5

96-0112 Rev W

July 2010

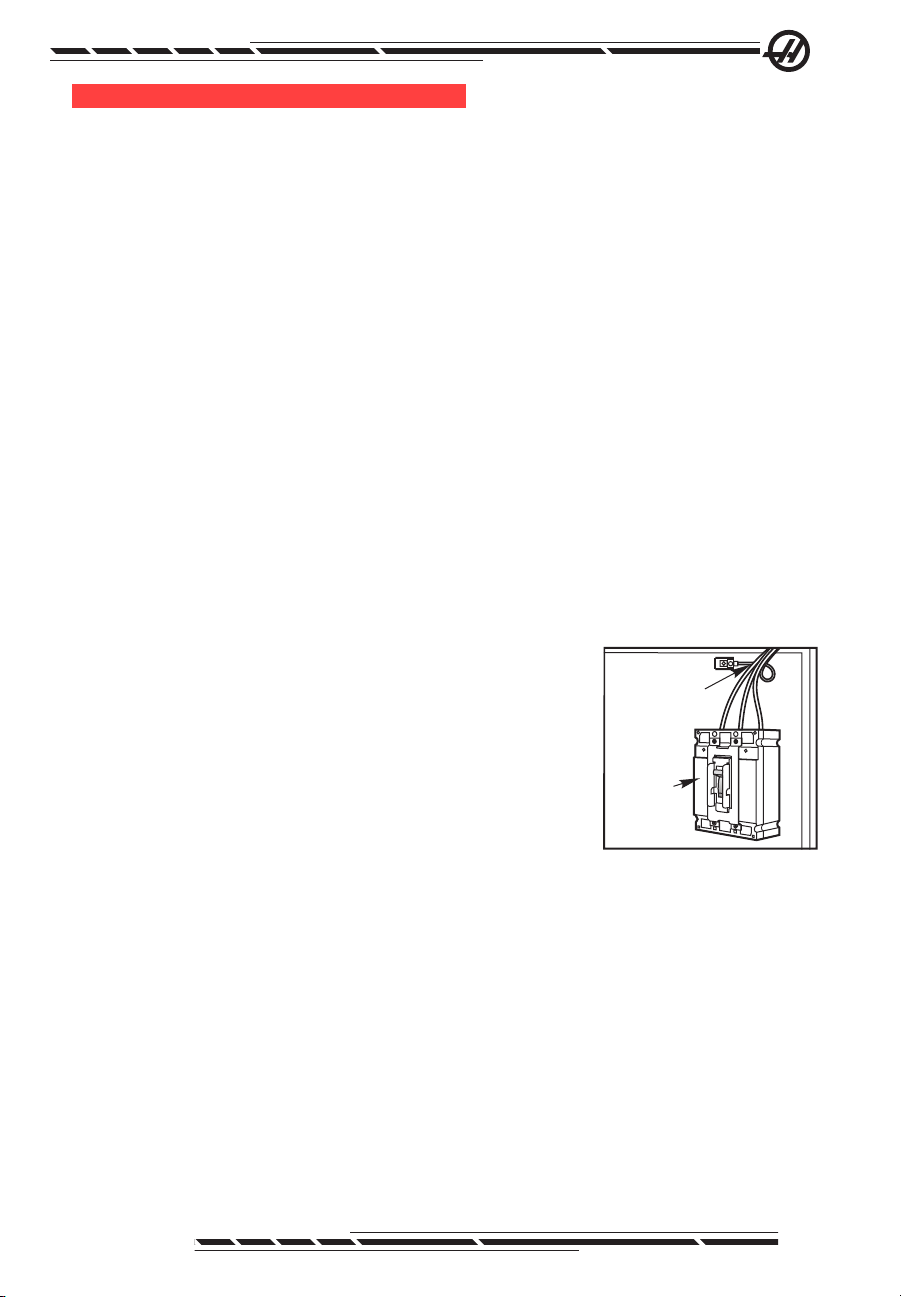

electricity requirementS

Important! Refer to local code requirements before wiring ma-

chines.

All machines require:

The power source must be grounded

Frequency range is 47-66 Hz

Line voltage that does not uctuate more than +/-5%

Harmonic distortion is not to exceed 10% of the total RMS voltage

Voltage Requirements

Input Voltage Low Volt. TL-1,2 - 208V 3PH / 240V 1PH ±10%

TL-3, TL-3B, TL-3HT, TL-3W, TL-4 - 240V

3PH

High Volt. 354-488V 3PH

Power Supply Breaker (Low Volt) TL-1,2 20 AMP 3PH / 40 AMP 1PH

TL-3 50A, TL-3B, TL-3HT 100A, TL-4 200A

Haas Circuit Breaker (Low Volt) TL-1,2 40A, TL-3 40A, TL-3B, TL-3HT 80A,

TL-4 200A

Power Supply Breaker (High Volt) TL-1,2 20A

TL-3 25A, TL-3B, TL-3HT & TL-3W 50A

Haas Circuit Breaker (High Volt) TL-1,2 20A, TL-3 20A, TL-3B, TL-3HT 40A

If service run from elec. panel

is less than 100’ use: TL-1,2 1PH - 8 GA Wire /

3PH - 10 GA Wire

TL-3 8GA Wire (High 12

GA.),

TL-3B, TL-3HT 4GA. Wire

(High 8GA), TL-4 0GA

If service run from elec. panel

is more than 100’ use: TL-1,2 1PH - 6 GA Wire /

3PH - 8 GA WIRE

TL-3 6GA. Wire (High 10 GA.), TL-3B,

TL-3HT 2GA. Wire (High 6GA.), TL-4 0GA

Warning!

A separate earth ground wire of the same conductor size as the input

power is required to be connected to the chassis of the machine.

This ground wire is required for operator safety and for proper opera-

tion. This ground must be supplied from the main plant ground at

the service entrance, and should be routed in the same conduit as

the input power to the machine. A local cold water pipe, or ground

rod adjacent to the machine cannot be used as a primary ground.

The maximum voltage leg-to-leg or leg-to-ground should not exceed 260 volts.

Main

Circuit

Breaker

Ground

Line L1 L2 L3