8/N/1

Scan for Modbus message used for scanning

Read new device types

The interface used is assigned via the suffix in the file name of the PCU

device type:

Input field Meaning

pcu_rtu.mod PCU Modbus via RTU (standard)

pcu_tcp.mod PCU Modbus via TCP

janitza_umg604_rtu.mod NAG Modbus via RTU (standard)

janitza_umg604_tcp.mod NAG Modbus via TCP

Save Saves the settings made

Note: Modbus TCP requires no configuration of the interfaces.

20/78 meteocontrol Power Control 03082012 - en

6.2 Assignment of Modbus device profiles

Under "Admin Measurement" menu item, "Device configuration" item the

Modbus device type is assigned for the corresponding Modbus client ID.

Fig. 5: Assignment Modbus client ID to the device type

Add serial device

Input field Meaning

Address Client ID of the Modbus device.

Device type Device type of the Modbus device

Scan for serial devices

Input field Meaning

Address space scan Number of client IDs to be scanned (standard:

1-20). Scan duration depending on the size of

the address range up to one minute.

Scan After a successful scan, the devices found are

listed under „Device configuration“

Add TCP/IP device

Input field Meaning

IP address Input of the IP address

Table of contents

Other Meteo Control Control Unit manuals

Popular Control Unit manuals by other brands

WAPRO

WAPRO WAGATE SVM-TG125 Installation & maintenance

USR IOT

USR IOT USR-WIFI232-A2 Hardware manual

Advanced Solar Photonics

Advanced Solar Photonics ASP-390M Safety & instruction manual

Festo

Festo CPX-FVDA-P Description

Linear Technology

Linear Technology DC1589A Quick start guides

V2

V2 City7 instruction manual