3

128-1019-004

Table of Contents

Contact.......................................................................................................................................................................................................2

Table of Contents.......................................................................................................................................................................................3

General Safety Rules..................................................................................................................................................................................4

NOVA ORION 18” DVR FEATURES..............................................................................................................................................................5

Lathe Specifications..............................................................................................................................................................................6

Package Contents.......................................................................................................................................................................................7

Assembling the Lathe.................................................................................................................................................................................8

Connecting Lathe Bed Sections ............................................................................................................................................................8

Attaching the Lathe Bed to Stand.........................................................................................................................................................8

Attaching the Headstock onto the Bed ................................................................................................................................................9

Locking the headstock into place .......................................................................................................................................................10

Attaching the Tool Rest onto the Bed ................................................................................................................................................11

Attaching the Tailstock onto the Bed .................................................................................................................................................11

NOVA ORION Bed Configuration ........................................................................................................................................................12

Connecting to Power ...............................................................................................................................................................................13

Ground Fault Interrupters (GFI)..........................................................................................................................................................14

Input Voltage Selection ......................................................................................................................................................................14

Setting Up Your Lathe ..............................................................................................................................................................................14

Workshop Environment .....................................................................................................................................................................14

Lathe Interface.........................................................................................................................................................................................15

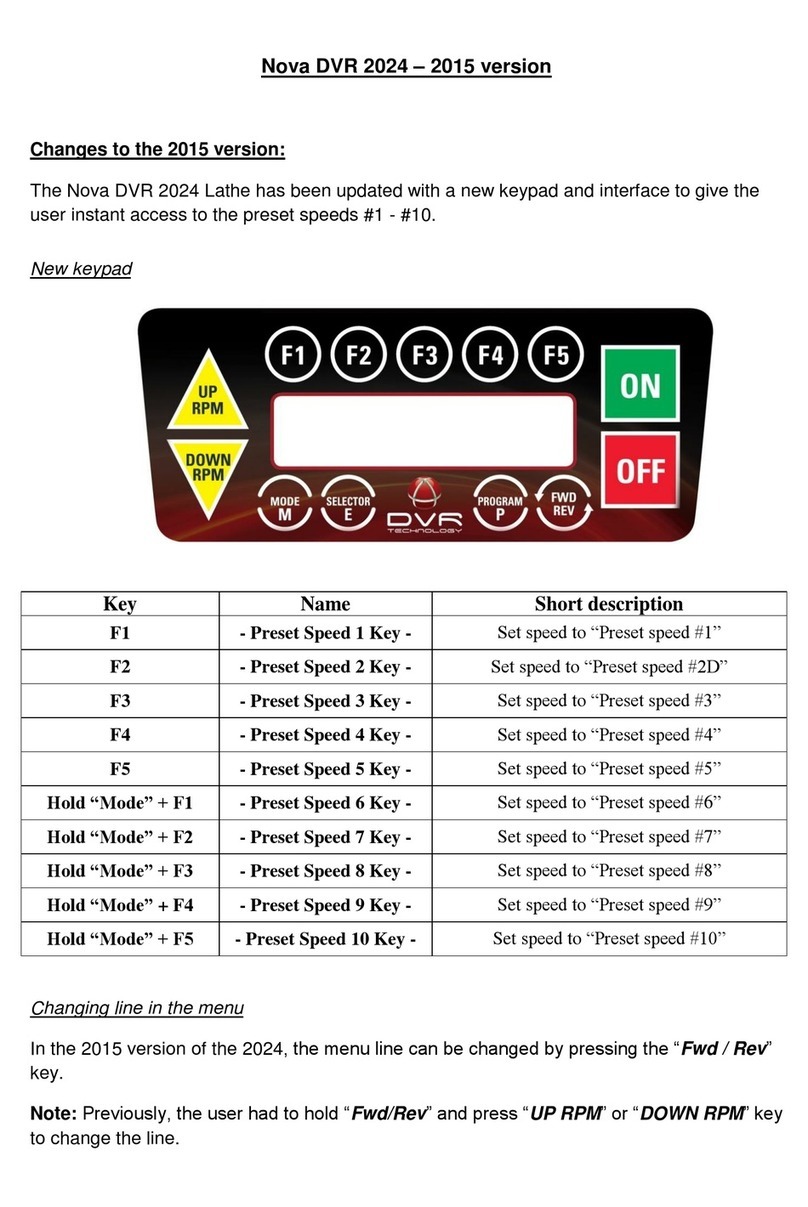

Keypad Buttons ..................................................................................................................................................................................15

Lathe Home Screen ............................................................................................................................................................................15

Operating the Lathe.................................................................................................................................................................................16

Starting Operation..............................................................................................................................................................................16

Running the Lathe ..............................................................................................................................................................................16

Stopping the Lathe .............................................................................................................................................................................17

Adjusting the Speed............................................................................................................................................................................18

Accessing the Main Menu ..................................................................................................................................................................18

Favourite Speed Function...................................................................................................................................................................19

Using the lathe speed chart................................................................................................................................................................21

Changing the Home Screen Display Mode .........................................................................................................................................22

Switching between forward and reverse ...........................................................................................................................................23

Using the Lathe Spindle Lock..............................................................................................................................................................24

Swivelling the Headstock....................................................................................................................................................................25

Changing the <F> Key Functionalities.................................................................................................................................................26

Wireless Remote ................................................................................................................................................................................28

Password Lock ....................................................................................................................................................................................29

Lathe Settings .....................................................................................................................................................................................30

Maintaining Your Lathe............................................................................................................................................................................31

Maintenance after each use...............................................................................................................................................................31

Monthly maintenance ........................................................................................................................................................................31

6-months Maintenance ......................................................................................................................................................................31

Cleaning the Tool slide .......................................................................................................................................................................31

Cleaning the Tailstock.........................................................................................................................................................................31

Firmware Update .....................................................................................................................................................................................32

Checking the Firmware Version..........................................................................................................................................................32

USB Mode...........................................................................................................................................................................................32

Troubleshooting.......................................................................................................................................................................................33

Mechanical Issue ................................................................................................................................................................................33

Electrical Issue ....................................................................................................................................................................................34

Teknatool Warranty.................................................................................................................................................................................35

NOVA Orion Headstock Breakdown.........................................................................................................................................................36

NOVA Orion Lathe Parts List ....................................................................................................................................................................37