CHINT NP2 Series Installation instructions

NO:2020.04

Standard:IEC/EN 60947-5-1

NP2 Series

Pushbutton

User Instruction

Safety Warning

1

2

3

4

Only professional technicians are allowed for installation and

maintenance.

Installation in any damp, condensed-phase environment with

inflammable and explosive gas is forbidden.

When the product is being installed or maintained, the power

must be switched off.

You are prohibited from touching the conductive part when

the product is operating.

1

2

01

NP2 series pushbutton is used in industrial control circuit with frequency

of AC 50Hz or 60Hz, rated operating voltage up to 415V and DC operating

voltage up to 250V. It is used to control electromagnetic starter, contactor,

relay and other electrical circuits. Pushbutton with indicator is also suitable

for applications that need signal light indication.

Use Purpose

Main Technical Parameters

Table 1 Main technical parameters

Environmental

conditions

Ambient temp. (℃)

Hot and humid

atmospheric conditions

Altitude

Pollution class/

installation category

Rated operating voltage

Ue(V)

Rated operating current

Ie(mA)

Rated insulation voltage

Ui(V)

Conventional thermal

current Ith(A)

Rated impulse withstand

voltage Uimp(kV)

Head protection class

Rated operating voltage

of button with indicator

Ue(V)

Technical parameters

-5℃~+40℃, average temperature should

not exceed +35℃ within 24h

Relative humidity should not exceed 50% at +40℃;

up to 90% at +20℃;

No influence below 2000m

Class 3/II

AC-15: 415/380/240/220; DC-13: 250/220/125/110

415

10

2.5

IP40, IP65 (part)

See product body for details

AC-15: 1.9/2.5/3/4.5; DC-13: 0.27/0.3/0.55/0.6

Rated operating current

of button with indicator

Ie(mA)

See product body for details

02

3

Installation

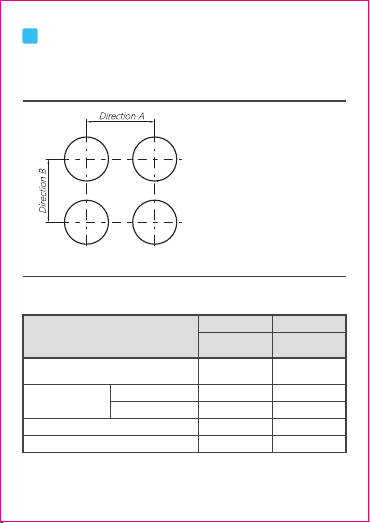

1) See Figure 1 and Table 2 for minimum distance between the center of

mounting holes. See Table 3 for installation dimensions of button control

box.

Figure 1 Minimum distance between center of mounting hole

Table 2 Minimum distance between center of mounting hole

Unit:mm

The diameter of the mounting hole for

+0.4

Φ22 panel mounting button is 22.3 0

mm; the metal head is suitable for

mounting panel with thickness of

1mm~6mm; the plastic head is suitable

for mounting panel with thickness of

1mm~4mm.

Type

Flat type, knob type, handle type,

key type, with indicator, signal light

Φ22 installation

dimensions

Φ22 installation

dimensions

Direction A Direction B

Mushroom type,

self- locking type

Dual head button

Dual head button with indicator

Φ30 Φ40

Φ60

30

30

65

30

30

50

50

65

50

60

03

Table 3 Installation dimensions of button control box

Unit:mm

Model

NP2-B1□□□□□

NP2-B2□□□□

NP2-B3□□□□□

Cable hole size Installation dimensions

Φ

Φ20

Φ20

20 2-Φ4.3, center to center distance 54

2-Φ4.3, center to center distance 54×68

2-Φ4.3, center to center distance 54×98

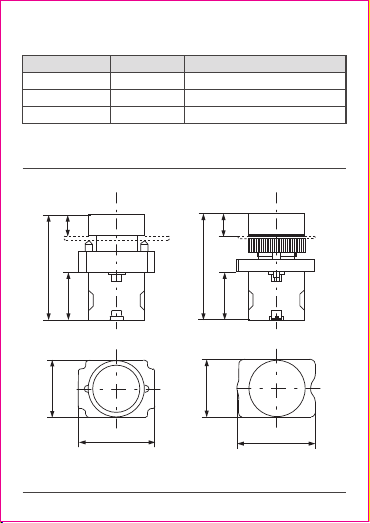

2) See Figure 2 and Figure 3 and Table 4 and Table 5 for product overall

dimensions.

DD

A

B

C

25

C A

B

25

Figure 2 NP2-BA□□ Figure 3 NP2-EA□□

Unit:mm

04

Table 4 Overall dimensions of different types of pushbuttons

Unit:mm

Model

NP2-BA□□ NP2-EA□□

NP2-BC□□/ NP2-EC□□

NP2-BS□□□/ NP2-ES□□□

NP2-BT□□/ NP2-BX□□

NP2-BD□□/ NP2-ED□□

NP2-BJ□□/ NP2-EJ□□

NP2-BG□□/ NP2-EG□□

NP2-BL8□□□/ NP2-EL8□□□

NP2-BW3□6□/ NP2-EW3□6□

NP2-BW3□8□/ NP2-EW3□8□

NP2-BW8□6□/ NP2-EW8□6□

NP2-BV6□/ NP2-EV6□

NP2-BV8□/ NP2-EV8□

/

A B C D

55/55

75/75

75/75

75/75

71/71

71/71

63/63

55/55

80/80

86/86

78/78

56/56

56/58

13/12

33/33

33/33

33/33

27/27

27/27

27(19)/27(19)

12/12

19/19

19/19

15/15

14/17

14/17

30/30

40/40

40/40

31/31

31/31

31/31

31/31

30/30

30/30

30/30

30/30

30/30

30/30

40/42

40/42

40/42

41/41

41/41

41/41

41/41

42/42

40/42

40/42

55/55

40/42

40/42

Note: For NP2-BG□□ NP2-EG□□B, the dimension outside the brackets is height

with key, the dimension inside the brackets is height without key.

/

Table 5 Overall dimensions of pushbutton control box

Unit:mm

Model

NP2-B1□□□□□

NP2-B2□□□□

NP2-B3□□□□□

Length Width Height Remarks

70

105

135

70

70

70

63

63

63

Height for empty case 52

Height for empty case 52

Height for empty case 52

Terminal tightening

torque N.m

M3.5

0.8 1.2~

Wire (Hard)

mm²

Wire (Soft)

mm² Remarks

1) Use hard wire or

soft wire for a single

connection.

One terminal can

connect up to two

conductors with

same sectional area

and type;

2) Wire strip length:

8mm.

8mm

8mm

2×

(0.5 2.5)~

2×

(0.5 2.5)~

05

3) See Table 6 for wire selection and tightening torque

Table 6 Wire selection and tightening torque

4) Installation procedure and method

① When installing metal head type button, insert the operation head

into the mounting hole from the front of the panel, then screw it into the

base from the back of the panel. Tighten the fixing screws at both ends

evenly (as shown in Figure 4). Do not overtighten the screws, the torque

should not exceed 0.25N·m. If the button is jammed after installation, adjust

the two fixing screws on the base and make sure they have the same

tightness.

②Before installing plastic head type button, remove the base first (insert

a screwdriver into the hole on the base and pry it up, as shown in Figure 5).

Tighten the nuts with a torque of 1.2N·m~1.8N·m.

③For NP2-B□□□□ NP2-J□□□□ buttons with cases, there are two

Φ21mm cable holes on both sides of their bottom covers. Before

installation, user should perforate the cable hole as needed (do not use too

much force). If IP40 is required for overall enclosure protection, user should

pay attention to the protection of the cable holes and the screw holes on

bottom cover. The cable holes can be protected by using cable connectors

with matching specifications or other effective measures. The tightening

torque for the installation of button box case should not exceed 1.2N·m.

,

06

4

Maintenance

Tighten the terminals of the button on a regular basis to make sure the

wires are connected securely.

Tighten the fixing screws of the button on a regular basis.

Disconnect the power before regular maintenance to ensure personal

safety.

It is recommended to conduct maintenance once a month.

See Table 7 for Analysis and Troubleshooting of Faults.

Figure 4 Assembly diagram of

metal head type base

Figure 5 Disassembly diagram of

plastic head type base

Table 7 Analysis and Troubleshooting of Faults

Symptons Cause analysis Troubleshooting method and precautions

The button

cannot be

operated

smoothly

There are foreign objects

like dust or greasy dirt

on the button operation

head or pushing rod of

contact assembly.

Remove the foreign objects like dust or greasy

dirt on the button operation head or pushing

rod of contact assembly, make sure the

environment is dry and clean after installing

the panel. Use proper lubricant at the moving

surface of the parts if necessary.

Check if the input voltage complies with the

rated operating voltage; check if there is any

short circuit or disconnection in the circuit.

The input voltage does

not comply with the rated

operating voltage, or

there is short circuit or

disconnection in the circuit.

The light

bead is not

bright

enough or is

not on at all

QC PASS

Test date: Please see the packing

ZHEJIANG CHINT ELECTRICS CO., LTD.

NP2 Series

Pushbutton

IEC/EN 60947-5-1

Check 31

07

In order to protect the environment, the product or product parts

should be disposed of according to the industrial waste treatment process,

or be sent to the recycling station for assortment, dismantling and recycling

according to local regulations.

5

Environmental Protection

NP2 Series

Pushbutton

User Instruction

Zhejiang Chint Electrics Co., Ltd.

Add: No.1, CHINT Road, CHINT Industrial Zone,North Baixiang,

Yueqing, Zhejiang 325603,P.R.China

E-mail: global-sales@chint.com

Website: http://en.chint.com

This manual suits for next models

3

Table of contents