-4-

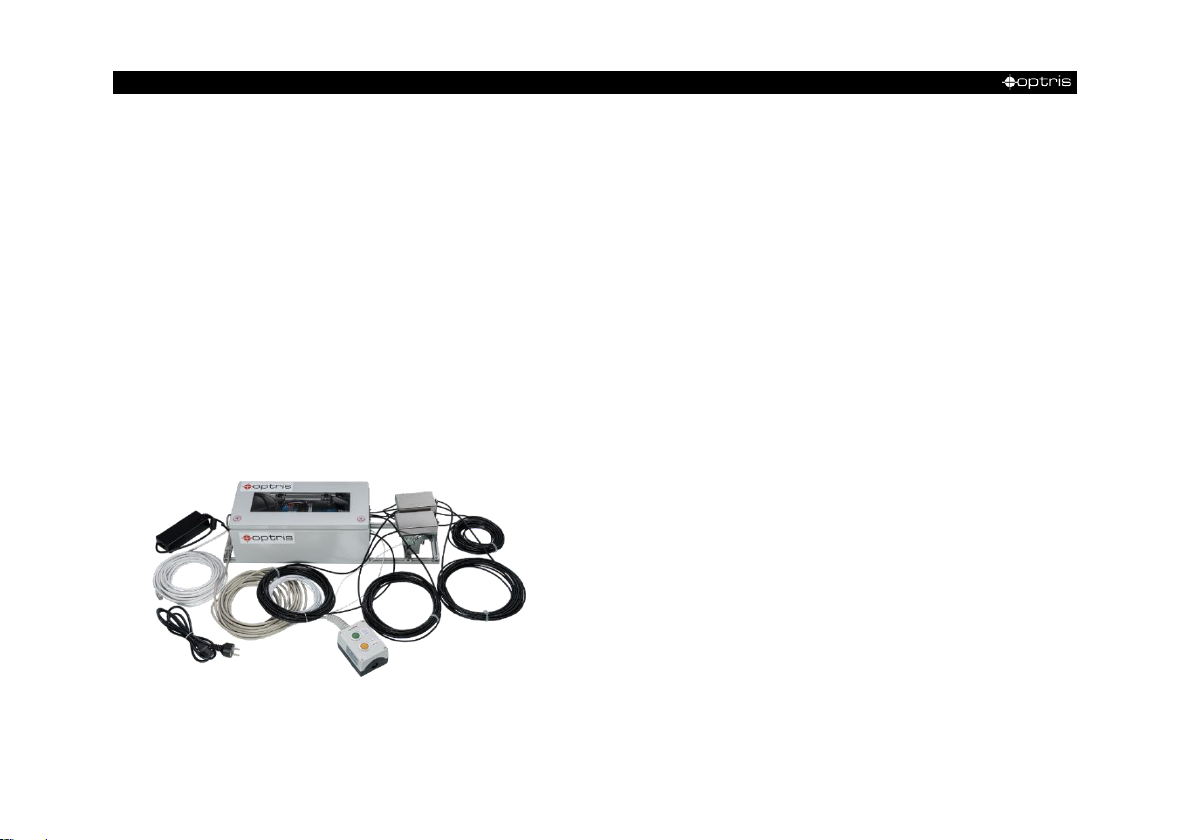

3Installation......................................................................................................................................... 20

3.1 Hardware installation .................................................................................................................. 20

3.2 Software Installation ................................................................................................................... 24

3.3 Electrical Installation................................................................................................................... 30

4Operation........................................................................................................................................... 32

4.1 Maintenance ............................................................................................................................... 35

4.2 Low-E measurement................................................................................................................... 36

5Basics of glass measurement......................................................................................................... 37

5.1 Reflection and transmission........................................................................................................ 37

5.2 Influence of different measuring wavelengths ............................................................................ 39

5.3 Hardening of glass sheets.......................................................................................................... 40

5.4 Referencing from below.............................................................................................................. 40

5.5 Angle dependency...................................................................................................................... 41