TeeJet BoomPilot User manual

BOOMPILOT®

INSTALLATION MANUAL

Automatic boom section control installation manual

for use with John Deere EL4 Controllers w/Matrix® Pro

Copyrights

© 2013 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced,

copied, photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without

prior written consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or

organizations.

Limitation of liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY

LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH

DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

Safety information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety

requirements.

As the operator of the vehicle, you are responsible for its safe operation.

The BoomPilot is not designed to replace the vehicle’s operator.

Do not leave a vehicle while the BoomPilot is engaged.

Be sure that the area around the vehicle is clear of people and obstacles before and during engagement.

The BoomPilot is designed to support and improve efciency while working in the eld. The driver has full responsibility for the quality and

work related results.

Disengage BoomPilot before operating on public roads or when not in use to prevent loss of vehicle control.

1

-040 R2 EN

BoomPilot®

Table of contents

REQUIRED COMPONENTS 2

PRINCIPLE OF OPERATION 4

INSTALLATION 4

1. LOCATE THE CONNECTION POINT FOR THE SDM HARNESS ......................................................................................................... 4

2. MOUNT & CONNECT SDM............................................................................................................................................................................ 4

3. DISCONNECT & RECONNECT HARNESSES & CABLES ....................................................................................................................... 5

4. CONNECT POWER/CAN/DATA CABLE TO BOOMPILOT HARNESS ............................................................................................... 6

5. SETTING CIRCULATION SYSTEM TYPE ON BOOMPILOT HARNESS ............................................................................................. 6

Ring Line Circulation System ........................................................................................................................................................6

Vacuum Re-circulation System......................................................................................................................................................6

6. ENCODE THE SECTION WIDTH IN THE MATRIX PRO:......................................................................................................................... 7

7. RECOMMENDED ELECTRONICS INSTALLATION ................................................................................................................................. 8

8. COMPLETE ELECTRONIC INSTALLATION ............................................................................................................................................... 8

SYSTEM CHECK 8

Check AUTOMATIC mode:............................................................................................................................................................8

John Deere: ...........................................................................................................................................................................8

Matrix Pro:..............................................................................................................................................................................8

Check MANUAL mode:..................................................................................................................................................................8

John Deere: ...........................................................................................................................................................................8

Matrix Pro:..............................................................................................................................................................................8

2www.teejet.com

BoomPilot®

REQUIRED COMPONENTS

Unpack the installation kit and identify the required parts for your installation.

Item Part Number Description Quantity

A 90-xxxxx* Matrix Pro guidance controller kit ....................................................................................................................................1

B 45-05845 Power/CAN/data cable ....................................................................................................................................................1

C 198-398 BoomPilot harness, John Deere Sprayers (9 sections + master)....................................................................................1

D 78-05072 BoomPilot section driver module (SDM)..........................................................................................................................1

E 020-040 Installation manual, John Deere EL4 Controllers ............................................................................................................1

F 98-05243 Matrix Pro BoomPilot setup guide ...................................................................................................................................1

*Part number is dependent on kit contents

Item Part # Description Illustration

A

Part

number is

dependent

on kit

contents

Matrix Pro guidance controller kit Matrix Pro 570G Matrix Pro 840G

B 45-05845 Power/CAN/data cable

POWER IN

CAN

RS-232

Power/DATA

45-05626

C 198-398 BoomPilot Harness, John Deere Sprayers

(9 sections + master)

xxx-xxx

xxyyxx

RLC-System

VRS

B A

B A

A B

Section Power

D 78-05072 BoomPilot section driver module (SDM)

E 020-040 Installation manual, John Deere EL4 Controllers

F 98-05243 Matrix Pro BoomPilot setup guide

3

-040 R2 EN

BoomPilot®

Figure 1: System diagram

POWER IN

CAN

RS-232

Power/DATA

45-05626

45-05845 3.3 m

Power/CAN/data cable

(included with FieldPilot

and BoomPilot kits)

10A fuseto RS-232

CAN

Tilt gyro

module (TGM)

TGM harness

Power

45-05625

45-05625 Power cable, COBO

(included with Matrix Pro kits)

NOT NEEDED WITH BOOMPILOT

xxx-xxx

xxyyxx

RLC-System

VRS

B A

B A

A B

JOHN DEERE EL-4

SectionPower

78-05072

BoomPilot section driver module (SDM)

(15 sections)

198-398

BoomPilot harness

John Deere Sprayers

(9 sections + master)

Existing John Deere rate controller

to existing flow control junction box

Matrix Pro 570 Matrix Pro 840

Existing system

Not needed

BoomPilot

Optional accessory

4www.teejet.com

BoomPilot®

PRINCIPLE OF OPERATION

The BoomPilot system controls the sections valves according to the GPS position. The GPS makes it possible to avoid overlaps or skips.

The Section Driver Module (SDM) is designed for switching active high when spraying. This means that a 12V signal is issued to control the

corresponding section valve.

The SDM is connected in parallel with the controller section switches.

The BoomPilot controls the section valves in automatic mode, and the controller section switches should be set to off unless the operator

wants to override the auto mode and thus force spraying.

The BoomPilot monitors the controller section switches that controls the valves in manual mode. The the Master switch can be used both in

automatic mode as well as in manual mode.

Figure 2: Principle of operation

SDM

Controller Section Switch

Valve

INSTALLATION

If there are questions concerning the installation of the BoomPilot system on this vehicle, or due to the changes in component

specications the parts supplied in the kit are not exactly as presented in this document, please contact your dealer or TeeJet

Customer service representative for clarication before installation. TeeJet Technologies is not responsible for misuse or incorrect

installation of the system.

NOTE: All references to left and right are stated as if the user is seated in the driver’s seat.

NOTE: BE VERY CAREFUL TO ABSOLUTELY SECURE ALL CABLES AND HOSES SO THAT THEY DON’T INTERFERE WITH THE MANY

MOVING PARTS OF THE MACHINE!

1. LOCATE THE CONNECTION POINT FOR THE SDM HARNESS

Locate the existing system’s ow control harness as it routes up to the side of the John Deere console.

2. MOUNT & CONNECT SDM

1. Mount SDM (E) as shown where LED’s can be seen for troubleshooting.

2. Connect SDM (E) to BoomPilot Harness (C).

Figure 3: Connect SDM

xxx-xxx

xxyyxx

RLC-System

VRS

B A

B A

A B

SectionPower

E

C

5

-040 R2 EN

BoomPilot®

Figure 4: LED description

Section power

On – boom section power is on

Off – boom section power is off

In/out error

Off – boom output is high or on

Blinking – boom output is low or off

Auto mode

On – auto mode is active

Off – manual mode is active

CAN data

Blinking – receiving console CAN messages

Off – CAN messages stop for > 3 seconds

CAN power

On – CAN power is on

Off – CAN power is off

3. DISCONNECT & RECONNECT HARNESSES & CABLES

The BoomPilot SDM harness (C) tees into the existing system’s connection between the John Deere rate controller and ow control harness.

1. Disconnect existing connection at the side of the John Deere controller.

2. Connect BoomPilot harness (C) to John Deere controller.

3. Connect BoomPilot harness (C) to existing John Deere ow control harness.

Figure 5: Disconnect existing connection

Disconnect

existing harness

from console

Figure 6: BoomPilot harness to flow control harness BoomPilot harness to controller

Connect C to

Controller

ow control harness

Connect to existing

6www.teejet.com

BoomPilot®

4. CONNECT POWER/CAN/DATA CABLE TO BOOMPILOT HARNESS

Connect Power/CAN/data cable (B) to BoomPilot harness (C).

Figure 7: Connect power/CAN/data cable to BoomPilot harness

POWER IN

CAN

RS-232

Power/DATA

45-05626

Power/CAN/Data Cable

BoomPilot Harness

xxx-xxx

xxyyxx

RLC-System

VRS

B A

B A

A B

Section Power

B

C

5. SETTING CIRCULATION SYSTEM TYPE ON BOOMPILOT HARNESS

The BoomPilot Harness (C) covers two different John Deere Sprayer types:

• Sprayers with Ring Line Circulation System (RLC-System).

• Sprayers with Vacuum Re-circulation System (VRS).

Ring Line Circulation System

Connect A to B (Section Power to RLC-System) ‘VRS Switch’ in postion ‘Non VRS’.

Figure 8: Ring Line Circulation System

RLC-System

VRS

B

C

A

B A

Section Power

Switch in Junction box

Vacuum Re-circulation System

Connect A to C (Section Power to VRS). VRS switch in position ‘VRS’

Figure 9: Vacuum Re-circulation System

B A

RLC-System

VRS

B

C

A

Section Power

Switch in Junction box

7

-040 R2 EN

BoomPilot®

6. ENCODE THE SECTION WIDTH IN THE MATRIX PRO:

The John Deere EL4 controller is always equipped with 9 section switches, but the number of sections on the sprayer boom will vary. This

combined with the xed ‘Center section’ on the EL4 controller will inuence on how the number of section and the widht’s are encoded in the

Matrix Pro.

JOHN DEERE EL-4

Example

The sprayer has 7 sections - each 4 meter. Encode the Matrix Pro as shown below:

Matrix Pro John Deere EL4 Width

Section 1 L4 0.01

Section 2 L3 4.00

Section 3 L2 4.00

Section 4 L1 4.00

Section 5 C 4.00

Section 6 R1 4.00

Section 7 R2 4.00

Section 8 R3 4.00

Section 9 R4 0.01

8www.teejet.com

BoomPilot®

7. RECOMMENDED ELECTRONICS INSTALLATION

The control console can be mounted to the operator’s preference. The GPS antenna should be mounted in the center on top of the cab on a

metal surface of at least 10 cm square.

Figure 10: Recommended electronics installation

Console

GPS

8. COMPLETE ELECTRONIC INSTALLATION

Refer to the Matrix Pro BoomPilot Setup Guide for further instructions on setting up and using your Matrix Pro for ABSC.

If not using a Matrix Pro, please refer to the owner’s manual supplied with the guidance system to complete the electronic installation and

setup.

SYSTEM CHECK

After connecting the power connector, it is time to make a system check. To check the system, it is necessary to have full GPS signal. To

obtain full GPS signal, the vehicle must be placed outside.

Check AUTOMATIC mode:

John Deere:

Section switches should be in the OFF position when working in Automatic mode. The Master switch will control the sprayer and should be

ON to enable automatic switching of the sections.

Figure 11: Automatic to all booms on mode

2.0 km/h 0.76 ha

Mark A

A

A

Matrix Pro:

• Turn on the Matrix Pro console

• Encode the number of sections and the width of each

(Refer to the Matrix Pro user manual)

• Wait for GPS signal

• Set the BoomPilot mode to AUTOMATIC

◄Status Bar Icon will change to green

• Drive forward (> 2 km/h)

• Observe that all valves open

• Check that the valves close when the Master switch is set to OFF

Check MANUAL mode:

John Deere:

• Set the section switches to ON

• Set the Master switch to ON

Matrix Pro:

• Set the BoomPilot mode to MANUAL

◄Status Bar Icon will change to red

• Check in the ‘Vehicle View Screen’ (Matrix Pro) that the section icons turn off and on according to the valve/switch status

• Observe that all valves are open

BoomPilot®

User manUal

TeeJet Aabybro

Mølhavevej 2

DK 9440 Aabybro

Danmark

www.teejet.com

A series of equipment-specic installation kits have been developed to work

in conjunction with your automated boom section control system. This kit

contains the necessary components and instructions to install ABSC on a

John Deere EL4 Controller. Please review this manual thoroughly before

beginning the installation process.

020-040-UK R2 EN English

© TeeJet Technologies 2013

Table of contents

Other TeeJet Control Unit manuals

Popular Control Unit manuals by other brands

Siemens

Siemens PM330 Hardware installation manual

Wilo

Wilo PLR Installation and operating instructions

Elettronica Progetti

Elettronica Progetti Multi-Pull EP095Mini Instructions for installation and use

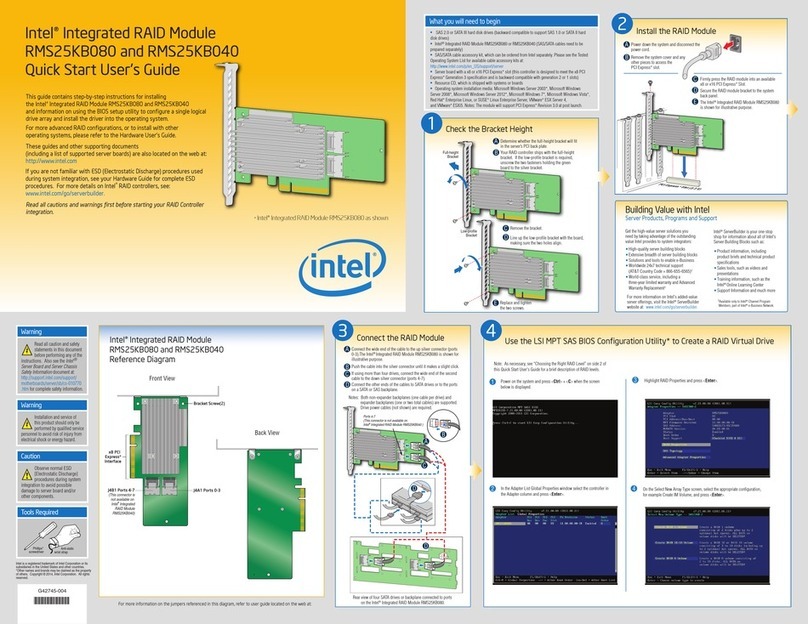

Intel

Intel RMS25KB080 Quick start user guide

MFZ Ovitor

MFZ Ovitor RS 300 K operating instructions

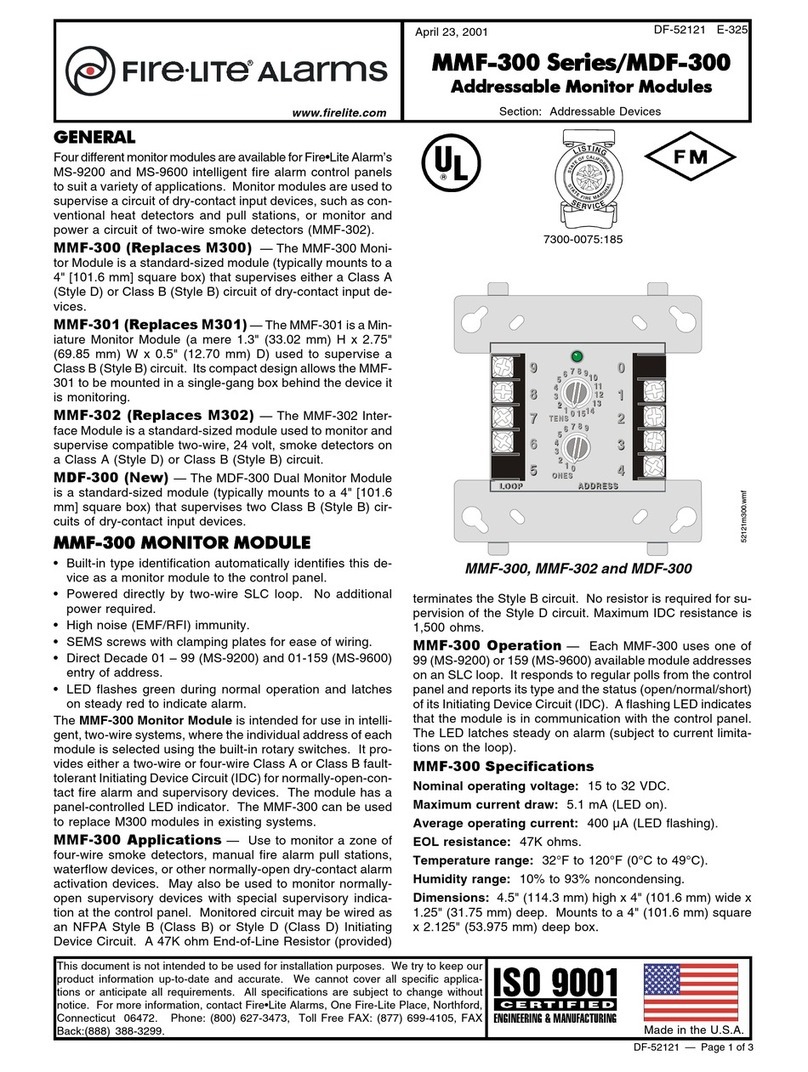

Fire-Lite Alarms

Fire-Lite Alarms MMF-300 Series quick start guide

Campbell

Campbell SDM-CD16D user guide

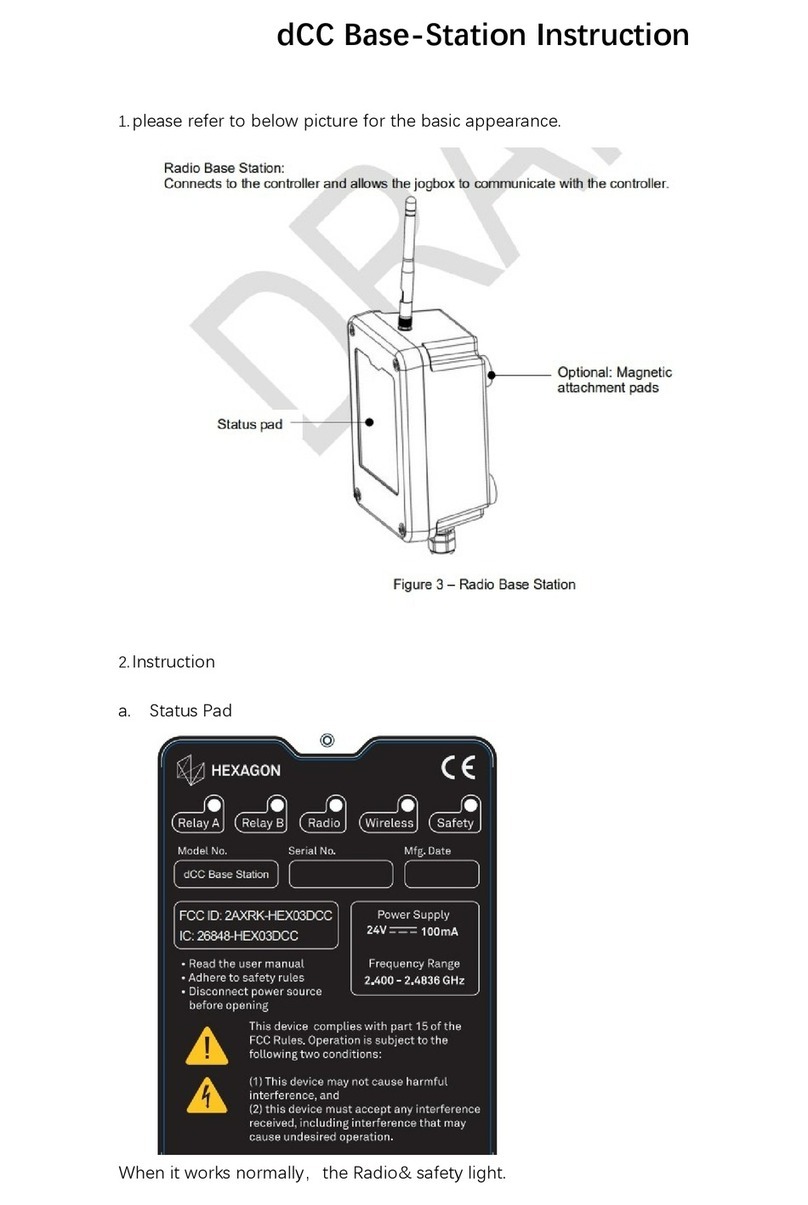

Hexagon Metrology

Hexagon Metrology HEX03DCC manual

Henkel

Henkel LOCTITE EQ VA40 CA operating manual

EMAC

EMAC SoM-A5D36 user manual

Equinox Systems

Equinox Systems SuperSerial PM16-RJ/422 Hardware manual addendum

Reflex

Reflex Reflexomat Basic RS 90 / 1 operating manual