TEK 2225 User manual

TEK

SERVICE

070-6299-00

MANUAL

Product

Group

46

OSCILLOSCOPE

SERVICE

THE FOLLOWING SERVICING INSTRUCTIONS ARE

FOR USE BY QUALIFIED PERSONNEL ONLY. TO

AVOID PERSONAL INJURY, DO NOT PERFORM ANY

SERVICING OTHER THAN THAT CONTAINED IN

OPERATING INSTRUCTIONS UNLESS YOU ARE

QUALIFIED TO DO SO. REFER TO OPERATORS

SAFETY SUMMARY AND SERVICE SAFETY SUM-

MARY PRIOR TO PERFORMING ANY SERVICE.

Please Check for

CHANGE

INFORMATION

at

the Rear of This Manual

First

Printing

OCT

1987

Revised

APR

1990

Scans

by

ARTEK

MEDL4

==-

Copyright

O

1987 Tektronix, Inc. All rights reserved. Contents of this

publication may not be reproduced in any form without the written

permission of Tektronix, Inc.

Products of Tektronix, Inc. and its subsidiaries are covered by W.S. and

foreign patents issued and pending.

TEKTRONIX, TEK, SCOPE-MOBILE, and are registered trade-

marks of Tektronix, Inc.

Printed in U.S.A. Specification and price change privileges are

reserved.

INSTRUMENT SERIAL NUMBERS

Each instrument has a serial number on a panel insert, tag, or

stamped on the chassis. The first number or letter designates the

country of manufacture. The last five digits of the serial number are

assigned sequentially and are unique to each instrument. Those manu-

factured in the United States have six unique digits. The country of

manufacture is identified as follows:

BOO0000 Tektronix, Inc., Beaverton, Oregon, U.S.A.

HKOOOOl Hong Kong

100000 Tektronix Guernsey, Ltd., Channel Islands

200000 Tektronix United Kingdom, Ltd., London

300000 SonyITektronix, Japan

700000 Tektronix Holland, NV, Heerenveen,

The Netherlands

Scam

by

ARTEK

MEDIA

3

2225

Service

TABLE

OF

CONTENTS

Page

LIST OF ILLUSTRATIONS

...................

iv

LIST OF TABLES

...........................

v

OPERATORS SAFETY SUMMARY

............

vi

SERVICING SAFETY SUMMARY

.............

vii

Section

1

SPECIFICATION

INTRODUCTION

..............

1-1

ACCESSORIES

..............

1-1

FOR MORE INFORMATION

.....

1-1

RECOMMENDED RECALIBRATION

.................

SCHEDULE 1-1

PERFORMANCE CONDITIONS

..

1-1

Section

2

OPERATING INSTRUCTIONS

PREPARATION FOR USE

........

2-1

SAFETY

....................

2-1

LINE VOLTAGE SELECTION

....

2-1

LINE FUSE

.................

2-2

POWER CORD

..............

2-2

INSTRUMENT COOLING

.......

2-2

INITIAL START-UP

...........

2-2

REPACKAGING

..............

2-3

CONTROLS. CONNECTORS.

AND INDICATORS

..............

2-4

POWER AlVD DISPLAY

........

2-4

VERTICAL

..................

2-4

HORIZONTAL

...............

2-5

Page

TRIGGER

..................

2-6

REAR PANEL

...............

2-7

OPERATING CONSIDERATIONS

. .

2-8

GRATICULE

................

2-8

GROUNDING

...............

2-8

SIGNAL CONNECTIONS

......

2-8

INPUT-COLIPLING

CAPACITOR PRECHARGING

...

2-9

OPERATOR'S CHECKS AND

ADJUSTMENTS

..............

2-10

INITIAL SETUP

.............

2-10

TRACE ROTATION

ADJUSTMENT

.............

2-10

PROBE COMPENSATION

.....

2-10

Section

3

THEORY OF OPERA'I'ION

SECTION ORGANIZATION

.....

3-1

INTEGRATED ClRClJlT

DESCRIPTIONS

.............

3-1

GENERAL DESCRIPTION

........

3-1

DETAILED CIRCUIT

DESCRIPTION

................

3-3

VERTICAL

.................

3-3

TRIGGER

..................

3-7

SWEEP AND SWEEP

GENERATOR LOGIC

........

3-10

HORIZONTAL

..............

3-12

FRONT PANEL

.............

3-14

Z-AXIS AMPLIFIER

.........

3-14

POWER SUPPLY

...........

3-16

Scam

by

ARTEK

MEDIA

=>

2225

Service

TABLE OF CONTENTS

(cont)

Page Page

Section

4

PERFORMANCE CHECK PROCEDLIRE Section

5

ADJUSTMENT PROCEDLIRE

INTRODUCTION

................

4-1

PERFORMANCE CHECK

..................

INTERVAL 4-1

STRUCTURE

................

4-1

TEST EQUIPMENT

REQUIRED

..................

4-1

LIMITS AND TOLERANCES

.....

4-1

PREPARATION FOR

CHECKS

...................

4-1

INDEX TO PERFORMANCE

CHECK STEPS

..............

4-3

VERTICAL

....................

4-4

INITIAL CONTROL

SETTINGS

..................

4-4

PROCEDURE STEPS

..........

4-4

HORIZONTAL

.................

4-8

INITIAL CONTROL

SETTINGS

..................

4-8

PROCEDURE STEPS

..........

4-8

TRIGGER

....................

4-12

INITIAL CONTROL

SETTINGS

.................

4-1 2

PROCEDURE STEPS

.........

4-1 2

EXTERNAL Z-AXIS AND

PROBE ADJUST

..............

4-1 5

INITIAL CONTROL

SETTINGS

.................

4-1

5

.........

PROCEDURE STEPS 4-1 5

INTRODUCTION

...............

5-1

..................

PURPOSE 5-1

...............

STRUCTURE 5-1

TEST EQUIPMENT

REQUIRED

.................

5-1

LIMITS AND TOLERANCES

....

5-1

ADJUSTMENTS AFFECTED

BY

REPAIRS

..................

5-1

PREPARATION FOR

ADJUSTMENT

..............

5-1

INDEX TO ADJUSTMENT

PROCEDURE STEPS

.........

5-3

POWER SLIPPLY AND

................

CRT DISPLAY 5-4

INITIAL CONTROL

SETTINGS

.................

5-4

PROCEDURE STEPS

.........

5-4

VERTICAL

...................

5-6

INITIAL CONTROL

SETTINGS

.................

5-6

PROCEDURE STEPS

.........

5-6

HORIZONTAL

................

5-13

INITIAL CONTROL

SETTINGS

................

5-13

........

PROCEDURE STEPS 5-13

TRIGGER

...................

5-18

INITIAL CONTROL

SETTINGS

................

5-18

PROCEDURE STEPS

........

5-18

EXTERNAL Z-AXIS AND

.............

PROBE ADJUST 5-22

INITIAL CONTROL

................

SETTINGS 5-22

........

PROCEDURE STEPS 5-22

Scam

by

ARTEK

MEDL4

*

2225

Service

TABLE OF CONTENTS

(cont)

Page

Section

6

MAINTENANCE

STATIC-SENSITIVE

COMPONENTS

.

.

..

.

..

.

...

..

.

..

6-1

PREVENTIVE MAINTENANCE

....

.

6-2

INTRODUCTION

..

.

..

.

.

.

..

.

.

.

.

6-2

GENERAL CARE

..

..

..

.

.

.

.

.

.

.

6-2

INSPECTION AND

CLEANING

.

.

..

..

.

..

.

.

.

.

....

.

6-2

Page

OBTAINING REPLACEMENT

PARTS

.

.

.

..

.

..

.

..

.

.

..

..

..

6-1

0

MAINTENANCE AlDS

.

......

6-1

1

INTERCONNECTIONS

..

..

.

..

6-1

1

TRANSISTORS AND

INTEGRATED CIRCUITS

.

.

.

..

6-1 1

SOLDERING TECHNIQLIES

...

6-12

REMOVAL AND REPLACE-

MENT INSTRUCTIONS

...

.

.

..

6-1

3

LUBRICATION

.

..

.

.

...

.

..

.

.

.

.

6-4

SEMICoNDUCToR

CHECKS

...

.

6-4

Section

7

OPTIONS AND ACCESSORIES

PERIODIC READJUSTMENT

.

.

.

.

6-4

TROUBLESHOOTING

.

.

..

.

.

.

.

.

..

.

6-4

INTRODUCTION

..

.

.

.

.

.

...

..

.

.

6-4

TROLIBLESHOOTING AlDS

.

..

..

6-4

INTRODUCTION

.

.

..

.

.

..

.

..

.

.

7-1

STANDARD ACCESSORIES

.

.

.

7-1

OPTIONS

.

..

.

.

..

..

.

.

.

.....

.

7-1

RIBBON-CABLE

CONNECTORS

.

..

.

..

..

.

.

.

..

.

6-6

TROUBLESHOOTING

Section

8

REPLACEABLE ELECTRICAL PARTS

EQUIPMENT

.

..

.

.

..

.

.

.

.

.

.

..

.

.

6-6

TROLIBLESHOOTING

Section

9

DIAGRAMS

TECHN~QL~ES

,

.

.

.

..

.

..

,,

.

.

.

6-7

Section

10

REPLACEABLE MECHANICAL PARTS

CORRECTIVE MAINTENANCE

...

6-10

INTRODUCTION

.

.

..

.

..

...

.

.

.

6-1

0

APPENDIX

MAINTENANCE

PRECAUTIONS

.

.

.

..

.

..

.

.

..

.

6-10

CHANGE INFORMATION

iii

Scam

by

ARTEK

MEDIA

=>

2225

Service

Figure

LIST

OF

ILLUSTRATIONS

Page

The 2225 Oscilloscope

..............................................................

viii

........................................

1-1 Max Input Voltage Vs Frequency Derating Curve 1-7

......................................................

1-2 Instrument dimensional drawing 1-8

...............................

2-1 Voltage Selector switch. fuse. and power-cord receptacle 2-1

....................................................

2-2 Power-cord and line-voltage data 2-2

2-3 Rear Panel

.......................................................................

2-7

.....................................................

2-4 Graticule measurement markings 2-8

2-5 Probe compensation

..............................................................

2-11

......................................................

2-6 Probe compensation locations 2-11

......................................

3-1 Block diagram of the Channel 1 Attenuator circuit 3-3

.........................................

3-2 Block diagram of the Channel Switching circuit 3-5

................................

3-3 Block diagram of the Sweep Generator and Logic circuit 3-10

.......................................

3-4 Block diagram of the Horizontal Amplifier circuit 3-13

3-5 Simplified diagram of the DC Restorer circuitry

........................................

3-15

5-1 Attenuator trimmer adjustments

......................................................

5-9

6-1 Multi-connector operation

...........................................................

6-6

Scam

by

ARTEK

MEDIA

*

2225

Service

OPERATORS SAFETY SUMMARY

The safety information in this summary is for operafing personnel. Warnings and cautions will also

be

found

throughout the manual where they apply.

Terms in this Manual Grounding the Product

CAUTION statements identify conditions or practices This product is grounded through the groundingcon-

that could result in damage to the equipment or ductor of the power cord. TOavoid electrical shock,

other property. plug the power cord into a properly wired recepta-

cle before making any connections to the product

WARNING statements identify conditions or practices input or output terminals. A protective ground con-

that could result in personal injury or loss of life. nection, by way of the grounding conductor in the

power cord, is essential for safe operation.

Terms as Marked on Equipment Danger Arising From Loss of Ground

CAUTION indicates a personal injury hazard not im-

Upon

loss

of

the

protective-ground connection,

all

mediately accessible as one reads the markings, or

accessible

conductive

parts,

including

knobs

and

a

hazard

property, including

the

itself' controls that may appear to be insulating, can ,-en-

DANGER indicates

a

personal injury hazard immedi- der an electric shock.

ately accessible as one reads the marking.

Use the Proper Power Cord

Symbols in this Manual

Use only the power cord and connector specified for

your product.

This symbol indicates where applicable

cautionary or other information is to Use only a power cord that is in good condition.

be found. For maximum input voltage

see Table

1-1

.

For detailed information on power cords and con-

nectors, see Figure

2-2.

Symbols as Marked on Equipment Use the Proper Fuse

1

DANGER-High voltage.

@

Protective ground (earth) terminal.

A

ATTENTION-Refer to manual.

Power Source

To avoid fire hazard, use only a fuse of the correct

type, voltage rating and current rating as specified in

the parts list for your product.

Do Not Operate in an Explosive

To avoid explosion, do not operate this instrument in

an explosive atmosphere unless it has been specifi-

cally certified for such operation.

This product is intended to operate from a power

source that does not apply more than

250

V

rms

DO Not Remove Covers or Panels

between the supply conductors or between either

supply conductor and ground. A protective ground To avoid personal injury, do not remove the product

connection, by way of the grounding conductor in covers or panels. Do not operate the product with-

the power cord, is essential for safe operation. out the covers and panels properly installed.

Scans

by

ARTEK

MEDU

=>

2225

Service

SERVICING SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to the preceding Operators Safety Summary

Do Not Service Alone

Disconnect power before removing protective

panels, soldering, or replacing components.

Do not perform internal service or adjustment of this

product unless another person capable of rendering

first aid and resuscitation is present.

Power Source

Use Care When Servicing With Power On

This product is intended to operate from a power

source that does not apply more than

250

volts rms

Dangerous voltages exist at several points in this between the supply conductors or between either

product. To avoid personal injury, do not touch ex- supply conductor and ground.

A

protective ground

posed connections or components while power is connection by way of the grounding connetor in the

on. power cord is essential for safe operation.

Scam

by

ARTEK

MEN

=>

Section

1-2225

Service

SPECIFICATION

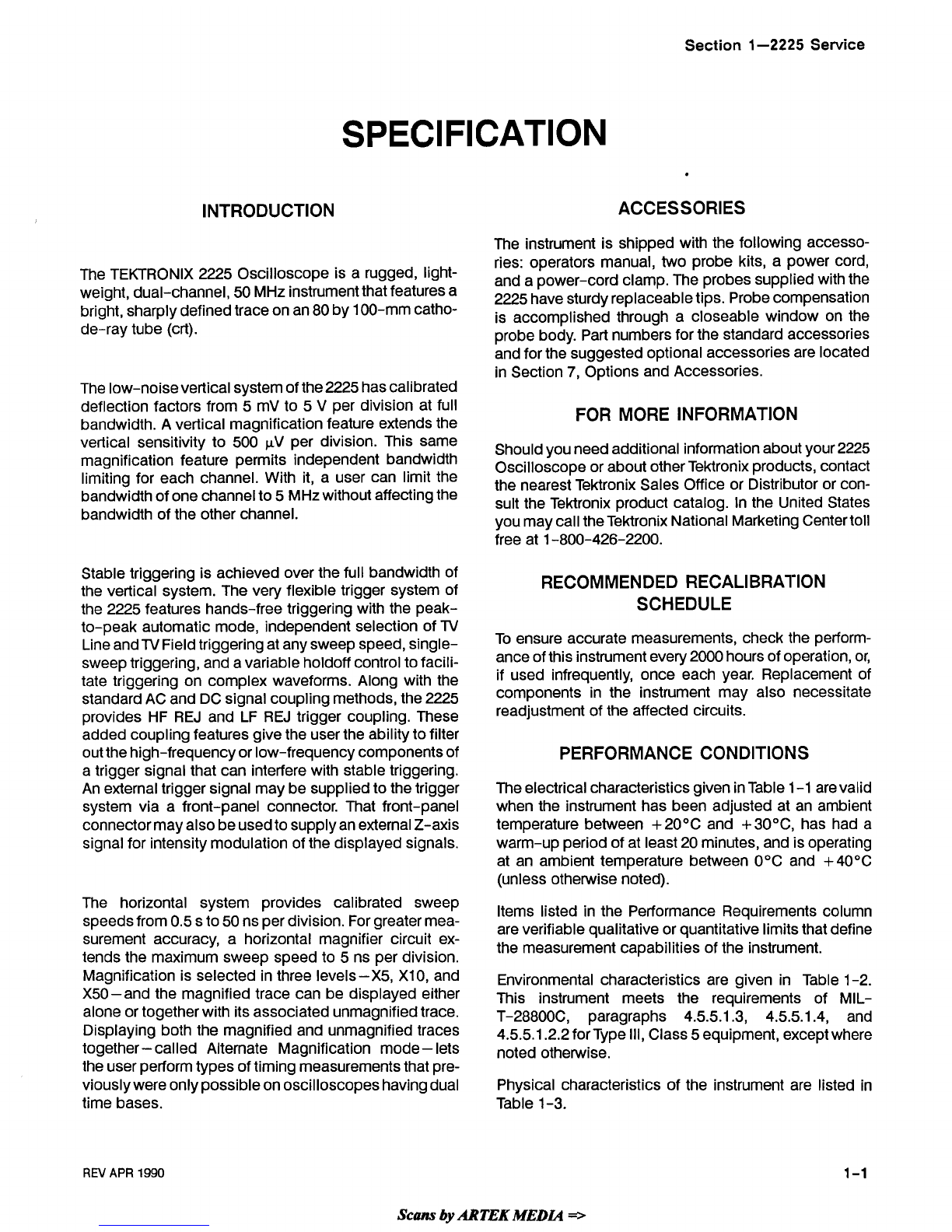

INTRODUCTION ACCESSORIES

The instrument is shipped with the following accesso-

ries: operators manual, two probe kits, a power cord,

The

TEKTRoNIX

2225

oscillosco~e

is

a

light- and a power-cord clamp.The probessuppliedwiththe

weight,dual-channel, 50MHz instrumentthat featuresa 2225

have

sturdy

replaceable

tips.

Probe

compensation

bright*

defined

trace

On

an

80

100-mm

is

accomplishedthrough a closeable window on the

de-ray tube (crt). probebody. Part numbersfor the standard accessories

andfor the suggestedoptionalaccessoriesare located

inSection

7,

Options and Accessories.

The low-noisevertical systemofthe2225hascalibrated

deflectionfactors from

5

mV to 5 V per division at full

bandwidth.A vertical ma~nificationfeature extendsthe

FOR MORE INFORMATION

vertical sensitivity to 506 FV per division. This same

Should

you

need

additional

infonation

about

your

2225

magnification

feature

permits independent

bandwidth

Oscilloscopeor about other TeMronixproducts,contact

limitingfor each channel. With it, a user can limit the

the

nearest

Tektronix

Sales

Office

or

Distributor

or

con-

bandwid'h ofone channel

'0

5 MHzwi'hout affectingthe

suit

the TeMronixproduct catalog.

in

fie

UnitedStates

bandwidth of the other channel. youmaycalltheTektronixNationalMarketingCentertoll

free at 1-800-426-2200.

Stabletriggering isachieved over thefull bandwidthof

the vertical system. The very flexibletrigger system of

the 2225 features hands-free triggering with the peak-

to-peak automatic mode, independentselectionof TV

LineandTVFieldtriggeringat anysweep speed,single-

sweeptriggering, and avariableholdoff controltofacili-

tate triggering on complex waveforms. Along with the

standardAC and DC signal couplingmethods,the2225

provides HF REJ and LF REJ trigger coupling. These

addedcouplingfeatures givethe userthe abilityto filter

outthehigh-frequency or low-frequency componentsof

a trigger signal that can interferewith stable triggering.

An externaltrigger signal may besuppliedto thetrigger

system via a front-panel connector. That front-panel

connectormayalsobeusedto supplyanexternalZ-axis

signalfor intensitymodulationof the displayedsignals.

RECOMMENDED RECALIBRATION

SCHEDULE

To ensure accurate measurements,check the perform-

anceofthis instrument every2000hoursof operation,or,

if used infrequently, once each year. Replacement of

components in the instrument may also necessitate

readjustmentof the affected circuits.

PERFORMANCE CONDITIONS

The electricalcharacteristicsgiveninTable 1-1 arevalid

when the instrument has been adjustedat an ambient

temperature between +20°C and +30°C, has had a

warm-up periodof at least20 minutes, and isoperating

at an ambient temperature between O°C and +40°C

(unless otherwise noted).

The

horizontal

'ystem provides

calibrated

sweep Items listed in the Performance Requirements column

'peeds

from

0'5

to

50

ns

per

division'

For

greatermea- a, verifiablequalitativeor quantitativelimitsthat define

surement accuracy, a horizontal magnifier circuit ex-

tends the maximum sweep speedto 5 ns per division. the measurement capabilitiesof the instrument.

Magnification is selectedinthree levels-X5, XlO, and Environmental characteristics are given in Table 1-2.

X50-and the magnifiedtrace can be displayed either This instrument meets the requirements of

MIL-

alone or togetherwithitsassociatedunmagnifiedtrace. ~-28800~,paragraphs 4.5.5.1.3, 4.5.5.1-4, and

Displayingboth the magnifiedand unmagnifiedtraces 4.5.5.1.2.2 forType Ill, Class5equipment, exceptwhere

together

-

called Alternate Magnification mode- lets notedotherwise.

theuserperformtypesoftimingmeasurementsthat pre-

viouslywereonlypossibleonoscilloscopeshavingdual Physical characteristics of the instrument are listed in

time bases. Table 1-3.

RN

APR

1990

Scam

by

ARTEK

MEDIA

==-

Specification-2225 Service

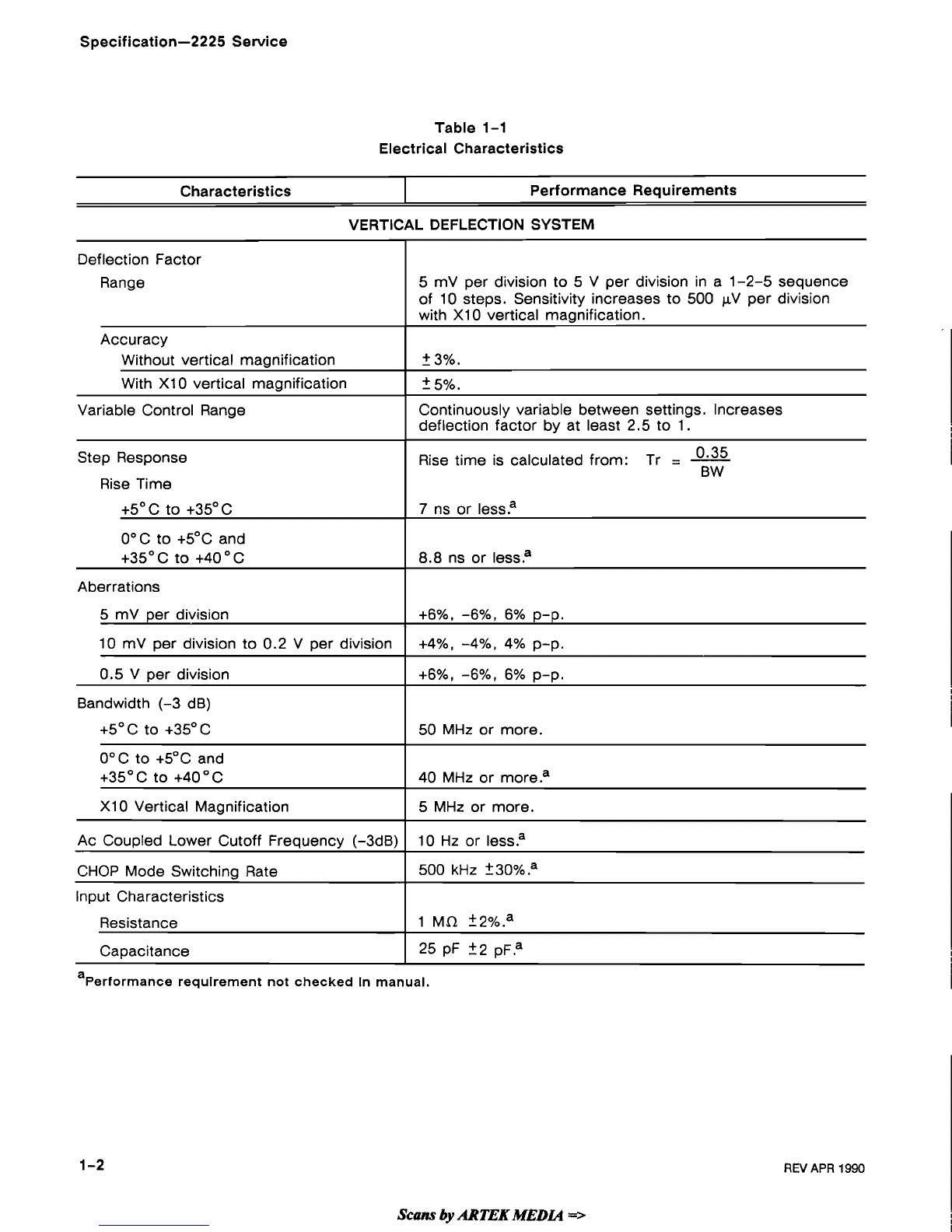

Table

1-1

Electrical Characteristics

VERTICAL DEFLECTION SYSTEM

Characteristics Performance Requirements

a

Performance requirement not checked in manual.

Deflection Factor

Range

Accuracy

Without vertical magnification

With XI0 vertical magnification

Variable Control Range

Step Response

Rise Time

+5" C to +35"C

0°C to +5"C and

+35OC to +40°C

Aberrations

5

mV per division

10 mV per division to 0.2 V per division

0.5 V per division

Bandwidth (-3 dB)

+5OC to +35OC

0°C to +5OC and

+35' C to +40°C

XI0 Vertical Magnification

Ac Coupled Lower Cutoff Frequency (-3dB)

CHOP Mode Switching Rate

Input Characteristics

Resistance

Capacitance

Scans

by

ARTEK

MEDLQ

=>

5 mV per division to 5 V per division in a 1-2-5 sequence

of 10 steps. Sensitivity increases to 500 pV per division

with XI0 vertical magnification.

2

3%.

2

5%.

Continuously variable between settings. Increases

deflection factor by at least 2.5 to 1.

Rise time is calculated from: Tr

=

-

0 35

BW

7

ns or lessa

8.8

ns or lessa

+6%, -6%, 6% p-p.

+4%, -4%, 4% p-p.

+6%, -6%,

6%

p-p.

50 MHz or more.

40 MHz or more.a

5 MHz or more.

10 Hz or lessa

500

kHz

?30%.a

1 Mi2 ?2%.a

25 pF +2 pFa

REV

APR

1990

Specification-2225 Service

Table

1-1

(cont)

Characteristics

With XI0 Vertical Magnification

I

At least 10 to 1 at 1 MHz.

Performance Requirements

Maximum Safe Input Voltage

(DC or AC Coupled)

Common-mode Rejection Ratio(CMRR)

Without Vertical Maanification

Trace Shift with VOLTSIDIV

Switch Rotation

400 V (dc

+

peak ac) or 800 V ac p-p at 10 kHz or lessa

(See Figure 1-1 for frequency derating curve.)

At least 10 to 1 at 10 MHz.

0.75 division or less; VOLTS/DIV Variable control

in the CAL detent?

Trace Shift as the VOLTSIDIV Variable

Control is rotated.

Trace Shift with CH 2 INVERT

Position Control Range

1 division or lessa

1.5 division or lessa

Trace Shift with XI0 Vertical Magnification

Channel Isolation

10.5 divisions above and below the center graticule

I

line at 25OC with the cabinet installed.

2.0 divisions or less?

Greater than 100:l at 10 MHz.

Trace Separation Range

I

At least

23

divisions.

TRIGGERING

Trigger Sensitivity

P-P AUTOITV LINE and

NORM Modes

5

MHz

I

50 MHz

I

TV FIELD

I

1

division of composite synca

I

I

Internal Signal

External Signal

External Input

I

0.3

div

40 mV

Lowest Usable Frequency in

P-P AUTO Mode

1.0 div

200 mV

A 1.0 division internal signal or 100 mV external signal

of 20 Hz or higher frequency will trigger.

Input Capacitance

1

25 PF 22.5

PFP

I

I

Input Resistance 1

Ma

Maximum Input Voltage

AC Coupled Lower Cutoff

Frequency (-3dB)

Scam

by

ARTEK

MEDL4

=>

I

400 V (dc

+

peak ac) or 800 V ac p-p at 10 kHz or lessa

(See Figure 1-1 for frequency derating curve.)

i

Internal Signal

External Signal 10 Hz or less?

20 Hz or less.a

a

Performance requlrement not checked

in

manual.

Specification-2225 Service

Table

1-1

(cont)

Characteristics

Trigger Level Range

NORM Mode

EXT Source

EXTI10 Source

Variable Holdoff Range

LF REJ Lower 3 dB point

HF REJ 3 dB point

Performance Requirements

Level may be set to any point of trace that can be

displayed.

At least 21.2 V, 2.4 V p-p.

At least 212 V, 24 V p-p.

Increases sweep holdoff time by at least a factor

of

8

at maximum holdoff?

30 kHz ?25%.a

30 kHz 225%.a

HORIZONTAL DEFLECTION SYSTEM

Sweep accuracy applies over the center eight divisions.

Exclude the first 25 ns of the sweep for magnified sweep

speeds and anything beyond the 100th magnified division.

Sweep Rates

Calibrated Range

Sweep

Accuracy

SECIDIV Variable Range

0.5 s per division to 0.05 ~s per division in a 1-2-5

sequence of 22 steps. The XI0 magnifier extends

maximum sweep speed to 5 ns per di~ision.~

Continuously variable and uncalibrated between calibrated

step settings of the SECIDIV switch. Decreases calibrated

sweep speeds by at least a factor of 2.5.

Unmagnified

X1

Magnified

X5 XI0 X50

Sweep Linearity

POSITION Control Range

Unmasnified

XI

Start of sweep to 10th division in XI, to 50th division

in X5, to 100th in X10, and to 500 division in X50 will

position past the center vertical graticule line.

Registration between Magnified and

Unmagnified traces

a

Performance requirement not checked in manual.

Magnified

X5 XI0 X50

0.2 division or less (measuredwhen switching from Magnifiedto

Unmagnified),alignedto center vertical graticule 1ine.a

Trace Shift between ALT and MAG

Modes

Scans

by

ARTEK

MEDIA

=>

Less than 1 divisiona

REV

APR

1990

Specification-2225 Service

Table 1-1 (cont)

Characteristics

X-Y OPERATION (XI MODE)

Performance Requirements

Sensitivity

Usable frequency range

Maximum Safe Input Voltage

Z-AXIS

5 V causes noticeable modulation. Positive-going

input decreases intensity.

DC

to 5

MHZP

400 V (dc

+

peak ac) or 800 V p-p ac at 10 kHz or less.a

(See Figure 1-1 for frequency derating curve.)

PROBE ADJUST SIGNAL OUTPUT

Deflection Factors

Accuracy

X- Axis

Y-Axis

Bandwidth (-3 dB)

X-Axis

Y-Axis

Phase difference between X-Axis and

Y-Axis Amplifiers

Same as vertical deflection system with variable controls

in the CAL detent.a

+

5%.

Same as vertical deflection systema

Dc to at least 2 MHz.

Same as vertical deflection systema

+3O from dc to 150 kHz with

DC

input coup1ing.a

POWER SUPPLY

Voltage into 1 MR Load

Repetition Rate

0.5 V +5%.

1 kHz -+5%.a

CATHODE-RAY TUBE

Line Voltage Ranges

115 V Setting

230 V Setting

Line Frequency

Maximum Power Consumption

Line Fuse

115 Setting

230 Setting

Nominal Accelerating Voltage

1

12,600

V

+60 V.a

a~erformancerequirement not checked

in

manual.

95 Vac to 128 Vaca

185 Vac to 250 Vacaa

48 Hz to 440

HZ.~

70 watts (80 VA)

.a

Display Area

Standard Phosphor

REV

APR

1990

UL 198.6 3AG

(1

I4 X 1 1/4 inch)

1.0 A, Slow.

0.5 A, Slow.

8

X

10 cma

GH (P31

)

.a

IEC127 (5

x

20 mm)

0.8 A, Slow.

0.4 A, Slow.

Specification-2225 Service

Table 1-2

Environmental Characteristics

a

Performance requirement not checked in

manual.

Characteristics

Temperature

Operating

Nonoperating

Altitude

Operating

Nonoperating

Relative Humidity

Operating (+30°C to +40°C)

Nonoperating (+30°C to +60°C)

Vibration

Operating

Shock

Operating and Nonoperating

Radiated and conducted

emission requirements

Scans

by

ARTEK

MEDLQ

=>

Performance Requirements

0°C to +40°C

(+32"F to +104"F)?

-55°C to t75"C

(-67"

F to +I67

"

F)

.a

To 4,570 meters (15,000 feet). Maximum operating

temperature decreased 1°C per 300 m (1000 feet)

above 1500 m (5,000 feet)

.a

To 15,250 meters (50,000 feet)

.a

5

cycles (120 hours) referenced to MIL-T-28800C para

4.5.5.1.2.2 for type Ill, Class 5 instruments. Operating and

nonoperating at 95% -5% to +0% relatiave humidity.

15 minutes along each of three major axes at a total

displacement of 0.015 inch p-p (2.4 g at 55 Hz) with

frequency varied from 10 Hz to 55

Hz

to 10 Hz in one

minute sweeps. Hold for 10 minutes at 55 Hz in each

of three major axes. All major resonances must be

above 55 Hz.a

30 g, half-sine, 11-ms duration, three shocks per axis

each direction, for a total of 18 shocks.=

Meets VDE 0871, Class

B

and FCC Docket 20870,

part 15, subpart

J

.a

REV

APR

1990

Specification-2225 Service

Table 1-3

Physical Characteristics

400

300

200

-

0

u

Y

4

w

100

a

+

0

0

-

m

50

I-

-I

0

>

20

10 10 kHz 50 kHz 100 kHz 500 kHz

I

MHz 50 MHz

6299-21

Characteristics

Weight

With Power Cord

Domestic Shipping Weight

Height

Width

With Handle

Without Handle

Depth

Without Front Cover

With Handle Extended

Figure 1-1. Max Input Voltage Vs Frequency Derating Curve.

Description

6.9 kg (15.2 Ibs) or less.

9.0 kg (19.8 Ibs) or less.

138 mm (5.42 in). (See Figure

1-2

for a dimensional

drawing).

385 rnm (15.2 in).

327 mm (12.9 in).

443 mm (17.3 in).

511 mm (20.1 in).

Scam

by

ARTEK

MEDIA

=>

Specification-2225 Service

Figure

1-2.

Instrument dimensional drawing.

Section 2-2225 Service

OPERATING INSTRUCTIONS

This section is divided into four subsections. The controls. Subsection three, Operating Consider-

first subsection, Preparation for Use, provides in- ations, provides the user with some of the more

structions for the user to follow before turning the general information on measurement techniques.

instrument on, especially for the first time. Sub- The last subsection, Operators Checks and

section two; Controls, Connectors, and Indicators; Adjustments, provides simple checks and adjust-

provides details on the operation of the front-panel ments to be made on a routine basis by the user.

PREPARATION

FOR

USE

SAFETY

This subsection tells how to prepare for and to pro-

ceed with the initial start-up of the TEKTRONIX 2225

Oscilloscope.

Refer to the Safety Summary at the front of this

manual for power source, grounding, and other

safety considerations pertaining to the use of the in-

strument. Before connecting the oscilloscope to a

power source, read both this subsection and the

Safety Summary.

This instrument may be damaged ifoperated

with the LlNE VOLTAGE SELECTOR switch

(on the rearpanel) set for the wrong applied

ac source voltage or if the wrong fuse is

installed.

LINE (MAINS) POWER-CORD

FUSE RECEPTACLE

REPLACING

FUSE

SELECTOR (MAINS) ATTACH POWER-

SWITCH CORD CLAMP

6299-23

LlNE VOLTAGE SELECTION

Figure 2-1. Voltage Selector switch, fuse, and

power-cord receptacle.

The oscilloscope operates from either a 115-V or a

230-V nominal ac power line with any frequency

from

48

Hz

to

440

Hz.

Before connecting the power

cord to a power source, verify that the LlNE

VOLTAGE SELECTOR switch, located on the rear

panel, is set correctly and that the proper line fuse is

installed. Referto Figure 2-1 and the instrument rear

panel.

To convert the 2225 for operation on another line

voltage range, set the LlNE VOLTAGE SELECTOR

switch to the required position and install the appro-

priate fuse (listed on the rear panel). The detach-

able power cord may need to be replaced to match

the particular power source. Power-cord option

numbers are given in Figure 2-1

;

fuse part numbers

are listed in Options and Accessories (Section

7).

Scans

by

ARTEK

MEDLQ

=>

Operating Instructions-2225 Service

LlNE FUSE

The instrument fuse holder is located on the rear

panel and contains the line (main) fuse. Use the

following procedure to verify that the proper fuse is

installed or to install a replacement fuse.

1.

Unplug the power cord from the power-input

source (if plugged in).

2. Press in the fuse-holder cap and release it with

a slight counterclockwise rotation.

3.

Pull the cap (with the attached fuse inside) out

of the fuse holder.

NOTE

The two types of fuses listed on the rear

panel are not directly interchangeable; they

require different types of fuse caps.

4.

Verify that the fuse is the same type listed on

the back of the instrument.

5.

Reinstall the fuse (or replacement fuse) in the

fuse-holder cap.

6.

Reinstall the fuse and cap in the fuse holder by

pressingin and giving a slight clockwise rotation

of the cap.

POWER CORD

A detachable three-wire power cord with a three-

contact plug is provided with each instrument for

connecting to both the power source and protective

ground. The protective-ground connector in the

plug connects (through the protective-ground con-

ductor) to the accessible metal parts of the instru-

ment. For electrical-shock protection, insert this

plug only into a power-source outlet that has a

properly grounded protective-ground contact.

Un~versal

%\

1

2r

1

240v

1

CEEIEC 83F'Lll,lV.Vll

1

;;

1

10-16A

8s 1363

240v'

"''

IEC 83

13A

Option

Number

Z

Reference

Standards

Line

Voltage

Plug

Configuration

North

ran

120v/

15A

North

Amerncan

240V/

15A

Abbreviations:

ANSl

-

American National Standards Institute

AS

-

Standards Association of Australia

BS

-

British Standards Institution

CEE

-

International Commiss~onon Rules for the

Approval of Electrical Equ~pment

IEC

-

International Electrotechnical Comm~ssion

NEMA

-

National Electrical Manufacturer's Association

(2931-21

)6083-35

Usage

Sw~tzerland

220V/

6A

Figure 2-2. Power-cord and line-voltage data.

120~

240V

INSTRUMENT COOLING

220V

To prevent instrument damage from overheated

components, adequate internal airflow must be

maintained at all times. Beforeturning on the power,

verify that the air-intake holes on the sides and rear

panel are free from any obstructions to airflow.

ANSI C73 11

5.15.~

IEC 83

ANSl C73 20

NEMA 6-15 P

IEC 83

INITIAL START-UP

Standard

A4

SEV

Up to now, you should have made the following

preparations:

A5

1.

Read the safety information.

After plugging the power cord into its receptacle,

2.

Verified that the LlNE VOLTAGE SELECTOR

secure it to the rear panel using the plastic clamp, switch is set for the source voltage to be used.

screw, and washer provided.

3.

Verified the fuse for correct type and rating.

Instruments are shipped with the power cord

ordered by the customer. Available power-cord

4.

Attached the power cord.

information

is

presented in Figure 2-2. Contact your

Tektronix representative or local Tektronix Field

5.

Ensured that there is adequate ventilation

Office for additional power-cord information. around the instrument.

Scans

by

ARTEK

MEDCQ

=>

Table of contents