Tek-Trol TEK-DP 1630A Series User manual

Technology Solutions

TP 1630A

EK- D

Instruction Manual

Flow Nozzle

Document Number:IM-1630A

www.tek-trol.com

www.tek-trol.com

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contact

Customer Support

796 Tek-Drive

Crystal Lake, IL 60014

USA

Tel: +1 847 857 6076

© COPYRIGHT Tek-Trol LLC 2021

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission. The information contained in this manual is subject to change without notice.

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

1

Table of Contents

1Safety Instructions............................................................................................... 2

1.1 Intended Use ................................................................................................................ 2

1.2 Safety Instructions from the Manufacturer..................................................... 2

Disclaimer...................................................................................................................... 2

Product Liability and Warranty............................................................................... 2

Information Concerning the Documentation ................................................... 2

1.3 Safety Precautions ................................................................................................. 2

1.4 Packaging, Transportation and Storage.......................................................... 3

Packing........................................................................................................................... 3

Transportation ............................................................................................................. 3

2Product Description............................................................................................. 4

2.1 Introduction.............................................................................................................. 4

2.2 Tools and equipment required............................................................................ 4

2.3 Nozzle flow meter overview.................................................................................. 4

3Installation Steps ................................................................................................. 4

3.1 Preparation............................................................................................................... 4

3.2 Flange Inspection ................................................................................................... 5

3.3 Nozzle Flow Meter Installation............................................................................. 5

3.4 Flange Reassembly ................................................................................................ 5

3.5 Leak Testing.............................................................................................................. 5

4Calibration and commissioning...................................................................... 5

5Maintenance and Troubleshooting ................................................................ 5

6Final Comments ................................................................................................... 6

7Flow Nozzle Diagrams ......................................................................................... 6

7.1 Flanged Type: Pipe-wall Tapping (Figure 1.) .................................................. 6

7.2 Flanged Type: Pipe-wall Tapping (Figure 1.) .................................................. 6

7.3 Weld-In type............................................................................................................. 7

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

2

1Safety Instructions

1.1 Intended Use

This installation manual is intended as a general guide for the installation of Tek-

Trol Flow Nozzle Meters supported in between flanges on a natural gas or other in-

line applications such as steam, water or other fluids, supplied by Tek-Trol and

based on end user supplied process data sets and information related to the units

supplied. ISO 5167-3:2003 specifies the geometry and method of use (installation

and operating conditions) of Nozzles and Venturi nozzles.

1.2 Safety Instructions from the Manufacturer

Disclaimer

The manufacturer will not be held accountable for any damage that happens by

using its product, including, but not limited to direct, indirect, or incidental and

consequential damages.

Any product purchased from the manufacturer is warranted in accordance with the

relevant product documentation and our Terms and Conditions of Sale.

The manufacturer has the right to modify the content of this document, including

the disclaimer, at any time for any reason without prior notice, and will not be

answerable in any way for the possible consequence of such changes.

Product Liability and Warranty

The operator shall bear authority for the suitability of the device for the specific

application. The manufacturer accepts no liability for the consequences of misuse

by the operator. Wrong installation or operation of the devices (systems) will cause

the warranty to be void. The respective Terms and Conditions of Sale, which forms

the basis for the sales contract shall also apply.

Information Concerning the Documentation

To prevent any injury to the operator or damage to the device it is essential to read

the information in this document and the applicable national standard safety

instructions. This operating manual contain all the information that is required in

various stages, such as product identification, incoming acceptance and storage,

mounting, connection, operation and commissioning, troubleshooting,

maintenance, and disposal.

1.3 Safety Precautions

Safety is paramount during a meter installation. Please adhere to current relevant

safety regulations regarding pipeline applications such as ASME, ISO standards or

client’s own safety procedures, always use appropriate personal protective

equipment during an installation, and ensure a safe working environment.

For additional information not discussed in this manual, please contact the

manufacturer.

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

3

Warnings and Symbols Used

The following safety symbols may be used in this manual were appropriate

relative to the measurement instruments described herein.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

NOTE

Indicates that operating the hardware or software in this manner may damage it

or lead to system failure.

1.4 Packaging, Transportation and Storage

Packing

The original package consists of

1. Tek-DP 1630A Flow Nozzle

2. Documentation

NOTE

Unpack and check the contents for damages or sign of rough handling. Report

damage to the manufacturer immediately. Check the contents against the

packing list provided.

Transportation

•Avoid impact shocks to the device and prevent it from getting wet during

transportation.

•Verify local safety regulations, directives, and company procedures with

respect to hoisting, rigging, and transportation of heavy equipment.

•Transport the product to the installation site using the original

manufacturer’s packing whenever possible.

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

4

2Product Description

2.1 Introduction

Nozzle flow meters are commonly used to measure the flow rate of natural gas in

pipelines and other gas fluids. This manual outlines the installation process for

nozzle flow meters that are installed in between flanges on a natural gas pipeline or

other applications as agreed in the supply documents. Flow nozzles are also used in

various industries, particularly for steam flow in the power sector. Due to their long-

documented history, flow nozzle designs and installation requirements are known

and recognized by national and international standards organizations such as ISO

5167 part 3.

2.2 Tools and equipment required

•Pipe wrenches and ancillary equipment related to bolt and nut sizes.

•Adjustable wrenches (if required)

•Flange gaskets and bolts designed for the pressure ratings per national

standards.

•Torque wrench

•Thread sealant

•Pressure gauges

•Calibration equipment

•Leak detection solution (Snoop or other applicable product – gas

applications only)

•Ventilation equipment if possibility of enclosed environment – (flameproof)

•Lockout/tagout equipment per user approved and agreed safety

procedure.

2.3 Nozzle flow meter overview

Please review the specifications and requirements of the nozzle flow meter before

installation,confirm the unitsupplied is labeled with correct serial number or tag

number per the order documentation and delivery notes and is applicable for the

application. This includes flow rate range, pressure and temperature rating, material

compatibility, and calibration details if laboratory calibration was asked for. Please

check the flow meter for any damage due to transport and contact Tek-Trol after

sales service if transportation issues are found.

3Installation Steps

3.1 Preparation

•Ensure the pipeline is depressurized and isolated from the gas source.

•Prepare the required tools and equipment.

•Identify the installation location and confirm alignment of flanges.

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

5

3.2 Flange Inspection

•Inspect the flanges for damage, corrosion, or wear make sure that correct

lifting procedures are used to prevent damage to the meter such as

correctly rated slings etc., according to end user/client procedures.

•Ensure the flanges are clean and free from debris during the installation.

3.3 Nozzle Flow Meter Installation

•Position the nozzle flow meter between the flanges or agreed installation

method with the flow direction arrow aligned with the gas flow direction.

•Place the gaskets on both sides of the flow meter, ensuring proper alignment

with flange bolt holes if the meter is installed between flanges.

•Insert and tighten the flange bolts through the bolt holes in a crisscross

pattern. Tighten evenly to avoid warping the flow meter or crushing the

gaskets on one side only.

•Use a torque wrench to achieve the nut and bolt manufacturer's

recommended torque settings for the bolts usually standardized per bolt

size, material and pressure rating.

3.4 Flange Reassembly

•Ensure the gaskets are properly seated and aligned.

•Reassemble the flange by tightening the bolts according to a crisscross

pattern, ensuring even distribution of pressure.

3.5 Leak Testing

•Conduct a leak test by applying a leak detection solution around the flange

joints and connection points gas applications, liquid applications fluid

should be visible.

•Observe for any bubbles forming, indicating a leak on gas applications.

•If a leak is detected, shut down the process disconnect and rectify the

leakage properly before proceeding, commence procedure from applicable

section.

4Calibration and commissioning

•Perform calibration according to the transmitter manufacturer's /end user

guidelines. If “Tek-Trol High Performance DP Transmitters and Flow

Computers” are being used, please refer to the specific installation manual

for advice and set up methodology for the selected transmitter type.

•Commission the flow meter by following client/user startup procedures

avoid a rapid opening of isolation valves in front and behind the flow meter

run.

5Maintenance and Troubleshooting

•Regularly inspect for leaks and damage.

•Follow the manufacturer's recommended maintenance schedule.

•If issues arise, consult the manufacturer's troubleshooting guide or seek

professional assistance.

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

6

6Final Comments

Proper installation of nozzle flow meters between flanges on natural gas pipelines or

other applications is crucial for accurate flow measurement and safe operation of the

meter.

Always follow the guidelines afore mentioned along with the manufacturer's

instructions for tertiary equipment and industry best practices to ensure a successful

installation and good performance.

NOTE

This manual provides a general overview of installation procedures. Always refer

to the specific nozzle flow meter data supplied and consult with qualified

professionals for accurate installation on your natural gas or other pipeline.

7Flow Nozzle Diagrams

7.1 Flanged Type: Pipe-wall Tapping

Fig 1. Flanged Flow Nozzle Type with Pipe Wall Low-Pressure Tapping

7.2 Flanged Type: Integral Low Pressure Tapping

The Tek-Trol Flanged Flow Nozzle with Integral Low-Pressure Tapping is provided

with the downstream tap integral to the nozzle's mounting flange. This design

provides the same ASME or ISO design flow contour but can be used in smaller pipe

sizes where the low-pressure tap may interfere with a pipe weld flange, and/or

flange bolting system. The low-pressure connection design is usually a 1/4" NPT (6

mm) unless specified otherwise in the supplied order documentation.

TechnologySolutions

Instruction Manual

Tek-DP 1630A

www.tek-trol.com

7

Fig 2. Flanged Flow Nozzle Type with Integral Low-Pressure Tapping’s

7.3 Weld-In Nozzle Type

Tek-Trol Weld-in Flow Nozzle types can be provided as a Mounting Ring Flow Nozzle

design that eliminates the need for welding dissimilar metals in the field. Basic pipe

wall pressure taps are incorporated with this nozzle design and is supplied as a

system with a complete flow metering section included if purchased in this

configuration.

NOTE

For special applications and in particular smaller line sizes, Weld-In Type Flow

Nozzles with Integral Metering Taps are available per Fig 2. This design includes a

short section of upstream and downstream pipe with flanged, bevelled, or socket

weld ends per the client’s requirements for end user installation using approved

welding procedures and standards.

Fig 3. Weld -In Flow Nozzle Type – Pipe Wall Low Pressure Tapping.

TEKMATION LLC reserves the right to change the designs and/or materials of its products without notice. The contents of this publication are the property of

TEKMATION and cannot be reproduced by any other party without written permission. All rights reserved. Copyright © 2022TEKMATION LLC

TEKMATION LLC DOC#TEK/ITPS/MNL/220915/1200A/r01.4

Flow | Level | Temperature | Pressure | Valves | Analyzers | Accessories | TekValSys

Tek-Trol is a fully owned subsidiary of TEKMATION LLC. We oer our customers a comprehensive range of products and solutions

for process, power and oil & gas industries. Tek-Trol provides process measurement and control products for Flow, Level,

Temperature & Pressure Measurement, Control Valves & Analyzer systems. We are present in 15 locations globally and are known

for our knowledge, innovative solutions, reliable products and global presence.

796 Tek Drive Crystal Lake, IL 60014,

USA

Sales: +1 847-655-7428

SAIF Zone, Y1-067, PO BOX No.

21125, Sharjah, UAE

Sales: +971-6526-8344

Tek-Trol LLC

www.tek-trol.com

Tek-Trol Solutions BV

Zinkstraat 24, 4823 AD Breda,

Netherlands

Sales: +31 76-2031908

Tek-Trol Middle East FZE

Support: +1 847-857-6076 Email: tektrol@tek-trol.com www.tek-trol.com

Table of contents

Popular Industrial Equipment manuals by other brands

Siemens

Siemens SIMOGEAR BA 2730 operating instructions

Phoenix Mecano

Phoenix Mecano LD1000C Assembly instructions

GSI Group

GSI Group PNEG-1088 installation manual

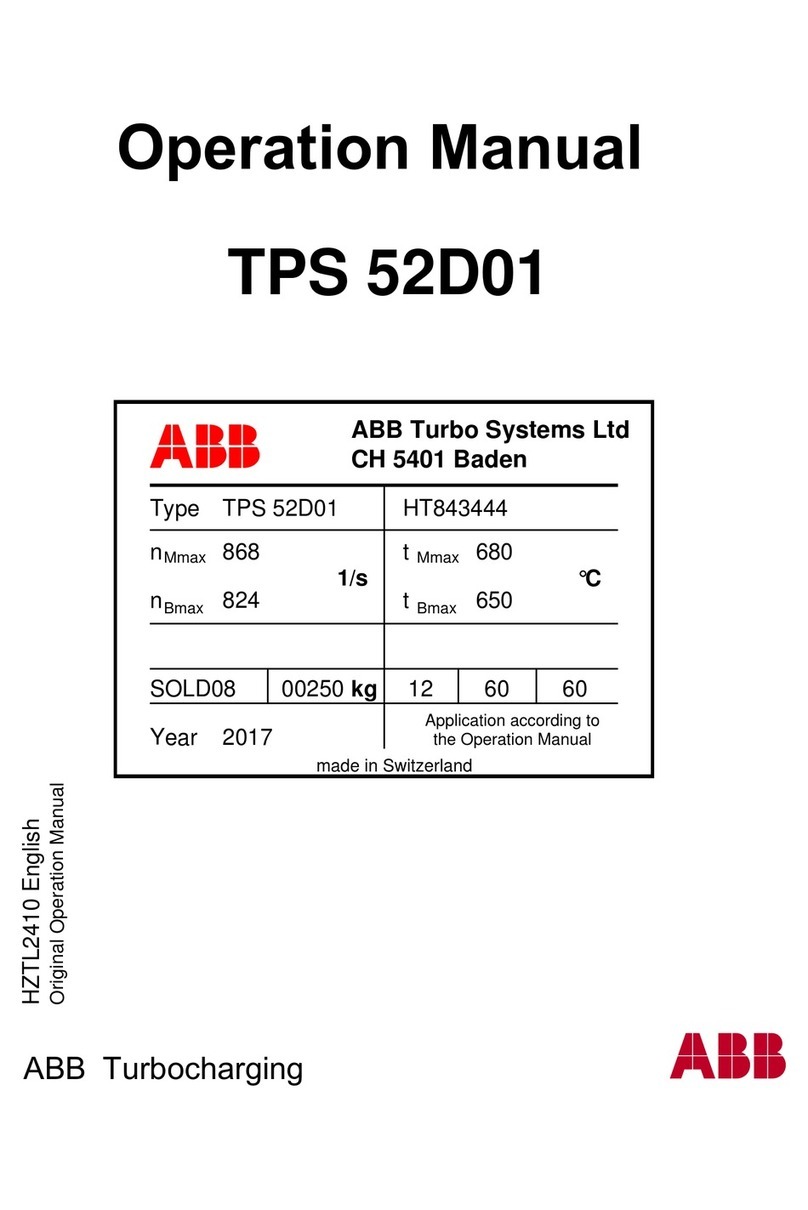

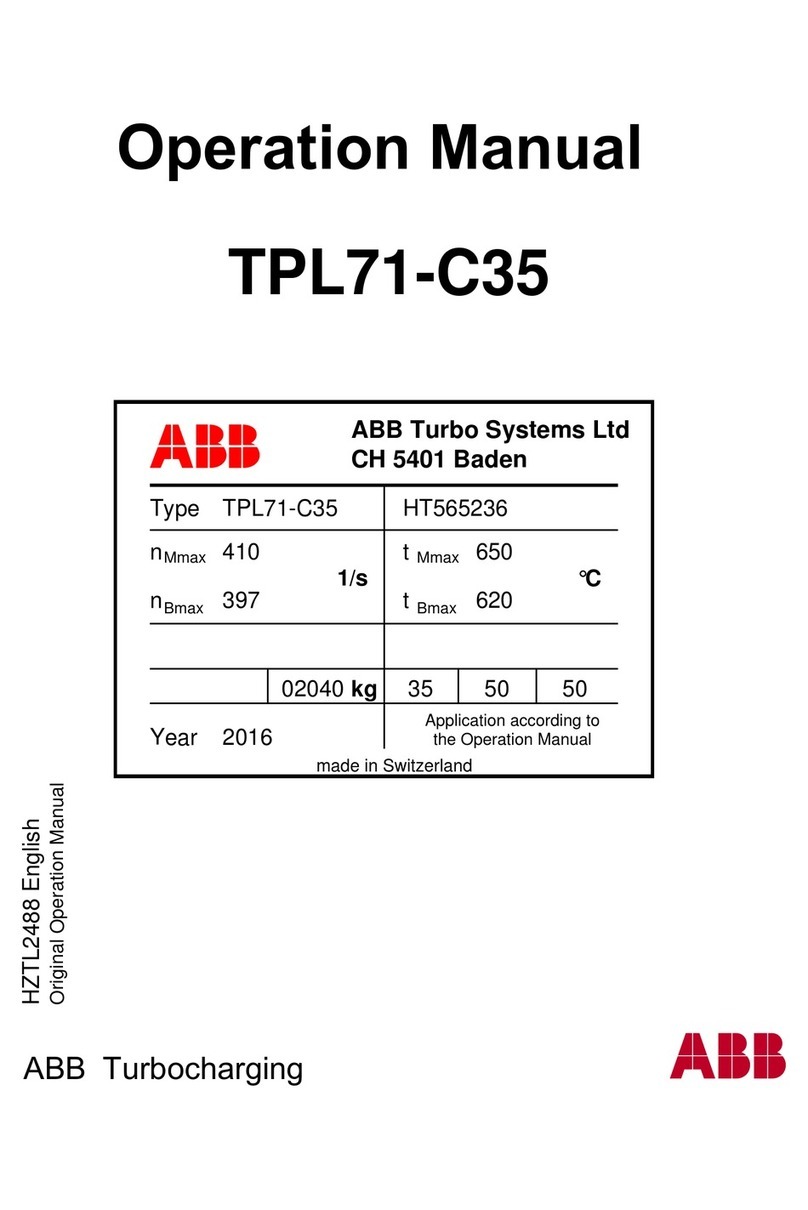

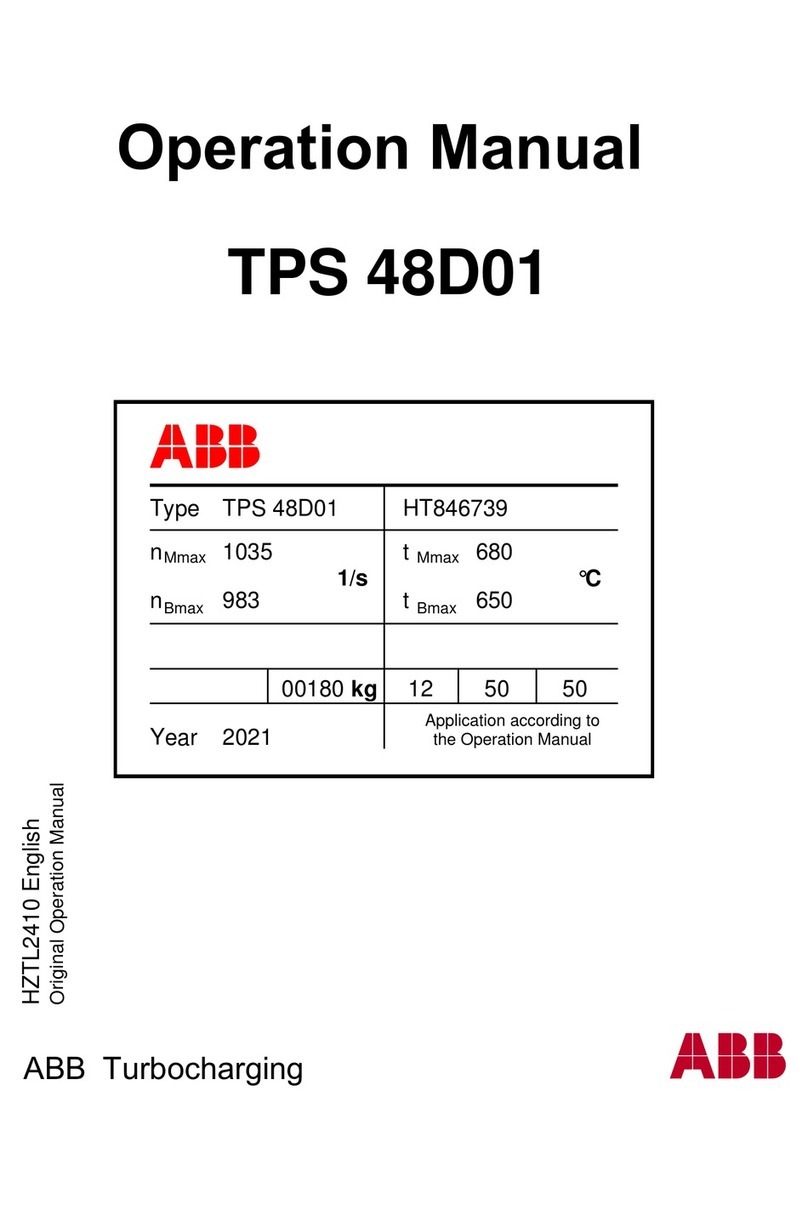

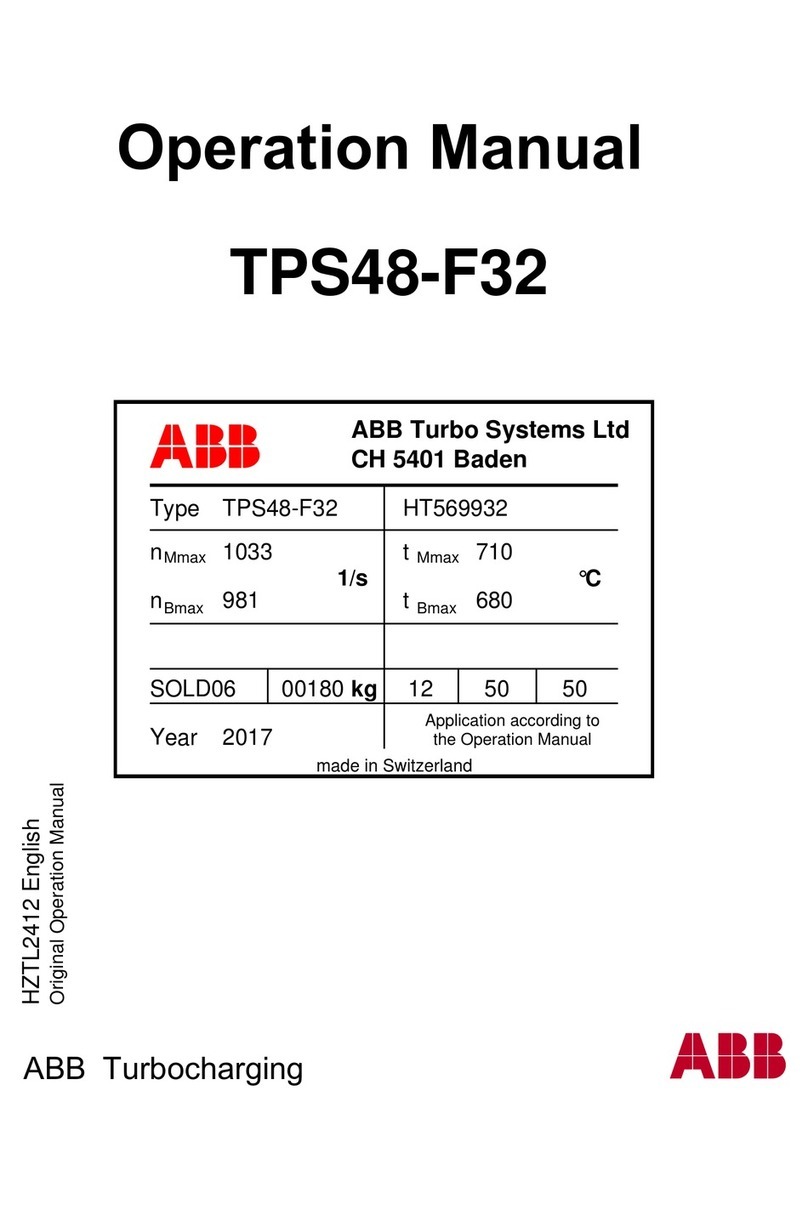

ABB

ABB TPL65VA33 Operation manual

Milltronics

Milltronics AIRANGER DPL PLUS instruction manual

Siemens

Siemens SIMATIC RTLS4030T EX1 operating instructions