TEKNA 702736 Service manual

TB-1016-A

Replaces TB-1016

Technical Bulletin

Professional Gravity

Feed Spraygun

Gun Repair Kit

No. 702736

askus@devilbissar.com

800.445.3988

www.autorenishdevilbiss.com

TB-1016-A

2

Table of Contents

Topic Page

EC Declaration of Conformity .................................................................................................................................3

Operational Description ............................................................................................................................................ 3

Construction Features, Materials of Construction, .................................................................................... 4

Specications & Technical Data

Safety Precautions.......................................................................................................................................................5

Installation, Operation, Preventive Maintenance & Cleaning, .............................................................6

Spray Gun Lubrication

Parts Replacement/Maintenance ..............................................................................................................7–12

A. Servicing Air Valve....................................................................................................................................7

B. Replacing Air Valve...................................................................................................................................8

C. Needle Packing, Fluid Insert, Spreader Valve Assembly...................................................... 9

D. Air Separator Seal ................................................................................................................................. 10

E. Chart 1 – Air Caps................................................................................................................................. 11

Chart 2 – Fluid Nozzles & Fluid Needles

F. Exploded View and Parts List ..........................................................................................................12

Troubleshooting Possible Problems in Operation ............................................................................ 13–14

Accessories................................................................................................................................................................... 14

Warranty

......................................................................................................................................................................... 15

NOTE:

When used with the HVLP cap, this gun can be used any-

where—both in mandated HVLP and unregulated areas.

When used with the High Efciency cap, this gun can be

used in unregulated areas and certain approved regulated

areas. See www.autorefinishdevilbiss.com for a complete

listing of approved areas and requirements for regulatory

compliance.

Consult your local air quality management agency with any

questions regarding HVLP or compliance requirements in

your area.

TB-1016-A

3

EC Declaration of Conformity

We, Finishing Brands UK, Ltd., Ringwood Rd, Bournemouth, Dorset, BH11 9LH, UK, as the manufacturer of the

Spray gun model TEKNA, declare, under our sole responsibility, that the equipment to which this document

relates is in conformity with the following standards or other normative documents:

BS EN 12100 PARTS 1 & 2: 2010, BS EN 1953: 1998+A1:2009; and thereby conform to the

protection requirements of Council Directive 98/37/EEC relating to Machinery Safety Directive, and;

EN 13463-1:2009, council Directive 94/9/EC relating to Equipment and Protective Systems intended

for use in Potentially Explosive Atmospheres protection level II 2 G X.

This product also complies with the requirements of the EPA guidelines, PG6/34. Transfer efciency certicates

are available on request.

D Smith, General Manager

June 2013

Technical Bulletin

TEKNA Gravity Feed Spraygun

IMPORTANT: Read and follow all instructions and Safety Precautions before using this equipment. Keep

for future use.

The TEKNA Gravity Feed Spraygun Kit complies to ATEX regulations 94/9/EC, protection level II 2 G X, Suitable for

use in Zones 1 and 2.

DeVilbiss Automotive Renishing reserves the right to modify equipment specication without prior notice.

Operational Description

The TEKNA spraygun is a lightweight professional gun designed to handle both water-based and solvent-based

coating materials. Both HVLP and high efciency models are available.

High volume, low pressure (HVLP) models are designed to reduce overspray and provide maximum transfer

efciency by limiting air cap pressure to 0.7 bar (10 psi) (complies with rules issued by SCAQMD and other air

quality authorities).

HVLP models will produce approximately 0.7 bar (10 psi) air cap pressure at 1.8 bar (26 psi) gun inlet pressure

with the trigger pulled. HVLP air cap #202 is designed for optimum basecoat applications. HVLP air cap #909

is designed for optimum clear coat applications. Two air cap test kits are available (see Accessories) which can

be utilized to set the exact air cap pressure.

High efciency models use air cap #7E7. These models are designed to provide optimum atomization of

virtually all waterborne or solvent-based common coating materials at increased application rates while

maintaining very high transfer efciency. High efciency models, when tested under recommended conditions

with automotive renishing materilas, have been found to exceed 65% transfer efciency.

High efciency models comply with SCAQMD rules and certain other air quality authorities. Refer to the website

www.autorefinishdevilbiss.com for a complete listing of approved areas and requirements for regulatory

compliance.

IMPORTANT: These guns are not designed for use with highly corrosive and/or abrasive materials and if

used with such materials it must be expected that the need for cleaning and/or replacement of parts will be

increased. If there is any doubt regarding the suitability of a specic material, contact your TEKNA Distributor or

TEKNA direct.

NOTE: This gun is not to be used with halogenated hydrocarbon solvents or cleaning agents such as

1,1,1,-Trichloroethane or methylene chloride. These solvents can react with the aluminium components

used in this gun and cup. The reaction can become violent and lead to an equipment explosion.

TB-1016-A

4

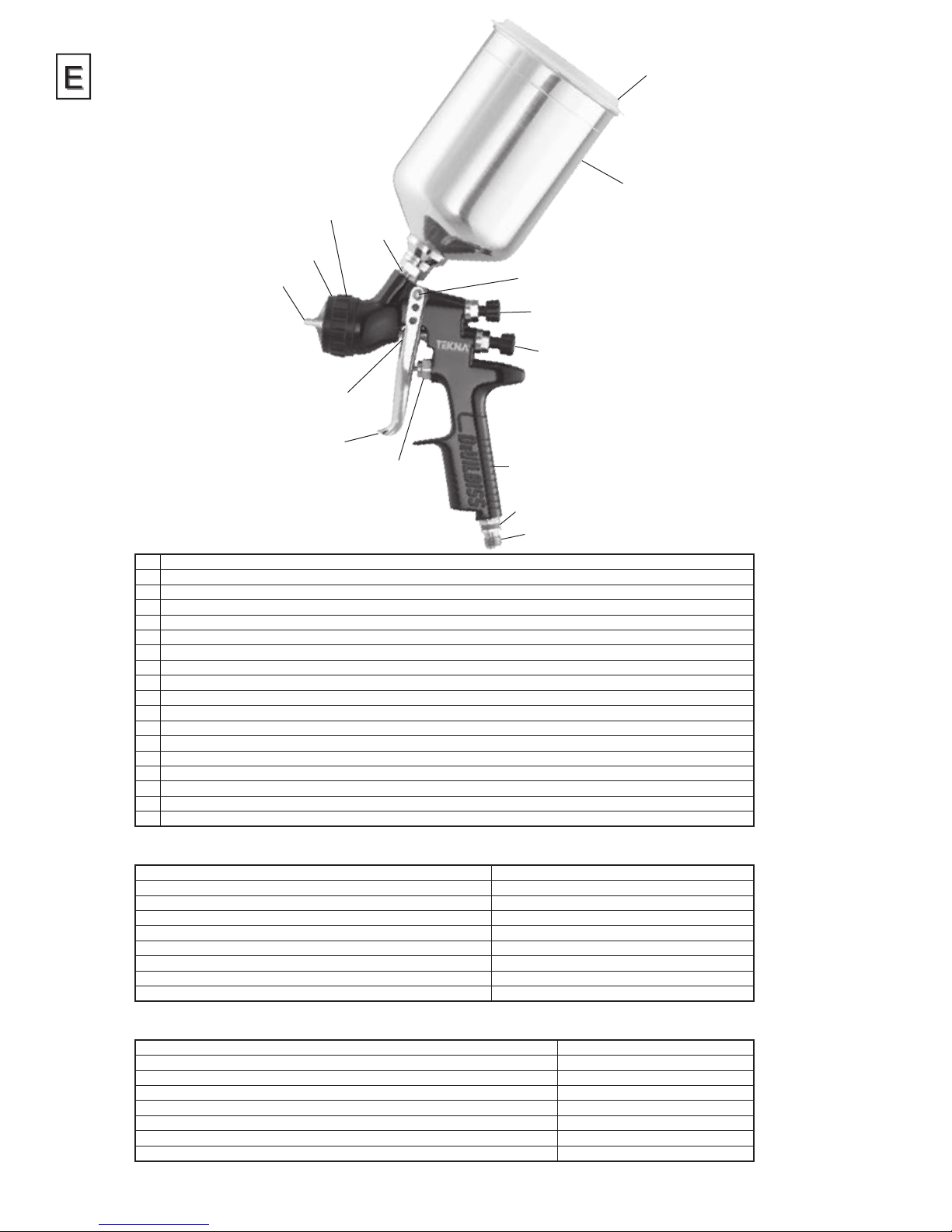

Construction Features

1Air Cap (nickel plated brass for long durability)

2Air Cap Retaining Ring (allows easy rotation of air cap)

3Fluid Nozzle (not visible, ideal for automotive topcoat systems)

4Fluid Needle (not visible)

5Fluid Inlet (3/8 BSP thread – accepts TEKNA & DeVilbiss cups)

6Air Inlet (universal thread, accepts G 1/4 & 1/4 NPS)

7Self Adjusting Needle Packing (packing not visible, for long packing life)

8Trigger (ergonomic for comfort)

9Trigger Stud & Screw (easy replacement design)

10 Fan Air Adjustment (stepless regulation for at to round spray)

11 Fluid Adjustment (stepless regulation of uid volume)

12 Removable Air Separator (not visible, for long gun service life)

13 Interchangeable Colour ID System (4 coloured rings supplied)

14 Forged gun body (ergonomic, good looking & durable, easy to clean)

15 900cc Aluminium Cup (easy clean) (shown) or 20 oz. Acetal Cup (waterbourne) (not shown)

16 Push On Lid w/Drip Free Vent (disposable/easy clean design) (aluminum cup) or screw-on lid w/vent (acetal Cup)

17 Air Valve (design offers low pull force & low pressure drop)

18 Gun acceptable for waterborne and solvent borne applications

Materials of Construction

Gun Body Anodized aluminium

Air Cap Nickel plated brass

Fluid Nozzle, Fluid Needle, Fluid Inlet, Trigger Stud Stainless steel

Air Separator, Air Cap Retaining Ring, Knobs Anodized aluminium

Springs, Clips, Screws Stainless steel

Seals, Gaskets Solvent resistant

Trigger Chrome plated steel

Handle Plug, Air Inlet, Body Bushing, Spreader Valve Body, Air Valve Nut Chrome plated brass

Air Valve Assembly Stainless steel, acetal

Specifications & Technical Data

Air Supply Connection Universal 1/4" BSP and 1/4" NPS

Maximum Static Air Inlet Pressure P1 = 12 bar (175 psi)

Nominal Gun Air Inlet Pressure for HVLP Models (with gun triggered) 1.8 bar (26 psi)

Nominal Gun Air Inlet Pressure for High Efciency Models – (with gun triggered) 1.5 bar (22 psi) (for compliance)

Air Consumption See Chart 1 on page 11

Fluid Supply Connection 3/8" BSP

Service Temperature 0 to 40°C (32 to 100°F)

Gun Weight (gun only) 478g (16.9 oz.)

1

2

3, 4, 12

5

16

15

9

10

11

14

13

6

17

8

7

TB-1016-A

5

Safety Precautions

This bulletin contains information that is important for you to know and understand. This information relates to USER SAFETY and PRE-

VENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular attention to

these sections.

NOTE

Important safety information – A hazard that may

cause serious injury or loss of life.

Important information that tells how to prevent damage

to equipment, or how to avoid a situation that may cause

minor injury.

Information that you should pay special attention to.

The following hazards may occur during the normal use of this equipment. Please read the following chart before using

this equipment.

HAZARD CAUSE SAFEGUARDS

Fire Solvent and coatings can be highly ammable or

combustible especially when sprayed.

Adequate exhaust must be provided to keep air free of accumulations of

ammable vapours.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present in the spray area.

Solvent Spray During use and while cleaning and ushing, solvents

can be forcefully expelled from uid and air passages.

Some solvents can cause eye injury.

Wear eye protection.

Inhaling Toxic Substances Certain materials may be harmful if inhaled, or if there

is contact with the skin.

Follow the requirements of the Material Safety Data Sheet supplied by your

coating material manufacturer.

Adequate exhaust must be provided to keep the air free of accumulations of toxic

materials.

Use a mask or respirator whenever there is a chance of inhaling sprayed

materials. The mask must be compatible with the material being sprayed and

its concentration. Equipment must be as prescribed by an industrial hygienist or

safety expert, and be NIOSH approved.

Explosion Hazard –

Incompatible Materials

Halogenated hydrocarbon solvents – for example;

methylene chloride and 1,1,1,-Trichloroethane are

not chemically compatible with the aluminium that

might be used in many system components. The

chemical reaction caused by these solvents reacting

with aluminium can become violent and lead to an

equipment explosion.

Guns with stainless steel internal passageways may be used with these solvents.

However, aluminium is widely used in other spray application equipment – such

as material pumps, regulators, valves, and cups. Check all equipment items

before use and make sure they can also be used safely with these solvents.

Read the label or data sheet for the material you intend to spray. If in doubt as to

whether or not a coating or cleaning material is compatible, contact your material

supplier.

General Safety Improper operation or maintenance of equipment. Operators should be given adequate training in the safe use and maintenance of

the equipment (in accordance with the requirements of NFPA-33, Chapter 15).

Users must comply with all local and national codes of practice and insurance

company requirements governing ventilation, re precautions, operation,

maintenance, and housekeeping. These are OSHA Sections 1910.94 and

1910.107 and NFPA-33.

Cumulative Trauma disorders

(“CTD’s”)

CTD’s, or musculoskeletal

disorders, involve damage

to the hands, wrists, elbow,

shoulders, neck and back.

Carpal tunnel syndrome

and tendonitis (such as

tennis elbow or rotator

cuff syndrome) are examples

of CTD’s.

Use of hand tools may cause cumulative trauma

disorders (“CTD’s”).

CTD’s, when using hand tools, tend to affect the upper

extremities. Factors which may increase the risk of

developing a CTD include:

1. High frequency of the activity.

2. Excessive force, such as gripping, pinching,

or pressing with the hands and ngers.

3. Extreme or awkward nger, wrist, or

arm positions.

4. Excessive duration of the activity.

5. Tool vibration.

6. Repeated pressure on a body part.

7. Working in cold temperatures.

CTD’s can also be caused by such activities as sewing,

golf, tennis, and bowling, to name a few.

Pain, tingling, or numbness in the shoulder, forearm, wrist, hands, or ngers,

especially during the night, may be early symptoms of a CTD. Do not ignore

them. Should you experience any such symptoms, see a physician immediately.

Other early symptoms may include vague discomfort in the hand, loss of

manual dexterity, and nonspecic pain in the arm. Ignoring early symptoms and

continued repetitive use of the arm, wrist, and hand can lead to serious disability.

Risk is reduced by avoiding or lessening factors 1-7.

WARNING CAUTION

CA PROP

65

PROP 65 WARNING

WARNING: This product contains

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

Table of contents