© 2008 W 542 - 12/08 6 of 8

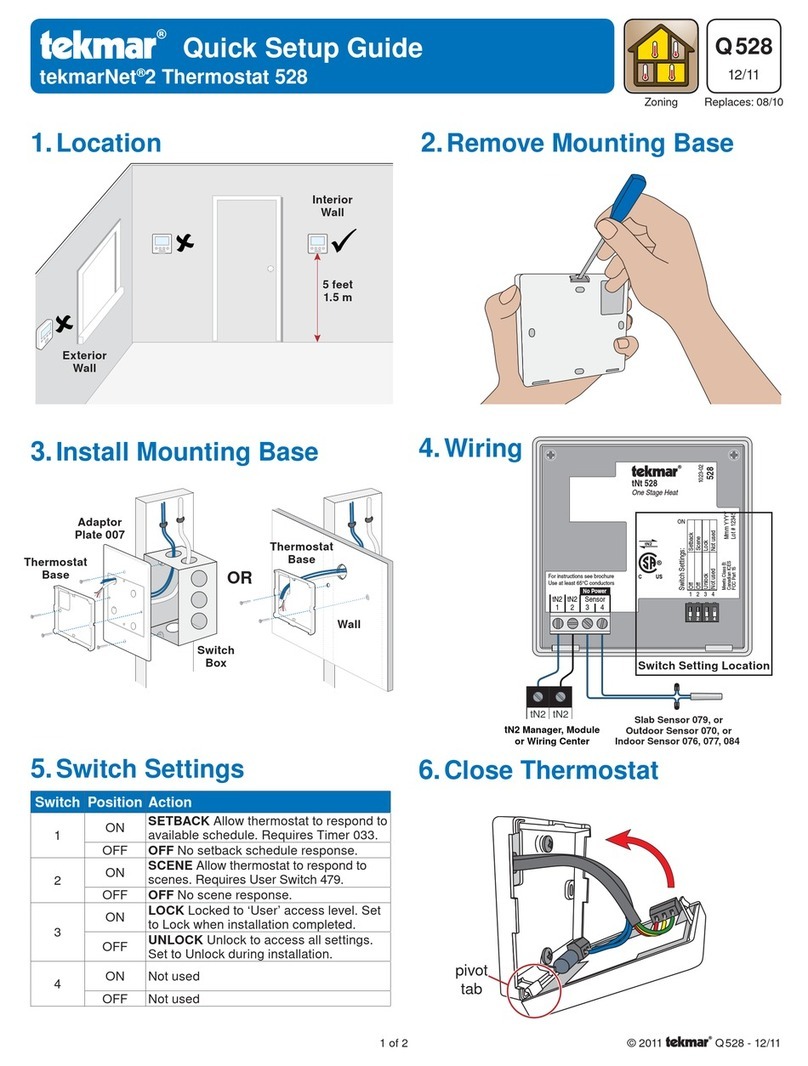

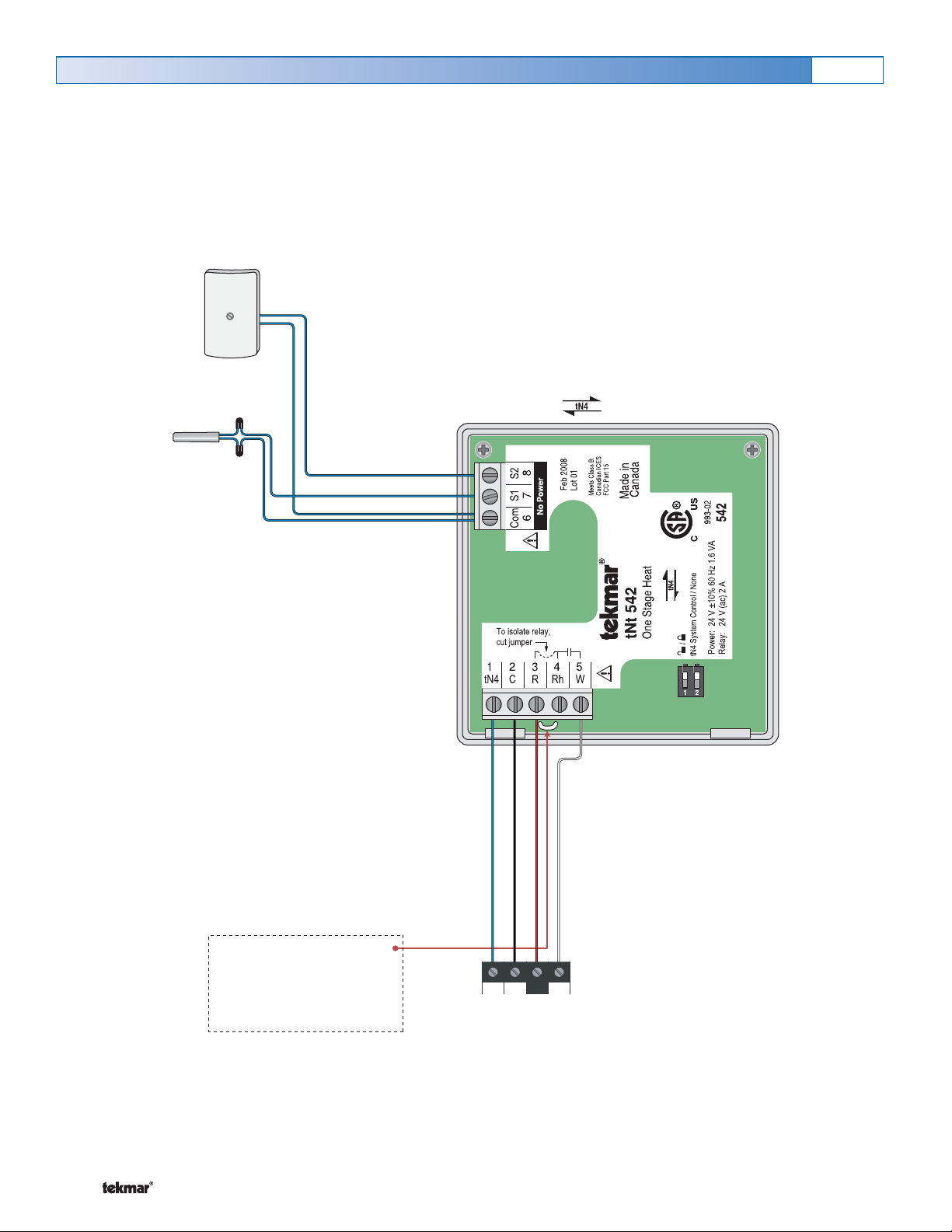

Wire the tN4 communication to terminals tN4 and C.

If a Zone Manager is used:

Connect the tN4 on the thermostat to the tN4 on the

proper zone of the Zone Manager used for the first stage

of heat. The C terminal is already connected.

If a Zone Manager is not used:

Connect the tN4 on the thermostat to the tN4 on another

tN4 device on the same tN4 bus.

Connect the C on the thermostat to the C terminal on

another tN4 device on the same tN4 bus.

tN4 Communication Terminals 1, 2

Wire the first stage of heating to the Heat 1 Relay.

(Rh - W)

Use these terminals as a switch to operate the first stage

of heating.

If a Zone Manager is used:

Connect W on the thermostat to W on the proper zone

of the Zone Manager.

If a Zone Manager is not used:

Determine if the factory jumper must be cut.

When the factory jumper is not cut, W is a powered

output that is internally connected to R.

When the factory jumper is cut, Rh W is an isolated

switch. No power is available from these terminals.

Heat 1 Relay Terminals 3 - 5

Wire 24V (ac) to terminals C and R.

If a Zone Manager is used:

Connect C on the thermostat to C on the proper zone

of the Zone Manager.

Connect R on the thermostat to R on the proper zone

of the Zone Manager.

If a 24 V(ac) transformer is used:

Connect C on the thermostat to C on the transformer.

Connect R on the thermostat to R on the transformer.

Power (24 V (ac)) Terminals 2, 3

Note: This connection is polarity sensitive.

Wiring the Thermostat:

The auxiliary sensors are connected to the thermostat on

terminals Com, S1 and S2.

• Connect sensor 1 to terminals S1 and Com.

• Connect sensor 2 to terminals S2 and Com.

Do not apply power to terminals 6 - 8, permanent

damage to the sensors and/ or thermostat will result!

Auxiliary Sensors Terminals 6 - 8

Do Not Apply Power

Thermostat

Universal

Sensor

Outdoor

Sensor

To various tekmar

sensors

8S2

7S1

6Com

tN4 C RW

Thermostat

Zone Manager

tN4 C R Rh W

12345

Thermostat

Zone Manager

or other tN4

thermostat

tN4 C R Rh W

12345

tN4 C RW

*Factory installed jumper

connects terminals R to Rh

(to isolate W relay, cut jumper)

Thermostat

Zone Manager

tN4 C R Rh W

12345

tN4 C RW