Teknic CLEARPATH MCVC Series User manual

U

SER

M

ANUAL

C

LEAR

P

ATH

U

SER

M

ANUAL

M

ODELS

MCVC,

MCPV,

SDSK,

SDHP

NEMA

23

AND

NEMA

34

F

RAME

S

IZES

V

ERSION

3.09

J

UNE

30,

2020

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

2

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

T

HIS PAGE INTENTIONALLY LEFT BLANK

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

3

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

T

ABLE OF

C

ONTENTS

T

ABLE OF

C

ONTENTS

...................................................3

Q

UICK

S

TART

G

UIDE

....................................................8

Please Read This Important Warning...........................................8

Before You Begin (Suggested Viewing Material) ..........................8

ClearPath Quick Setup...................................................................9

Required Items ..................................................................9

Install ClearPath MSP Software ........................................9

Secure Your Motor.............................................................9

Check DC Bus Power Polarity.......................................... 10

Power Up Your ClearPath................................................ 10

Connect ClearPath to Your PC..........................................11

Open ClearPath MSP (Motor Setup Program).................11

Spin Your Motor Under MSP Software Control.......................... 12

Spinning a Model MCPV or MCVC.................................. 12

Spinning a Model SDHP or SDSK ................................... 17

If You Experience a Motor Shutdown or Warning......................20

Auto-Tuning................................................................................. 21

Before You Seek Technical Help..................................................22

S

AFETY

W

ARNINGS

...................................................23

Personal Safety Warnings............................................................23

CE Compliance Warnings............................................................23

General Disclaimer ......................................................................24

I

NTRODUCTION

..........................................................25

What is a ClearPath Motor?.........................................................25

Parts of a ClearPath Motor ..........................................................27

Example Application: Absolute Positioning Mode .....................28

Summary of Operation ....................................................28

Overview: Configuring a ClearPath.............................................29

Overview: ClearPath I/O .............................................................30

P

OWERING A

C

LEAR

P

ATH

S

YSTEM

............................. 31

Selecting a DC Bus Power Supply................................................ 31

ClearPath Operating Voltage........................................... 31

Notes on "Lower Voltage" Bus Power Supplies...............32

Teknic Power Supplies.....................................................33

Before Powering a ClearPath...........................................33

Power Supply Switching and Fusing ...............................34

Basic Power Connection (2 motors) ............................................35

Power Chaining (multiple motors)..............................................35

Using a Power Hub ......................................................................36

Power Hub Overview Diagram........................................36

Power Hub: Things to Know............................................37

Power Hub: Compliance Notes ....................................... 37

Parts of a Power Hub .......................................................38

Connections For a Single Power Hub System.................39

Connections For a Dual Power Hub System ...................40

Auxiliary (24V) Logic Power Supply ...............................40

Power Hub LED Codes .................................................... 41

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

4

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

Power Hub: Things to Know............................................42

I

NPUTS AND

O

UTPUTS

................................................43

I/O Connector Parts and Pinout..................................................43

ClearPath Inputs ..........................................................................44

Input Current Draw .........................................................44

Warning: Inductive Loads and ClearPath I/O ................45

The Enable Input .............................................................46

Inputs A and B: The Control Inputs ................................46

Input Wiring ....................................................................47

ClearPath Output (HLFB)............................................................48

HLFB Modes: Common To All ClearPath Op Modes......49

HLFB Modes: For ClearPath Positioning Modes............ 51

HLFB Modes: For ClearPath Velocity Modes .................53

HLFB Output: For ClearPath Torque Modes.................. 55

HLFB Output Wiring Examples ......................................56

U

SER

S

OFTWARE

(C

LEAR

P

ATH

MSP).........................60

Section Overview......................................................................... 60

MSP Minimum System Requirements....................................... 60

Installing MSP............................................................................. 60

Communicating With ClearPath Via MSP ................................. 60

Items Required for Communication Setup ..................... 61

First-Time Communication Setup................................... 61

Tour of ClearPath MSP Software.................................................62

Main UI Overview............................................................62

Mode Controls..................................................................62

Torque Limit Setup..........................................................63

Dashboard........................................................................68

MSP Menus ......................................................................69

MSP Software Scope .................................................................... 81

Overview ..........................................................................81

Scope Features .................................................................81

Scope User Interface & Controls .....................................82

O

PERATIONAL

M

ODES

:

MCVC

AND

MCPV .................89

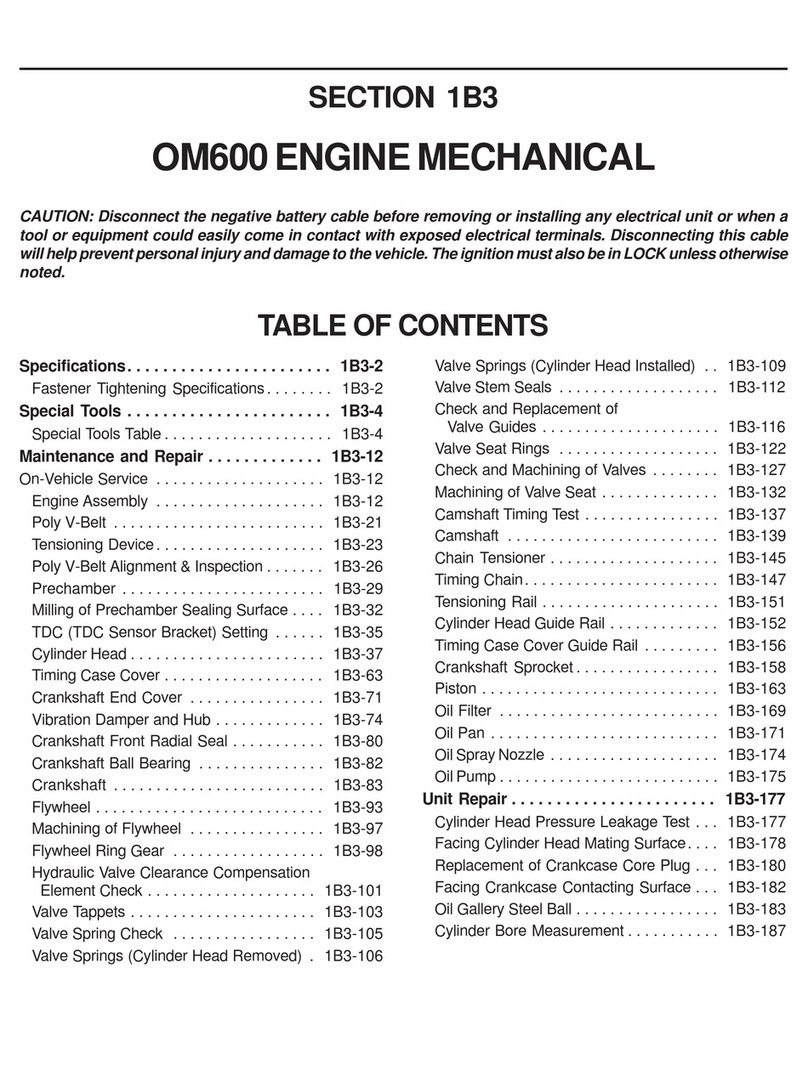

Table of Operational Modes: Models MCVC and MCPV ............89

Follow Digital Torque Command (Bi-Polar PWM Command)... 91

Mode Description ............................................................ 91

I/O Functions................................................................... 91

Mode Controls..................................................................92

Setting a PWM Deadband................................................94

Follow Digital Torque Command (Unipolar PWM Command)..95

Mode Description ............................................................95

I/O Functions...................................................................95

Mode Controls..................................................................96

Follow Digital Torque Command (Frequency Command) .........97

Mode Description ............................................................97

I/O Functions...................................................................97

Mode Controls..................................................................98

Ramp Up/Down To Selected Velocity .........................................99

Mode Description ............................................................99

I/O Functions...................................................................99

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

5

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

Mode Controls................................................................100

Spin On Power Up ..................................................................... 101

Mode Description .......................................................... 101

I/O Functions................................................................. 101

Mode Controls................................................................102

Manual Velocity Control............................................................ 103

Mode Description..........................................................103

I/O Functions................................................................. 103

Mode Controls................................................................ 105

Description of Encoder/Knob Settings ......................... 105

Follow Digital Velocity Command (Bi-Polar PWM Command with

Inhibit) ....................................................................................... 107

Mode Description .......................................................... 107

I/O Functions................................................................. 107

Mode Controls................................................................108

Setting A PWM Deadband (Optional)........................... 110

Follow Digital Velocity (Bipolar PWM Command with Variable

Torque)........................................................................................ 111

Mode Description ........................................................... 111

I/O Functions.................................................................. 111

Mode Controls.................................................................113

Follow Digital Velocity Command (Unipolar PWM Input) .......114

Mode Description ...........................................................114

I/O Functions..................................................................114

Mode Controls.................................................................115

Follow Digital Velocity Command (Frequency Input)...............117

Mode Description ...........................................................117

I/O Functions..................................................................117

Mode Controls................................................................ 118

Move to Sensor Position .............................................................119

Mode Description ...........................................................119

I/O Functions................................................................. 120

Mode Controls.................................................................121

Move to Absolute Position (2-Position, Home to Switch) ........ 122

Mode Description .......................................................... 122

I/O Functions................................................................. 122

Mode Controls................................................................ 123

Move to Absolute Position (4-Position, Home to Hard Stop) .. 124

Mode Description .......................................................... 124

I/O Functions................................................................. 124

Mode Controls................................................................ 126

Move to Absolute Position (16-Position, Home to Hard Stop). 127

Mode Description .......................................................... 127

I/O Functions................................................................. 127

Mode Controls................................................................128

Move Incremental Distance (4-Distance, Home to Hard Stop)129

Mode Description .......................................................... 129

I/O Functions................................................................. 129

Mode Controls.................................................................131

Move Incremental Distance (2-Distance, Home to Hard Stop)132

Mode Description .......................................................... 132

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

6

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

I/O Functions................................................................. 132

Mode Controls................................................................ 133

Move Incremental Distance (2-Distance, Home-to-Switch) .... 134

Mode Description .......................................................... 134

I/O Functions................................................................. 134

Mode Controls................................................................ 135

Move Incremental Distance (1-Distance, Home-to-Switch)..... 136

Mode Description .......................................................... 136

I/O Functions................................................................. 136

Mode Controls................................................................ 137

Pulse Burst Positioning..............................................................138

Mode Description ..........................................................138

I/O Functions.................................................................138

Mode Controls................................................................ 139

Multi-Sensor Positioning: Bi-directional (Home to Hard Stop)140

Mode Description ..........................................................140

I/O Functions.................................................................140

Mode Controls.................................................................141

Multi-Sensor Positioning: Unidirectional (Sensorless Homing)142

Mode Description .......................................................... 142

I/O Functions................................................................. 142

Mode Controls................................................................ 143

Multi-Sensor Positioning: Unidirectional (Home to Sensor)... 144

Mode Description .......................................................... 144

I/O Functions................................................................. 144

Mode Controls................................................................ 145

Follow Digital Position Command: Unipolar PWM Command 146

Mode Description .......................................................... 146

I/O Functions................................................................. 146

Mode Controls................................................................ 147

Follow Digital Position Command: Frequency Command .......148

Mode Summary..............................................................148

I/O Functions.................................................................148

Mode Controls................................................................ 149

O

PERATIONAL

M

ODES

:

SDSK

AND

SDHP ................150

Step & Direction.........................................................................150

Mode Description .......................................................... 150

I/O Functions.................................................................150

Mode Controls.................................................................151

Step and Direction Timing............................................. 152

Quadrature Input....................................................................... 153

Mode Description .......................................................... 153

I/O Functions................................................................. 153

Mode Controls................................................................ 155

A

PPENDIX

A:

LED

B

LINK

C

ODES

..............................156

A

PPENDIX

B:

M

ECHANICAL

I

NSTALLATION

.................160

Mounting Dimensions: POWER4-HUB....................................160

Mounting Dimensions: ClearPath NEMA 34.............................161

Mounting Dimensions: ClearPath NEMA 23............................ 162

Motor Mounting Considerations................................... 163

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

7

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

Connecting ClearPath to a Mechanical System......................... 163

Motor Connection: General Tips and Guidelines ......... 163

Notes on Coupling Selection.......................................... 165

Installing Pulleys and pinions ....................................... 166

About End-of-Travel Stops........................................................ 167

Hard Blocks.................................................................... 167

Elastomeric (rubber) Stops ........................................... 167

Pneumatic (dashpots).................................................... 167

End Stops and Hard Stop Homing................................ 167

Fan Mounting and Cooling........................................................168

A

PPENDIX

C:

M

ATING

C

ONNECTORS AND

C

ABLE

P

INOUTS

............................................................................... 169

Mating Connector Information ................................................. 169

Cable Pinout: CPM-CABLE-CTRL-MU120............................... 170

Cable Pinout: CPM-CABLE-CTRL-MM660.............................. 170

Cable Pinout: CPM-CABLE-PWR-MM660................................171

Cable Pinout: CPM-CABLE-PWR-MS120..................................171

A

PPENDIX

D:

C

OMMON

S

PECIFICATIONS

................... 172

A

PPENDIX

E:

G

ROUNDING AND

S

HIELDING

................ 173

Protective Earth (PE) Connection ............................................. 173

Grounding and Shielding........................................................... 173

Power Returns ........................................................................... 174

A

PPENDIX

F:

C

IRCUIT

S

CHEMATICS

.......................... 175

POWER4-HUB Schematic (simplified)..................................... 175

A

PPENDIX

G:

C

LEAR

P

ATH

P

ART

N

UMBER

K

EY

......... 176

A

PPENDIX

H:

M

ISCELLANEOUS

T

OPICS

..................... 177

Homing .......................................................................................177

Introduction....................................................................177

Terms Used In This Section........................................... 178

Homing Settings ............................................................ 179

Typical Homing Sequences............................................ 185

Precision Homing .......................................................... 187

Homing Methods Listed by Operational Mode............. 189

MSP Motion Generator..............................................................190

Motion Generator Controls ........................................... 190

Encoder and Input Resolution .................................................. 192

Introduction................................................................... 192

Terms used in this section ............................................. 192

Native Resolution .......................................................... 192

Positioning Resolution................................................... 193

Input Resolution Setting in MSP................................... 193

RAS and g-Stop (Vibration and Resonance Suppression)........ 195

RAS (Regressive Auto-Spline)....................................... 195

g-Stop Tuning ................................................................198

A

PPENDIX

H:

L

OGIC

P

OWER

S

UPPLY

S

IZING

............. 200

I

NDEX

......................................................................201

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

8

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

Q

UICK

S

TART

G

UIDE

This section was designed to help you get your ClearPath motor up and

running quickly and safely.

I

TEMS

C

OVERED IN THIS

S

ECTION

•How to download and install ClearPath MSP (setup and

configuration software)

•How to power up your ClearPath motor

•How to connect your ClearPath to a PC and establish

communication

•How to spin your unloaded1ClearPath motor under MSP software

control

P

LEASE

R

EAD

T

HIS

I

MPORTANT

W

ARNING

Always use caution and common sense when handling motion control

equipment. Even the smallest ClearPath motor is powerful enough to

seriously damage fingers, turn a tie into a noose, or tear out a patch of hair

and/or scalp in just a few milliseconds (by comparison, it takes between

100 and 400 milliseconds to blink). We’re not trying to scare you (...OK

maybe a little) but we do want all ClearPath users to stay safe and fully

intact. These devices are very powerful and can be extremely

dangerous if used carelessly. Please read and understand all safety

warnings in the ClearPath User Manual before operating a ClearPath

motor.

B

EFORE

Y

OU

B

EGIN

(S

UGGESTED

V

IEWING

M

ATERIAL

)

Check out the ClearPath overview video. This is a great way to learn

about ClearPath motors (and Teknic as well). Note: There's a great

ClearPath demonstration at time reference 3:50.

Try watching a few ClearPath operational mode videos. There is

a separate short video for most ClearPath operational modes. Each video

includes an overview of the operating mode, a brief discussion of software

controls and settings, and a demonstration featuring a real mechanical

system.

ClearPath Video Links

https://www.teknic.com/watch-video/

https://www.youtube.com/channel/UC4Q91tGO80QMSHyy1SoHrtg

1Unloaded means with nothing attached to the motor shaft. ClearPath comes factory

preconfigured for unloaded operation. ClearPath must be tuned whenever it is

connected to a new type of mechanical system.

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

9

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

C

LEAR

P

ATH

Q

UICK

S

ETUP

R

EQUIRED

I

TEMS

•ClearPath motor

•DC Bus Power supply (with cables) 24-75 VDC

•Windows PC (Win 7, 8.1, 10)

•USB cable (USB type-A to micro-B)

•Clamp or vise

I

NSTALL

C

LEAR

P

ATH

MSP

S

OFTWARE

MSP is a free download from Teknic's website. Click here for a direct link.

To install MSP, save the zip file to your local computer, extract the .exe

file, and run it.

S

ECURE

Y

OUR

M

OTOR

Injury Warning: To prevent broken toes, and damage to your motor,

always secure your ClearPath motor to a stable, flat, level work surface

before operating it; otherwise, your motor will buck and jump during

operation. A “quick-grip” style clamp or vise is recommended.

Tip: If you use a vise to secure your motor, you can preserve the motor's

finish by taping the vise jaws or by placing scrap cardboard or wood

between the vise and the motor body. Do not over tighten vise.

CLAMP MOTOR

to a stable work surface.

Clamp it!

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

10

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

C

HECK

DC

B

US

P

OWER

P

OLARITY

Damage Warning: Reversing DC power polarity to your ClearPath

motor will permanently damage it.

Before you connect DC power to your ClearPath motor, use a voltmeter

to verify that DC bus power is wired with the proper polarity. This is

particularly important if the cables were not made by Teknic.

For Teknic DC power cables (PN: CPM-CABLE-PWR-MS120), test DC

voltage at pins 3 and 2 as shown below (pin 3 is v+ and pin 2 is GND).

This should display a positive voltage reading.

2 (GND)

4

Teknic IPC-5

Power Supply

VDC

ClearPath

Voltage Range

24-75VDC

1

3 (V+)

Power Connector

(Molex 4-pin)

Polarity test from pin 3 (V+) to pin 2 (GND) shows a positive 75 volts

P

OWER

U

P

Y

OUR

C

LEAR

P

ATH

1. Begin with the power supply turned off or unplugged.

2. Connect the DC power cable from the power supply to the

ClearPath motor's 4 pin connector.

3. Turn on (plug in) the power supply.

2

3

1

Power up sequence

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

11

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

C

ONNECT

C

LEAR

P

ATH TO

Y

OUR

PC

Connect ClearPath to a USB port on your PC with a high quality USB type-

A to micro B cable (Teknic PN: CPM-CABLE-USB-120). If this is a first-time

connection, wait for ClearPath to automatically install its driver software

before proceeding. This should only take a minute or so.

Damage Warning: Do not use USB cables of unknown origin (e.g.

found in a junk drawer) with your ClearPath. Non-standard cables may be

incompatible with ClearPath, and may even damage your motor.

Micro-B

Type ‘A’

Windows PC

(Win 7, 8.1, 10 with

MSP application installed)

ClearPath

Motor

USB Comm Port

Teknic Part #

CPM-CABLE-USB-120

Connect ClearPath to your PC

O

PEN

C

LEAR

P

ATH

MSP

(M

OTOR

S

ETUP

P

ROGRAM

)

After you open MSP, ClearPath will attempt to establish communication

with your PC. If all is well, you will briefly see a window like the one

below.

Open MSP (Motor Setup Program)

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

12

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

S

PIN

Y

OUR

M

OTOR

U

NDER

MSP

S

OFTWARE

C

ONTROL

The best way to learn about a ClearPath operational mode is to try it

under software control. MSP includes simple software controls that

emulate hardware inputs and outputs, so you can try different modes of

operation without wiring a single switch or sensor.

Note: ClearPath Soft Controls are great for test, development and

training, but are not meant to be used as the control system for your

machine.

S

PINNING A

M

ODEL

MCPV

OR

MCVC

Spinning Step & Direction models (SDSK and SDHP) is covered in the

next section.

For models MCPV and MCVC we will use the mode Ramp Up/Down To

Selected Velocity. Feel free to try any mode available in the Mode drop

down menu. Each mode is described in its own section later in this

manual.

1. Open MSP software. The "Tuning" dialog will appear. For now

select the bottom option (run with no load).

2. From the MSP menu, select Setup>Units>Counts; RPM;

RPM/s. This just tells MSP how to display distance, velocity,

and acceleration.

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

13

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

3. Select Mode>Velocity>Ramp Up/Down to Selected Velocity.

4. A dialog window will open (see below). Please read all of the

text presented, especially if you're unfamiliar with how the op

mode works. Click OK to proceed.

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

14

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

5. The mode controls window will appear as shown below. To

follow along, enter the settings as they appear below.

Enter maximum

desired motor

acceleration rate.

Enter target velocity for

each input state here.

Check here to set

motor deceleration

rate to same value

as acceleration rate.

Soft Inputs and LEDs emulate

hardware inputs. For use only

when Soft Controls are active.

Caution:motor may spin when

enabled.

Enter maximum

desired motor

deceleration rate..

Displays commanded velocity

(when using hard inputs).

Displays commanded velocity

(when using soft inputs).

Hardware Input Status LEDs

Light = Input asserted (on)

Dark = Input de-asserted (off )

Check to turn on Soft

Controls. Override cannot

be activated when ClearPath

is hardware enabled.

Adjust settings for RAS

TM

(or

optional g-Stop

TM

) to convert

standard trapezoidal move

profiles into profiles that reduce

noise,resonance,and vibration.

Click to openTorque

Limit Setup dialog.

Displays HLFB

output status.

Torque Override Indicator

When lit,the main torque limit is being

overridden by a secondary,user-set torque

limit (e.g.,when an axis is homing,the main

torque limit may be overridden by the

separate homing torque limit setting).

Mode Controls for mode "Ramp Up/Down to Selected Velocity"

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

15

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

6. Click the Override Inputs checkbox. This turns on the software

controls. You may notice that the other Soft Controls are no

longer grayed out.

Soft Controls

Use to emulate hardware inputs.

Override Inputs

Check here to turn on Soft Controls.

Note:Override cannot be activated

when ClearPath is hardware enabled.

Enable Control

Check to energize motor windings.

Uncheck to de-energize.

Input A Control

Check here to assert Input A.

Uncheck to de-assert.

Input B Control

Check here to assert Input B.

Uncheck to de-assert.

Check "Override Inputs" box to turn on Soft Controls

7. Safety check! Before proceeding, make sure that the motor is

securely clamped down and the shaft is safely positioned away

from fingers, clothing, hair, cables, etc.

8. Click the Enable Control. Caution: the motor is now

energized and capable of motion.

Motor Status

Currently indicates the

motor is Software Enabled

Emergency Stop Button

Click here (or hit ESC on keyboard)

to immediately trigger a shutdown.

Toggle Enable Control to clear.

Enable ClearPath using Soft Controls

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

16

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

9. Make some moves. With the motor enabled, change Inputs

A and B as shown below to spin at different velocities. Feel free

to experiment. Try changing velocities, accelerations, and RAS

settings.

+10 RPM

A on B off

0 RPM

A off B off

-100 RPM

A off B on

+500 RPM

A on B on

Change velocity and direction by checking Inputs A and B

A

DDITIONAL

N

OTES

•The direction of shaft rotation is set by entering a "+" or "-" sign

in front of the velocity settings (see top of figure above). "+" will

cause CCW rotation, "-" will cause CW rotation.

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

17

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

S

PINNING A

M

ODEL

SDHP

OR

SDSK

Note: Spinning ClearPath models MCVC and MCPV is covered in the

previous section.

ClearPath SD models have one mode: Step and Direction. We'll open that

mode and get the motor spinning using MSP software controls.

1. Open MSP software.

2. Establish USB communication to your motor.

3. The "Tuning" dialog will appear. For now select the bottom

option (run with no load) and hit "Next".

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

18

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

4. In MSP, Select Mode>Step and Direction. The mode controls

window will open.

5. Set Units to RPM as shown in the figure below. This just tells

MSP in what units to display distance, velocity, and

acceleration.

6. Disable homing (see figure below).

7. Click the Override Inputs checkbox. This turns on the

software controls. You may notice that the other Soft Controls

are no longer grayed out.

Soft Controls

Use to emulate hardware inputs.

Override Inputs

Check here to turn on Soft Controls.

Note:Override cannot be activated

when ClearPath is hardware enabled.

Enable Control

Check to energize motor windings.

Uncheck to de-energize.

Jog motor

clockwise

Jog motor counter-

clockwise

Check "Override Inputs" to turn on Soft Controls

8. Safety check! Before proceeding, make sure that the motor is

securely clamped down and the shaft is safely positioned away

from fingers, clothing, hair, cables, etc.

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

19

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

9. Check the Enable checkbox. Caution: the motor is now

energized and capable of motion.

Enable using Soft Controls

10. Make some moves. With the motor enabled, click the jog

button. Change direction by checking Input A. Test different

velocity and acceleration settings.

Click and hold to jog buttons to spin your ClearPath-SD motor

C

LEAR

P

ATH

MC/SD

U

SER

M

ANUAL

R

EV

.

3.09

20

T

EKNIC

,

I

NC

. T

EL

.

(585)

784-7454

I

F

Y

OU

E

XPERIENCE A

M

OTOR

S

HUTDOWN OR

W

ARNING

•If you see a small triangular warning icon (figure below)

anywhere in the Mode Controls section, hover your cursor over

the triangle to read the message (like a tool tip).

Hover cursor over "warning triangle" to read its message

•If you exceed your power supply’s capability, ClearPath will tell

you. You’ll see warnings or shutdowns in the Exceptions field at

lower right of the UI. (This does not mean that the motor is

broken.) Try lowering the acceleration and/or velocity of your

moves until the warning goes away.

•The majority of shutdowns are caused by weak power supplies,

mechanical problems, and/or inappropriate settings. If your

ClearPath experiences a shutdown, it is reporting a problem, but

is not necessarily causing the problem.

•You can clear most shutdowns by toggling the Enable Input, but if

you don’t fix the underlying problem, you will probably continue

to have shutdowns.

•IF THE STATUS LED FLASHES RED, your ClearPath motor has

identified an internal hardware problem and needs to be returned

for repair or replacement.

This manual suits for next models

4

Table of contents

Other Teknic Engine manuals