Table of contents

1 General 3

2 Description of the system elements 4

2.1 Illustration of the system elements 4

2.2 Functionality of the system 4

2.3 Intended use 5

2.4. Residual risk 5

3 Safety instructions 6

3.1 Definition of the hazard symbols 6

3.2 General safety instructions 6

4 Storage, transport and installation of the device 7

5 Commissioning 8

5.1 Connecting an extraction element 8

5.2 Electrical connection 9

5.3 Precoating of the filter cartridges 9

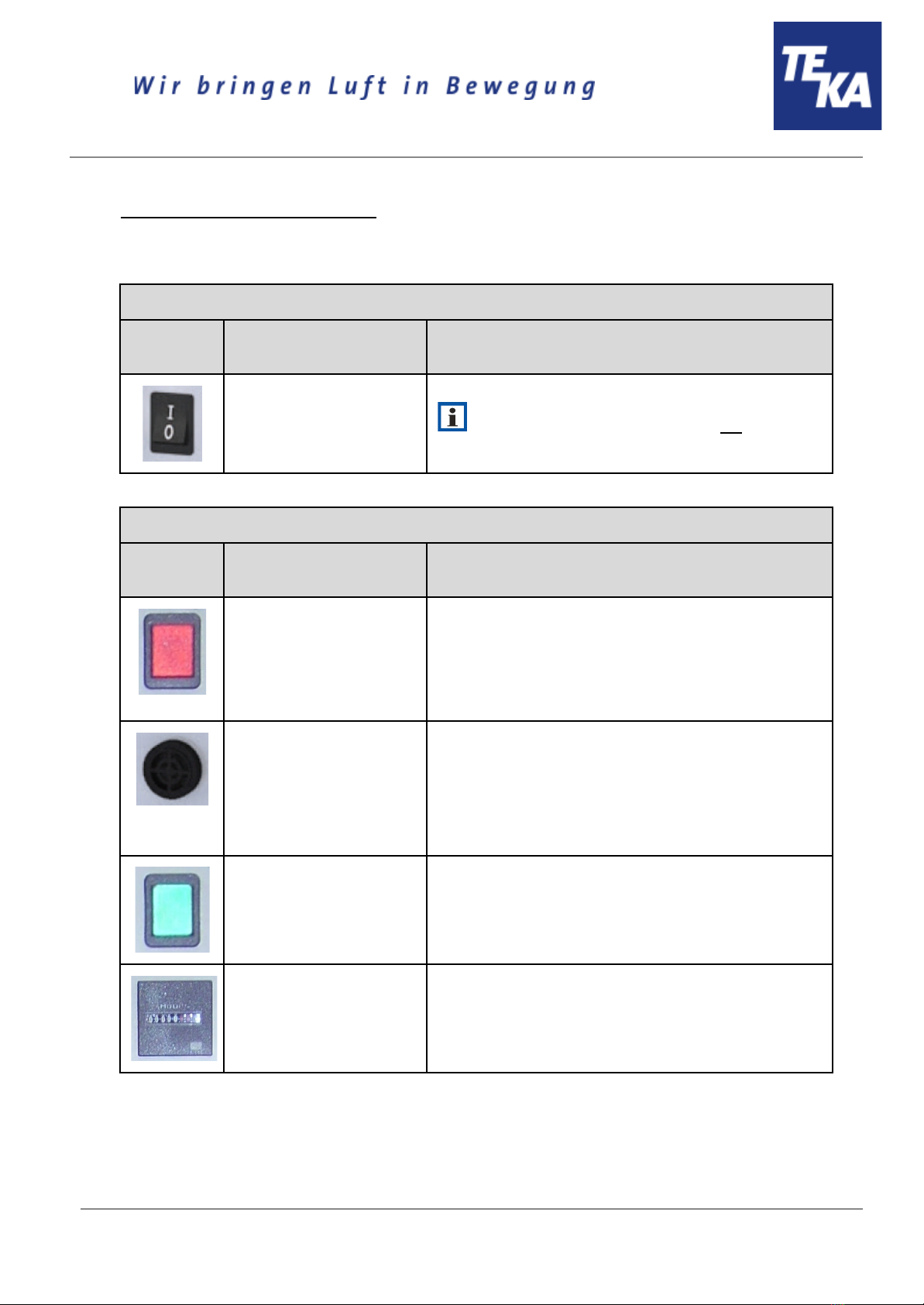

6 Operating the system 10

6.1 Explanation of the operating elements 10

7 Maintenance 11

7.1 Reset to maintenance state 12

7.2 Cleaning the filter cartridges 12

7.3 Replacing the filter cartridges 13

7.4 Emptying the dust collecting tank 17

7.5 Precoating of new filter cartridges 18

8 Dismantling / Disposal 19

9 Diagnostics and troubleshooting 19

10 List of spare parts 20

11 Technical data 21

12 EC declaration of conformity 22

13 Training protocol 23

14 Maintenance intervals 24

14.1 Usage-related maintenance 24

14.2 General maintenance 24

14.2.1 Visual inspection of the device 25

14.2.2 Functional test of the device 25

14.2.3 Electrical test of the electrical lines and earthing connections 26

BA_StrongMaster-1-und-2_IFA_20230808_EN