1

Table of Contents

1.General Safety Requirements........................................................................................... 1

2. Safety Terms and Symbols............................................................................................... 2

3.General Characteristics.................................................................................................... 2

4.Junior User Guidebook .................................................................................................... 3

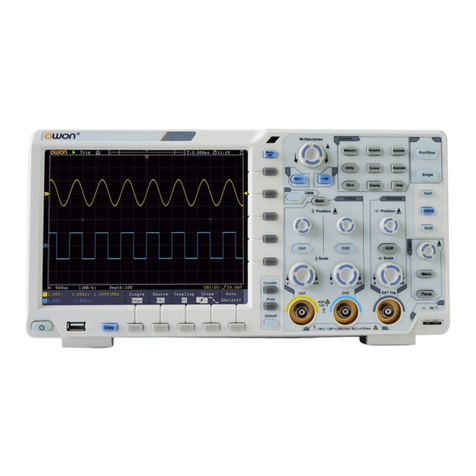

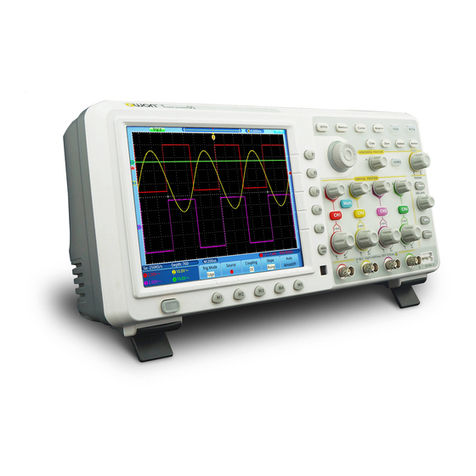

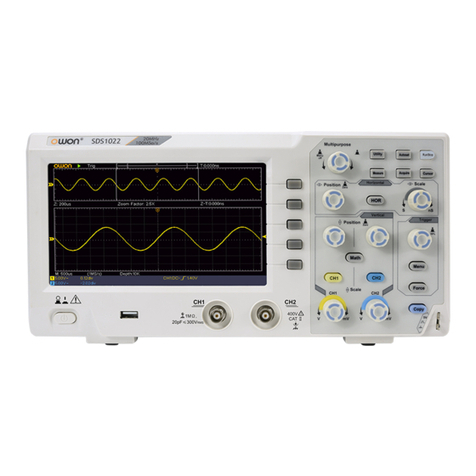

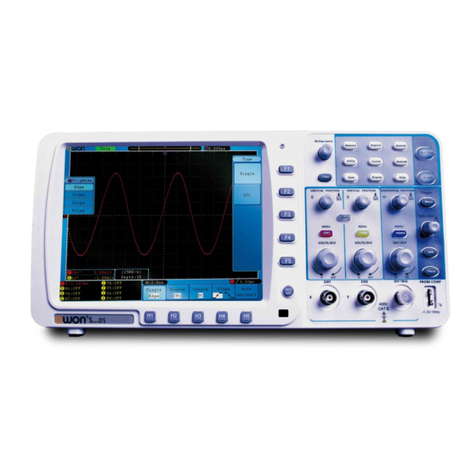

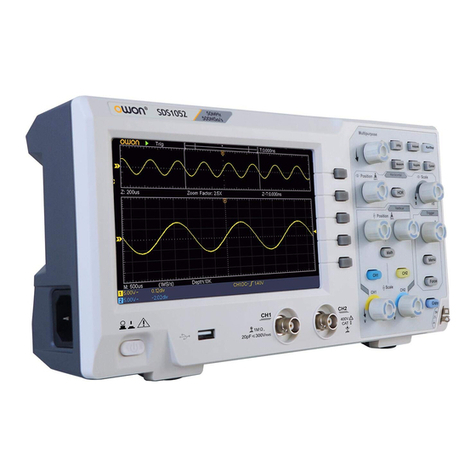

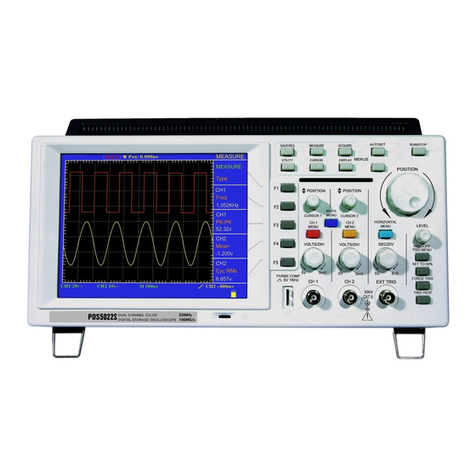

4.1 Introduction to the Front Panel and the User's Interface.................................................. 4

Front panel ............................................................................................................................................... 4

Control(key and knob) area...................................................................................................................... 5

4.2Digital Storage Oscilloscope .................................................................................................. 7

User interface introduction....................................................................................................................... 7

How to implement the General Inspection ............................................................................................... 9

How to implement the Function Inspection ............................................................................................. 9

How to Implement the Probe Compensation.......................................................................................... 10

How to Set the Probe Attenuation Coefficient ....................................................................................... 11

How to Use the Probe Safely.................................................................................................................. 12

How to Implement Auto-calibration ...................................................................................................... 12

Introduction to the Vertical System........................................................................................................ 12

Introduction to the Horizontal System.................................................................................................... 14

Introduction to the Trigger System......................................................................................................... 14

4.3Logic Analyzer ...................................................................................................................... 16

LA input connection............................................................................................................................... 16

User interface introduction..................................................................................................................... 16

How to acquire data................................................................................................................................ 17

How to observe and analyze the data ..................................................................................................... 17

Display systems...................................................................................................................................... 18

Trigger system........................................................................................................................................ 19

Threshold voltage system....................................................................................................................... 20

Sampling system .................................................................................................................................... 21

5.Advanced User Guidebook............................................................................................. 23

5.1Digital Storage Oscilloscope ................................................................................................ 24

How to Set the Vertical System.............................................................................................................. 24

Implementation of Mathematical Manipulation Function...................................................................... 28

Using FFT function..............................................................................................................................................28

Application of VERTICAL POSITION and VOLTS/DIV Knobs......................................................... 33

How to Set the Horizontal system .......................................................................................................... 33

How to set trigger system....................................................................................................................... 36

How to Operate the Function Menu ....................................................................................................... 45

How to Implement Sampling Setup ....................................................................................................... 45

How to Set the Display System.............................................................................................................. 47

How to Save and Recall a Wave Form................................................................................................... 50

How to Implement the Auxiliary System Function Setting.................................................................... 52