IMPORTANT AIRANGER DPL PLUS FEATURES

FIXED FEATURES

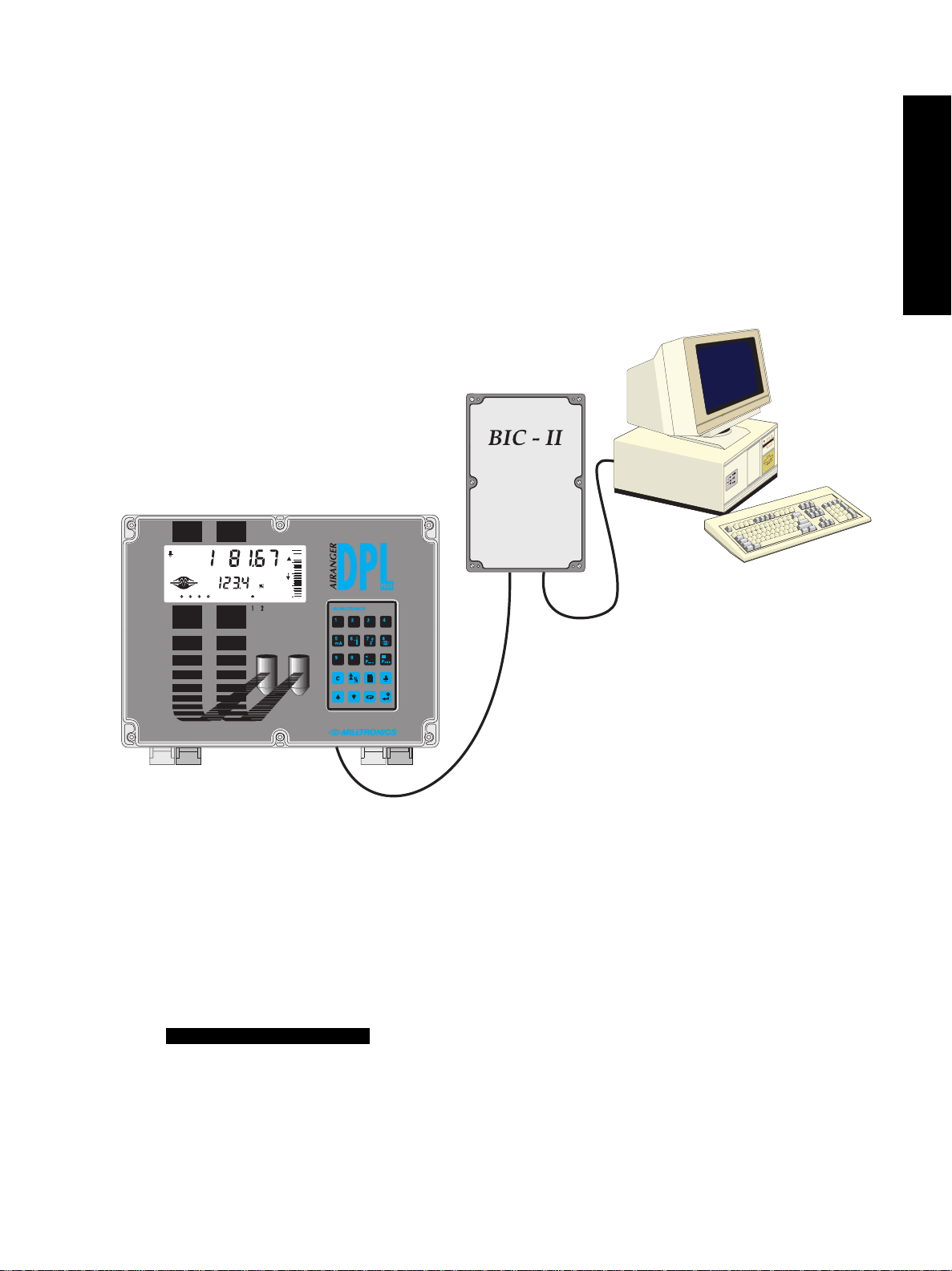

ENCLOSURE: Chemical resistant, light weight, dust tight, liquid tight, easy to work with.

LCD: Large digits for Reading and programming value displays.

Custom Graphic Symbols for continuous indication of operating conditions.

PROGRAMMER: 20 tactile feedback keys for easy access to programming and operating functions.

Magnetic mounting and infrared interface permit removal on programming completion.

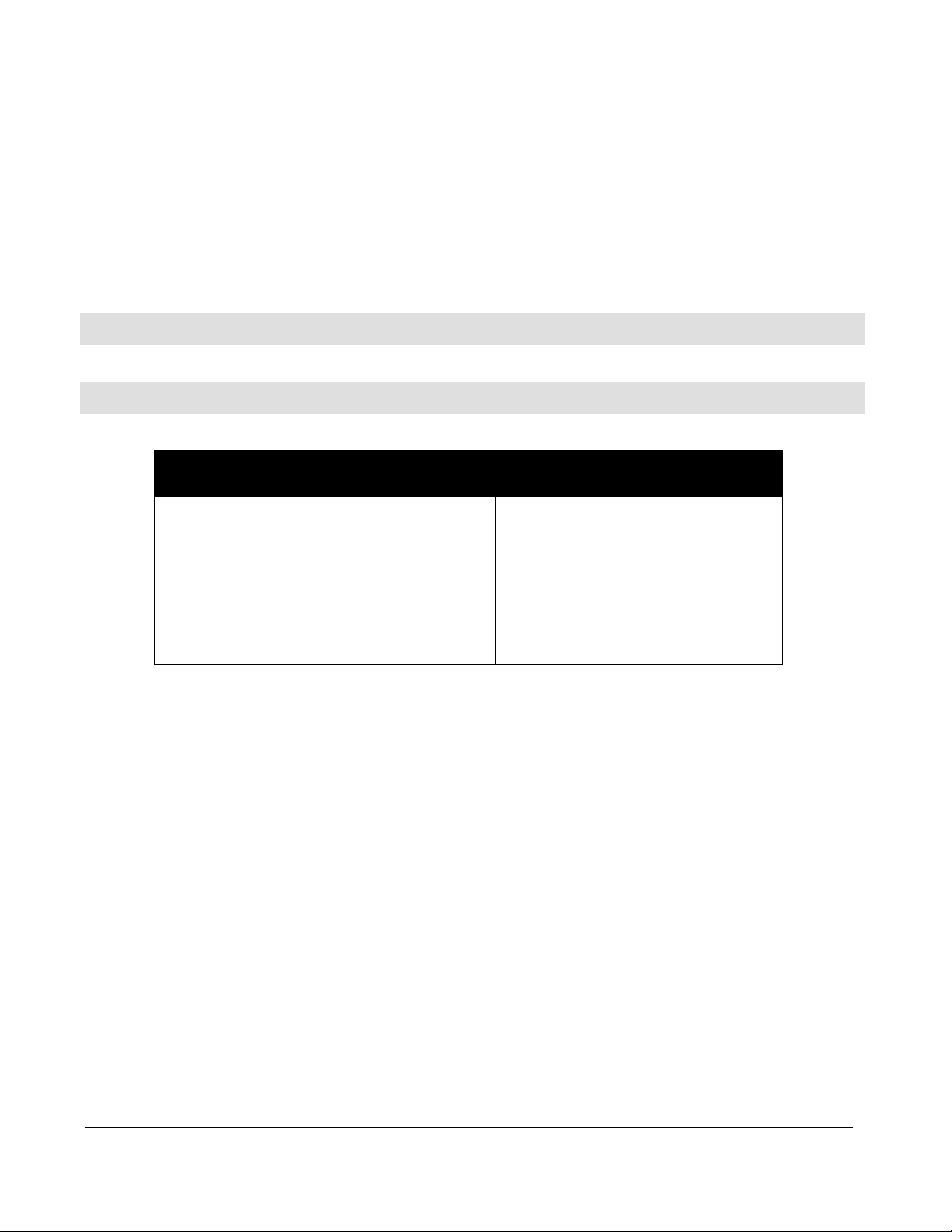

SCANNING: Substantially reduces equipment costs for an additional vessel (present or future).

COMMUNICATIONS: Simplex transmission of measurement and operating condition data.

Compatible with the Milltronics BIC-II for buffered conversion to RS-232C or RS-422.

SPEED: Fast 16/32 bit microprocessor at 16.7 MHz clock speed.

1 vessel (point) per second scanning speed capability.

RELIABILITY: Surface Mount Technology (SMT), also provides for full features in a compact design.

Sonic IntelligenceTM ensures all measurements are accurate and reliable.

Immune to power interruptions. All programming is stored indefinitely. Dynamic

operating data is retained for one hour and updated immediately on power resumption.

PROGRAMMABLE FEATURES

Typically, a very small percentage of the programmable features require operator alteration. However, for

demanding measurement requirements any operator programmable feature may be adjusted as desired.

Following is a list of some of the features that make the DPL+ easy to program, yet versatile enough to

handle complex level measurement requirements.

GENERAL FEATURES

DIRECT ACCESS: Any operator programmable feature may be accessed directly.

SCROLL ACCESS: Single button "scroll forward", single button "scroll back", to key features.

OPERATION: Select "level","space","distance","difference","average", or "tripper" operation.

MATERIAL: Liquid or Solid; automatically adjusts echo processing with one entry.

RESPONSE: Slow, medium, fast, surge, or turbo response to material level changes, one entry.

UNITS: Display Readings in m, cm, mm, ft, in, %, or any other units desired.

ADDITIONAL FEATURES (use as desired)

VOLUME: 8 pre-programmed tank shape options

2 universal tank shape programming methods

FAILSAFE: Numerous failsafe options for process control equipment activation.

RELAYS: 8 functions including level, rate of change, pump control, temperature and more

Fixed or independent on/off setpoints

mA OUTPUTS: Based on level, space, distance, volume, difference, or average.

4 range selections, 0-20, 4-20, 20-0, or 20-4 mA

Adjustable range and over-range limits

PL-508 8